AGV-120 is one of the most popular (and only) gas water heaters in the Soviet Union with the possibility of using them as a boiler and a gas water heater. It is one of the first domestic models equipped with automatic equipment that prevents the supply of natural gas to the burner after a certain temperature has been reached. All modern gas pumps have a more efficient design with higher efficiency and lower energy consumption. However, the principle of operation is based on the design features of the 120th model.

Domestic AGV-120 Source Youla

Advantages and disadvantages

Installing an AGV-120 or other modification of a gas water heater has the following advantages:

- Independence from the availability of electricity. This criterion in most cases is one of the main ones when choosing a suitable unit. For the operation of the AGV-120 model, no electricity is required at all, both during ignition and subsequent operation.

- Low cost. Compared with foreign automatic devices, domestic AGVs are more advantageous due to the low cost of the model itself and other components.

- Economical. Gas water heaters are considered one of the most profitable in terms of gas consumption.

- Maintainability. The model was developed more than fifty years ago and does not have any complex electrified components or mechanisms. Any routine repairs, maintenance and prevention can be carried out independently (if you have certain skills and tools).

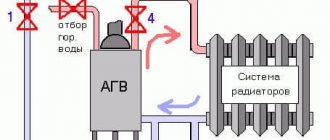

Schematic illustration of the connection of AGV-120 Source diafilmy.su

The disadvantages of units of this type include the following features:

- Big size. To install an AGV of any model, almost a cubic meter of room space is required. This value, given that such units are mainly installed in small kitchens or boiler rooms, negatively affects the remaining free space.

- Lack of aesthetics in appearance. Visually, the AGV-120 looks very utilitarian and does not represent anything valuable in terms of improving the interior. The history of the model dates back to the late 60s – early 70s. therefore, it cannot be combined with modern interiors. In addition, we should not forget about the obligatory chimney, bulky radiators and heating system piping.

- Low efficiency. This factor is reflected in comparison with high-tech modern equipment. It should be emphasized that this disadvantage during the era of the “reign” of the AGV-120 was compensated for by the low cost of natural gas.

AGV boilers in the apartment

To install the device indoors, you need permission from the relevant city service. Installing the unit in an apartment in a low-rise building will not cause any difficulties with documents. To install an AGV, a removable chimney ducted outside through a specially made hole in the wall is sufficient. The main thing is to correctly calculate the boiler power, since the device may not be suitable for large apartments without high-quality insulation.

Short description

AGV-120 is a unit designed for water heating of rooms not connected to centralized heating. It runs on natural gas, the tank volume is 120 liters, which explains the name of the model “gas water heating device 120 liters”.

Heating of the coolant in them is carried out without the use of circulation pumps. The first models did not have a coil inside. Later it began to be installed, which had a positive effect on the efficiency of the device. The device can simultaneously perform 2 functions:

- Act as a heating boiler.

- Act as a source of hot water supply.

Made in the form of a cylindrical tank filled with water. The tank walls are made of galvanized steel. From the outside, the structure is protected by a sheet steel wall. The water is heated by a flame tube, which is located in the central part of the tank and performs 2 functions:

- The above-mentioned heating of the coolant.

- The removal of combustion products, that is, is the lower branch of the chimney.

AGV-120 in modern design Source kaminy-kazan.ru

Diagram of a capacitive water heater AGV 120 Source diafilmy.su

Reducing heat loss and the likelihood of accidental fire is ensured by the gap between the walls of the tank and the main body. The space between them is filled with slag. The type of burner is circular with an internal rim and five connecting branches. It is made of cast iron, the fire holes are directed towards the top.

The supply of cold coolant is carried out at the bottom of the tank. The outlet of the heating system heated into the pipeline is at the top. If the AGV 120 acts as a water heater and boiler, a “return” branch is connected to the lower liquid supply pipe.

Healthy! “Return” is a branch of the pipeline through which the cooled coolant, having overcome the entire pipeline, returns to the boiler for the next heating.

Automatic gas water heater AGV 120 Source youla

The thermostat is responsible for monitoring and regulating the water temperature. Its thermoelement is installed inside the working volume. The burner is automated thanks to an electromagnetic valve and a thermocouple.

Nuances of operation

When using gas equipment from ZhMZ, you should know: the burner, when starting, creates noise - cotton. In some modifications it is minimized - it turns on more smoothly.

The chimney is installed outside the residential premises. The diameter of the chimney is 14 cm. Under its pipe there is a container for collecting soot, which needs to be cleaned from time to time.

Floor-standing devices are installed in separate rooms, on the lower level of the building. The new equipment comes with instructions, connection diagram and technical data sheet.

Specifications

The AGV-120 gas boiler was developed on the platform of the AGV-80 water heater, which became the first Soviet unit of this type. The device of the modified model was almost identical to its predecessor, but differed in technical characteristics, reflected in greater productivity and power. During many years of operation, both models have proven themselves to be positive.

