European companies are considered recognized leaders in the production of heating equipment.

However, their products have considerable flaws, which are generated by the very approach to creating heating boilers.

Overload with electronics, an abundance of unused or unclaimed functions and other excesses increase the price, but significantly complicate the operation of the units.

Domestic manufacturers prefer a completely different approach to the production of gas boilers, relying on the reliability and unpretentiousness of their models.

Let's consider one of the Russian models of gas boilers - Siberia.

Model Siberia 17

Siberia 17 floor-standing gas boilers are designed and manufactured by Rostovgazoapparat CJSC.

They have high reliability, which is created due to the simplicity of the design and the absence of multiple additional functions that complicate the design and create a heavy load on the unit components.

Siberia 17 boilers are single-circuit, since the designation of double-circuit models contains the letter “K” (combined).

The units are non-volatile, which significantly increases their reliability and stability. They are characterized by low fuel consumption, unpretentiousness, ease of control and quiet operation.

Siberia boiler. Floor. Wall.

Siberia - [saɪˈbɪərɪə] from the translation of the English language, means our native, beloved Siberia. The Siberia boiler is a gas heating unit, manufactured in three modifications: floor-mounted, wall-mounted and with a cast-iron heat exchanger. Today it is a prominent representative of the products of JSC Rostovgazoapparat, the largest domestic company in the industrial market of domestic gas heating.

In addition to boilers, under the Siberia brand, the Rostov plant produces aQua gas water heaters, made in a traditional wall-mounted style. We must pay respect to the brand and note that this is one of the most popular brands of heating equipment on the Russian market. The undisputed leader of the latest generation on the domestic market is the Siberia boiler.

A wide range of power, a balanced series of Siberia units facilitates meeting the needs of diverse consumer requests. The Siberia boiler serves as a source of heat generation in a private water heating system. Floor-mounted and wall-mounted boilers provide the consumer with hot water supply due to the secondary circuit. Siberia boilers were developed taking into account all the unpredictable realities of our lives.

Engineers were able to design equipment with stable performance indicators, despite the possible significant differences in gas pressure in the gas pipelines. The units were initially designed to be completely independent from electrical networks.

Floor-standing boiler Siberia

Serial production of a floor-standing gas device from a Rostov enterprise offers the consumer a unit in nine power gradation modifications. The name of the device is in accordance with the rated thermal power calculated in kW: Siberia (Siberia Boiler) 11, 11K, 17, 17K, 23, 23K, 29, 29K.

In addition, the product is divided into single- and double-circuit versions. The double-circuit device contains the index “K” in its name and has the ability to bring cold water, for its owner, to a hot state. If the consumer does not need DHW, the manufacturer offers to save a little and purchase a single-circuit model.

In general, Siberia devices represent a modified version, known in the 70s as AGV-80 and AGV-120. The new equipment has received modern, modernized equipment. The latest generation of Siberia devices is not afraid of gas pressure surges and does not require connection to the electrical network, as it is ignited using a piezoelectric element.

Increased flue gas efficiency reaches 90%. As a key thermal insulation material, the body structure is equipped with basalt slabs, increasing not only the efficiency of heat conservation, but also providing increased noise insulation. The speed of water preparation in hot water supply mode when heated at Δt=35°C is:

- Siberia 11K - 3.8 liters per minute;

- Siberia 17K - 5.5 liters per minute;

- Siberia 23K - 7 liters per minute;

- Siberia 29K - 8 liters per minute.

The indicators are quite modest, and the amount of hot water is barely enough to provide one water collection point. So, for shower lovers, we advise you to additionally think about purchasing an indirect heating boiler. The approximate heating area of the boiler, depending on the quality of insulation of the house, ranges from 125 to 400 m2. The connecting thread of the gas supply fittings for Siberia 11 kW boilers is G½, for all others, including the most powerful 35 kW size = G¾. Overall dimensions do not change and have the same values for the entire line: HxWxD = 850x280x560 mm.

