Automatic air vents have not yet appeared that would not leak periodically. Which, in general, is not difficult to eliminate temporarily. Why do they leak, how to deal with it, and also why such devices are needed in heating, and how to use them correctly...

Why do you need an air vent?

Any closed pressure coolant system must have one or more air vents. At least one of them is automatic, releasing air on its own, without human intervention, as accumulation occurs.

This ensures the operability of the system and prevents airing. In an air-filled system, the coolant does not move normally, the equipment does not operate stably, noises and pops are heard - small water hammers. Equipment and pumps wear out faster.

Or the air lock will stop the movement of the coolant completely. Without a small device - an automatic air vent - the system will not work normally - airing will occur.

Where does the air in heating come from and how is it removed?

Air is dissolved in water (in the coolant) and is released when there are changes in pressure and temperature, forming bubbles that accumulate in the upper part of any system.

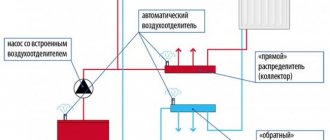

To remove air, it is necessary to install air vents in many characteristic places of the system, and automatic ones at the most important points where air accumulation is likely. To quickly, constantly bleed off the gas.

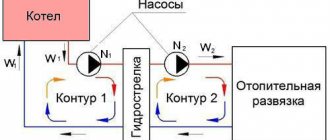

They also make separators - sections of pipe with a significant difference in diameter. In the area where the pressure decreases (the movement of the liquid accelerates), air bubbles are released, then they accumulate at the expansion - where they are removed by the described device.

Automatic air vent design

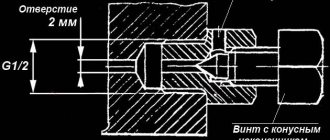

The device is based on a body with a float. The float is connected to a needle release valve, which is located at the very top. If the body is filled with water, the float closes the valve, and the outlet is closed. When air appears, water is displaced, the float sags, the hole opens, and air, accordingly, comes out.

The design of the automatic air vent may be different, the body is steel or bronze, the lever mechanism from the float to the needle may vary. But there is one peculiarity - always strictly vertical installation, only in this position the device works.

A corner design is also possible - the so-called. radiator automatic air bleeder, which is screwed into the end of the structure, usually instead of a radiator plug.

In what places are they located?

The safety group for non-automated heating systems (solid fuel boiler) is equipped with an automatic air vent. In automatic boilers, such a device is always provided inside.

As a rule, for a small home system, one such air valve is sufficient, which is complemented by Mayevsky taps - manual devices for bleeding air. They are installed at the end of each radiator.

Where to locate - automatic air bleed points

In branched systems, automatic air vents are installed in several places. In addition to the boiler device, the following are also installed:

On each collector, including underfloor heating.

- On high, U-shaped non-standard bends, for example, on the edge of a door.

- At the top point of the highway of each floor in a multi-story building.

Equipment of radiators with Mayevsky taps

At the end of each radiator there must be a manual valve for bleeding air. The simplest device - a manual valve - the Mayevsky tap received the greatest popularity. When the valve is unscrewed, the accumulated air is released. The coolant will flow out after the air.

Radiators are usually installed horizontally, or so that the edge with the valve is 1 cm higher. This is enough to reliably capture and remove air. In large networks, it is advisable to tilt one of the series-connected radiators a little more and equip it with a corner automatic air vent. Such a device will serve as a separator.

Why does it flow

Plaques and salt deposits gradually form on the needle valve of the air vent. The hole no longer closes tightly - water oozes out - the device leaks.

It is necessary to disassemble the device and very carefully clean the valve needle, seat, and other parts from deposits with a soft tool. If the cleaning is normal (which is not easy to achieve), then you can forget about the leak for a while, until the next accumulation. It is also important to assemble the housing without leakage; FUM tape is usually used to seal the threads, and the housing itself is tightened by hand.

How to install

There are a couple of important nuances in installing an automatic air vent. It must stand vertically, the valve hole must be straight up, otherwise it will not work. Accordingly, to install it in the main line, a tee of the corresponding thread diameter is screwed in - 1/2 inch.

