Home owners quite often have the question of why their gas boiler smokes. This phenomenon has various reasons. The soot emitted during operation of the unit settles on the walls of the chimney, as well as on objects located next to it. The caustic particles contained in soot destroy equipment parts. Therefore, this problem needs to be resolved immediately.

The chimney collects soot on the inner walls.

If smoke comes into the room from a gas boiler

A wall-mounted or floor-standing boiler and AOGV can smoke for two main reasons: a malfunction of the chimney or poor gas quality.

First of all, it is necessary to inspect the chimney and carry out the following work:

- The presence of traction is checked. This can be done either with a special measuring device, or by holding a lit match. The flame should deviate noticeably towards the boiler. If this does not happen, it means that the chimney for some reason does not pull smoke out.

- View the pipe using a mirror and a flashlight. If necessary, remove snow and foreign objects. If you cannot do this yourself, call a chimney sweep.

- If you heat with damp wood, you need to clean out the accumulated tar from time to time.

- Replace the chimney with a suitable type and diameter for this model. For example, the Lemax Premium device requires a chimney with a diameter of 200 mm. Increase the length of the pipe; in your house, its end should end above the ridge of the roof. Insulate the outside with glass wool.

- Inspect the chimney for cracks. Pay special attention to connecting seams. Remove right angles when turning and make transitions smooth.

In the room where the gas boiler is located, a window must be open to allow air to enter. This is especially true during the cold season in high-rise buildings, where a layer of cold air may prevent combustion products from escaping.

If you heat with a gas boiler and use cylinders rather than a centralized gas pipeline, it is important to purchase high-quality liquefied gas from trusted manufacturers. The Ross Lux model allows you to do this.

Specifics of cleaning a coaxial chimney

The coaxial type of chimney is a structure consisting of several pipes. One is placed inside the other, but they are isolated from each other by a partition. When using this type, air is taken from the street and not from the room. Therefore, there is no need to organize a separate ventilation system. This type is often used for geysers and boilers.

We recommend reading: Requirements for ventilation of premises when installing a gas boiler

One pipe is needed to bring in cold air from the street, the other pipe releases heated air. This provokes the formation of condensation. If the pipes are installed correctly, the liquid will flow down.

This type of chimney is less prone to blockages. But it is necessary to carry out its maintenance at least once a year. Simply remove the outer casing. Then you should inspect the condition of the pipes. If there are signs of dirt, blockages and deposits, they are removed. Afterwards the casing returns to its place.

The quality of chimney cleaning Lemax or another type and its regularity determine the safety of those living in the house and the proper operation of the equipment. Therefore, it is necessary to constantly diagnose the condition of the structure for blockages and soot accumulation. If contamination is detected, it is removed using a suitable method. In order to clean the structure less frequently, it is recommended to carry out preventive measures that reduce the rate of soot and scale formation.

Why is it important to fix the problem immediately?

Even small pops are warning beacons indicating that the equipment is faulty. If the problem is not solved immediately, it will get worse in the future. The boiler may turn off, in addition to popping noises, an open flame comes out of the boiler, etc.

Despite the fact that modern equipment is equipped with good protection systems, the owner must still use it competently, maintain it in a timely manner, remove blockages, etc. Then the boiler or column will work for a long time, efficiently and without failures.

If you find that the boiler slams when turned on or makes noise during operation, and the reason cannot be determined, contact the experts. They will advise you on this issue, and if necessary, they themselves will diagnose and eliminate the cause of incorrect operation. Call.

Frequent causes of burner and boiler igniter extinguishing

If the gas boiler goes out, it is necessary to carry out diagnostics to determine the cause of the system failure. Although there are several reasons for extinguishing, there is one common catalyst that causes the cessation of operation - a lack of air flow to the burner.

If the cause of the attenuation is not eliminated, the situation will worsen:

- Soot is released and settles on the burner device.

The flame on the igniter shifts.

- The thermocouple stops working and the protection turns on.

At low atmospheric pressure, a gas boiler simply cannot operate. Taking this factor into account, manufacturers of modern boilers install a system of forced air injection into the burner and removal of combustion products, which partially solved the problem of spontaneous equipment shutdown.

