Installation from scratch or modernization of the heating system necessarily affects heating devices, since old equipment is removed and new equipment, more economical, is installed in its place. This process does not consist of delicate work, so anyone who wishes can handle it. Hiring specialists is quite expensive, so you have to save money if the family budget has limitations.

Electric boilers

It must be said that electric heating is the most efficient of all existing ones.

Not only are the efficiency of boilers about 99%, but in addition they do not require chimneys or ventilation. There is practically no maintenance of the units as such, except for cleaning once every 2-3 years. And most importantly: equipment and installation are very cheap, and the degree of automation can be any. The boiler simply does not need your attention. No matter how pleasant the advantages of an electric boiler are, the main disadvantage is just as significant - the price of electricity. Even if you use a multi-tariff electricity meter, you will not be able to beat a wood-burning heat generator in terms of this indicator. This is the price to pay for comfort, reliability and high efficiency. Well, the second disadvantage is the lack of the necessary electrical power on the supply networks. Such an annoying nuisance can immediately cancel out all thoughts about electric heating.

Types of radiators

The market offers a fairly wide range of heating radiators, differing from each other both in design features and raw materials. According to the first criterion, devices are divided into three groups: sectional, panel and pipe. The first were described above, the second are two panels made by stamping and connected by welding. There is space left between the panels to be filled with coolant. Still others are presented in the form of a pipe in two or several levels, on which aluminum plates are mounted, enhancing the heat transfer of the device.

According to the second criterion, they are divided into:

- cast iron;

- steel;

- aluminum;

- bimetallic.

Calculation of the heating system and selection of boiler power

It is impossible to select equipment without knowing the amount of thermal energy required to heat the building. It can be determined in two ways: simple approximate and calculated. All sellers of heating equipment like to use the first method, since it is quite simple and gives a more or less correct result. This is a calculation of thermal power based on the area of heated premises.

They take a separate room, measure its area and multiply the resulting value by 100 W. The energy required for the entire country house is determined by summing up the indicators for all rooms. We suggest a more accurate method:

- by 100 W, multiply the area of those premises where only 1 wall, on which there is 1 window, is in contact with the street;

- if the room is a corner one with one window, then its area must be multiplied by 120 W;

- when a room has 2 external walls with 2 or more windows, its area is multiplied by 130 W.

If we consider power as an approximate method, then residents of the northern regions of the Russian Federation may not receive enough heat, and residents of the south of Ukraine may overpay for equipment that is too powerful. Using the second, calculation method, heating design is carried out by specialists. It is more accurate, as it gives a clear understanding of how much heat is lost through the building structures of any building.

Before you begin the calculations, you need to measure the house, finding out the area of the walls, windows and doors. Then you need to determine the thickness of the layer of each building material from which the walls, floors and roofs are built. For all materials in the reference literature or on the Internet, you should find the value of thermal conductivity λ, expressed in units of W/(m ºС). We substitute it into the formula for calculating the thermal resistance R (m2 ºС / W):

R = δ / λ, here δ is the thickness of the wall material in meters.

Now you can find out the amount of heat lost through the external building structure using the formula:

- QTP = 1/R x (tв – tн) x S, where:

- QТП – lost amount of heat, W;

- S is the previously measured area of the building structure, m2;

- tв – here you need to substitute the value of the desired internal temperature, ºС;

- tн – street temperature in the coldest period, ºС.

Design specifics of heating devices

Structurally, batteries are divided into groups: radiators, convectors and registers.

Review of popular heating devices

Radiator is the most common type. This is a heating device consisting of vertical separate compartments. In classic collapsible products, sections are independent working elements. They are joined in the required quantity using threaded internal connections. This assembly scheme gives the batteries versatility.

Before installing or possibly completing a heating radiator, it is necessary to perform a calculation in accordance with the required thermal power. According to calculations, the number of sections of prefabricated batteries is selected. The horizontal cavities of radiators obtained by connecting sections are called collectors. Top and bottom.

Modern technologies have mastered the production of less versatile, but more reliable non-separable radiators using welding and solid casting methods. They do not have joints and seals characteristic of collapsible radiators. Design - for every taste.

A convector is a one-piece heating device made of a tubular or cavity heat exchanger with rows of heat-removing fins. Convectors are available in the following versions:

- Wall-mounted.

- Floor (duct)

- Skirting.

A register is a non-separable heating device made of straight, smooth horizontal pipes, arranged and combined in a certain way.

Details about the types of radiators

Radiators differ in the material used for their manufacture.

Within one variety there may be different design solutions, sometimes unexpectedly original.

The heating appliance market can offer:

- Radiators are cast iron. The ancestors of the batteries of this group. Relatively inexpensive. Can withstand each operating mode. They serve up to 50 years. The main disadvantage is that they are heavy, which, however, helps retain heat for a long time when the heating is turned off.

- Steel radiators. Such batteries are structures made of steel pipes. They work in any conditions, but are less durable than their cast iron counterparts. They have low heat transfer.

- Aluminum radiators. Made from lightweight, aesthetic material, these batteries dissipate heat better than anyone else. They are resistant to all operating temperatures, but are afraid of water hammer. Aluminum is very demanding on the quality of the coolant.

- Bimetallic radiators. Steel insides clad in aluminum – that says it all. The main characteristics are the same as those of steel, heat transfer is almost like that of aluminum. The price is steep.

- Copper radiators. These are “eternal” heat emitters for any room. Their only and most significant disadvantage is their extremely high cost.

- Radiators are plastic. Innovation in the radiator family. So far they are suitable only for autonomous heating systems of private houses with a coolant heated to no more than 80⁰C.

Aluminum devices are the most sensitive to operating conditions. These radiators reliably serve only 15 years. Their use is only possible in autonomous heating systems.

Externally, popular models of radiators made of different materials are similar:

Image gallery

Photo from

Heating radiator made of cast iron

Heating device made of steel

Lightweight aluminum battery

Heating radiator made of copper

Characteristics of the convector variety

Convectors are significantly inferior in heat transfer to radiators, but in some cases they successfully complement or replace them:

1. Wall convectors. Batteries in this design are usually made of steel, so they are cheap. They are not resistant to water hammer, and their use in centralized heating systems is undesirable.

Convectors designed as panels look like closed radiators, are very attractive, and fit perfectly into any interior design.

But made in the form of pipes bristling with plates, such batteries are only suitable for installation in utility rooms.

2. Floor convectors (duct). An excellent solution for creating a thermal curtain at the door of a balcony or loggia. Made from durable, corrosion-resistant materials, they are unpretentious to operating requirements.

