Automatic vent for hot water supply

Today we have to find out why we need to install an air vent in the water supply system. In addition, we will find out in which part of the water supply circuit it can be installed, what kind of air vents can be used there, and how to solve the problem of air in the water supply without an air vent. Let's get started.

Technical parameters and functionality of air valves

In order for the water supply and heating system to function properly, experts recommend installing an air valve. This device allows you to protect the water supply from the accumulation of free air, and therefore protects it from damage. The presence of air bubbles, pockets, and vacuum contribute to the appearance of damage. Depending on the type of air vent, its functionality will change, but the technical parameters remain the same:

- Material. The main raw material for production is brass coated with nickel. Sometimes manufacturers use bronze, but the products are rare and have a high cost.

- Installation features. The air vent must be installed at the highest point of the heating or water supply system.

- The maximum pressure for heating pipes is 10 bar.

- The temperature of the working environment is from 100 to 120 degrees.

- The outlet can be located on the top or side.

- The diameter of the connection pipes is ½, ¾, 1 inch or 3/8.

- Models can be angular or straight.

- The float inside the structure is made of polypropylene or Teflon.

- The service life of parts reaches 30 years.

Variety of models for sewerage

*

Air valves are small-sized devices that can be independently installed into the system. They perform the function of removing air from the pipes, preventing the accumulation of air pockets.

Range

We offer to buy air vents for water treatment as part of an aeration kit. To order, write by email or call.

The three most popular models of air vents in Russia are:

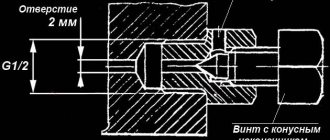

- ARI S-050 manufactured in the USA by ARI Flow control Accessories LTD is the oldest player on the Russian market and the most expensive (such a valve costs about $100). At the same time, it gets clogged more often than others, but never breaks. It lasts a very long time. Requires periodic cleaning. The kit includes an already rotating drainage angle with an internal thread of unknown diameter. Based on our experience, we do not recommend removing it from its seat. Then the connection may leak slightly. The range includes valves with connection sizes 1/2″, 3/4″ and 1″. You can screw the 3/8 tube, heated with a lighter, directly into the air vent fitting. After the plastic hardens, a thread of the required size is formed on it. You can wind a couple of skeins of fum on it and screw it in again. This results in a reliable connection. Cost around $100

- RACI 5361 manufactured in Italy by RACIVENT has not been on the Russian market for as long as ARI, but has proven itself very well over the years. The most resistant valve to contamination. There is only 1″ connecting size. Outlet 3/8 internal thread. An additional fitting for the outlet tube must be purchased. The valves are very high quality, cost around $70

- UNIRAIN ARV-1″A, manufactured in Spain by UNIRAIN, is the most budget-friendly valve for air exhaust, with good quality, resistance to contamination - a good working option. Cost about $45.

- There is a Chinese analogue of the Raci valve on the market - they are the same in shape, but without a label on the plastic. They only work at high pressure.

Air vent valves operate reliably only at a pressure of 2 atmospheres or higher

Tell friends

Design features

The operating principle is based on the application of gravity to the float. If the float is in the raised position, the valve will be closed. If the tap is opened, the float will drop. Inside, the structure contains a rocker arm that is connected to a spring-loaded spool. When air enters the system, the float begins to compress downward, the spool opens, providing an opening for the release of accumulated gases. In principle, the operation of the air valve can be observed as the body fills with water as air escapes, and the spool closes automatically.

This device is installed in the water supply system.

There is a protective cap on the fitting - it serves as a fuse against heat loss in the event of possible malfunctions. The cap also protects against dust and dirt, preventing them from penetrating into the system when bleeding air. For example, an automatic air valve controls the release of air itself. It can operate at temperatures from -10 to +110 degrees, so it is installed both in the water supply and heating systems.

Why is this device needed?

A signal that a valve needs to be installed is the following symptoms: the appearance of unpleasant odors and/or the appearance of extraneous sounds.

Any deviation from the norm is a clue about improper sewer design. The valve is needed to compensate for the pressure in the system. It not only replaces the ventilation riser, but also allows you to solve the following problems:

- Helps out when you can’t install a fan riser.

- Reduces heat loss through ventilation.

- Improves the functionality of the entire sewer system.

- One of its tasks is to protect against the failure of the fan element.

Main types of air vents

*

Automatic air valves allow you to remove accumulated gases in pipes, preventing them from malfunctioning. There are 3 types of air vents on sale - lever, membrane and cylindrical.

