We have a TERMO gas boiler, single-circuit 10 kW, made in Ukraine.

So, he worked, he worked, for 4 years. Everything was fine and in order. True, the factory thermocouple burned out in the second year, and I changed it, but that's a different story.

This fall, when it got cold, we started using it. But it started making loud popping noises when switching to low flame. Well, there is such an automation that when the water inside gets hot enough, in accordance with the temperature regulator, the boiler, to save money, turns off the gas supply to the main burner and only a small burner, the so-called igniter, remains burning.

Then, when the water cools down, the automation again begins to supply gas to the large burner. So, it was precisely when the boiler went into “sleep mode” that for some reason gas collected inside and then detonated. And for the entire time (5-10 minutes) everything was fine. And so every time.

I assumed that perhaps the boiler was dirty inside with soot. I decided to take it apart and clean it.

ATTENTION: Do not under any circumstances attempt to disassemble or repair gas equipment, as Is it dangerous . If problems arise, you must contact the gas service (104) and call a specialist.

My guess is that cravings have gotten worse.

I started with the chimney. I took apart the galvanized steel sockets and found nothing inside. As I expected, there was no soot there. I checked the traction. But everything was fine in the chimney: the match instantly went out when brought to the chimney. Then I looked into the boiler, it was also clean.

Then I moved on to the main block. Checked the injectors. But both injectors were clean and the holes were open. The burners were also clean.

During disassembly, I broke the large nozzle, because... it was conical and made of duralumin, and sat very tightly at the entrance to the lid plate. I had to replace it with a bronze analogue. But unfortunately I didn’t find one with a cone, so I had to additionally seal the entrance to the plate with tow. The seal is necessary so that it does not draw in air.

By the way, the diameter of the hole in the nozzle is very important . The diameter should be the same. It was smaller on the bronze nozzle and I drilled it out.

And, in the end, I found out the reason for the drop in traction. The draft in my boiler comes from the bottom of the boiler. The boiler has no bottom. But there was a net installed there. And over the course of 4 years, a dense layer of dust formed at the bottom of the mesh, just like felt.

The mesh is removed along the slide in which it sits. Then I vacuumed the mesh. And installed everything in place. Now the boiler does not slam.

Let me say it again: Do not attempt to make repairs yourself. Such work must be entrusted to a specialist. Gas leaks can have FATAL consequences.

Welcome to the De Dietrich Thermique forum!

#1 20-03-2013 14:34:28

Copper (mini explosion) when igniting

The boiler is 5 months old, in its first winter, I recently noticed that when ignited, the piezo crackles, the gas flow is clearly audible, sometimes it’s normal, and sometimes there’s a bang and it seems like the boiler will burst. what could it be? I didn’t notice this all winter, only when it started to get warmer outside, by the way I noticed that this mostly happens when the boiler temperature is 33-37 degrees (up to 40). I took off the combustion chamber cover and wiped the burners with a toothbrush, using a cloth, it seemed a little better, less often, but it still slammed.

Positioning the thermometer correctly

There are two types of thermostat:

- Built-in - measures the temperature of the coolant, does not respond to external conditions.

- Remote - measures the air temperature in the room, does not react to the temperature inside the boiler.

With the first type, everything is clear - nothing can be changed, the thermometer does not involve transfer. The remote type must be positioned correctly - otherwise, every ventilation or operation of household appliances will disrupt the heating operation throughout the house.

Experienced craftsmen advise placing the device in the part of the room that cools most slowly. As a rule, it is located at a considerable distance from the boiler, so heating is also extended over time. Reducing the temperature to the lower limit will mean cooling the entire room - the heating will begin to operate normally.

In order for the burner to perform long, uniform cycles, you should not install a thermometer:

- Near windows, doors, cracks in walls.

- Near household appliances.

- Close to the floor or ceiling.

- In the basements.

#5 20-03-2013 20:13:38

Re: Pop (mini explosion) when igniting

1. Check the position of the electrode (gap: 3 mm) 2. Pressure for minimum power (mbar) – 2.4 3. Gas pressure for rated power (mbar) – 13.8 4. Unlikely. Most likely, we are talking about delayed ignition (ignition of gas), when there is already a lot of gas in the firebox.