3. Skirting convectors. Capable of operating in all conditions and modes, these batteries are ideal for creating a microclimate where all other heaters would look cumbersome.

The baseboard type is appropriate in bathrooms and storage rooms adjacent to cold street walls and unheated entrances.

Brief description of heating registers

Once upon a time, batteries of this group were made handicraft using conventional welding. Registers can be used in any heating systems, but due to their unsightly appearance they are used mainly in auxiliary rooms: garages, storerooms, basements. Sometimes they can be seen in the entrances of old high-rise buildings.

Modern heating devices for this group.

Shiny chromed metal registers can decorate the design renovation of any living space

Calculation of thermal power of batteries

The stage of preliminary selection of batteries is completed, you can proceed to calculating the thermal power required from them. The calculations are based on a relative power of 100 W for heating 1 m² of standard room.

The full formula includes many correction factors and looks like this:

Q = ( 100 x S ) x R x K x U x T x H x W x G x X x Y x Z,

Where:

S = area of the heated room, where:

R – additional parameter for rooms oriented to the east or north = 1.1;

K – correction for the presence of external walls in the room:

one = 1.0; two = 1.2; three = 1.3; four = 1.4;

U – insulation coefficient of street walls:

low = 1.27 (without insulation); average = 1.0 (plaster, surface thermal insulation); high = 0.85 (insulation performed according to special calculations);

T – weather indicator of the period of lowest temperatures in ⁰С:

up to -10 = 0.7; up to -15 = 0.9; up to -20 = 1.0; up to -25 = 1.1; up to -35 = 1.3; below -35 = 1.5;

H – ceiling height index in meters:

up to 2.7 = 1.0; up to 3 = 1.05; up to 3.5 = 1.1; up to 4 = 1.15;

W – characteristic of the room located on the floor above:

unheated and uninsulated = 1.0 (cold attic); unheated but insulated = 0.9 (attic with insulated roof); heated = 0.8.

G – degree of window quality:

serial wooden frames = 1.27; frames with single glazing = 1.0; frames with double glazing = 0.85;

X – ratio of the area of window openings to the area of the room:

up to 0.1 = 0.8; up to 0.2 = 0.9; up to 0.3 = 1.0; up to 0.4 = 1.1; up to 0.5 = 1.2;

Y – battery surface openness value:

fully open = 0.9; covered with window sill = 1.0; obscured by a horizontal projection of the wall = 1.07; covered with a window sill and front casing = 1.12; blocked on all sides = 1.2;

Z – battery connection efficiency (1.0 ÷ 1.13; for more details, see the section below).

The calculated value must be multiplied by a conditional coefficient of 1.15. It will provide some heat reserve to enable more precise adjustment of devices to operate in low-temperature mode.

What is needed for installation

Installation of heating radiators of any type requires devices and consumables. The set of necessary materials is almost the same, but for cast iron batteries, for example, the plugs are large, and they do not install a Mayevsky valve, but instead, somewhere at the highest point of the system, they install an automatic air vent. But the installation of aluminum and bimetallic heating radiators is absolutely the same.

Steel panel ones also have some differences, but only in terms of hanging - they come with brackets, and on the back panel there are special arms cast from metal, with which the heater clings to the hooks of the brackets.

These are the arms that hook the hooks

Mayevsky crane or automatic air vent

This is a small device for releasing air that may accumulate in the radiator. Placed on the free upper outlet (collector). It must be on every heating device when installing aluminum and bimetallic radiators. The size of this device is significantly smaller than the diameter of the manifold, so you will also need an adapter, but Mayevsky taps usually come complete with adapters, you just need to know the diameter of the manifold (connection dimensions).

Mayevsky crane and method of its installation

In addition to the Mayevsky crane, there are also automatic air vents. They can also be installed on radiators, but they are slightly larger in size and for some reason are only available in a brass or nickel-plated case. Not in white enamel. In general, the picture is unattractive and, although they deflate automatically, they are rarely installed.

This is what a compact automatic air vent looks like (there are more bulky models)

The side-connected radiator has four outputs. Two of them are occupied by the supply and return pipelines, on the third they install a Mayevsky valve. The fourth entrance is closed with a plug. It, like most modern batteries, is most often painted with white enamel and does not spoil the appearance at all.

Where to install the Mayevsky plug and tap for different connection methods

Shut-off valves

You will need two more ball valves or shut-off valves that can be adjusted. They are placed on each battery at the input and output. If these are ordinary ball valves, they are needed so that, if necessary, you can turn off the radiator and remove it (emergency repairs, replacement during the heating season). In this case, even if something happens to the radiator, you will cut it off, and the rest of the system will work. The advantage of this solution is the low price of ball valves, the disadvantage is the impossibility of adjusting heat transfer.

Radiator taps

Almost the same tasks, but with the ability to change the intensity of the coolant flow, are performed by shut-off control valves. They are more expensive, but they also allow you to adjust the heat transfer (make it less), and they look better externally; they are available in straight and angular versions, so the piping itself is more accurate.

If desired, you can install a thermostat on the coolant supply after the ball valve. This is a relatively small device that allows you to change the heat output of a heating device. If the radiator does not heat well, you cannot install them - it will be even worse, since they can only reduce the flow. There are different thermostats for batteries - automatic electronic ones, but more often they use the simplest one - mechanical.

Related materials and tools

You will also need hooks or brackets for hanging on walls. Their number depends on the size of the batteries:

- if there are no more than 8 sections or the length of the radiator is no more than 1.2 m, two mounting points on top and one on the bottom are sufficient;

- For every next 50 cm or 5-6 sections, add one fastener at the top and bottom.

You also need fum tape or linen winding and plumbing paste to seal the joints. You will also need a drill with drills, a level (preferably a level, but a regular bubble one will do), and a number of dowels. You will also need equipment for connecting pipes and fittings, but it depends on the type of pipes. That's all.

Correct installation of heating radiators

The efficient operation of the heating system largely depends on the correct installation of these devices. Firstly, the wall behind the heating radiator must be level and strong, otherwise problems may arise with the installation. First, you should mark the middle of the opening, after which a horizontal line is drawn 10-12 cm below the window sill line. This line will mark the upper limit of the location of the heating device. If the heating system operates using a circulation pump, then it is permissible to hang the heating radiators strictly horizontally, and if the heating system operates on the basis of natural circulation of the coolant, then it is necessary to withstand small slopes along the coolant flow, about 1-1.5 degrees, but no more. With large slopes, coolant circulation deteriorates and stagnation may occur.