Polypropylene pipelines have their own tee with metal threads soldered into place. The security group comb provides its own outlet. But the air vent is leaking, so how can you disassemble it without draining the coolant from the system?

Application of shut-off valves

The automatic air vent is a frequent maintenance device. It needs to be disassembled and cleaned to prevent leaks. But it is not at all necessary to release the coolant and reduce the pressure in the system.

How does air enter the circuit?

There are two types of contours:

Peculiar automatic air vents in an open-type heating system allow coolant to pass through them, which circulates by gravity. The direction of circulation is determined by the design of the circuit. It always maintains a slope from the highest point, on the supply flow, to the lowest, on the return. There should be no air pockets. Air enters the heating system together with the coolant, which is in contact with it in the expansion tank. Then it is drawn into the flow in the form of small particles, since it is impossible to bleed air from the heating system from a coolant with a temperature of 20 degrees. The hotter the water, the more intense the process of separation of bubbles from the coolant occurs. The liquid pushes the bubbles upward. Accordingly, they reach a peak point where they find a way out.

Since expelling air from heating is one of the key tasks for safe and efficient heating of premises, equipment specially designed for this purpose is installed in the circuit.

Closed systems are sealed and circulation in them occurs thanks to a pump. In such circuits the flow rate is higher. They are designed in such a way that air pockets are formed in them. In this case, the installation of special equipment is required, since it is necessary to bleed air from the heating system while maintaining its tightness. It's called an automatic heating system air bleeder. Since the system is not in contact with the environment and is sealed, oxygen can only enter it with the coolant.

In addition to the transit of oxygen by the coolant into the circuit, airing can occur:

- due to mechanical damage;

- due to repair work;

- in case of leakage;

- after verification work.

Since it is not possible to prevent oxygen from entering the system, it is necessary to ensure that it finds a way out. For this purpose, several types of equipment are used to perform the task. They can work autonomously or in manual mode.

Types of equipment and principle of its operation

- open type expansion tank.

How to remove air from a closed heating system with a simple tank? It can perform the function of an air vent only in open circuits. Since it is not possible to ventilate a closed circuit heating system using a tank. Only sealed tanks are installed in them. The open tank is at the peak of the circuit, where oxygen bubbles tend to flow. The problem is that the water is enriched with it in the same tank, so there is a high level of air in the coolant, which is there until the liquid is heated;

Installed at the highest point or in a place where oxygen accumulates. The threaded part of the heating system air bleeder comes in two diameters: ½ or ¾ inch. In shape they can be flat or bent at a right angle, like the letter “g”. The air outlet hole is located either at the end or on the side of the housing. Works offline. Air is released from the heating system when the pressure in the system rises to a critical level. Consists of a valve and a float. The working principle is that when oxygen rises, the float moves down and opens the valve. As soon as a release occurs, the float rises, returning to its original position, and closes the valve;

- air separator for heating.

Placed on the feed. Unlike an automatic air vent, it does not remove the oxygen that itself separated from the coolant and rose up. The air separator in heating independently separates oxygen particles and gets rid of them. It is designed in such a way that the flow mixes when encountering obstacles. Barriers may include:

Air separator for heating

Since they are installed in the area behind the boiler, where the temperature is highest, their operation becomes more efficient. Oxygen is more readily separated from hot water. Automatic air discharge from the heating system is carried out continuously. Works autonomously without human intervention;

Removing air from the heating system requires human intervention. The tap is located at the end of the heating radiator. This is the white “twist” on the battery with a bolt screwed into it in the middle. There is a hole in the plastic, small as a needle, since this is more than enough to bleed air from the heating radiator. In order to do this, you need to prepare a vessel for water, a half-liter jar will do, unscrew the tap a little and after the hissing stops and a trickle of water starts flowing, close it. That's it, the plug has been removed.

The air vent in the heating system, depending on the type, can be installed not only at the top point of the circuit. They are also installed in problem areas and downstream of the boiler.

How does an automatic air vent work?

The cold coolant poured into the heating line tends to release air when heated; to bleed it, automatic air release from the heating system is used.

The operating principle of all automatic devices is to open the bleed hole when air appears in the internal area of the air vent housing. The element that reacts to the presence of air is a float immersed in the inlet pipe of the device, which is connected to a valve that closes the air outlet hole. The automatic device works according to the following principle (Fig. 3):

- When the heating is functioning normally, the float located in the space of the cylindrical working chamber is in the upper position and the cone-shaped rod connected to it closes the outlet channel.