Installation of a floor-standing boiler Siberia

- Gas burner equipment. The Siberia boiler has incorporated the best elements that the market can offer at the best prices. The European companies Polidoro and Worgaz have been identified as suppliers of stainless steel gas burners. Responsible for power modulation:

— AOGV-11.6-3, AOGVK-11.6-3, AOGV-17.4-3 and AOGVK-17.4-3 automatic 630 EUROSIT; — AOGV-23.2-1, AOGVK-23.2-1, AOGV-29-1 and AOGVK-29-1 automatic 710 MINISIT;

— AOGV-35-1 automatic 820 NOVAmv;

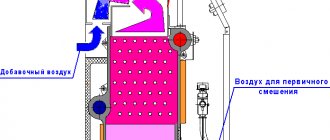

Let us remind you that AOGV is an abbreviation for Gas Water Heating Unit. Using multifunctional gas valves, the flow rate of the gas supply is regulated. The automation is equipped with a modulation thermostat and is a completely energy-independent device; it ignites the Siberia boiler using piezo ignition without requiring an electrical connection. Imported automatic equipment smoothly regulates the flame size and does not interrupt the operation of the product in conditions of a drop in main gas pressure.

- Heat exchanger. The Siberia floor-standing gas boiler produced in Rostov has one of the lowest heat loss rates. This became possible with the use of a new steel heat exchanger design patented by the company. The structure is surrounded by a heat-insulating layer of basalt wool. The innovative heat exchanger design helped raise the efficiency value to 90%, and the basalt wool layer retains precious thermal energy. Removal of combustion products is carried out through a chimney with natural draft.

Since we are considering a floor-standing boiler, it is necessary to take the necessary safety measures for the placement of equipment. The room where the device is installed must be provided with good ventilation with a constant flow of air, for example in the form of a window or vent. The walls in the room must be built of fireproof material, or lined with fireproof panels, preferably made of basalt fiber.

The base for the product should be a cement-concrete platform; the forced placement of the unit on a wooden floor has recommendations for carrying out work to construct an insulating substrate. The insulation is equipped with a 3 mm steel sheet, on top of an asbestos sheet. Insulation should be done with a gap between the housing dimensions of at least 100 mm.

Floor standing boiler Siberia technical specifications

Wall-mounted boiler Siberia

Siberia TopLine is a line of gas wall-mounted units. The models also have the latest generation equipment. Single-circuit ones perform the heating function. Double-circuit ones come with expanded functionality and are already capable of organizing hot water supply for residential and industrial buildings. The two-circuit model is given by the abbreviation AOGVK-23.2-1 in which the last letters “VK” stand for: combined water circuit.

The main feature of some similar Western-made boilers is their focus on European operating conditions. The main and significant difference between the production of the Russian competitor is that all structural parts and equipment of TopLine have been optimized in accordance with the requirements of Russian realities. The front side is covered with a polymer layer of “white titanium” with a glossy sheen. The Siberia wall-mounted boiler is the ideal answer to the decision to provide heat to private households and apartment buildings.

The manufacturer offers two boiler options with the same rated thermal power of 24 kW:

- Siberia Top Line 24 - with an open combustion chamber KGDO-24-3 model 0015.01 Siberia. Natural smoke removal with a standard gas outlet pipe diameter of 130 mm.

- Siberia Top Line 24C—with a closed combustion chamber, with a built-in fan KGDZ-24-3 model 0015.02 Siberia. Smoke removal using a coaxial system with dimensions (air supply/exhaust gas exhaust) 100/60 mm. An alternative way to remove combustion products and supply air flow for the combustion process is possible by constructing parallel pipes with dimensions of 80/80 mm.

Specifications

Both wall-mounted product options operate on natural gas. The established operating parameters correspond to a nominal pressure of 1274 Pa (130 mm water column). However, the Siberia boiler provides stable performance characteristics at pressures ranging from 65 mm water column. Art. up to 280 mm water column It should be taken into account that a decrease in pressure below 130 mm water. Art. linearly reduces the thermal power of the device.

Equipment of the wall-mounted boiler Siberia Top Line 24

- The copper heat exchanger is supplied by French supplier Gianoni. The bithermic design kit combines two heat exchangers: a heating circuit and a DHW circuit.