Correct installation of heating radiators

Wall mount

The mount for heating radiators differs in its design, depending on the type of radiator. Aluminum and bimetallic radiators are attached using special hooks with a bend at the ends. They also come with dowels. To hang such batteries, you need to drill holes in the hay, the diameter of which corresponds to the diameter of the dowels. The distance to the wall is adjusted by screwing or unscrewing such fasteners.

Hooks for cast iron batteries are thicker. This is a fastener for aluminum and bimetallic

When installing such hooks, it should be taken into account that almost the entire load falls on the upper hooks, and the lower ones serve as clamps, eliminating the possibility of displacement.

To install the brackets correctly, it is better to place the battery against the wall and mark the mounting points. After this, you can begin drilling holes and further installing fastening elements. Then they just start installing the heating battery.

Floor mounting option

Legs for installing aluminum and bimetallic radiators on the floor

It is not always possible to hang even light radiators on walls, especially if they are made of plasterboard or laid out of lightweight concrete. In this case, it is possible to install them on the floor, as special legs or fasteners are available. Some types of heating devices are equipped with such legs. In fact, this mounting option is used quite rarely, since few people are satisfied with the appearance of such a heating system.

Other types of connection

There are more profitable options than the bottom connection, which reduce heat loss:

Diagonal view

- Diagonal. All experts have long come to the conclusion that this type of connection is ideal regardless of the piping scheme in which it is used. The only system where this type cannot be used is a horizontal bottom single-pipe system. That is, the same Leningrad woman. What is the essence of a diagonal connection? The coolant moves diagonally inside the radiator - from the upper pipe to the lower. It turns out that hot water is evenly distributed throughout the entire internal volume of the device, falling from top to bottom, that is, naturally. And since the speed of water movement is not very high during natural circulation, the heat transfer will be high. Heat loss in this case is only 2%.

- Lateral, or one-sided. This type is very often used in apartment buildings. The connection is made to the side pipes on one side. Experts believe that this type is one of the most effective, but only if the system has coolant circulation under pressure. There are no problems with this in city apartments. And to provide it in a private house, you will have to install a circulation pump.

What is the advantage of one type over others? In fact, correct connection is the key to effective heat transfer and reduced heat loss. But in order to connect the battery correctly, you need to prioritize.

Take, for example, a two-story private house. What to prefer in this case? Here are several options:

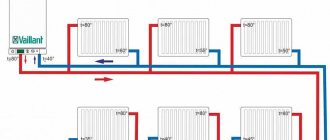

Two and one pipe systems

- Install a one-pipe system with side connection.

- Install a two-pipe system with a diagonal connection.

- Use a single-pipe scheme with lower wiring on the first floor and upper wiring on the second.

So you can always find options for connection diagrams. Of course, you will have to take into account some nuances, for example, the location of the premises, the presence of a basement or attic

But in any case, it is important to correctly distribute the radiators among the rooms, taking into account the number of their sections. That is, the power of the heating system will have to be taken into account even with such an issue as the correct connection of radiators

In a one-story private house, connecting the battery correctly will not be very difficult, given the length of the heating circuit. If this is a single-pipe Leningrad circuit, then only a lower connection is possible. If it is a two-pipe scheme, then you can use a collector system or a solar one. Both options are based on the principle of connecting one radiator to two circuits - coolant supply and return. In this case, top pipe distribution is most often used, where distribution along the circuits is carried out in the attic.

By the way, this option is considered optimal both in terms of operation and during the repair process. Each circuit can be disconnected from the system without turning off the latter. To do this, a shut-off valve is installed at the point where the pipes are separated. Exactly the same one is mounted after the radiator on the return pipe. You just have to close both valves to cut off the circuit. After draining the coolant, you can safely carry out repairs. In this case, all other circuits will operate normally.

Features and rules of placement

Any heating equipment is a complex system where each component has its own role

The most important part of the entire system is the heat exchange units, which are the final link in the transfer of heat energy in the house. These include ordinary radiators, convector devices of open or closed type, water floor heating devices, which are profiles of pipes laid on the basis of certain rules

Any type of radiator is installed indoors according to general rules. There is a specific installation procedure that must be followed. The installation procedure will not cause any particular difficulties, but there are many nuances in this matter. So, first of all, they affect the installation site. In most cases, the heating installation is placed in areas of the most significant heat loss, for example, under window openings. Even modern energy-saving double-glazed windows cannot trap warm air in the room. Old wooden frames need not be mentioned.

If there is no radiator structure under the windows, cold air masses descend along the wall and spread across the floor. The situation changes after installing the battery: warm air rising to the ceiling prevents cold air from falling down. Remember that the effectiveness of such protection depends on the size of the heating device: it must be at least 70% of the width of the window. For this reason, small radiators will not provide the appropriate degree of comfort. In the lateral zones there will be areas with a cool air mass descending to the lower level. You will be able to see the “sweating” of glass and walls. The collision points of heated and cold air will become covered with condensation, and dampness will form in the room.

Therefore, do not try to purchase a sample that has the highest heat transfer. They are suitable for areas with harsh climatic conditions. In this case, it would be useful to install a heat curtain at the front door. This is the second problem area in private residential buildings. Residents of the first floors of apartment buildings often encounter it. The principles for placing the heater are simple: installation is carried out close to the entrance. Determine the site based on the layout features and pipe laying capabilities.

The heating installation should be placed exactly in the center of the window. Before installation, find the center and mark it. Then, in both directions, calculate the interval to the fastening points. The gap between the product and the floor should be from 8 to 14 centimeters. If you make it smaller, cleaning under the radiator will be difficult; a larger distance will cause the formation of zones with cool air.

Measure 10-12 centimeters between the window sill and the radiator and begin installation. A closer location will worsen convection and reduce thermal output. The distance between the wall and the back wall of the device is 3-5 centimeters. Thanks to this gap, normal convection and heat distribution will be ensured. A shorter distance will cause dust to settle on the wall.

In addition, batteries can be installed in:

- extended interwindow spaces are a popular alternative option;

- corners and “blind” walls of corner rooms - enhance heating of spaces characterized by increased heat loss due to increased exposure to wind;

- bathrooms, pantries, bathrooms, in which one or two sides are connected by a load-bearing wall;

- unheated entrances, hallways of private houses;

- apartment corridors of the first floors of multi-storey buildings.

Single-pipe horizontal

The simplest version of a single-pipe horizontal heating system with a bottom connection.

When creating a heating system for a private house with your own hands, a single-pipe wiring diagram may turn out to be the most profitable and cheapest. It is equally suitable for both one-story and two-story houses. In the case of a one-story house, it looks very simple - the radiators are connected in series to ensure consistent flow of coolant. After the last radiator, the coolant is sent through a solid return pipe to the boiler.