- If air accumulates in the upper part of the tank, the float goes down along with the locking rod and the air valve opens, air is released from the device.

Rice. 4 Automatic air release valve from the heating system

Device

There are various designs of automatic air bleed valves on the market; let’s look at the design and operation of one of the most common types.

This model (Fig. 4.) has a composite body made of brass, including the main part 1, which is screwed into the pipeline, and its cover 2 with a locking mechanism, connected to the base through an o-ring 10.

In the non-operating state, the liquid entering through the inlet pipe from below lifts the plastic float 3; it, through a flag, presses on the spring-loaded (spring 7) holder 5 with spool 6, which locks the passage channel in the nozzle 4.

Jet 4 is located in the side part of the air vent and is connected to the body through an o-ring 8; in the upper part of the device there is a plug 9, which regulates the passage channel of the air outlet or closes it completely if necessary.

When air appears in the float chamber, it displaces the water in which float 3 floats, the element lowers along with the flag, and spring 7 pushes the spool holder away from the outlet channel - the air is released. When the volume of discharged air decreases, water enters the working chamber again, the float floats up and closes the channel using a locking mechanism.

Typically, when connecting an air vent, adapters from a shut-off check valve are used, which is a spring-loaded locking mechanism and an associated flag. When the air vent is screwed in, it presses on the shut-off valve flag, the latter goes down and opens the way for water to the vent body.

When dismantling the drain for replacement, maintenance or repair work, the released spring-loaded flag together with the shut-off valve rises up and blocks the coolant flow channel.

Fig.5 Manual air valve of the heating system in the battery

Specifications

The main material used for the manufacture of housings for manual and automatic air valves for bleeding air from heating systems is nickel-plated brass (bronze is used much less frequently); vent valves have the following characteristics:

- Installation - at the highest points of the heating circuits in a straight section.

- The permissible temperature of the working environment is from 100 to 120º C.

- Maximum pressure 10 bar (atmospheres).

- The connecting diameter of the outlet pipes is 1/2″, 3/4″ (the most common sizes are indicated in the metric layout as Dy 15 and Dy 20, which corresponds to 15 and 20 mm), 3/8″, 1″ inch.

- Connection type - straight and angular.

- The location of the outlet fitting is on the top, on the side.

- Contents – sometimes supplied with shut-off valve

- Working medium – water, non-freezing coolants with glycol content up to 50%.

- The material used to make the float is polypropylene, Teflon.

- The service life of brass devices can reach 30 years.

How to remove a plug from a circuit

Before removing air from the system, it must be detected. Options:

- before you bleed the air from the heating system yourself, would it be better to call a technician and get it over with?;

- try to find it yourself by knocking on the pipes. The sound in the area where the traffic jam is located will be different;

- check the uniform heating of the radiators. The top should be warm, there may be a slight difference from the bottom. The main thing is that the temperature at the top is higher. If this is not the case, then there is a problem in the batteries.

To remove air from the radiators in a private heating system, it is enough to use a Mayevsky tap. In other cases, you must first check the condition of the equipment responsible for this process. If it is in working condition, you can increase the pressure so that the plug comes out on its own, or refuel the system. If the circuit is filled from scratch, then you need to fill in water in several stages, without rushing. In this case, all taps, except the drain, must be open. We need to provide more options for oxygen to escape. Some craftsmen remove the cork by tapping along the contour. The method works, but this does not mean that you need to take a hammer and hit the pipe harder. No, you need to know how and where to hit, otherwise there will be no use, only harm.

In addition to the familiar Mayevsky taps, modern heating systems commonly use a device such as an automatic air vent. Its task is to remove air from a certain section of the heating network without human intervention. How this important device works, the principle of its operation and its installation location - all these nuances will be discussed in this article.

Causes and consequences of air locks in an open heating system with natural circulation

If the pipe slopes in the system are correctly designed, then all the air will be released through the open expansion tank, which is located at the top point of the heating circuit. There can be several reasons for an air lock:

- After repairs, air remained in the heating radiators;

- Incorrect (too fast) filling of the system at startup;

- The circuit is filled with water through an expansion tank;

- When heated, air begins to be released from the water, which was previously in a dissolved state;

- When filling the circuit, water was supplied from above.

