A country:

This section of the catalog presents heating boilers from the manufacturer Beretta. The extensive experience gained in the production of residential heating equipment has made it a world-famous brand - synonymous with quality and modern technology. The range includes floor-wall, single-circuit and double-circuit models. The range of available capacities is wide enough so that a suitable option can be selected for any task.

With a strong focus on residential heating, Beretta's product range is increasingly introducing solutions that maximize energy efficiency through the intelligent integration of multiple energy sources.

Beretta gas boilers

Beretta is a brand owned by the large Italian company Riello SpA

Initially, it was a metalworking shop, which gradually switched to the production of gas boilers. Today, Beretta products are sold in many countries around the world and are among the leaders in quality, reliability and demand among customers.

Gas boilers are produced on the basis of advanced developments, taking into account many years of experience in the production of heating equipment . All units are maximally adapted to the technological operating conditions in the country where they will be sold.

For operation in Russia, the possibility of gas or water pressure drops is taken into account, and operation in conditions of severe frosts or power supply voltage drops is provided.

The company’s main goal is to create the most reliable boiler that is resistant to all external loads and does not fail due to changes in operating conditions . At the same time, the functionality and additional capabilities of the units are not limited and fully comply with European requirements for quality and safety.

The pump does not work - what to do?

If a failure of the circulation pump is noticed, it is necessary to stop the system and call a technician.

There can be several reasons for failure, from power problems to mechanical problems. The first reason is determined by testing and checking the condition of the pump motor.

The second reason can be detected by checking the condition of the moving parts of the pump, the absence of difficulties in rotating or moving parts of the mechanism, breakage or wear of gears and other elements.

The decision to repair or replace the pump is made based on the results of an examination of the performance and condition of the unit’s parts. If the forecast for repair work is favorable, the pump is restored, otherwise a complete replacement is necessary.

Kinds

Beretta produces all types of modern gas boilers, which can be divided into groups according to appropriate characteristics.

According to the installation method, we offer:

- Floor-standing boilers. They are installed directly on the floor or on a special platform, have greater weight and increased dimensions due to more durable and massive parts designed for high power and performance.

- Wall-mounted models designed for hanging installation on load-bearing walls or on special supporting structures (ramps). They have compact dimensions, the power of the units is limited to 35 kW.

By functionality:

- Single-circuit, designed only to power the heating system.

- Double-circuit, capable of simultaneously heating the coolant and preparing hot water for household needs.

By heat transfer method:

- Convection. Heating of liquids occurs according to the usual method - in the flame of a gas burner.

- Condensation. These units have a two-stage heating cycle - first, primary heating occurs due to thermal energy obtained from the condensation of water vapor from the exhaust smoke, and then a second stage of heating occurs in the burner flame.

IMPORTANT!

It must be taken into account that the operation of condensing boilers is possible only when the difference in temperature outside and inside the premises is no more than 20°, which excludes the possibility of use in most regions of Russia. You need to know this when choosing a boiler, since the difference in prices between condensing and convection boilers is quite significant.

By type of combustion chamber:

- Open (atmospheric). Smoke removal occurs naturally, using a chimney draft (stove type). The air required for combustion is taken directly from the room in which the boiler is installed.

- Closed (turbocharged). The air intake occurs from the outside, the burner is completely isolated from the internal atmosphere of the living space. The smoke is removed by the turbocharger fan.

Turbocharged models are more stable and reliable in operation, practically independent of external conditions, which cannot be said for boilers with an open combustion chamber.

Story

Work process in the workshop of the Beretta factory in Gardone

Beretta is one of the oldest companies in the world. It has been owned by the same family for about 500 years. It was founded in 1526, when the gunsmith Bartolomeo Beretta of Gardone Val Trompia, in Brescia, Lombardy, Italy, received 296 ducats for 185 arquebus barrels from the Venetian arsenal. The invoice for this transaction was preserved in the company's archives.

In 1918, the Beretta Model 1918 became the second submachine gun in the Italian army. Beretta produced rifles and pistols for the Italian army until 1943, when Italy surrendered. However, northern Italy was under German control, which captured Beretta and produced the weapon until Germany's surrender in 1945. At this time, the external treatment of the weapon was worse than before or in the middle of the war, but its effect remained excellent.

In 1938, Japan entered into a contract with three Italian firms, including Beretta, to supply rifles. Between 60,000 and 120,000 rifles were produced and delivered until 1949.

Series and models related to them

Beretta gas boilers are available in different model ranges and lines.

Floor standing boilers are available in three series:

- Avtonom. A series of energy-independent single-circuit boilers with a massive cast-iron heat exchanger. They have a piezo ignition system and can be connected to a room thermostat and an external boiler. A total of 8 models are offered with power from 18 to 86 kW.