Advantages and disadvantages of the scheme

First, we will look at the main advantages of the scheme:

- ease of implementation;

- excellent option for small houses;

- saving of materials.

A single-pipe horizontal heating circuit is an excellent option for small spaces with a minimum number of rooms.

The scheme is really very simple and understandable, so even a beginner can handle its implementation. It provides for a serial connection of all installed radiators. This is an ideal heating layout for a small private house. For example, if this is a one-room or two-room house, then “fencing” a more complex two-pipe system does not make much sense.

Looking at the photo of such a circuit, we can note that the return pipe here is solid, it does not pass through the radiators. Therefore, this scheme is more economical in terms of material consumption. If you don’t have extra money, this type of wiring will be the most optimal for you - it will save money and allow you to provide heat to your home.

As for the shortcomings, there are few of them. The main disadvantage is that the last radiator in the house will be colder than the very first one. This is due to the sequential passage of the coolant through the batteries, where it releases the accumulated heat into the atmosphere. Another disadvantage of a single-pipe horizontal circuit is that if one battery fails, the entire system will have to be turned off at once.

Despite certain disadvantages, this heating scheme continues to be used in many small private houses.

Features of installation of a single-pipe horizontal system

When creating water heating for a private house with your own hands, the scheme with single-pipe horizontal wiring will be the easiest to implement. During the installation process, it is necessary to mount the heating radiators, and then connect them with pipe sections. After connecting the very last radiator, it is necessary to turn the system in the opposite direction - it is advisable that the outlet pipe runs along the opposite wall.

A single-pipe horizontal heating circuit can also be used in two-story houses; each floor here is connected in parallel.

The larger your home, the more windows it has and the more radiators it has. Accordingly, heat losses also increase, as a result of which the last rooms become noticeably cooler. You can compensate for the temperature drop by increasing the number of sections on the latest radiators. But it is best to install a system with bypasses or with forced circulation of the coolant - we will talk about this a little later.

A similar heating scheme can be used to heat two-story houses. To do this, two chains of radiators are created (on the first and second floors), which are connected in parallel to each other. There is only one return pipe in this battery connection diagram; it starts from the last radiator on the first floor. The return pipe coming down from the second floor is also connected there.

What types of radiators are there?

The most common types of batteries these days are:

Cast iron radiators

Good old cast iron radiators are known for their reliability. Although they are installed less and less now, quite recently they were installed in every apartment. The most significant drawback is the enormous weight. They are extremely durable (batteries installed back in Soviet times still work properly in some apartments), are not afraid of high pressure and low quality coolant, and transfer heat perfectly.

Aluminum radiators

Aluminum - modern models. These analogues are lightweight and stylish in appearance. The coolant in these batteries passes directly through the housing, so high-quality liquid is important, otherwise the radiators will quickly become unusable. Aluminum models are cheap, but are not popular due to their pickiness about the coolant.

Bimetallic radiators

Such models are similar to cast iron, but they are more modern, lighter and have better (compared to cast iron) heat transfer. The batteries consist of a steel core and an aluminum body, which eliminates the disadvantage of aluminum analogues. The advantages of this model make it the most popular today.

Steel batteries

The service life of such models reaches 25 years, they are relatively lightweight and give off heat well. Batteries of this type are ideal for small private houses.

Choosing the type of batteries is always difficult. We recommend taking either cast iron ones, if you have someone to help with their installation, or bimetallic ones, they are lightweight and you can install them yourself.

Gravity heating system and its implementation scheme

Until a certain time, a gravity heating system in private houses was the only possible one. It was probably its widespread use that created the myth about the simplicity and cheapness of gravity heating. In fact, it is the heating scheme based on the natural movement of the coolant that is the most difficult to implement and resource-intensive.

Moreover, gravity heating only works effectively in one-story houses. In two-story buildings, overheating of the second floor inevitably occurs, to eliminate which it is necessary to install additional bypasses, which will also lead to an increase in the cost of the heating system.

In higher-rise buildings, a gravity heating system is not used.

Another important condition for the successful implementation of a gravity heating system is the presence of an attic, where a heating expansion tank must be installed and supply manifolds (arms) must be laid.

If there is no attic, but the house has an attic, the expansion tank must be installed in the living room, connecting it to the sewer system to discharge excess coolant if necessary. It should be remembered that in a gravity system the expansion tank is open and its location inside the house is possible only when water is used as a coolant. If the heating system is filled with antifreeze, the vapors of which are dangerous to humans, an open expansion tank cannot be installed in the room.

Another condition for normal operation of gravity heating is the installation of the boiler below the return level, for which the boiler is placed in a special recess or in the basement. And finally, the installation of pipes of such a system must be carried out with a slope, ensuring free directed movement of the coolant towards the boiler.

As you can see, the scheme of a gravity heating system cannot be called simple. It has too many disadvantages, but only one advantage - uninterrupted operation of the heating system in the absence of electricity.

Installation nuances

There are two types of bimetallic radiators: partially or completely bimetallic.

In the first case, aluminum is used for the manufacture of vertical collectors, which requires special care during installation. There are the following requirements for how to correctly connect a bimetallic battery:

There are the following requirements for how to properly connect a bimetallic battery:

When connecting fittings and manifolds, be careful not to use excessive force. As a rule, the accompanying documentation contains detailed installation instructions

A torque wrench is very convenient in this regard, allowing you to control the applied force. When using linen winding, it is important not to overdo it with its quantity. Otherwise, some of the effort will go into it, which will ultimately lead to the appearance of microcracks.

After the coolant gets into them, the process of peeling off the paint will begin. As a result, sooner or later a leak will appear. It is best to apply sealant and a little flax. It is better to avoid using paint in systems where antifreeze acts as a coolant. This will lead to rapid corrosion of the seal and the appearance of a leak.

- The battery must be mounted in a strictly horizontal position. An exception is when an air vent is used, when, for greater efficiency in releasing gases, a slight forward angle deviation along the circulation path is allowed. It is prohibited to make a slope in the opposite direction, because this disrupts circulation.

- When hanging the radiator, you must use three brackets: two on top and one on the bottom. The upper elements take on the entire load. Due to the lower fasteners, the desired direction is set.

- To ensure effective air exchange, the following parameters should be adhered to: distance to the floor - from 60 mm, to the window sill - from 100 mm.

In some cases, the manufacturer may recommend other distances, depending on the design features (the differences are usually a few centimeters). However, the gap between the rear surface of the battery and the wall remains unchanged - 30-50 mm.