“The dependence on the weather and on the set temperature to 38-40 degrees is confusing” - the ignition parameters do not depend on this. Further modulation of the boiler power will depend on them.

Bottom line

Now it’s clear why the gas boiler often turns on. And that the frequency of turning on and off the burner of a gas heating boiler is a very variable and very individual value. This directly depends on a large number of factors. Manufacturers guarantee that the boiler will provide the specified temperature range, regardless of whether the burner is turned on or off. At the same time, the intensity of fuel combustion helps prevent its overconsumption due to clocking.

The operating mode of the gas boiler is selected strictly in accordance with the time of year and the required thermal index in the room. To avoid very frequent switching on and off of equipment, you need to determine the correct location for installing the thermostat and stabilize temperature intervals. And also adjust the gas burner and resolve the issue with the thermal capacity of the heating circuit.

#14 14-01-2014 04:55:26

Re: Pop (mini explosion) when igniting

Clap when igniting at low heating temperatures due to fuel (gas) pressure. When atmospheric temperature increases, gas pressure remains the same as at low temperatures. In this regard, I suggest installing an additional valve on the gas supply that regulates the gas supply, or simply pressing the supply on the supply valve, as I do. I live in Dzhambul (that is, in the south) in our area there is only 3 months of winter and in each month there is a maximum of -15 weeks and the rest of the days are warm. So you have to press periodically. The boiler is in its third year. Thank you!

Is your gas boiler noisy? This symptom may indicate a problem with the heating system. In order for you to cope with breakdowns, you need to find the reasons. You should not constantly ignore the problem, because it can lead to complete failure of the boiler. If the device makes a lot of noise, crackles, or beeps, start troubleshooting.