- MAXIMA. A series of powerful energy-independent single-circuit boilers. The line includes 11 models with power from 90 to 279 kW. They have impressive dimensions and are capable of cascading up to 4 units, creating a high-power station.

- NOVELLA E. Single-circuit energy-dependent boilers with a capacity of 18-78 kW (10 models in total). Designed for use in private homes. Can be used in conjunction with an external indirect heating boiler (Novella 55 rai).

There are 4 series of Beretta wall-mounted boilers:

- MYNUTE BOILER. The series consists of three energy-independent models with a power of 24-28 kW. They have a built-in storage boiler with a capacity of up to 60 liters.

- CIAO. The line consists of 6 dual-circuit models with a bithermal heat exchanger. The boiler power is 16, 24 and 28 kW. The combustion chamber is open or closed.

- CITY. Consists of 8 models of single- and double-circuit gas boilers with a separate heat exchanger. The combustion chamber is both open and closed. Power 24, 28 and 35 kW.

- EXCLUSIVE. There are 7 models available with a power of 24-35 kW. There are single- and double-circuit design options, with an open and closed combustion chamber. They have a push-button control panel with an LCD display and a separate heat exchanger.

Condensing boilers:

- CITY GREEN. One model with a power of 25 kW. Double-circuit turbocharged boiler with separate heat exchanger.

- EXCLUSIVE GREEN. 5 models with power 16, 25 and 35 kW. Single- and double-circuit turbocharged boilers with a separate heat exchanger.

The choice of Beretta models is very wide and can satisfy the wishes of any buyer.

Beretta Novella Avtonom

This unit can be used in heating systems with natural circulation of coolant of any type. Boiler power ratings range from 24 to 71 kW. The heat exchanger is made of cast iron, which indicates the high reliability of the units. The boiler can operate in low temperature mode.

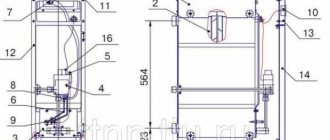

Floor-standing gas boiler BERETTA NOVELLA AVTONOM 24

The package includes a single-stage burner made of stainless steel. If necessary, you can switch the operation of the equipment to liquefied gas. Models with power starting from 55 kW are equipped with an exhaust hood, thanks to which combustion products are well removed even with low draft. The flame is ignited by a piezoelectric element; there is also a system for monitoring the presence of draft in the chimney. There is a knob for adjusting the coolant temperature on the control panel.

Specifications

Let's look at the technical characteristics of Beretta gas boilers:

| Parameter | Meaning |

| Boiler type | Heating |

| Fuel type | Natural or liquefied gas |

| Functions | Heating, hot water supply |

| Installation method | Floor or wall |

| Heat exchanger type | Separate, combined, copper or cast iron |

| Model power range | 16-279 kW |

| Combustion chamber type | Open or closed (atmospheric or turbocharged) |

| Energy consumption | 220 V 50 Hz or non-volatile models |

Floor-standing

Their main difference from the mounted versions is their greater power. The power range in the Novella Avtonom and Novella RAI series is 24,000–71,000 W. The most powerful series is Novella Maxima, which features floor heaters with a heating capacity of up to 290,000 W.

Floor-standing versions provide natural ventilation. Only devices marked RSI are equipped with forced ventilation: they have a closed firebox and are connected to a coaxial chimney. Floor-standing models are capable of heating rooms up to 700 m². Single-circuit versions can be equipped with a BKN (indirect heating boiler) with a capacity of 120/220 liters.

Advantages and disadvantages

The advantages of Beretta gas boilers include:

- Reliability, high quality of all components and structural parts.

- Wide selection of power, design and other equipment features.

- Availability of all modern functionality.

- There are both volatile and independent models that can operate without being connected to a power supply.

- Compact, attractive appearance of the models.

- Quiet operation, low fuel consumption.

The disadvantages of the units are:

- Sensitivity to water and power quality. They need additional equipment that purifies the water and stabilizes the current voltage.

- Many users consider the cost of boilers and maintenance to be excessively high.

NOTE!

The disadvantages of Beretta boilers are observed in almost all imported gas boilers, so they can be attributed to the specific design of the units.

How to clean the heat exchanger

Beretta boilers are equipped with either separate or bithermal (combined) heat exchangers. In the first case, flushing gives a greater effect; the second type of heat exchangers is difficult to flush due to the design features.

There are two washing methods:

- Mechanical. Requires disconnecting the heat exchanger from the boiler. The results of such washing are not particularly successful, since it is extremely difficult to clean the internal surfaces mechanically.

- Chemical. Does not require dismantling the heat exchanger, but is done using a special device. It has a fairly high efficiency, is able to eliminate scale and extend the service life of the unit.

For washing, special reagents are used to dissolve scale and remove it from the internal cavity of the heat exchanger tubes. The procedure should be performed every 2-3 years, depending on the quality of the water. To carry out the work, you must invite a specialist from the service center.