Video on heating battery connection diagrams

Video about the difference between natural and forced circulation of coolant in a heating system:

Video clearly demonstrating the differences between different heating system schemes:

Scheme for effectively connecting heating batteries with a two-pipe system:

The heating efficiency directly depends on the choice of battery connection diagram for your home. With the right option, heat loss is minimized. This allows you to get maximum effect with the least amount of fuel used. You can install the batteries yourself

It is important to take into account the features of your home so that cold radiators do not interfere with a comfortable life in a cozy home

Please tell me what to do if my radiator pipes directly “stick” to the wall of the house, is this not a minus? For example, when I was already doing putty at home myself, I noticed that it was not convenient, since I could not properly straighten the walls. And is it worth replacing old Soviet cast-iron radiators with new, but more beautiful steel or cast-iron appliances?

Free consultations with an engineer on the arrangement of technological networks Ask your question

Join on social media networks

Add a company

Popular from this category

- What is the best way to cover a heating radiator: options for masking radiators

- How to paint a heating radiator: technology for painting radiators

- Calculation of heating radiators: how to calculate the number and power of batteries

- How to choose an infrared carbon heater: an overview of various designs

Visitors are currently discussing

Ventilation in the cellar: technology for constructing a proper ventilation system Design and calculations

Rainwater collection system: how to arrange storage tanks for water use in the house Other

SMS socket: how a socket controlled by gsm works and is installed Sockets and switches

Ejector for a pumping station: operating principle and installation rules Pumping equipment

Installing a heating battery with your own hands - step-by-step instructions

Let's consider the process of installing a bimetallic battery connected laterally to a single-pipe heating system. It is worth saying that in this case the work was carried out in a building where the temperature in the radiators was relatively low, because the supply and bypass were made of metal-plastic pipes. Before you begin installing the battery yourself, familiarize yourself with the structure and characteristics of the heating system in your home. For your apartment or cottage, connecting pipes may need to be made from materials that are more resistant to high temperatures.

Sectional view of a metal-plastic pipe

Let's divide the process of installing a heating battery with our own hands into several separate stages:

- dismantling the old radiator;

- installation of a new bypass and shut-off valves;

- installing the battery and connecting it to the connection.

Preparing for work. Removing the old battery

Do-it-yourself installation of a heating battery begins with preparing the tools and dismantling the old radiator. In this example, we will be talking about a standard cast iron product, which still heats many apartments. You can read how electric convectors are installed in our article.

Step 1: Bring home a new battery. Unpack it, check if everything you bought is there. Also inspect the radiator itself to see if it has any damage or defects.

Unpacking a New Battery

Step 2. Cut the packaging of the new battery into two equal parts. Use one as a backing for the radiator - this way you won’t scratch it on the floor covering. Place the second part of the package behind the heating riser - when dismantling using a grinder, a sheet of cardboard will protect the wall from contamination.

Radiator packaging

Cutting packaging into pieces using a knife with a retractable blade

A sheet of cardboard behind the heating riser and bypass. You can see a basin on the floor - you will need it if there is still water left in the pipes

Step 3. Prepare everything you need to dismantle the old and install a new radiator - fittings, taps, pipes, tools. Determine for yourself what should be located where - searching for something necessary for installation, but lost in the clutter, can significantly slow down the work of replacing the battery.

In the hands of the master is a conductor - a spring, with which you can bend metal-plastic pipes with high precision

Step 4. Remove the three-way valve connecting the heating riser, bypass and supply line. First, loosen it with an adjustable wrench. If water starts to drip, immediately screw everything back in - most likely, the riser was not closed properly. And if everything is in order, continue working on dismantling the crane.

Three way valve

The tap needs to be loosened with an adjustable wrench.

The crane has been dismantled

Step 5. Next, disconnect the old battery and line from the riser. First, unscrew the nut on the thread strip. Then determine how far this thread can be cut so that you can then mount a tee connecting the inlet, bypass and riser without any problems.

The nut on the thread strip is unscrewed

Thread

It is necessary to determine how far the thread can be cut

Advice! In some cases, old paint applied to the nut and connection of the riser to the bypass and liner may interfere with operation. You can remove it using a regular knife with a retractable blade or a metal brush.

Step 6: Remove the battery from its mountings.

Removing the battery

Wall Mounts

Step 7. According to the previously determined mark on the threads connecting the heating riser to the battery, trim using a grinder.

Trimming threads with a grinder

Trimming the thread on the supply pipe

Step 8. Remove the old battery and take it to a place where it will not interfere with further work. Given the high weight of the cast iron radiator, if possible, do this in tandem with someone else.

The battery is removed

Step 9: Remove the old battery mounts from the wall. If they hold particularly tightly, use a hammer and chisel.

Old fasteners need to be removed

Removing old fasteners

Old fasteners removed

Online calculator - calculating the number of heating radiator sections

Installation of a new bypass and shut-off valves

After you have gotten rid of the old battery, you need to prepare the riser for installing a new radiator. To do this, you need to install new shut-off valves and place a bypass between the lower and upper pipes.

Step 1. Screw the nipple to the tee from one of the horizontal sides.

A nipple is screwed to the tee

Step 2. In turn, screw a ball valve to the other side of the nipple, which in this case will play the role of a locking device on the new battery.

A ball valve is screwed to the nipple

Step 3. Attach a press fitting to the vertical branch of the tee to connect the entire structure with a bypass made of a metal-plastic pipe.

A press fitting is attached to the tee

Step 4. Screw another press fitting to the currently free side of the tap to connect it to the metal-plastic supply pipe.

In the diagram shown here you can see the design of the locking and connecting unit

Step 4. Disassemble the resulting structure and twist it again, but with a wound sealing thread.

Advice! If desired, FUM tape can be used instead of thread. The main thing is that all threaded connections in the assembly, without exception, are reliable and sealed.

Step 5. Repeat the previous operation, but for the second shut-off and connecting assembly, which will be located on the lower pipe of the riser.

Fitting the resulting assembly to the riser pipe

Step 6. Prepare the threads on the riser pipes - wrap a large amount of sealing thread around it so that the future connection is as tight as possible.

Thread preparation

Step 7. Mount the shut-off and connecting units on the upper and lower riser pipes. Complete the final tightening of the thread using an adjustable wrench, being careful.

The resulting assembly on the riser pipe

Step 8. Measure the distance between the riser pipes. Cut the metal-plastic pipe to the same length.

The distance between the riser pipes is determined

Step 9. Insert the pipe into the lower press fitting, determine how much longer it is than necessary. Perform another trim.

The pipe is inserted into the lower press fitting

Step 10. It will be very difficult to simply insert a pipe between the tees - it is longer than the distance between the edges of the press fittings. Therefore, first bend the future bypass a little manually or using a jig.