Lever

The lever mechanism located inside the structure is more sensitive to contamination of the working environment. The device is considered productive and is used on pipelines and heating systems that use water.

A traditional lever air vent consists of:

- brass body;

- a hollow plastic float moving inside;

- a rocker arm, which is pivotally connected to the float;

- an elastomeric spool located at the end of the rocker arm;

- spring loaded;

- fixed clip;

- lever mechanism.

Side connection model

*

As the water level decreases, the float begins to descend and pulls the lever along with it. This, in turn, opens an oval outlet. Thanks to this process, excess air comes out. Such devices are considered common and are suitable for water supply or heating systems.

Membrane

Membrane-type aerators are made from polyvinyl chloride. The most common use case is at the entrance to the system, where it is necessary to get rid of excess air and air pockets, as well as to prevent pressure drops. Some craftsmen suggest using a bypass valve, which maintains the medium pressure at the required level. This happens due to a bypass through a branch pipeline. The resulting air will not be able to re-enter the system due to the membrane closing the hole.

Cylindrical

The air vent of a cylindrical design has an oblong shape. Such models are often produced automatically; they have a cylinder-shaped float. Models have a side or direct connection; their structure includes a body with a cover, a float, a jet and a spool. There is a shut-off valve located at the bottom, through which the product is connected to the plumbing or heating system. The design must have a sealing ring to protect it from leaks.

Principle of operation

So, let's look at the operating principle of a sewer air valve:

- When draining water, the liquid passes into the sewer pipeline. The process is accompanied by a decrease in pressure.

- Due to the difference with atmospheric pressure, the air valve opens. Air enters through the holes on the side.

- The pressure normalizes after the required volume of air enters the pipeline. As a result, the device takes its original position, which in turn creates a tight system.

The whole process happens very quickly, and as a result of the water seal being activated, unpleasant odors from the sewer do not enter the room.

The air valve for sewerage consists of a body, which is made of high-rigidity polymers. The top part is removable, allowing inspection and cleaning.

The gasket made of rubberized material ensures a tight fit. An air hole is provided, resulting in an opening and closing mechanism. Such a device allows you to equalize the negative pressure in the structure. In normal condition, air flows through the fan pipe.

Note! This device protects the room not only from methane, but also from harmful microorganisms and fungal spores.

Types of locking mechanism

*

All existing heating air valves, sewerage or water supply can be divided according to the design of the locking mechanism. The following types are distinguished:

- Rotary. The models are fixed to the pipeline thanks to an insert. A spool or lever is used to control the air flow. When there is a strong influx of air, the spool turns and air passes through. This type is considered safe and reliable.

- Ball. Such valves are convenient for use on small diameter pipes. The mechanism consists of a ball and a spring, they control the flow of water and air. It is appropriate to use the devices on the system in front of the washbasin or shower.

- Lifting. If the apartment has a vertical riser with a wide pipe diameter, then a lifting type of locking mechanism will come in handy. The essence of the work is to change the position of the membrane made of polyvinyl chloride. The flow lifts the device from below, but reliable fasteners prevent it from rising back.

- Wafer. A small wafer-type air valve is mounted using a thread and can be used on plastic or metal water pipes. The flexible membrane is the working part of the mechanism; its position changes under the influence of water flow.

An example of installing a device under a sink.

A large selection of air valves can be found in plumbing supply stores. The buyer must decide in advance what type of product is needed for installation in the water supply, sewerage or heating system.

Where does air constantly come from in the heating system?

This question is asked quite often and I don’t know the exact answer to it. Just guesses.

Air can be taken from the water itself, in which it is somehow present. If there is a lot of water, then there will be a lot of air. After freshly filling the heating with water, air is actively released for several months.

Air can collect in dead ends, such as closed expansion tanks, and escape gradually. Through the same water. This process is even longer. Hang closed expansion tanks upside down, as I described in the article about open and closed heating systems.

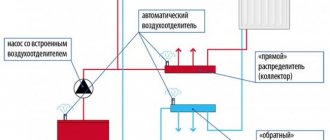

If you have a special air trap in the form of a vertical pipe with an automatic air vent at the end, then this can also be a source of bubbles. The fact is that automatic air vents often “freeze” and stop venting air. Then the tube is filled with air and the bubbles accumulated in the tube are torn off from below by the air flow and carried into the system. In this case, I say that bubbles begin to circulate throughout the system.