Device

The Beretta gas boiler has two main components that work in close conjunction - a gas burner and a heat exchanger.

Entering the boiler, the coolant passes into the heat exchanger, where it is heated to a certain temperature . Then it leaves the primary and immediately enters the secondary heat exchanger, where it transfers a small part of the thermal energy to prepare hot water.

After this, it enters the three-way valve, acquires the temperature set by the operating mode and is discharged into the heating system.

The movement of liquid occurs under the action of a circulation pump . Smoke and combustion products are removed using a turbocharging fan.

The operation of all devices (in volatile models) is monitored by an automatic control board connected to a system of self-diagnosis sensors.

They detect problems and immediately notify the user about them using a special code message on the display.

Installation features

The user needs to be aware of the main requirements for installing the device:

- It is prohibited to place the device in a living room.

- In the utility room the boiler is placed in any convenient place. In the kitchen, the device should not be mounted above the dining table or above the stove.

- The distance specified in the instructions is maintained between the wall, surrounding objects and the device.

- The body and chimney become very hot during operation. If the device is placed near a heat-sensitive surface, this area must be insulated.

- Before entering the boiler, a shut-off valve must be installed on the gas pipeline. This device is not included in the package. If the water quality is poor, it is recommended to install a filter.

Upon completion of work, it is necessary to check the tightness of all connections. After this, they begin to check the equipment.

Operating and setting instructions

Operation of Beretta gas boilers occurs in automatic mode, which does not require any special actions from the owner.

The only procedures he must periodically perform are:

- Filling or draining water from the heating circuit when switching the boiler to winter/summer mode.

- Cleaning the housing from dust and dirt.

- Every year you need to invite a technician from the service center to perform technical inspection and maintenance of the boiler.

Temperature adjustment is carried out in operating mode, performed from the control panel and is not difficult at all.

Download instructions

Download instructions for Beretta gas boilers.

Primary setup is an adjustment to the factory settings and is performed by a specialist who installs and first starts the system.

All these actions are designed to limit the pressure range of gases and liquids, improving the operation of the boiler and increasing its service life.

IMPORTANT!

Self-repair or other intervention in the boiler design automatically terminates the warranty agreement, so in case of any problems you should contact a specialist.

Reviews

CIAO 24 CSI: Konstantin A., Voronezh

Heats and warms water at the same time. Reliable, but not particularly economical - it consumes a lot of gas and electricity. I did not install a stabilizer, but the device works stably without it and tolerates power surges normally. Electricity consumption monthly is 60 kWh. I installed a temperature sensor, saving 50% on electricity. At minimum, the water heats up to 40 degrees. You can open two taps at the same time - to wash and wash dishes, for example. The downside is energy dependence. When the lights go out you have to freeze. I’m not going to install an uninterruptible power supply, it costs a lot of money. Not a bad heater, but I wouldn’t choose it again - the shortcomings are too serious.

Avtonom 24 Novella 24 RAG: Polina T., Korolev

It has been working for 6 years. It doesn't need electricity - that's a plus. It's quiet. Cons: poor performance of piezo ignition. It happens that the flame blows out. One winter, due to unfortunate circumstances - the direction of the wind and icicles - the combustion products began to blow back. Because of this, the smoke detector was triggered. To get out of the situation, they changed the circuit: they removed the sensor and directly connected the contacts. The door was closed and the window was opened. When the thermocouple burned out, I had to order and wait for a new one. The wait was long, and the installation itself lasted 15 minutes.

Beretta brand gas boilers make a good impression: consumers appreciate their technical characteristics, functionality and low cost. All products are adapted to domestic conditions - the heaters can operate at low gas and water pressure. Belonging to the class of inexpensive heating equipment, Italian boilers meet all international quality standards.

Price range

The cost of Beretta boilers is in the range of 37-495 thousand rubles, depending on the installation method, set of functions and unit power.

The basic configuration of boilers does not include a chimney and other additional devices, so it is necessary to determine their cost in advance and purchase all related devices that ensure the safety and durability of gas boilers.

NOTE!

The cost of servicing the units is quite high, so saving on concluding a warranty agreement is not recommended.

How to run self-diagnosis

The self-diagnosis system is a network of sensors located on all important and critical parts and components of the boiler.

They do not need to be started, since they operate in continuous mode, from the moment they are turned on until the unit stops operating.

Therefore, launching self-diagnosis of a gas boiler as a separate function is impossible. Moreover, if it occurs to someone to stop the operation of the system, then no result will be obtained - it is impossible to stop the process using standard methods, and turning off the sensors is regarded by the control board as the same error, causing the boiler to block.

The self-diagnosis system is an integral part of the gas boiler operation process, ensuring the safety of the equipment and notifying the owner or repairman about the location of the defective unit.