Future bypass bends

Step 11. Insert the metal-plastic pipe sequentially into the lower and upper press fittings. Align it between the tees - a crooked bypass will spoil the appearance of the heating radiator.

The pipe is inserted into the lower press fitting

The pipe is inserted into the upper press fitting

Bypass equalization

Step 12. Perform crimping on the corresponding fittings and edges of the metal-plastic pipe. After this, the installation of the bypass and shut-off and connecting valves can be considered complete.

Pressure testing of fittings

Price for bypasses for heating

bypass for heating

Boiler connection

It should be noted that the wiring of gas, diesel and electric heat generators is almost the same. Here we must take into account that the vast majority of wall-mounted boilers are equipped with a built-in circulation pump, and many models are equipped with an expansion tank. First, let's look at the connection diagram for a simple gas or diesel unit:

The figure shows a diagram of a closed system with a membrane expansion tank and forced circulation. This tying method is the most common. The pump with a bypass line and a sump tank is located on the return line, and there is also an expansion tank there. The pressure is controlled using pressure gauges, and air is removed from the boiler circuit through an automatic air vent.

When the heat generator is equipped with its own pump, as well as a circuit for heating water for domestic hot water needs, the pipe layout and installation of elements is as follows:

Shown here is a wall-mounted boiler with forced air injection into a closed combustion chamber. To remove flue gases, a double-walled coaxial flue is used, which is led out horizontally through the wall. If the firebox of the unit is open, then you need a traditional chimney with good natural draft. How to properly install a chimney pipe made of sandwich modules is shown in the figure:

In country houses with a large area, it is often necessary to connect a boiler with several heating circuits - a radiator, heated floors and an indirect heating boiler for DHW needs. In such a situation, the optimal solution would be to use a hydraulic separator. It will allow you to organize independent circulation of coolant in the boiler circuit and at the same time serve as a distribution comb for the remaining branches. Then the basic heating diagram for a two-story house will look like this:

According to this scheme, each heating circuit has its own pump, thanks to which it operates independently of the others. Since coolant with a temperature of no more than 45 ° C should be supplied to heated floors, three-way valves are used on these branches. They add hot water from the main line when the temperature of the coolant in the heated floor circuits drops.

With solid fuel heat generators the situation is more complicated. Their strapping should take into account 2 points:

- possible overheating due to the inertia of the unit; the firewood cannot be extinguished quickly;

- formation of condensation when cold water enters the boiler tank from the network.

To avoid overheating and possible boiling, the circulation pump is always placed on the return side, and on the supply side there should be a safety group located immediately behind the heat generator. It consists of three elements: a pressure gauge, an automatic air vent and a safety valve. The presence of the latter is crucial; it is the valve that will relieve excess pressure when the coolant overheats. If you decide to heat your house with wood, then the following wiring diagram is required:

Here, a bypass and a three-way valve protect the furnace of the unit from condensation. The valve will not allow water from the system into the small circuit until the temperature in it reaches 55 °C. Detailed information on this issue can be obtained by watching the video:

Many homeowners install two different heat sources in the furnace room. They must be properly tied and connected to the system. For this case, we offer 2 schemes, one of them is for a solid fuel and an electric boiler working together with radiator heating.

The second scheme combines a gas and wood heat generator, supplying heat to heat the house and prepare water for hot water supply:

About special radiators designed for the lower connection scheme

As noted earlier, special batteries with bottom connections are sold today. Their design is such that optimal heat transfer is ensured. Radiators consist of a pair of steel plates connected to each other by welding, thereby forming technological channels for the movement of working fluid. The plates are varnished in two layers for high-quality protection against corrosion.

Bimetallic radiators Titan (Marek) 500/96 with bottom connection

To connect the radiator with your own hands, you need to prepare:

- L- or T-shaped tubes;

- building level;

- multiflex nodes;

- FUM tape;

- thermal insulation;

- pipe cutter;

- nuts in the required quantity.

It is advisable that the bottom connection of the batteries be made in the early stages of renovation of the apartment/house, because the pipes in this case are laid inside the floor (or wall). Keep this in mind when planning the installation of a concrete floor screed.

It is better to connect the radiator in the early stages of repair

If for one reason or another the pipes cannot be laid into the floor, then in the future they can be covered with a plinth or plasterboard box.

Skirting for radiator pipes

Single pipe heating system

With a single-pipe heating system, the coolant enters the radiator, passes through it and returns again to the same pipe. In this case, the temperature of the coolant gradually decreases as it moves from one heating device to another. As a result, the first radiator is the hottest and operates with full heat transfer. To ensure the calculated heating power, the second radiator must be of greater power, and the third heating device must be even more powerful.

In private homes, it is difficult to accurately calculate the required power of heating devices when connecting them to a single-pipe system. As a rule, the selection of radiators occurs “by eye”, which leads to uneven heating of the room: in one room close to the boiler it will be hot, and in the other, on the contrary, it will be cold.

It remains to add that it is also impossible to achieve real savings on pipes when installing a single-pipe heating system.

Connection methods

Radiators can be connected to pipes in different ways, depending on the installation location and the route of pipes in the room and, of course, the heating scheme:

When the connection method is selected (see diagram), you must:

- Wipe all joints and pipes with sandpaper and degrease them.

- Secure the radiator. This can be a temporary fixation or an installation one, depending on the complexity of the arrangement of the heating system pipes according to your scheme.

- We screw in the adapters, which, by turning, can be adjusted to the direction of the pipes to which the elements are connected. If, for example, they are located on the floor, then the adapter is screwed down with a thread; if the pipes go deep into the room, then the direction of the adapter changes. So the main thing is to look carefully at the layout of a single-pipe heating system.

- Adapters for pipes, preferably made of domestically produced polypropylene, as experts advise, are attached to the main pipe using a soldering iron.

- We install the tap on top and the plug on the bottom, as shown in the diagram, or vice versa.

Recommendations for choosing and connecting radiators

An ordinary homeowner, going to a heating equipment store and seeing a wide selection of different radiators there, can conclude that choosing batteries for his home is not so easy. But this is the first impression; in fact, there are not so many varieties of them:

- aluminum;

- bimetallic;

- steel panel and tubular;

- cast iron

Sectional batteries made of aluminum alloy have the best heat transfer rates; bimetallic heaters are not far behind them. The difference between the two is that the former are made entirely of alloy, while the latter have a tubular steel frame inside. This was done for the purpose of using the devices in centralized heat supply systems of high-rise buildings, where the pressure can be quite high. Therefore, installing bimetallic radiators in a private cottage makes no sense at all.