If you have an exceptionally strong circulator installed and there is a small hole in the system, then I think air may be sucked into the hole due to the Venturi effect. I have observed this many times in a water supply system, when there is a hole from which water does not flow, but into which air is sucked in by the flow of water. That is, if you turn off the water, water flows out of the hole. And if you open the water at the end, the water stops flowing from the hole. But in reality, I have never seen this in heating systems. In heating systems, the water speed is not so high. But this does not mean that this can never happen.

Personally, in my heating system, the air stops bothering me about six months after freshly filling the heating with water. I don't have automatic air vents. All valves are manual only. But my system is small and my house is small.

Applications for air valves

The devices are usually used in sewerage, heating, and water supply systems. The main task of the valves is to prevent air from getting inside the pipes, and if it does end up there, to remove it, ensuring normal functioning of the system without interruptions or breakdowns.

This shut-off valve is used in the following situations:

- If the plumbing is located far from the common riser.

- If the sewerage system is not provided with normal ventilation.

- If the system has a predisposition to burst pressure release.

A device installed near the siphon.

An air valve will protect the pipeline from damage, because it will help stabilize the air pressure. A variety of models will allow you to modernize the system. The use of a kinetic air valve ensures that no vacuum is formed. It is used to let air in and out of the system before it is filled with fluid. Using electrically driven air valves will help you not have to control the process of changing the air flow, since the device will do everything on its own.

Pros of using the device

*

Before installing an air valve for water or heating, you need to understand the main advantages of all models. The main advantage of using the products will be timely prevention of system breakdown, because the design will not allow air to disrupt the normal functioning of the pipeline. Another bonus is the prevention of odors from the sewer pipe, but this also requires the organization of normal supply ventilation in the apartment.

Accessories for the device

Installing an aerator allows you to save on possible subsequent repairs and allows you not to expose the ventilation riser to the street. Such valves can be used on heating systems and plumbing. The device ensures stable, uninterrupted operation of all systems.

Installation instructions

The first step is to turn off the water supply riser in the apartment or house. Then select the area where the valve will be located and cut it out with a grinder. Clean the end surfaces of the pipe from nicks.

To ensure a tight seal, a rubber gasket must be placed in the socket (if the installation is threaded, instead of the gasket, use plumbing film). After this, install the aerator and firmly fix it into the riser.

We recommend that you read: The use of an American tap in various types of pipelines

For one apartment, at least 3 valves are required for internal sewerage - one for each consumer.

Aerators must be accessible so that they can be easily inspected and cleaned. And cleaning is needed once a year.

Basic installation rules

You will need a compensating pipe, a clamp, couplings, and a tool for cutting pipes. If the valve is installed in a new sewer, then no tools are needed - everything is done manually.

Work algorithm:

- shut off the water supply to the system;

- make a cut on the selected section of the pipe;

- remove a section of pipeline that is identical in size to the valve;

- install the air valve and secure it with clamps;

- fill all joints with sealant;

- check the system: open the heating valves and fill the pipes with liquid, checking them for leaks.

Example of device installation

When installing the device in a sewer, it is necessary to connect the water supply and drain the tank several times. The valve is adjusted manually, and if the device is equipped with an electric shutter, the process occurs automatically.

When installing things on their own, many apartment owners make mistakes. For example, they do not clean the joints with the pipe before installation, which leads to accumulations of waste. One of the omissions is the presence of a chamfer, which must be removed before assembling the socket joints. Do not forget that the air valve must be mounted at the highest point of the system.

Alternative replacement options

If for one reason or another it is not possible to install a CM or an automatic air vent, you can use alternative methods to de-air the heating system.

Installation of a water tap

Typically this element is installed at the outlet of the heating system. Using such taps, you can fill the system with coolant and drain it. In a private house, if there is an autonomous heating system, the same tap is installed at the entrance, which greatly simplifies the process of detecting steam-air plugs in the system.

To completely de-air the system, the system is filled with coolant through the initial tap, and it is drained through the final tap. The process continues until the working fluid begins to flow out in a uniform stream, which will indicate the complete absence of steam-air plugs in the heating circuit.

Loosening the radiator plug

You can bleed air from the radiator, and at the same time the pipelines, by unscrewing the top plug on the side opposite to the supply line by 0.5 - 1 turn. The air in the radiator, and after it the coolant, will rush into the resulting gap. Despite the effectiveness of this method, it is highly undesirable to use it, since there is a high probability of coolant escaping onto walls, ceilings, carpets, etc.

Using an expansion tank

If the speed of movement of the coolant is low, which is typical for gravity heating systems, it is advisable to provide the possibility of natural de-airing. To do this, a vertical outlet is installed in the upper part, at the end of which an empty membrane-type compensation tank is mounted.