Conclusions and useful video on the topic

You can find out why there is a bang when you turn on the Conord boiler from the following video:

This video explains in detail why the wick of the Conord boiler does not light, and how to fix this problem yourself:

Like any other equipment, gas boilers can break down from time to time, thereby depriving the residents of the house of heat, which is so necessary during the cold season. To restore the operation of a gas boiler, it is enough to correctly determine the type of breakdown, after which you can carry out the repair yourself without resorting to the help of a specialist. The article revealed the most common malfunctions of Conord boilers, as well as ways to eliminate them - replacing broken parts and cleaning contaminated systems.

The main reasons for the attenuation of gas energy-dependent and mechanical units

What type of boiler do you have?

- Volatile (automation runs on mains power).

- Mechanical (independent of electricity).

Why does the gas boiler go out? The reasons for their breakdowns may be different.

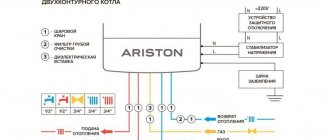

2-circuit non-volatile boiler

Volatile boilers have a more complex design. They may turn off when:

- lack of electricity;

- voltage drops and surges in the network;

- incorrect factory settings that need to be adjusted;

- The remote control, if there is one, may malfunction.

If there are problems with electricity in your area, it is better to purchase and install a voltage stabilizer in advance. And if you are just going to buy a boiler and are studying this issue, opt for a mechanical unit.

Mechanical boilers can go out due to strong gusty winds blowing into the chimney.

What to do if a strong wind blows out a gas boiler

If you determine that the problem is a consequence of air penetrating inside the chimney, then it is first recommended to check how well the entire structure is designed and constructed.

Next, you should make sure that the system as a whole is in good condition. Check the chimney design with the actual installation. Check if everything meets the stated requirements. If even minor inconsistencies are found, this is a reason to rebuild the chimney or modify it.

There are a number of criteria, compliance with which guarantees the uninterrupted and full operation of the heating installation:

- diameter, length, which are indicated in the project must comply with the approved documentation;

- the inside of the chimney is clean so that air can flow freely;

- the structural element of the chimney passing outside the room must be insulated.

If violations in the design were previously identified, then increasing the length is a simple and frequently used solution. The method is considered if there are some obstacles near the house (another building, trees) that interfere with the free movement of wind flows, forming turbulence.

When choosing this method, you should check if there are any other problems. Otherwise, the action performed will be inappropriate. Moreover, new difficulties may arise.

Installation of a draft regulator to “break” it

The most popular method is installation inside the chimney:

- 50 cm above the point of connection to the chimney;

- or in the same plane as it.

It should be noted that the practical application of this option must be discussed with specialists. If the structure is installed incorrectly, the rupture may in the future cause emergency situations or gas accumulation in the home.

Diameter change

There are a number of rules that will tell you what and how to do to prevent the gas boiler from blowing out:

- providing the recommended amount of oxygen;

- increasing the temperature for better fuel combustion.

Using a sandwich chimney (there is another pipe inside, but of a smaller diameter with insulation) significantly reduces heat loss, and the walls will warm up faster. The size of the sandwich directly depends on the size of the smoke exhaust channel. For help with calculations, you can contact specialists who will select the right product and assist in installation.

Content

The easiest way to identify the cause of flame extinction in a gas boiler is if it is of the energy-dependent type. Most often, the gas in such units stops burning due to a power failure or power surge. The burner ignition electrodes and circulation pumps require constant power supply. These classic long-burning wood-fired boilers for the home can do without connecting to a 220 V network. This will not work with volatile gas boilers.

Checking the connections of all electrical circuits

Due to electrical problems in the gas boiler:

The settings are reset or they are set incorrectly;

Remote control is disabled;

The fire goes out because the electric igniter is not receiving current;

The sensors are de-energized, causing the automation to forcibly extinguish the torch.

To get rid of these problems, the boiler must be equipped with a stabilizer and an uninterruptible power supply. Only the energy sector can eliminate power surges and accidents in the village electrical network. At home, you can only install additional electrical equipment for safety reasons.

UPS for gas boiler

The stabilizer levels out changes in current parameters, and the uninterruptible power supply provides power to the heat generator in question when the lights are completely turned off. But when choosing them, you need to make sure that the labeling says “pure sine”. Only this technique is intended for gas boilers. Conventional rectifiers and UPSs for computers will not work here.

