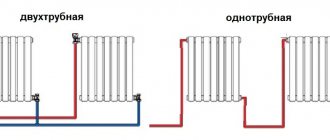

Properly done heating is warm, comfortable and economical. There are quite a lot of radiator connection diagrams in practice:

- parallel connection (one-way circuit);

- diagonal (cross);

- single-pipe (apartment version);

- single-pipe with jumper (apartment version);

- two-pipe scheme (apartment version);

- single-pipe lower (autonomous heating);

- single-pipe bottom with jumper or tap (autonomous heating);

- two-pipe lower (saddle);

- two-pipe diagonal (autonomous heating, with or without pump).

In this article we will look at the heating radiator connection diagrams listed above.

If in an apartment with ways to connect radiators to a centralized heating system, we don’t have much choice, that is, when replacing the radiator, repeat the existing connection diagram. Then for autonomous heating (at home, cottage, cottage, etc.), we will try to decide on the most efficient and economical one.

Parallel connection of heating radiators (one-sided circuit)

Not a very efficient connection, since the radiator does not fully warm up.

This is especially true when the radiator is more than one meter in length (panel type), or more than ten sections (bimetal, aluminum). Heat losses are significant. Therefore, when installing large radiators in your apartment, use a diagonal connection. About him below.

Advantages and disadvantages of steel radiators

Stainless steel radiators have a number of advantages:

- have a long service life due to the simplicity of the design;

- have sufficient strength. High-quality models use steel with a thickness of 1.2…1.5 mm;

- allow for independent connection;

- have an attractive design.

In addition, tubular batteries, due to their ability to withstand pressure testing up to 20 atmospheres and resistance to water hammer, can be installed in “high-rise buildings” with central heating. The same cannot be said about panel batteries with low pressure testing.

The disadvantages include:

- susceptibility to corrosion under the influence of moisture and aggressive additives. It increases many times over with a long absence (2 weeks or more) of coolant in them;

- welds, especially in panel-type products, are sensitive to water hammer and may even burst during crimping;

- unstable paint coating.

However, despite the listed disadvantages, the basic performance characteristics of these products are high, and their price is very attractive.

Single-pipe scheme (apartment version)

This connection scheme is very common in apartment buildings (from 9 floors and above).

One pipe (riser) descends from the technical floor, passes through all floors and enters the basement, where it enters the return pipe. In such a connection system, there will be heat in the upper apartments, since, having passed through all the floors and given off the heat to the bottom, the water in the pipe will cool down.

And if there is no technical floor (5-story buildings and below), then such a system is “ringed”. One pipe (riser) rises from the basement, passes through all floors, goes through the apartment on the top floor to the next room and descends, also through all floors, to the basement. In this case, it is not known who is lucky. On the ground floor, in one room, it may be warm where the pipe rises, but in the next room it is cold, where the same pipe descends, giving off heat to all apartments.

Pipe sizes

Forced circulation

If a constantly running circulation pump is installed in the system, the following conditional pipe passages are used when designing the circuit:

- filling - 25 mm;

- connections for a radiator length of up to 10 sections - 15 mm;

- connections for radiator lengths exceeding 10 sections - 20 mm.

The ratio of the filling diameters and liners is clearly visible in the photo.

Please note: for a steel pipe, the nominal bore (DN) approximately corresponds to the internal diameter. Polymer and metal-polymer pipes are marked with an outer diameter; as a rule, it is one step larger than the internal one. So, for polypropylene, diameters 32, 20 and 25 should be used, respectively.

Natural circulation

If the circuit is intended to operate in natural circulation mode, the main task of the designer is to minimize its hydraulic resistance. How to achieve this?

The instructions are not complicated:

- heating pipes with minimal roughness are used - metal-plastic or polypropylene;

- The filling diameter increases to at least 40 millimeters.

Single-pipe circuit with jumper (apartment version)

This option is slightly better than the previous one, since the goal is to heat all the radiators in the apartments, along the riser, evenly.

By reducing the resistance created by the radiators with such a jumper, the coolant passes through the entire riser, partially entering (mixing) into the radiator, thereby heating all floors evenly.

The main thing here is to make sure that none of the residents put a tap on the lintel (and close it), otherwise this whole “undertaking” of the engineers with the lintel will be covered with a “copper basin”. In some houses, knowing about such cases, they simply reduce the diameter of the lintel.

The tap on the jumper is needed in case of an accident or repair - if the radiator “leaks” (breaks), it is removed for replacement. Then the jumper serves as a bypass between the apartments so that the flow of coolant stops.