It should be noted that heating installation in a private home will be cheaper if you purchase steel panel radiators. Yes, their heat transfer rates are lower than those of aluminum ones, but in practice you are unlikely to feel the difference. As for reliability and durability, the devices will successfully serve you for at least 20 years, or even more. In turn, tubular batteries are much more expensive, in this respect they are closer to designer ones.

Steel and aluminum heating devices have one useful quality in common: they lend themselves well to automatic control using thermostatic valves. The same cannot be said about massive cast iron batteries, on which it is pointless to install such valves. This is due to the ability of cast iron to heat up for a long time and then retain heat for some time. Also because of this, the rate of heating of the premises is reduced.

If we touch on the issue of appearance aesthetics, then the cast-iron retro radiators currently offered are much more beautiful than any other batteries. But they also cost incredible amounts of money, and inexpensive Soviet-style accordions MS-140 are only suitable for a one-story country house. From the above, the conclusion suggests itself:

Installation of cast iron radiators

Despite the abundance of batteries made of steel, aluminum and copper, cast iron is in no hurry to lose ground. Sometimes there is no point in choosing other options. For example, apartment owners will only waste their money if they buy bimetallic products: the installation of any heating radiator - cast iron, aluminum, steel or bimetallic - is not much different.

There is no point in re-describing how to properly install heating radiators; you just need to pay attention to certain subtleties that can arise when working with a cast iron battery.

- If the installation is carried out on a concrete wall, ordinary brackets will do. In the case when the installation is carried out in a wooden cottage, additional installation of support legs for the product will be required.

- For better quality work, it is better to turn to friends for help - remember that cast iron is not fluff, and moving it yourself is quite problematic.

- It is strictly forbidden to weld a battery in a wooden house, so you will either have to abandon the steel pipeline or use squeegees.

Radiator location in the room

Even the most expensive radiator will not give the desired effect if it is connected incorrectly or installed incorrectly on the wall. Standard options for mounting heating radiators are under window openings, next to entrance doorways, in places where there are unremovable drafts. But there are also standard requirements for mounting heating batteries on walls and other surfaces:

- Under the windowsill. There is always room for a battery under it, since other interior items are simply not needed there. All drafts from the window are minimized by the heat flow from the radiator. With this arrangement of the device, its total length should not be more than ¾ of the width of the entire window. If this rule is observed, the thermal output will be maximum. The radiator should be mounted in the center of the window, the tolerance to the left or right should not be more than 2 cm.

- Between the window sill and the radiator there must be a height distance of at least 10 cm (or at least ¾ of the thickness of the heating radiator), but no more than 15 cm, otherwise the plane of the window sill will retain the entire heat flow or not reflect it when mounted high.

- The distance between the battery and the wall on which it is mounted should not be less than 2 cm. A smaller distance provokes the accumulation of debris and dust, which, in turn, reduces the heat transfer of the device.

These requirements are not enshrined in GOST, therefore they are advisory. If there are no other recommendations from the manufacturer, then it is best to take these tips into account when attaching any radiator. But most often, the manufacturer in the radiator’s passport indicates the optimal scheme for installing it on the wall, which should be used.

Conclusion

After considering the main options for connecting heating devices to the heating system, their main disadvantages, as well as the advantages of each connection option, clearly emerge. In addition, the considered options for optimizing heat transfer can be applied to any scheme, and recommendations for mounting radiators are always needed when installing a heating system in an apartment or in a private house.

Installation locations for heating radiators

As a rule, heating radiators are placed under windows. This is necessary so that the warm air rising upward cuts off the cold air penetrating into a person’s home from the window, since windows have the least resistance to low temperatures. The greatest effect can be achieved if the width of the heating device is at least 70 percent of the width of the window opening. The heating battery is installed:

- Strictly in the middle of the window opening, with a deviation of no more than 2 cm.

- The distance of the battery to the floor is from 8 to 12 cm.

- The distance to the window sill is from 10 to 12 cm.

- The distance to the wall is from 2 to 5 centimeters, if you count from the back wall of the battery. Distances from radiator to window

If you follow these simple recommendations, heating radiators will work effectively, heating the premises.

Main options

There are several different heating systems and several options for connecting them. In particular, heating can be single-pipe or double-pipe, forced or natural circulation.

Single-pipe heating network options imply a connection in which the coolant moves from radiator to radiator in one line, passing them sequentially. As a rule, this is the scheme that is used everywhere in apartment buildings of old buildings, while at the same time, in new city apartments, a two-pipe connection option is already being made.

The second pipe serves to remove coolant from the radiator after it has been supplied there through the first. This allows the coolant to have the same temperature in all parts of the heating circuit and regulate its movement, therefore, the temperature in each specific heating device. The connection diagram for heating batteries in an apartment depends on the underwater piping. It is impossible to convert a one-pipe scheme to a two-pipe one if the rest of the apartments use a one-pipe system.

Now let's look at the question of how to connect a heating radiator, depending on the needs and capabilities of each of these systems.

Enter exit

Strictly speaking, each of the presented options for how to properly connect heating batteries has its own advantages and disadvantages. For example, the simplest method is a single-pipe connection, from one side of the radiator the coolant is introduced into the upper part, and from the lower part it is discharged further.

The most common connection option, it is also called standard. There is virtually no loss of thermal energy. It is best to supplement this connection with a bypass to allow adjustment and repair of the radiator.

As a rule, serial connection of heating batteries is carried out according to the described or the following schemes.

The simplest method is a single-pipe connection, from one side of the radiator the coolant is introduced into the upper part, and from the lower part it is discharged further.

Diagonal

Despite its high efficiency, it is quite rare, apparently due to the complexity of strapping and the consumption of additional materials. This is done as follows: the coolant is introduced into the upper part of the radiator and its outlet is made from the lower part on the opposite side.

Leningradka

The most correct connection of the heating battery when it comes to horizontal installation of the riser. The input is made from the side closest to the coolant current, the output is from the opposite side, and both connections are located at the bottom of the battery.

Leningradka is often supplemented with a bypass in order to be able to control the flow of coolant and regulate the temperature in the radiators. It is named so because it was developed and first used in Leningrad.

However, despite all the originality and controllability of the considered system, it has a significant drawback, namely heat loss, which will amount to up to 15% of the total figure. Which, you see, is not very good when you heat your house with gas at your own expense.

We discussed above the main methods of connecting heating batteries used for single-pipe networks. It is impossible to connect heating batteries in parallel in a one-pipe system, since it is not possible to supply coolant separately to each heating element.

For a two-pipe system, there is no need to build tricky series connection schemes; usually in such networks radiators are connected in a standard way, less often diagonally.