As mentioned earlier, the name of the unit reflects the volume of the coolant reservoir - 120 liters. The manufacturer's technical documentation indicates 14 kW of thermal power, with a lower thermal performance of only 10 kW. This also affects the rate of heating of the water in the working volume. It will take at least an hour to heat up to 80°C. And this is subject to an optimally functioning system (high-quality gas, clean burner, igniter, unclogged heat exchanger and chimney).

Comparative technical characteristics Source prootoplenie.com

The boiler is designed for installation to heat rooms with an area of 75-85 m2. It is also capable of acting as a source of hot water supply with a temperature range from 30 to 95°C.

Operating principle in simple words

The design and operating principle of the AGV-120 are quite simple. The unit is a tank with a vertical metal pipe installed inside it. The rest of the space between them is filled with coolant. In most cases, ordinary water is used for this.

At the bottom there is a gas firebox in which a gas burner burns. The resulting thermal energy and combustion products pass through the pipe, transferring their heat to it. Naturally, its metal walls heat the water placed in the tank. Then everything is carried out according to the classical law of physics: the hot water rises and begins its movement along the risers of the heating system.

Healthy! The hotter the boiler is heated, the faster the water circulates in the system (for pipelines with a natural coolant circulation system).

The principle of operation and design of AGV-120 using a clear example Source prootoplenie.com

Modern boilers have an automatic control system that is responsible for supplying gas to the igniter and burner. This happens due to the readings of the built-in temperature sensor, the function of which is to control the temperature of the liquid.

After the value reaches the set value, the automation closes the damper and shuts off the gas pipeline. Only a small pilot light burns, serving as a kind of lighter. When the coolant temperature drops, the sensor is triggered again and the damper opens. The gas enters the firebox, ignites and the process of heating the liquid resumes.

Healthy! Automation of gas equipment significantly reduces the number of accidents during domestic consumption of natural gas. For example, if the pilot flame goes out as a result of low pressure in the gas pipeline, a clogged chimney or other malfunction, the boiler will not be able to start.

Criteria for choosing wisely

The efficiency of the system largely depends on the correct choice of gas boiler. The determining factors when choosing an AGV installation are:

- The area of the heated room.

- Unit power.

- Possible heat loss.

The boiler should be selected taking into account all the characteristics of the room

The range of standard AGW power values is quite wide: from 11 kW to 35 kW and above.

Tip: The optimal power parameter of the device is calculated using the formula. To do this, 1 kW of unit power is divided by 10 sq.m of heated premises area.

Heat loss largely depends on the type of building materials used in the construction of the house. If materials with high heat losses are used in the construction of a building, then an additional 25% is added to the initial power of the unit.

The specific power is determined by the climatic characteristics of the area and is calculated for each region separately. For example, for northern regions, characterized by lower temperatures in winter, it is 1.5-2 kW. For southern regions - from 0.7 to 0.9 kW.

Of no small importance is the value of water pressure in the heating system, as well as the value of pipe resistance. To obtain more accurate calculations, experts recommend taking into account the total length of the forward and return pipelines, while setting a coefficient for the resistance of the material.

Boiler for a medium sized house

Important point: In the simplest economy class models, the material for the manufacture of the heat exchanger is steel. More expensive wall-mounted models are equipped with stainless heat exchangers, which are highly technologically advanced. Floor-standing units have cast iron heat exchangers, which are famous for their good heat capacity.

For heating private houses with an area of 100-200 sq.m, among the models of domestic manufacturers, the most popular types of gas boilers are:

- AOGV – gas water heating device;

- AKGV is a complex gas water heating device.

In addition to the main heating circuit, these devices have a circuit for supplying hot water. The heating of the coolant for water supply in units of this type is carried out through a copper coil, which is located around the perimeter of the tank, and the water for supply to the radiators is heated in the boiler itself.

Boiler connection system

The main advantage of these systems is their efficiency and low cost. Depending on the modification (floor or wall model), you can choose different installation options. But in any case, a separate room must be allocated for installation of the unit.

Among the significant disadvantages it is worth highlighting:

- Insufficient compactness of equipment. The unit occupies a total room space of at least 1 cubic meter.

- Energy dependence – the need to connect to a power supply.

AGVs from foreign manufacturers, such as RINNAI, FERROLI and ANIERIA, are more expensive. They are famous for their high reliability and ease of operation. In some models, the necessary parameters can be set electronically. But imported units also require an electrical connection.

But in any case, the choice of AGW is determined by the availability of energy resources. The use of automated control systems allows intervention on the part of the owner to be kept to a minimum.

Design and principle of operation

As already mentioned, the AGV 120 device is built on the principle of the first Soviet gas water heater AGV-80. The difference lies in the almost twice the power of the unit, the combination and modernization of individual components and mechanisms. For example, the thermostat here is replaced by a bellows temperature regulator, which includes a thermal cylinder, a capillary and a bellows.