Malfunctions and repairs of Navien boilers

The Navien Ace 24k coaxial gas boiler was installed and installed. I read in the instructions that when operating according to air temperature, the water will be heated to the temperature set in operating mode according to the air temperature. Something does not work. I do this. I set the extract air temperature, for example, to 65, the boiler brings the temperature to 65. I switch it to air temperature control mode. The device begins to further increase the ambient temperature to 80 and operates in this mode until the air temperature reaches the desired one. What should be done? Or are there inaccuracies in the instructions? It's not the boiler, it's the remote control. Remove the remote control from the bracket, there is a sticker on the back, you have version v1.0, but you need v1.2 or v1.3. Can anyone tell me what is wrong with the boiler? The display shows error 02. I checked the flow valve, it works, the three-way valve is also functioning. It feels like the gas supply is not opening. Check the overheating sensor and the pump. If the pump is running and there is coolant circulation, the heat exchanger may be clogged. I want to put into operation the Navien Deluxe 16K wall-mounted boiler. I plan to carry out commissioning myself. Please advise the stages of this work. It’s clear about adjusting the gas pressure, there is a U-shaped liquid pressure gauge, I’ll check it. 1. Should the CO system be filled to a pressure of 2-2.5 kgf/cm2? 2. I read somewhere else that the shaft of the boiler circulation pump needs to be turned with a screwdriver? 3. Air from CO, besides radiators, where else and how to remove it? 4. How to put the device into debug mode? Check the gas inlet pressure, put the boiler into debugging mode and adjust the pressure to min. and max. I have 0.6 bar when cold, when it works up to 1.2 - 1.5 it rises, it seems to me that it’s more and unnecessary, not the pump itself, but unscrew the plug bolt and bleed air from the pump when the system is filled (I don’t have a pump rotor turn there is no slot for a screwdriver). The device has an automatic air vent; when the pump starts, the coolant circulates and will slowly expel all the air. debugging mode dip switches: 1) - 1 on. — the pump will start for 2 hours and will circulate the coolant through the CO (drive air out of the system). 2) - 1 off, 2 off. 3 incl. — the boiler goes into forced operation mode for min. power set to min. gas pressure. 3) - 1 off, 2 on. 3 off — the boiler switches to max mode. power we set the gas pressure. 4) - 1 off, 2 off. 3 off — We are glad that everything worked out, the device works as it should. All manipulations with dip switches should be carried out with the boiler turned off. Navien Ice 24k boiler malfunction. If error 02 occurs, one solution is to open the top plug on the boiler body. It's helping so far. But how to carry out repairs? The gas pressure was checked, the expansion tank was pumped up, the coaxial chimney was cleaned (without dismantling) by blowing and cleaning with wire. Now it works, I close the lid periodically (every day or two) - again error 02. Error 02 - Insufficient amount of water in the heating system or open circuit of the flow sensor (Turbo only). What does the top plug on the boiler body have to do with this problem? Check the CO flow sensor or the heat exchanger and filter are clogged. The gas boiler Navien Deluxe 24k Turbo is in operation, the old version with a twist. It operates at 13K coolant temperature with almost no clocking. 1. What kind of work is generally included in boiler maintenance? 2. The boiler began to behave strangely. This consists of three points. When heating hot water, the “winter” mode heats the water according to the temperature on the remote control up to 60 degrees, and I decide the water temperature by mixing in cold water. Problems occur when the water pressure is very weak, then it can start to overheat, but overall it worked fine. Now, even if I open several hot water taps without mixing, the boiler rises to 75-80 degrees, turns off, the temperature drops to 40-50, it turns on again. The cycle repeats. But at one moment it may start heating normally, i.e. the temperature will start to stay at 60 degrees. I'm just not 100% sure whether to interrupt the bug it is necessary to turn off the hot water so that the three-way valve works. When heating for heating, a similar situation occurs. I set the coolant to 57 degrees, it heats it up to 57 and turns off. Although it should stabilize at this temperature. The temperature drops to 52 degrees, the boiler ignites and the cycle repeats. The boiler almost always lights up the second time, it started 1.5-2 weeks ago. In the morning I knocked on the 3-way valve, the heating device seemed to work fine. Yesterday I cleaned the filters in the CO, it seemed to have stopped overheating. I adjusted the maximum throttle and it was lowered. It seemed to light up the first time. Overheating at the hot water supply has also become easier, but one thing really confuses me. At 13K the minimum pressure should be 11mm of water column. I have already completely unscrewed the adjusting screw, and the pressure is about 20mm. How can we deal with this and what determines the fact that it is not possible to further reduce the minimum pressure? Electronics always have the potential to freeze. Works at temp. indoors and during this winter there were two cases when it did not turn on when the lower threshold was reached - it