If the coolant circulates without a pump, naturally, the connection is always made in a diagonal way, since it provides the least resistance in the path of the coolant.

The process of preparing for connection from the boiler

Preliminary work is very important before installing heating radiators:

- Inspection of the current harness. The study will make it possible to create a similar system, which will have a positive impact on operation.

- Checking components for the radiator. The kit must contain: Mayevsky tap, shut-off valves, brackets.

Some models include adapters and gaskets, sometimes you need to purchase them in addition. When replacing manually, you will need tools - wrenches of suitable size. And you also need to purchase a sealant.

- Checking the pipes for compatibility with the new battery. The outer layer of the bimetallic device is made of aluminum, which is not compatible with soft materials. For example, copper piping or taps will need to be replaced. Otherwise, the system faces rapid destruction.

- Selecting a location for the battery. This especially applies to mounts if an old device is being replaced.

- Conducting an examination of the radiator for visible damage, surface integrity, and coating.

- If the components are fully compliant, they proceed to replacement. At the preparatory stage, water is drained from old batteries.

Having completed the preparation, proceed to choosing a connection diagram. The first paragraph states that you should choose an option similar to the old one. This will avoid rebuilding the entire system and will maintain the current efficiency. The work process is quite simple and is described below.

Important! Upon completion, a set of tests is carried out, known as crimp testing. It includes water, heat and pneumatic tests

Radiator selection

You should start by choosing a radiator, and the main criterion for choosing will be the operating pressure for which the radiator is designed. For a private house with its own heating system, a radiator with a working pressure of 6-7 atmospheres will be sufficient, but if you need to connect a radiator to the central heating system of an apartment building, it must withstand a pressure of at least 10 atmospheres.

Currently, the consumer is offered two options for aluminum radiators - standard or European and reinforced. The latter can operate under pressure reaching 12 atmospheres. When connecting to a central heating system, you must choose among reinforced radiators.

The number of sections plays a big role

Next you need to decide on the required number of sections. To do this, we determine the amount of heat. Necessary for heating the room and divide by the heat transfer of one section of the selected radiator.

The amount of heat required for a standard room can be taken equal to 1 kW per 10 m 2 of room area. For non-standard premises and more accurate calculations, we will use a ready-made table:

Radiator power table

It should be remembered that the connection diagram for a battery of more than 12 sections must be double-sided, diagonal or saddle. With a one-sided battery connection scheme consisting of a large number of sections, a “pocket” of cold water will form on the side of the radiator opposite the pipes. “Extra” sections simply won’t work; we end up with harmful ballast.

Using forced injection, the battery can be expanded to 24 sections, even with one-way supply, but the radiator in this case must be reinforced.

It should be remembered that coolant must be supplied to reinforced radiators under high pressure only through metal pipes. Metal-plastic may not withstand such pressure, and the consequences will be the most dire.

It should also be taken into account that the heat transfer of the radiator indicated in the documentation is relevant only for one-sided or diagonal supply of coolant to the radiator. When using bottom feed, feel free to subtract 10-15 percent.

If the heating system is installed in a private house, then it is possible to choose the general heating arrangement yourself - one- or two-pipe.

Geometry of placement of heating radiators

An important role in creating a comfortable atmosphere from the heating system is the placement of heating radiators.

There are certain building standards for the placement of heating radiators both relative to the wall and relative to the floor. SNiPs determine that the minimum gap between the bottom edge of the battery and the floor cannot be less than 5 centimeters.

typical battery installation diagrams

It is also necessary to provide a gap between the body of the heating radiator and the wall surface. It must also be at least 5 centimeters. Only in this case will normal circulation of air heated by the battery be ensured.

In accordance with existing standards, we calculate the installation locations of the batteries and mark the points for their fastening.

What is required for efficient heating operation

Let us immediately note that you should not just spy on your neighbor’s method of connecting heating radiators and decide to carry out the installation yourself. Proper execution of the work may depend on several factors, so the owner of a country house often needs specialist advice.

Only after deciding on the method of connecting the devices can you decide to do the work yourself.

The efficiency of heating batteries depends on several factors:

- power of thermal heating devices, their dimensions;

- places for installation in premises;

- connection methods.

The installation process itself

Before starting work, it is necessary to completely shut off the heating circuit, drain the water from the system, and the pump will help remove any remaining water efficiently. Using a level, carefully check the battery hung on the supports vertically and horizontally.

- You need to unscrew all plugs from the device.

- Connect a valved bypass, which is only required for a single-pipe circuit. To connect to a two-pipe circuit, a bypass is not needed; only a squeegee with a valve connected to it is used for connection.

Using threaded connectors, we connect the battery to the system, using tow or another sealant to seal the joints (if you have experience in welding, the joints between the connectors and the pipeline can be welded).

A bypass is required for connection to a single-pipe circuit - connection diagram: 1 - tee for metal-plastic pipes; 2 - direct control valve; 3 - direct shut-off valve; 4 — adapter for metal-plastic pipes; 5 - rotating valve for air release

It is important to note that there is no need to remove the packaging from aluminum, bimetallic and steel devices until installation is completed.

Installation is complete, but some more pressure testing will be required. To do this, you will need to call a plumber. Both his experience and the device will be useful, which does not make sense to buy for the sake of installing several batteries.

Scheme selection

The choice of pipe layout depends on the connection system: single-pipe and two-pipe , and the method of water circulation in the pipes: natural and forced (using a circulation pump).

Single-pipe - based on serial connection of radiators. Hot water, heated by the boiler, passes through all heating sections through one pipe and goes back into the boiler. Types of wiring for a single-pipe scheme: horizontal (with forced water circulation) and vertical (with natural or mechanical circulation).

When installed horizontally, the pipe is installed parallel to the floor; the radiators should be located at the same level. The liquid is supplied from below and removed in the same way. Water circulation is carried out using a pump.

With vertical wiring, the pipes are located perpendicular to the floor (vertically), the heated water is supplied upward, and then goes down the riser to the radiators. Water circulates independently under the influence of high temperatures.

The two-pipe system is based on parallel connection of radiators to the circuit, that is, hot water is individually supplied to each radiator through one pipe, and water is discharged through the second. Types of wiring - horizontal or vertical. Horizontal wiring is carried out according to three schemes: flow-through, dead-end, and collector.

Connecting convectors to the heating system is carried out using the following methods: bottom, top, one-sided and diagonal (cross). The circulation of liquid inside it depends on the installation plan of the battery.

For one-pipe and two-pipe systems, vertical wiring is primarily used for houses containing two or more floors.