Problems with a solid fuel boiler

Sometimes the heating device smokes due to the banal filling of the ash pan.

Before looking for another possible source of problems, you should empty the ashpit and check the condition of the grate. The second most common problem with a solid fuel boiler is a clogged chimney. The reason is poor quality fuel. When using damp firewood or wood with a high resin content, not only soot is formed, which easily crumbles after tapping on the chimney casing. Resinous soot with a high moisture content adheres firmly to the walls, after which it hardens and narrows the diameter of the pipe.

ATTENTION! If damp firewood is used and the smoker is not properly insulated, this leads to the formation of condensation. In combination with soot, it turns into a caustic substance that can damage the chimney. When the pipe is corroded, traction is disrupted.

Common problems with turbocharged models

The indicated difficulties also arise in turbocharged vehicles. And since this technique has an isolated combustion compartment and additional components, it is characterized by the following difficulties:

- The hood or coaxial chimney is covered with ice.

- The integrated air blower is broken.

The culprits of the first problem are accumulated condensation and adhered snow.

You can avoid it by protecting the chimney from aggressive factors - installing a deflector.

If ice plugs have already formed, they can be melted with a hairdryer or a torch - a spray can.

As a rule, condensate settles in pipes of convection modifications, for example Lemax PRIME-V10.

Traffic jams form here due to temperature differences in air flows coming from the street and heading outside. They block the path to the combustion compartment.

The solution lies in lighting the chimney with a portable burner. When you remove the plug, insulate the pipes.

If the boiler has a built-in blower, as in the Baxi ECO-4s 24 model, and it goes out during operation or the wick does not start immediately, pay attention to the sounds that appear.

With stable functions there are measured beeps. Excessive noise is a sign of a problem.

Turbocharging, as a rule, is not repaired, but quickly replaced.

If there are no sounds when the device is operating, it means that the automatic mechanism is preventing the safety valve from opening and the filter does not ignite.

Call specialists to replace the turbocharger. Because this work is quite complex and associated with a certain risk.

How to understand that there is a need for chimney cleaning

There are signs by which you can determine that your chimney needs cleaning. This will allow you not to miss the moment and not aggravate the contamination situation to the point where the equipment fails.

Important to remember!

Martyanov Pavel

Specialist in the field of gas equipment maintenance, 20 years of experience

Ask a Question

Timely maintenance of chimney systems is not only a guarantee of stable operation of gas equipment, but also a guarantee of your safety. Exhaust gases are extremely dangerous to human life and health.

The burner does not turn off and constantly works

When the heat exchanger becomes clogged, the water begins to heat up more slowly. The turbine continues to pump new fluid. The burner is in constant operation, trying to achieve the desired temperature value for the water.

Read a detailed article on this topic: Why does the gas boiler not turn off and constantly work?

The pressure in the hot water supply circuit has dropped

This happens as a result of improper operation of the heat exchanger or leaks in the pipeline system. Depressurization of the fluid supply circuit could also occur.

We recommend reading: Why the pressure in the heating system drops, reasons and solutions

Rumble and extraneous sounds in the operation of the circular pump

Blockages prevent water from circulating normally. Therefore, the pump is overloaded during operation. This is indicated by equipment malfunctions, extraneous noise, or engine overheating.

Also read with this article: The main reasons why a gas boiler hums

Gas consumption has increased

The formation of blockages is one of the reasons why gas consumption increases. This is due to the need for more fuel for the boiler. When cleaning is carried out and scale is removed, gas consumption returns to normal.

Methods for cleaning a gas boiler

There are several options. These include traditional methods: mechanical and chemical methods. In not the most difficult cases, hydrodynamic cleaning is chosen. Sometimes serious help is needed.

Mechanical

This method involves the use of simple tools. Manual cleaning allows you to avoid wasting money and time, but its effectiveness is low. The mechanical method does not at all guarantee an excellent result, so its use can be called a half-measure. Actions with “crazy” hands will only help if cleaning is carried out regularly.

The role of tools is the usual tools - brushes, brushes, toothbrushes, and a vacuum cleaner is also used in the fight for cleanliness. All mechanical devices should not have sharp edges, since they can easily damage unit parts. The required element is disconnected from the system and carefully treated with brushes, trying not to damage the surface. To clean the inside, use a brush or blow out the parts with a vacuum cleaner.