- The American company Honeywell is a supplier of gas automation. The external control element includes: a magnetic valve, a thermal regulator and an element that stabilizes the gas pressure on the burner;

- Soft ignition function by piezoelectric element;

- Ionization flame control sensor;

- Gas filter equipment;

- Heat-resistant burner Made in Italy made of high-alloy stainless steel from the supplier Polidoro equipped with electronic modulation, which allows smooth adjustment of the flame combustion value to the specified parameters of the consumer;

- The anti-blocking circulation pump is supplied by the German company Grundfos;

- Diaphragm expansion internal tank from the European company Zilmet;

- Possibility of connecting a temperature sensor located in the room via a switch;

- Temperature adjustments for the heating system and domestic hot water are made separately from each other;

- Moderate heating during the cold period using the “anti-freeze” function, preventing the heating system from defrosting;

- The Siberia boiler is equipped with a liquid crystal screen;

Siberia boiler Pros and benefits

As we can see, the equipment largely consists of high-quality elements from well-known European suppliers. A competent unifying design gives us a boiler of the highest class.

- Russian boiler with European components;

- Wide sales and service network to serve its customers;

- The average price is up to 30,000 rubles, making the boiler accessible to the general population;

- The service life is 10 years, after an inspection and thorough diagnostics, in case of positive assessments, the operation of the boiler can be continued;

- Easy boiler control;

- Low noise levels;

- Thanks to the wide range, there is a good opportunity to select a Siberia boiler with optimal parameters for the customer’s premises.

Minuses

- European spare parts for components from Europe;

- The price of the boiler is close to foreign analogues, for example, products of the Proterm company;

- The main competitor, the Zhukovsky floor-standing boiler ZHUK, can be purchased cheaper;

- Mandatory installation by the seller's service department.

In general, the Siberia boiler, based on customer reviews, is characterized as a product of high quality and worthy of close attention. We recommend watching a good review with an assessment of the mistakes made in the review video:

teplogalaxy.ru

What functions does it have?

The main function of the unit is to heat the coolant for the heating circuit of a private house or other premises.

Additional functions of the boiler are:

- Thermometer providing visual control of coolant temperature.

- Piezo ignition system.

- The presence of a two-stage burner, pilot (pilot) and main.

- Availability of gas, flame and draft control.

All components and blocks of the boiler are conveniently located and allow for easy maintenance or repair.

IMPORTANT!

It is not recommended to do independent work or repair the unit, especially if the warranty period has not yet expired. You should use the services of technicians from service workshops.

Technical characteristics of a gas boiler

Let's look at the technical characteristics of the single-circuit boiler Siberia 17:

| Options | Values |

| Boiler type | Gas convection |

| Installation type | Floor |

| Fuel type | Natural or liquefied gas |

| Functionality | Preparation of coolant for heating systems |

| Efficiency | 90 % |

| Serviced area (maximum) | 170 m2 |

| Boiler power | 17 kW |

| Power supply | Absent |

| Burner type | Atmospheric (open type) |

| Burner material | Stainless steel |

| Ignition type | Piezo |

| Chimney diameter | 125 mm |

| Weight | 59 kg |

| Dimensions | 850×280×560 mm |

| Guarantee period | 24 months |

| Service life with proper maintenance, maximum | 25 years |

Floor-standing gas boiler Siberia 17K

Rostov-on-Don, Lenochnaya, 3

+7+7

Purpose: home water heating and hot water supply. Siberia boilers are resistant to significant changes in gas pressure, are completely energy independent, and have increased efficiency. The design uses basalt fiber - a key element of thermal insulation for spacecraft.

Technical equipment:

- Heat exchanger made of carbon structural steel;

- Automation unit (SIT): magnetic valve, modulating thermostat with active instant on/off function, thermoelectric flame control device with re-ignition lock, pressure stabilizer, piezo ignition, gas filter;

- Atmospheric burner made of heat-resistant stainless steel (Polidoro);

- Capillary thermometer with increased capillary volume;

- Thermal insulation foil using basalt fiber;

- Powder enamel coating of the body.

| Model | power, kWt | Peculiarities | Chimney diameter, mm | Dimensions, mm (HxWxD) | More details |

| 11 | 11,6 | heating only | 130 | 850x280x560 | |

| 17 | 17,4 | heating only | 130 | 850x280x560 | |

| 23 | 23,2 | heating only | 140 | 850x380x560 | |

| 29 | 29 | heating only | 140 | 850x380x560 | |

| 35 | 35 | heating only | 140 | 850x380x560 | |

| 11K | 11,6 | heating + hot water | 130 | 850x280x560 | |

| 17K | 17,4 | heating + hot water | 130 | 850x280x560 | look |

| 23K | 23,2 | heating + hot water | 140 | 850x380x560 | |

| 29K | 29 | heating + hot water | 140 | 850x380x560 |

| Model | 11 | 11K | 17 | 17K | 23 | 23K | 29 | 29K | 35 |

| Rated thermal power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29 | 29 | 35 |