The consequences are not difficult to predict - stopping circulation, cold batteries, rapid corrosion of the internal surface of system elements. To avoid this, it is enough to install manual air vents on all radiators - Mayevsky taps.

Design and principle of operation of the air vent

Due to various circumstances, an air lock may appear in water heating systems, preventing the normal circulation of the coolant. As a result, part of the radiator or several batteries located on the same branch or riser cool down. So that the air that appears can leave the system on its own, an air vent operating in automatic mode is installed at certain points.

The device is a sealed metal case with a connecting pipe located at the bottom. Inside the body, in the chamber, there is a float made of polymer material, connected by a rod to a needle valve, the hole of which is made at the very top of the lid. The air vent device is shown in detail in the diagram:

The normal state of the air separator is when the body is filled with coolant, the float is raised to the maximum upper position, and the needle valve is closed. Over time, air from the network enters in small portions into the chamber of the device and displaces water.

The float gradually lowers and at a critical point begins to open the valve communicating with the atmosphere through draft. Thanks to this, all the air accumulated in the chamber under water pressure quickly leaves it through the open hole. This is the operating principle of the automatic air vent, as shown in the figure:

After all the air has gone out, water takes its place in the chamber, raising the float to its original position. The valve closes and the air vent goes into standby mode. The automatic float air vent also plays a very important role when emptying the system or its section. Since when the coolant level in the chamber decreases, the lever will open the valve, this will allow air to enter the system and thereby speed up its emptying.

Ball

Sewage flooding is especially likely in high-rise buildings, where several apartments are located on one vertical pipe. Even one plastic bag may be enough to clog the riser, and then yes, not finding its way, will rush back, splashing out of all the drain holes. This situation is especially likely in old houses, where the pipes are covered on the inside with thick crusts of deposits.

The risk of backflow of waste water is especially high in apartments on the ground floor. Often at night in such apartments it is necessary to plug the drains with rags, plugs and other improvised plugs. But if valves are installed on the first floors, water can break through on the second floor. Up to the third floors, the pressure is usually not enough, and if it is strong enough, it will simply destroy the blockage and the water will go into the pipe.

So, it’s worth installing a check valve if:

- Your apartment is located on the first or second floor.

- You live in an individual home: a cottage, a dacha, a private house.

- The house was built a long time ago and there has been no major repair of the sewer system or replacement of risers.

- According to neighbors, there are frequent cases of sewer blockages in the house.

In this case, the small costs of purchasing and installing protective devices will pay off handsomely, allowing you not to worry about sudden costs and hassle.

If your home has a common riser valve installed, it can reduce the risk of flooding. But in problem apartments it is better to install separate valves on each drain to be completely sure.

Device

In 2022, there are many options for such a unit. They differ in materials, sizes and shapes, locking methods and many other parameters. But all types of valves have the same purpose - to cut off sewer water in the pipe that rushes sharply in the opposite direction.

Almost any design has the following elements:

- The pipes through which drained water enters and leaves the valve.

- A handle that closes the valve forcibly. It can be used when cutting off drains at night, or when trying to unclog a sewer system.

- A removable cover that allows you to inspect the condition of the valve and, if necessary, clean its parts from contamination.

- Locking mechanism. A ball valve is a rubber ball, but membranes, flaps and other devices can also be used.

The valve will not work if the “input” and “output” are reversed. Typically, the direction of movement of the drains in the valve is shown by an arrow marked on the body. Take this into account during installation!

Types of Automatic Air Valves

Based on their design, devices can be divided into 3 types:

Note. Despite external differences and different areas of application, the principle of operation of the air vent remains unchanged.

The most common are traditional devices with a direct connection pipe. The scope of their application is very wide. Automatic air separators are primarily designed to release air through the highest points of the pipeline network. To do this, they are placed at the very top of vertical risers, where, according to the laws of physics, all air accumulations that appear in the pipes tend to fall. If it were not for the automatic air vents in the heating system, it would have been very difficult to manually release air from the highest points.