dropped 2 degrees lower. It is also very common for gas valves to open at different intervals. A Navien Ace 16K boiler has been installed and connected and has been in use for more than 3 years. Error code 10 began to appear frequently. How to fix this? Error 10 indicates that the heat exchanger inside the combustion chamber is clogged. This is dirt, combustion products that clog the heat exchanger plates. After cleaning, the error will disappear. But the first time it is better to call a specialist, because... To clean it, you need to remove and disassemble the combustion chamber. Tell me about the settings of the Navien Deluxe 24k coaxial boiler, engineering mode on the remote control. By holding down the + and - buttons, you can change the switch-on temperature and set it to 10, i.e., in theory, at a set temperature of 65 degrees after turning off, the boiler should turn on at 55 actual, but it turns on at a temperature of 41 degrees. What am I doing wrong. I have a remote control like 1.30, so I think it’s just a set of numbers on the back and 130 at the end, and the controller board has 12 dips and two buttons for adjusting the maximum gas pressure. I hope that many malfunctions due to the adjusted gas pressure are purely visual when set to min. power and at max. Based on the dips, I didn’t see much difference in the flame. And I tried this: I turned it on, and the burner went out, then I turned it in the opposite direction, started the boiler a little, and everything became normal. When starting up, the thumping sound is not loud and stopped beating when it warmed up. I made the adjustment myself after setting up the servicemen; they had an electronic device. True, according to the new manual, they set the dips, in my opinion, to 9 kW (deluxe 13). Navien Ace Turbo 13k boiler malfunction. Sometimes it started giving error 11. Water level sensor. It looks like it doesn't have this sensor? Error 11 - Malfunction of the automatic valve for filling the heating system with water. These models do not have an automatic valve for filling the heating system with water. The error may appear after error 02 appears three or more times in a row. The wall-mounted boiler Navien Ice Turbo 24 is in operation. It only works on heated floors, two loops of 110 m each. I want to install an additional 25*80 pump. Will the original pump block (slow down the flow)? It might be better to install a jumper instead of the original pump, and throw the wires on an additional one. pump? Maybe you can advise how to connect an additional pump? Two pumps cannot be installed in one line, either in parallel or through a hydraulic separator. I did it the simple way, through the hydraulic arrow. The hydraulic separator is in front of the manifold, and the pump is on the supply side and there is no jumper. We have been using a Navien GA 35kn floor-standing gas boiler since last year and have not seen any problems to date. But yesterday the boiler went out by itself and wrote error 03 (no gas supply), I removed the gas hose (yellow), gas is flowing. In short, gas reaches the boiler, and then there is silence. What could be the reason? Error 03 can indicate several things: 1. no or low gas pressure. Check on the gas stove. If the flame on the stove has not changed, then you need to check the gas line to the boiler. It’s better if gas workers do this with a device, measure the pressure, and check it safely. If you don’t know how to handle gas, it’s better to call a professional. 2. If everything is in order with the gas, then you need to look at either the gas valve in the boiler (it could be clogged with debris) or the ignition transformer, which gives a spark. In any case, this work must again be done by a master. 3. If at some moments the boiler still lights up, then everything is in order with the transformer. It is necessary to check the valve for dirt or gas pressure. Also check all contacts and wires to ensure they have not come loose. It's hard to judge from a distance, but in principle it's something like this. Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. It is not possible to adjust the fan run-on. I set it to 30 seconds, but still 2 minutes. spins. There are two parameters for the fan - summer and winter, maybe you only change the summer one? You have a board with 12 DIP, perhaps there is some kind of mismatch with the remote control, there is no reliable information, on boards with 10 DIP and code 30010973A everything is changed and configured. When the water temperature in the CO drops to 10 (according to the sensor in the boiler), the antifreeze mode will work and the pump will turn on. The danger is in the condensation that inevitably drips onto the maintenance. I advise you to open the plastic plug on the boiler body at temperatures below 10-15. Navien Deluxe 13k has been in use for 4 years. A month ago, it started to start only the third time, and sometimes (with a frequency of about once a week) it gives error 03. I cleaned the electrodes to no avail. Tell me in which direction to look for the cause. First of all, check the gas pressure. You can’t visually determine for sure without a device, but at least how your gas stove burns. If the fire is good, then there are no problems with gas. Next you need to look at the gas line to the boiler for contamination. You also need to look at the gas valve; if there is a lot of dirt in the gas line, the filter mesh at the inlet (inside the valve) will be clogged. It is advisable to carry out this work by a specialist, because