| Reduced gas consumption | |||||||||

| natural, m3/h | 1,18 | 1,18 | 1,76 | 1,76 | 2,3 | 2,3 | 2,94 | 2,94 | 3,75 |

| liquefied, kg/h | 1 | 1 | 1,21 | 1,21 | |||||

| Approximate heating area, m2 | up to 125 | up to 125 | 100–200 | 100–200 | 100–250 | 100–250 | 150–300 | 150–300 | 150–400 |

| Flue gas efficiency, % | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Water temperature setting limit, °C | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 |

| DHW at Δt=35°C, l/min | 3,8 | 5,5 | 7 | 8 | |||||

| Connecting thread of fittings, inch | |||||||||

| for gas supply | G½ | G½ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ |

| Inlet/outlet | |||||||||

| to the heating part | G1½ | G1½ | G2 | G2 | G2 | G2 | G2 | G2 | G2 |

| to the water heater parts | G½ | G½ | G½ | G½ | |||||

| internal diameter of the chimney, dm, not less | 1,25 | 1,25 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Overall dimensions, mm | |||||||||

| height | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 |

| width | 280 | 280 | 280 | 280 | 380 | 380 | 380 | 380 | 380 |

| depth | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 |

| Weight, kg | 52 | 56 | 56 | 59 | 65 | 70 | 70 | 76 | 90 |

terma.su

Advantages and disadvantages

The advantages of the single-circuit floor-standing boiler Siberia 17 should be considered:

- Reliability, stability.

- Silence.

- Energy independence.

- Simplicity of design and control.

- Unpretentiousness, all maintenance consists of cleaning and checking traction.

- Low cost.

The disadvantages of boilers can be considered:

- Lack of hot water heating function.

- Some difficulty starting the boiler.

- Lack of a display showing the current operating mode and other parameters.

NOTE!

The disadvantages of the model are due to its design and are typical for all similar units.

Model overview

Siberia17К

Floor installation. Simple design. Minimum functions. Having found out how much the 17 K modification costs, as well as technical parameters, consumers willingly purchase it. Two circuits. Heating capacity 17.4 kW. Heats an area up to 200 square meters. Efficiency 90%. Open combustion chamber. Fuel consumption – 1.21 kg/h and 1.76 m3/h – liquefied and natural gas, respectively. Mechanical control type. Protection – gas control. Weighs 59 kg. Width 28 cm. Height and depth are standard for Siberia - 85 and 56 cm, respectively.

Siberia KCHGO-25

Single-circuit floor-standing convection boiler. Heating of an area up to 270 sq. m. Estimated price 37,700 rubles. 25,000 W – heat output. Cast iron heat exchanger. 2.45 m3/h of natural gas. Mechanically controlled. Gas control. 115 kg – weight.

AOGV-17.4

Floor installation. Does not respond to pressure changes in gas pipes. Non-volatile. Thermal insulator with basalt fiber. Auto control. Steel radiator. Heats up to 180 sq. m. SIT. Equipped with a magnetic valve that resists contamination. Piezo ignition.

TopLine 24

Wall-mounted version. Copper heat exchanger. Capacity 12 l/min at 25 °C - it decreases with increasing temperature. Depending on the power of the device, you can heat an area of 30-200 square meters.

AOGV 11.6

Budget modification. Approximate price – 10,000 rubles. One circuit. 11.6 kW – heat output. Efficiency – 87%. Floor installation. No auto-ignition. Open camera. Non-energy independent, like all Siberia gas devices.

Device

The main design elements of the Siberia 17 gas boiler are an open type burner combined with a steel heat exchanger.

Together they perform the main task - heat the coolant . At the exit from the heat exchanger, the liquid enters a three-way valve, where the colder “return” is mixed into the hot flow to obtain the desired temperature.

The prepared coolant flows by gravity into the heating circuit.

Water moves under the influence of convection currents, moving hot layers up and cold layers down.

Taking this into account, the system must be installed in compliance with the standard slope, ensuring coolant circulation.