Closed heating systems under pressure are equipped with boiler safety groups, which are located on the supply pipeline leaving the heat generator. Along with the safety valve and pressure gauge, this group also includes an automatic air valve. Its task is to bleed air when the boiler tank is filled with water. If the piping of the unit is done prudently, then, if necessary, it can always be cut off from the rest of the system and emptied using an air vent, and refilled after servicing.

Note. Safety groups for heating must be installed on boilers that burn solid fuel.

Air vent devices are also used in some models of circulation pumps. The goal is to ensure uninterrupted operation of the pumping unit. The fact is that the pump can only move an incompressible medium - water or other liquid. The entry of air into the area of the unit's impeller threatens to completely stop the circulation of the coolant, which is what the air vent of the circulation pump is designed to prevent. Any air or steam from the boiler that enters this area will be immediately released and the pump will continue to operate.

Installation principles

The automatic air release device is installed vertically - for both straight and corner models, the cap covering the outlet is directed upward. A ball valve or shut-off valve must be installed in the pipeline before the drain valve.

Attention! An exception is the air vent in the boiler safety group - there should be no shut-off valves between this unit and the boiler pipe.

A shut-off check valve allows you to clean the air vent or replace a faulty device without draining all the coolant from the circuit. The automatic air vent with a check valve is easy to use.

When installing an automatic Mayevsky crane, use a wrench rather than an adjustable wrench to control the tightening force of the fasteners. In this case, you should not hold the device by the body, so as not to break it. Hold the air vent by the hexagon under the cylindrical chamber.

Corner and radiator air vents

In different heating systems, many situations may arise when it is necessary to remove air pockets in the most inaccessible or remote places. It is impossible to list them all, as there are too many options. Where it is not possible to install a simple valve because the threaded pipe at the end is in a horizontal position, an angled air vent will do. Its pipe, coming out from the bottom, turns at an angle of 90º and can be connected to a horizontal section.

It should be noted that an angular air vent with an external threaded connection is no different from a conventional straight valve except for a rotated pipe and can be used instead of it if necessary.

Often, to automatically bleed air from batteries, instead of the traditional Mayevsky tap, some users install an angle valve. This can be relevant in an unpleasant set of circumstances, when gases are constantly formed in the network and this happens precisely in radiators. The reason is a chemical reaction of substances sometimes present in water with the aluminum alloy of batteries at elevated temperatures. There is no point in installing a valve with an angle pipe, because there is a special automatic air vent for radiators, shown in the photo:

These devices are designed for batteries only and have a suitable threaded connection. Instead of manual taps, it is preferable to place them on heaters made of aluminum or partially bimetallic, where there is also contact between the alloy and water. In other situations, the radiator air vent is mounted at will, but there is no doubt that it will bring ease of use.

Note. It is still better to equip traditional cast-iron batteries included in the centralized heating network with a Mayevsky manual tap and drain pipe.

For ease of maintenance and cleaning, complete devices are available for sale - automatic air vents with a valve. The latter is a small threaded adapter with a spring-loaded petal valve inside. The adapter is screwed onto the thread directly in front of the air vent and serves so that when the system is in operation, it can be removed and cleaned or replaced. Air vents from DANFOSS, VALTEK and many other well-known brands are equipped with similar adapters.

Another option for a manual air vent

This valve is produced by the same companies that make automatic valves. There is also a cone here, but the design of the device is somewhat different. In addition there is a handle. It is, of course, more convenient to use than a key. The principle of operation is similar: turn in one direction, the cone moves away from the hole, the air comes out. Turned it in the opposite direction and closed the hole.

This is another manual air vent. There is also a shut-off cone here, but of a slightly different shape

A little about prices. The price of the Mayevsky faucet is $1.2-1.5, manual valves of other types start from $2. It’s hard to say how much the most expensive one might cost, but there are “antique” models that offer to buy for $20.

How does air affect heating performance?

Air in the heating system is one of the reasons for heat transfer disturbances

reduction (sometimes partial) of circulation. When the heating system becomes airy, it causes a decrease in the efficiency of its operation and excessive fuel consumption;

Air in the heating system can lead to pipe leaks

Where does the air come from in the system?