you might do something wrong. Also, remove the cover of the device and try turning it on/off. several times in this position. If at the same time the boiler ignites, then it is necessary to carry out an air adjustment, because the wrong proportion of air-gas enters the device. Malfunction of the Navien Ace 24k boiler with turbine. Recently leaked. I opened the lid and it turned out that the primary heat exchanger was damaged. I didn't wait a bit for a wash. Therefore, the question arose: will there be only one option in the store, or are there good ones, and there are “so-so” heat exchangers? And another question: what rubber bands, lubricants and other consumables should I take right away, since I want to carry out an inspection and immediately replace small things? The boiler is three years old, I installed it myself, I will do the repairs myself. From my own experience, I will say that if during repairs you see a leak in the connection of a silicone ring, just one, then change everything, you will see for yourself that they have lost their shape and become oval in cross-section. When replacing the heat exchanger, remove the copper and rubber rings from the old ring and put them on the new one; if the rings leak, lubricate them with silicone. The Navien Deluxe 24 wall-mounted boiler installed in the heating system displays error 10. Why? Error 10 indicates several signs: 1. check the chimney, if it is clogged and exhaust gases cannot escape normally, then the protection is triggered and error 10 appears. 2. the air sensor on the burner is faulty. If the boiler is many years old, then it is better to simply replace it with a new one. 3. The burner fan is unstable. In this case, there is also an error 10. 4. Often you can not change the air sensor by adding a silicone tube. Navien Ice 16K boiler malfunction, error 02 is on. Low water level in the heating system, pressure 2 atm. What could be the problem? The fact is that these models do not have a coolant pressure sensor, they have a coolant flow sensor, and if for some reason there is no circulation, for example: the filter is clogged, the tap is closed, the heat exchanger is clogged, the circulation pump is faulty, etc. the boiler perceives this as error 02. Malfunctions of the Navien Ace 16k Coaxial boiler have arisen: The impeller has fallen apart, after replacing it I noticed that the operation of the hot water supply is somehow strange. It consists of this: 1. the first radiators are heating up a little - everything is clear here - the 3-way valve needs to be replaced - I will replace it one of these days. 2. after opening the hot water tap, the boiler ignites at full power, quickly warms up to 40 (it doesn’t matter what temperature it is set to and weakly depends on the flow rate) and goes out, after a second it lights up again, burns for a full couple of seconds, goes out again. (doesn't modulation work on DHW?). Considering that the settings had gone wrong and the minimum gas pressure was too high, I adjusted the water pressure gauge - yes, the readings were slightly different from the parameters in the fall, but this is explained by the fact that after the winter the gas workers might not have reduced the pressure in the main (private house, 600 m before the hydraulic fracturing, in winter everyone is heated with gas). I adjusted the settings for 16 kW, minimum pressure 16 mm, maximum 43 mm (H2O), after turning off the setting and switching to heating using the coolant, it was visible how the flame modulated within the set limits. However, after switching to DHW, the pressure increased to 80mm! (naturally, it was visible that the flame was maximum and audible.) While the resistor on the board was forcibly reduced to 50mm H2O. Actually, what I want to ask is: 1. The first radiator heats up when the DHW is heated - a replacement 3-way valve. 2. The DHW heats up weakly - it doesn’t reach 60, never - the secondary heat exchanger needs to be replaced. 3. when working on hot water supply, the flame, instead of modulating and maintaining a given temperature, is “regulated” by periodic ignition at full, it seems, rated power. (computer? primary heat exchanger?) 4. noise appeared again when closing the DHW tap while the burners were burning, the pump was making noise, it seemed like it was distilling boiling water. When removing the hose from the boiler to the hot water supply line, the hose was clogged with something hard and lamellar (like scale). Could the 3-way valve not switching completely cause all the other symptoms? It is necessary to do a full check of the boiler and replace parts: Three-way valve - jammed due to destruction of the pusher coating (clean the old one, sort it out, put it in stock - it can still work for some time). Replace the secondary heat exchanger - it may be clogged with solids. (rinse in citric and oxalic acid). We installed and connected the wall-mounted boiler Navien Ace 24. It gives error code 03. At the moment it turns on, the flame lights up and goes out after heating, then it cannot turn on, it just strikes and that’s it. Replaced the ignition sensor (no use). After several attempts to ignite, it shows error 03. A year ago the technician changed the pump, the signs were the same. 1. The pump has absolutely nothing to do with it! Error 03 indicates that the boiler cannot re-ignite. The reason may be mainly due to the gas valve being clogged with dirt and dust. There is a small mesh inside that protects from dirt. Over time it accumulates there, you just need to clean it out. This time. 2. If everything is clean there, and the boiler behaves the same, then you need to look not at the ignition sensor, but at the ignition electrodes. They also need to be cleaned carefully. 