If this is not possible, it is necessary to connect an external circulation pump, which will ensure more active flow movement. However, in this case, the energy independence of the boiler ceases.

Smoke removal also occurs naturally, using stove-type drafts. This is an important and crucial point, since weak draft will cause smoke in the premises and the impossibility of operating the boiler. Proper installation and connection of the chimney will help ensure the necessary conditions.

IMPORTANT!

The connection and first start-up of the boiler must be carried out by employees of the guarantee organization.

Localization and translation problems

The game was released simultaneously in English and French.

In Russia, in other CIS and Baltic countries, the game was published by 1C under the name “Siberia”

. This name is not a completely correct translation of the original name - "Syberia" - since the name of the game did not refer to the region of Siberia, but to the mythical island of Siberia, where mammoths live (the region of Siberia itself is called "Siberia" in English). However, the publishers considered the name “Siberia” to be more harmonious and suitable for the Russian market.

The game has been localized. The following actors took part in the dubbing: Lada Mosharova (Kate Walker), Nadezhda Podyapolskaya (Momo), Alexander Bykov (Oscar, Dan), Dmitry Nazarov (hotel owner, rector of Barrokstadt University, captain Malatesta, Boris Sharov), Alexander Kotov (Marson, Hans Voralberg), Alexey Kolgan, Ivan Litvinov, Natalia Litvinova, Nina Luneva, Yuri Naumenko.

Console versions (PlayStation 2 and Xbox) do not have official localization.

There are several Russifications - both official and pirated. The quality of the translation of each of them was subject to justified criticism. The most common complaints converged on criticism of the translation authors’ ignorance of the cultural allusions of the work, and the approach to the Syberia text as an ordinary game text that does not require special knowledge from the translator.

In this article, proper names are given in accordance with the official Russification from (the original name is indicated in brackets).

On February 11, 2015, the game was published for iOS by "".

For which rooms is it best suited?

The floor-standing gas boiler Siberia 17 is designed for heating rooms up to 170 m2.

This is a common size for a medium-sized private home, large apartment, office or commercial space, etc.

The purpose of the premises is housing or public purposes; such boilers are not suitable for industrial or production workshops due to fire safety or technological restrictions.

Drafts and instability of air flow can have a constant impact on draft, causing the boiler to shut down . This is the main factor limiting the use of units in production conditions.

Start-up and operating instructions

The launch is carried out after connecting communications and checking the tightness of all connections.

Needs to be attached:

- Heating circuit forward and return pipelines.

- Gas pipeline.

- Make-up pipeline.

- Chimney.

After connecting the communications, the system is filled with water until it flows out of the signal pipe.

Then open the gas valve, press the pointer handle (all the way) and at the same time press the piezo ignition button of the pilot burner . You must hold it for up to 1 minute until a flame appears on the pilot burner.

After this, the pointer knob is set to position 4, the main burner lights up and the boiler begins to function.

Operation of the units involves periodically cleaning them from dust and soot, changing the current temperature settings as desired, and monitoring the general condition of the system.

If unusual or alarming signs appear, turn off the gas valve and immediately call a technician from the service center to inspect and repair (adjust) the device.

Any independent intervention in the mechanism can cause an accident and failure of the equipment..

Gas boiler SIBERIA 17 (AOGV-17.4/3)