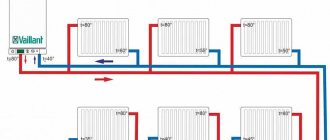

Two-pipe (apartment version)

This option is almost ideal for apartment buildings. There is a supply pipe (supply) and a “return” pipe.

The heat transfer when using such circuits is greater. The heating of the radiator and the room itself is better. There is no need to install a jumper in case of an accident.

Don’t forget to install a “Mayevsky tap” on the radiators to remove air from the heating system and remember the previous advice about diagonal connections when installing long radiators.

From apartments in multi-storey buildings we will move on to autonomous heating.

A competent approach to choosing the type of connection

The first thing you should pay special attention to is the radiator installation diagram. Often the efficiency and functionality of the battery depends on it. Also, if installed incorrectly, temperature control and the pressure in the battery increases significantly, which can lead to inevitable deterioration in operation. If you decide to carry out the installation yourself, without any skills, there is a high probability that you will encounter many problems and spoil the intended interior of the room.

Single-pipe circuit with bottom connection (autonomous heating)

This method of connecting radiators is outdated and ineffective.

How many times, in practice, have we had to redo such heating. The coolant in the pipes of such a system “flows” where it is “easier” (through a pipe that has a larger diameter). And it doesn’t want to “go” into the radiator (which has resistance).

The radiator does not warm up well, only from the bottom, and not always and not for everyone. Cannot be adjusted. Heat loss is large (up to 30%).

Single-pipe bottom with jumper or tap (independent heating)

Bottom connection of the heating radiator with a tap on the jumper.

The same option, only slightly improved (modified). Things are already better here (you can try to regulate).

Using a jumper of a smaller diameter on the “bed” or a shut-off valve, we “drive” the coolant into the radiator, and if we also use a diagonal connection, then this option has a right to exist. You need to start regulating such a system from the boiler, using taps. Go ahead.

Design and design of steel radiators

Steel batteries replaced cast iron, which were previously used everywhere. At first, such batteries were much inferior to their predecessors in terms of parameters.

Now, thanks to modern technologies, they have good performance characteristics while remaining affordable. They come in panel and tubular types.

Panel

Each panel consists of two stamped profiled sheets, connected by a weld along the entire perimeter. Inside there are elongated vertical channels formed during stamping. They are designed to circulate coolant.

To improve heat transfer, sometimes ribs can be welded to the panels on the reverse side. The battery can consist of 1...3 panels, the sides of which are usually covered with casings.

According to the connection, there are universal models, as well as models connected from the side or from below, depending on the passage of the heating circuit pipes. Products with a bottom connection use a built-in thermostat, so their price is higher than the cost of other models.

Tubular

Tubular batteries, consisting of several rows of pipes connected to collectors, are used less frequently because they are more expensive than panel batteries. Pipes can be located both vertically and horizontally.

This design makes the heat transfer of radiators very efficient, allowing rapid heating of the battery, as well as its rapid cooling with automatic regulation.

Double-pipe bottom (saddle)

Two-pipe heating system with bottom supply.

This option is better than the previous ones, as it has a “supply” and a “return”. Works and adjusts well. But this option also has minor drawbacks and heat loss.

And now we have come, in my opinion, to the most effective radiator connection scheme.

Classification of panel devices

Panel radiators come in three types:

- profile;

- smooth;

- hygienic.

In the manufacture of profile devices, sheet steel is used, all external surfaces are coated with a protective powder coating. Moreover, the neutral anti-corrosion varnish, which is also used in manufacturing, significantly extends the service life. The color can be any - there are no restrictions here.

The second and third types of radiators are used in educational institutions, hospitals and kindergartens. Vivid examples are the products of brands such as, say, Purmo or Kermi.

Important! The advantage of tubular batteries over panel batteries is that the former can be turned in any direction, while the latter should be purchased with a predetermined connection. And in old buildings, pipes do not always fit new batteries. Although this problem can be solved - this requires relocating the pipeline

Two-pipe system - diagonal connection diagram (autonomous heating)

Two-pipe system, diagonal connection.

Over eighteen years of working as an installer, I have come to the conclusion that this scheme (see Fig. 9) is the most effective. Excellent adjustability. There is practically no heat loss. Possibility to balance and save on pipe diameter.

Conclusion - I tried to cover in detail the topic of all existing radiator connection diagrams. And I hope you will be able to evaluate all the pros and cons of each of the above, choosing the most effective and economical for yourself. Good luck.