3. You also need to look at the gas pressure. It should be normal. 4. If the pump does not work, error 02 is displayed. You can also determine whether it is intact by unscrewing the plastic plug in the center of the pump; the shaft will be visible; it rotates or not when the boiler is turned on. If it spins, the pump has nothing to do with it. In operation, the Navien Deluxe 13K boiler maintains a constant DHW temperature of 45 degrees, although the remote control indicates 30 degrees. The water flow is normal, central water supply. Tell me what needs to be done to reduce the temperature of the hot water supply, is the water too hot? I think that the hot water supply gets so hot because the water itself is not very cold when it flows from a cold tap. DHW water is heated above the set temperature, that is, it overheats only under three conditions: 1. At a given water flow rate, which is indicated by the manufacturer as nominal for a given boiler, but with increased gas pressure when the boiler is operating in DHW mode. The gas valve is not set to the maximum gas pressure specified by the manufacturer, that is, more gas enters the burner per unit time than is required to heat cold household water to the temperature selected by the user. Water is the norm. Gas - a lot. 2. The opposite situation. The flow rate (flow) through the secondary heat exchanger of household (sanitary) water is less than the value that is considered nominal for a given boiler, with a correctly configured (adjusted) maximum gas pressure. Water is not enough. Gas is normal. The root cause may be any dirt that increases hydraulic resistance to the household flow. water in the boiler. The hot water tap is not fully open. A clogged secondary heat exchanger, a clogged filter, the water supply pipes themselves, if they are already overgrown. Weak inlet pressure of cold domestic water. Anything that slows down the flow (flow). 3. 1+2. And water is not enough. And there’s a lot of gas. I recently purchased and installed a Navien GA 35 floor-standing gas boiler. Questions arose: 1) why do I need an extract air temperature regulator (on the front panel), if the temperature is set by a remote control? 2) is it possible to reduce the boiler power, since I am not heating some rooms yet due to renovations? Wall-mounted boilers, as I understand it, have such a function. 1. The boiler can operate without a remote control. That's when you need it. In order for the boiler to work this way, you need to bridge the contacts connecting the room remote control to the boiler. (usually orange). 2. There is no point in reducing power. If the heating area is less planned, then the gas consumption will simply be less in general. Reduce the temperature if you want to save on power, that's all. I recommend using the mode on the heating remote control in radiators. But this is individual, how convenient. Just at the mode of air temperature, the boiler works in maximum mode, turning off and turning on until it reaches the desired room temperature. This mode wears out the boiler more than on radiators. Damage to the boiler Navien Ice 13 shows error 02. What is the reason? Firstly, on the codes of errors, see the boiler passport. There are decryptions, some mistakes can be corrected by yourself. Secondly, 02 can show 2 reasons: a) the low water level in the boiler b) poor circulation in the heating system. In this case, check the filters, clean them, if possible. Or frighten air from batteries. The Navien Deluxe 20K boiler is installed in the system today after the gas pressure drops the stove stopped heating water. After the pressure stabilized the furnace during the reboot, it gives out error 03. The gas supply tap is blocked, but the valve is in the open position what to do? Error 03 is a signal that for some reason the boiler cannot light up. There is no gas, but mainly for this reason. When starting the boiler during ignition, a weak crack is heard for a few seconds? If so, then the spark arises, but there is not enough gas. Usually, after the gas is given again, the air goes first. It doesn't burn. Lower this air on the gas-plate until the gas stove lights up normally. Ideally, you need to check a few things with an error of 03: the ignition transformer or the cleanliness of the gas valve. The work of the double -circuit gas boiler Navien ACE 24 kW. The life is 2.5 years. Today I noticed that the temperature of hot water does not gain 40 degrees (the regime for maximum heating of water is set). Although the pressure of water, as before. A week ago, the boiler did not work for heating. As a result, the temperature in the room fell from 21 to 16 degrees. Restored everything eliminated. Remove the lid and check the boiler at hot water mode, turning on the tap from the mountains. water. At the same time, heating does not work at this moment. Touch the heating pipe (metal parts). They must cool quickly. If heating and hot water suddenly work at the same time, then the problem is in the 3rd chassis. If everything is fine, then it means either you need to clean the main heat exchanger from the outside from the garbage and inside from the scale, and also check the heat exchanger of the hydroelectric power plant from the heating side. It was quite during this period that the same scope could hide.