Description

The floor-standing gas single or double-circuit energy-independent heating boiler Sibiriya 17 (AOGV-17.4) is equipped with an imported automation unit. Does not require connection to an electrical network. In terms of thermal characteristics and design, they are not inferior to foreign analogues. The design of Siberia 17 boilers uses modern components from leading global manufacturers. Designed for heating residential premises, as well as industrial and commercial facilities. Features of gas floor-standing boilers Siberia 17 Heat exchanger: - High reliability of the heat exchanger tank due to the use of an automatic welding process and the use of high-quality steel in devices with a steel heat exchanger; — Stable supply of hot water for domestic needs in a copper flow-through secondary circuit of double-circuit boilers (they have the designation K in the model name); — Possibility of using the device in heating systems with both natural and forced circulation of coolant; — Using a layer of thermal insulation to protect against burns and increase the efficiency of the boiler; — High quality of materials used and assembly of the device; — The Sibiriya 17 boiler is easy to install and maintain; EUROSIT automation: - Safety, reliability, simplicity and ease of operation of boilers are ensured by the use of modern imported automation units 630 Eurosit (Italy) with very accurate temperature control; — Piezoelectric ignition system; — Saving gas consumption due to the optimal choice of operating modes of the gas burner; — Ease of control due to the ergonomic arrangement of automation units; — Security system with flame control and draft sensor; — There is no need for additional adjustment on the combined gas valve; — The device is completely energy independent and does not require connection to an electrical network; Gas burner - The Siberia 17 floor-standing gas boiler is equipped with a gas burner device with a WORGAS burner (Italy), made of stainless steel and preventing burnout at low gas pressure; — Environmental cleanliness due to the low content of nitrogen and carbon oxides in the exhaust gases; — Stable operation of the boiler at low gas pressure in the network (up to 550 Pa); — Ease of use due to the easy process of replacing and cleaning the burner; — When replacing nozzles (main burner and igniter), the device can operate on liquefied (cylinder) gas; Technical characteristics of gas boilers Siberia 17 Main parameters: Nominal thermal power, kW: 17.4 Efficiency, %, not less: 90 DHW water consumption at 35 °C, l/min: 5.5 Natural gas consumption, cubic m/h : 1.76 Liquefied gas consumption, kg/h: 1.21 Overall dimensions, mm: 850x280x560 Weight, kg: 59 Connecting thread of fittings: for supplying and draining water DHW: G 1/2 for heating system: G 2 for water supply : G 2 Nominal gas pressure: Natural gas (methane), Pa: 2940 Liquefied gas (propane/butane), Pa: 1274 Nominal water pressure: Heating system pressure, kPa: 150 DHW water pressure, kPa 588.40 Chimney: Diameter chimney, mm, not less than: 125 Vacuum in the chimney, Pa: 2.94 / 29.4

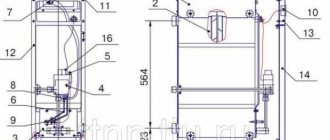

Fig.9. The design of the floor-standing boiler Siberia 17 1 is gas exhaust; 2 - heat exchanger; Z – main burner; 4 – gas valve; 5 — cover with piezo ignition; 6 - thermocouple; 7 — traction sensor; 8 — thermal breaker; 9 — ignition burner (pilot burner), 10 — thermometer; 11 - cover; 12 – left/right side wall; 13 - panel; 14 - anterior wall; 15 - frame; 16 – thermostat indicator knob (magnetic valve button). Starting the boiler Siberia 17 To turn on the device, perform the following operations: - check the filling of the device and the heating system with water - this is controlled by the appearance of water from the signal pipe of the open system; when the heating system is closed, by the appearance of water from the automatic air release valve, close the tap on the water supply; — check the presence of draft by holding a lit match to the window above the draft sensor. If there is a draft, then the match flame is drawn into this hole; — open the gas valve on the gas pipeline; — set the indicator knob of the gas block thermostat to the “off-0” position clockwise until it stops; — turn the pointer knob counterclockwise to the “pilot-*” position; — press the thermostat indicator knob button (magnetic valve button) all the way, bleed off the air; Press the piezo ignition button until it clicks, and the pilot burner should ignite. Hold down the pointer button for up to one minute. If there is no flame on the pilot burner, repeat the operation after two minutes. — release the pointer button. The pilot burner flame must not go out. Turn the indicator knob to mark “4” to supply full gas flow to the main burner. After the main burner ignites, set the desired water heating temperature by turning the thermostat indicator knob. The temperature is adjusted from mark “1” to mark “7” (counterclockwise). The time of flame propagation over the entire fire surface is no more than 2 s. When the maximum water temperature in the heat exchanger of the Siberia 17 boiler is reached, the main burner will turn off. When the water temperature in the heat exchanger drops, the main burner turns on. If the appliance turns off, check the presence of draft in the chimney. Ignition should only be carried out when there is draft. Restarting the unit after an emergency shutdown can technically be done 60 seconds after switching off the flame control device.

This requirement is ensured by the design of the gas supply control device 630 EUROSIT. Turning the pointer knob button from the “pilot” position is possible only after the flame control thermocouple has cooled in the blocking position. When restarting the boiler, turn the pointer knob to the “off - 0” position and repeat the start. To turn off the device you must: turn the pointer knob to the “off-0” position; close the gas valve in front of the device.