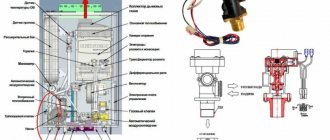

Diagram of AGV-120 and its automation unit Source cotlix.com

In the image above, under the letter “a”, are indicated:

- 1 – device body.

- 2 – reservoir.

- 3 – thermometer.

- 4 – metal coil.

- 5 – traction breaker.

- 6 – base of the chimney pipe (fire pipe).

- 7 – thermal cylinder.

- 8 – rod extension pipe.

- 9 – combustion compartment.

- 10 – burner.

- 11 – igniter and its thermocouple.

- 12 – automatic block.

In the same image, under the letter “b”, a schematic design of the automation unit is shown, which is responsible for the independent operation of the equipment. The decoding of the digital designations for it is as follows:

- 1 – automation unit housing.

- 2 – gas supply valve to the igniter.

- 3 – gas supply valve to the burner.

- 4 – rod.

- 5 – valve.

- 6 – rotary levers.

- 7 – spring.

- 8 – thermal cylinder.

- 9 – adapter nipple.

- 10 – capillary pipeline.

- 11 – spring pusher.

- 12 – bellows.

- 13 – block for adjusting temperature settings.

- 14 – key.

- 15 – electromagnet.

- 16 – spring.

- 17 – safety membrane.

Installation features

To install the AGV, you first need to study the instructions. Basically, the device is installed in a separate boiler room, if possible. But theoretically it can be installed in the kitchen or bathroom (the area of the latter must exceed 6 m²).

It is important to take care of the installation of high-quality ventilation (the air for the system is taken from the room itself, and the oxygen in it is burned out) and the hole through which the chimney pipe will pass. Moreover, the latter provides the opportunity to clean up debris. The walls around the AGV, as well as the floor, must be finished with non-combustible materials.

Before installation, it is recommended to consult with specialists, as there are restrictions. For example, the distance from the AGV to the wall must be at least 2 m.

There are requirements for the length of the chimney pipe and diameter, restrictions regarding wiring, and regarding the angle of laying the pipes. Equipment installation work must be entrusted to professionals - they must have permits to provide such services.

First start

Before starting the AGV-120 gas boiler for the first time, you should make sure that the tank is filled with water or other coolant. To do this, you need to open the water tap and evaluate the rate of flow of water. If it breaks out under a certain pressure, then the level corresponds to the nominal level. If a weak stream is detected, add the required amount through the filler pipe of the unit.

How the initial launch is performed Source Avito

Ignition is carried out as follows:

- Open the gas shut-off valve.

- Place a lit match or lighter near the igniter. At the same time (with the other hand), turn the igniter valve handle.

- Make sure that the flame that appears on the igniter burns independently. To do this, remove or extinguish the match or lighter.

- After 1-2 minutes. Pull the solenoid valve key down as far as it will go and make sure that when released, it remains in this position.

- Slowly open the gas supply valve to the main burner.

- Given enough gas, it will ignite. The main burner will light up.

Important! If the burner does not light up and the igniter goes out, re-ignition is allowed no earlier than after 2-3 minutes.

Thermocouple check

In order to check the AGV-120 thermocouple, you should unscrew the union nut, which is located to the left of the solenoid valve. Then you need to turn on the igniter and use a multimeter to measure the value of the constant voltage at its contacts.

Removing the AGV-120 thermocouple Source tskl.ru

Possible faults

Other malfunctions, the occurrence of which is foreseen by the manufacturer and specified in the technical documentation for the unit, include a whole list. You can read its contents below.

Possible malfunctions of the AGV-120 Source 1-teplodom.ru

The pilot flame goes out

The reason may be that the core does not hold the armature. This happens due to the appearance of oxidation in the place where the magnetic valve connects to the thermocouple. To fix the problem, use a spanner to unscrew the nut connecting the magnetic valve and clean the contact washer under it. After that, return everything to its original place.

Another cause of malfunction is the accumulation of oxide on the poles of the core and the plane of the armature. In this case, you will need to tighten 2 screws, unfasten the plastic cap on the start button and the anchor. Gently wipe the surface with a soft, dry cloth, being careful not to damage the polished base of the assembly. Reassemble the unit in the reverse order of removal and install it in its original place.

Gas burner for AGV-120 Source chipmaker.ru

The third, most popular reason for the igniter to fade is the lack of voltage at the thermocouple tip. This happens due to burnt out contacts. Here you will need to change the node to a new, functional one. It is strictly prohibited to press or tie the start key to the magnetic valve.

The igniter smokes or is interrupted

This occurs due to clogged gas supply nozzles. The problem is solved by cleaning them. Work can be performed with the unit turned off and cooled down. The second and more effective method is to dismantle the unit and completely wash it.

Removed igniter AGV-120 Source images.ru