The appliance is noisy when heating water

Modern boilers operate quietly, so vibration, noise, and extraneous sounds should alert you. What could be an indirect reason:

- Incorrect installation, connection.

- Incorrect setting.

- Wear of components.

There are also very specific reasons why the boiler is humming.

High oxygen content

The water in the pipes is oversaturated with oxygen, which causes bubbles to form when heated. This effect leads to increased noise and vibration not only of the device, but also of the batteries.

Air accumulation in the system

If the boiler knocks and puffs, it is necessary to bleed the air in the pipes. Modern radiators have taps installed. By unscrewing them, you can remove the accumulated air.

Scale formation

A high content of salts in water leads to their deposition on the walls of the heat exchanger. Therefore, when heated, the unit will hiss. In addition, the heating rate and heat transfer are reduced. It is recommended to clean the radiator once a year. To do this, a pump with a reagent is prepared, and the cleaning liquid is pumped through the hoses.

Fan problems

The fan operates in models with a closed chamber and forced removal of combustion products. Why does it make strange sounds when rotating, whistling:

- The grease in the bearings has dried out due to placement above the burner. When exposed to high temperatures, the lubricant dries quickly, which leads to bearing wear. The part is disassembled and lubricated.

- Unbalanced blades, accumulation of dirt and dust. The blades are cleaned and rotated.

Excessive pressure in the heating pump

The pump produces high pressure; its settings need to be adjusted. Too high pressure in the system can lead to an emergency. The values can be adjusted by switching the white lever on the terminal box.

A lack of water in the system leads to serious overheating. First of all, check the thermostat settings, set them to lower values. Measure the pressure and add coolant if necessary.

- If the boiler howls, it is due to an incorrect setting of the gas valve or bypass (jumper pipe).

- When operating at high power, the gas meter may rattle.

- A worn valve makes rattling sounds.

Possible nuances

Today there are many gas wall-mounted boilers from various manufacturers on the market. The principle of operation of the units for all models is essentially the same, but each brand has its own nuances that may be related to the causes of malfunctions and, as a result, poor water heating.

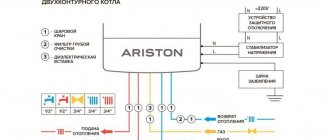

- "Ariston" is an Italian brand that is distinguished by its reliability. The brand’s boilers are adapted to domestic utilities and operating conditions. The most common cause of malfunctions is hard water, which contributes to the formation of blockages in the heat exchanger and circulation pump.

- "Navien" - Korean autonomous gas boilers. They are easy to use and effective. A special feature of the modification is the presence of two heat exchangers and the absence of a control panel on the body. The reason why the Navien boiler does not heat hot water well may be a stop in the operation of the equipment. This is due to the air pressure sensor, which, in the presence of reverse draft in the smoke exhaust unit, sends a signal to the control board, which causes the gas supply valve to the burner to close.

- "Vailant." German quality is fully reflected in the units under this brand. Since the device is of European origin, its heat exchangers most often suffer, becoming clogged due to the poor quality of the conductive heat fluid.

- “Baksi” is another representative of Italian manufacturers of autonomous heating equipment. He has simple and reliable boilers. The main reason why the Baksi does not heat the water, as noted by specialists servicing such units, is a manufacturing defect, which is sometimes found in this model line - a South Korean manufacturer. He provided a certain algorithm for controlling heating equipment. Incorrect settings may be the answer to the question of why the boiler stopped heating water.

- Proterm is a subsidiary of the German company. When operating these boilers, you need to monitor the quality of the heat-conducting fluid and use cleaning filters to prevent clogging of the heat exchanger.

- “Buderus” is another “German” in the domestic market of autonomous heating equipment, which has proven itself on the positive side. Like all Europeans, malfunctions can be caused by the formation of limescale inside the heat exchange system, as well as clogging of the working fluid flow sensor.

Decoding the code

In the instructions, error 16 is interpreted unambiguously - heat exchanger overheating. The emergency thermostat sends a signal to the electronic board and the boiler operation is blocked. In practice, it is more difficult with Navien. An increase in temperature is also caused by other reasons: a lack of coolant, a decrease in the speed of its movement along the circuit. According to the fault table, in such situations code 02 appears.

The nuance is that it is generated based on a command from another sensor - a flow switch, characterized by an operation threshold. The device reacts if the value of the monitored parameter is below critical. In the case when the water level and its circulation are minimally acceptable, and the Navien boiler operates at an increased mode, and error 16 appears.

The DHW flow sensor of the Navien boiler has failed

Conclusion: to troubleshoot a problem, it is wrong to deal with the Navien heat exchanger alone. In order to determine the cause of error 16, a comprehensive diagnosis of the boiler and heating circuit is carried out.