It would seem that everything is being made airtight, and the question would be quite reasonable: where does the air in the heating system come from? It is quite difficult to answer unequivocally, there are many such reasons, of which it is worth noting:

- Failure to comply with the requirements regarding compliance with pipe slopes during the installation process;

- Incorrect filling of water, as a result of which the heating system becomes airy;

- Loose connections of various components and parts can be a source of air entry, which will air the heating system;

The absence of special automatic devices (air vents) that automatically remove air from the system, or their incorrect operation;

The reasons for airing in the heating system outlined above do not cover all possible situations when and how this can happen. But they make it possible to understand why the heating system is becoming airy, and to take timely measures to eliminate this phenomenon.

Recommended reading:

Installation locations for air vents

How to prevent air from entering the system?

Here it is necessary to consider several situations - when filling the system with coolant and during its operation. Its design must include air vents and Mayevsky taps, allowing for de-airing of the heating system. The recommendations given apply to a closed system with forced circulation.

Installation of air vents

They are placed in critical places, such as pipeline bends or their highest points. In many cases, when the heating system is constantly airing, they help cope with this problem. There are manual and automatic.

- Manual air vents. These include, first of all, the Mayevsky crane, named after the inventor. Installed at the end of the battery, thanks to it you don’t have to think about what to do if the heating system is airy. With its help, you can independently release the accumulated air.

- Automatic air vents. They allow you to solve the problem of how to ventilate the heating system without additional participation and expense.

Filling the system with water

It is carried out from the bottom up with cold water. In this case, all taps must be open, except those that drain water. Thanks to this filling, the heating system will not be aired; as the water rises, it will squeeze the air out of it. Filling is carried out smoothly; with a sharp rise in water, the formation of closed volumes and the formation of air bubbles is possible.

Filling the heating system with water

As soon as water flows through the open tap, it is closed, and so they gradually rise higher until the entire system is filled. After this, it is quite possible to start the pump; if everything is done correctly, then circulation will occur, and there is no need to rack your brains about how to bleed the heating system.

Installation recommendations

Regardless of the type of automatic air intake for heating, you need to ensure that the exhaust cap faces up during installation. Bleed valves in systems are usually installed after ball valves or shut-off valves. An exception to the rule is the boiler safety group: secondary intermediate fittings are not used in this case.

Thanks to the shut-off check valve, it becomes possible to carry out maintenance or replacement of the air vent without emptying the entire heating system. Therefore, having such a device is very convenient. Only wrenches are suitable for installing an automatic bleeder: they, unlike adjustable ones, allow you to measure the effort required to screw the fastener. During installation work, it is not recommended to hold the device by the body to avoid damage. For these purposes, the design provides a hexagon at the bottom of the cylindrical chamber.

Removing air from the system during operation

However, with all the measures taken, the formation of traffic jams is possible during operation. The reasons why the heating system will air are discussed above, and we will not return to them again. However, it is necessary to consider how to properly ventilate the heating system during its operation.

When faced with such a task, you need to act as follows:

- Determine the place where the air has collected. This can be done by noise or pipes and radiators, they are colder in such places.

We are looking for a point located higher in the direction of movement of the coolant, at which there is a Mayevsky valve through which air can be released.

This is a universal, standard algorithm of actions that allows you not to think about how to eliminate air from the heating system.

The operation of heating any home largely depends on its correct installation and provision of the necessary conditions during operation. One of them is the lack of air in the heating system. The use of the necessary equipment and proper operation will create the prerequisites for its long-term and trouble-free operation.

Mayevsky crane

If air accumulates in the heating radiators, it is necessary to use a special key or a screwdriver to turn the slot on the gas vent disk one or two turns counterclockwise. After this you can hear hissing. The coolant will begin to come out with the air in a small stream. But when the coolant begins to flow out in a continuous stream, you need to close the tap and turn the key or screwdriver in the opposite direction.

When turning on the heating system, it is necessary to carry out such a procedure, but during the year it will not be superfluous to check the presence of air a couple of times. After the heating season has ended, it is recommended to check the presence of air. But for this you cannot drain the coolant. After turning off the radiators, you can turn the tap a little. This will create a small hole through which the coolant will not be able to flow, and the resulting air will escape.