With the onset of cold weather, the issue of home heating becomes more pressing. In the chilly off-season, centralized systems are often not turned on until the last minute, and then alternative heating systems come to the aid of freezing residents.

One of the simple solutions are considered to be heating elements for heating radiators, which can become an effective addition to the heating system. In some situations, the device can easily cope with the role of the main heat source, for example, in seasonal premises.

Before you decide to buy a device, you need to find out more information about it, don’t you agree? We have prepared a review article about the design of radiator heating elements, their classification, advantages and disadvantages. The material identifies the main criteria for choosing an electrical appliance and describes the features of its installation.

Heating element for a radiator: why is it needed?

Like any other heating element for heating, a radiator is designed to heat the coolant and maintain its operating temperature. The device can be installed in almost any heating device that has an internal cavity filled with liquid. Thanks to this, its scope of application is quite wide.

Radiator heating elements can act as the main or additional heating source. They are very good as heat sources for rooms with a relatively small area, which are used periodically during the cold season.

For example, various utility rooms or for heating a garage. In this case, the heating element is mounted in an autonomous radiator; it usually has impressive dimensions.

A radiator with a built-in heating element is practically no different in appearance from traditional batteries. During the off-season, when the central heating is not yet turned on, it will help residents not to freeze

The battery is not connected to the heating system and is filled with coolant, which circulates exclusively within the radiator body.

In such cases, technical oil with a low viscosity is chosen as a coolant, which allows you not to be afraid of the radiator completely freezing during non-working hours. It turns out to be an analogue of an oil-type radiator, only larger in size.

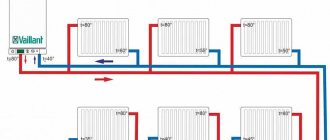

Radiator heating elements have proven themselves quite well as the main source of heat for country houses that are heated periodically. The system is set up similarly to that described above, but only the heating elements are mounted in batteries installed in each room.

It is possible to organize such heating for houses with permanent residence. In this case, the batteries can be filled with ordinary water, since there are no plans to allow the system to freeze. True, such options are used extremely rarely due to the high cost of electricity.

More widely, radiator heating elements are used as additional heat sources. They can be built into an existing heating system with a liquid coolant and come into operation when the main heating is not functioning for some reason.

This solution is especially suitable for houses with centralized heating. During the period when it is turned off, heating elements literally save apartment residents from freezing.

The so-called heating registers are very popular among DIYers. You can easily assemble them with your own hands and thus create practical heating for a garage or utility room

Another good option is to connect the devices to an autonomous heating system with a solid fuel boiler. This will allow maintaining a comfortable temperature in the rooms even at times when the owner is not able to supply fuel on time.

If it is possible to use a multi-tariff meter, it may be practical to switch to night heating with electricity when it is relatively cheap. During the day the boiler will start working again.

Practice shows that it is not economically profitable to use radiator heating elements as an additional heat source for autonomous systems running on gas. This type of fuel itself is relatively cheap, so replacing it with more expensive electricity does not make sense.

If boilers using liquefied gas or diesel fuel are used indoors, the benefits will be obvious. But only if you have a two-phase electricity meter.

Solid fuel heating boilers with heating elements

Currently, boilers operating only on solid fuel are rarely used. Instead, the domestic market offers a wide selection of combined and universal heating units that operate not only on solid fuel, but also on other types of energy carriers. A wide range of electric solid fuel heating boilers is offered to consumers.

This type of units is intended for heating residential, domestic, agricultural and other premises. A number of models can be used as both the main and backup sources of heat supply. They are also installed for use with other types of heating systems.

A heating element solid fuel boiler has the following advantages:

How does an electrical appliance work?

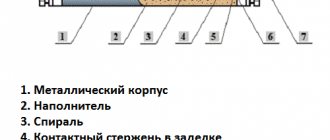

The design of the device is practically no different from other types of heating elements. The body of a tubular electric heater is made of a seamless or electric-welded thin-walled metal tube. Its diameter can vary, and its cross-section can be flat or round.

Carbon steel is most often used as the material for the manufacture of the case, but stainless steel can also be chosen if the working surface of the device will be heated to temperatures above +45°C.

To protect the metal from corrosion and extend the service life of the heating element itself, the steel body is chrome or nickel plated. A spiral of nichrome wire is used as a heating element.

The element has a high resistivity, due to which it heats up quickly. The spiral is placed inside the body, and the remaining free internal cavity contains filler.

The design of a radiator heating element necessarily contains a spiral, which is responsible for heating the device. It has high resistance, so when current passes, it heats up quickly (+)

The housing has high electrical insulating properties and at the same time transfers heat well. Purified quartz sand or periclase can be used as a filler - this is the name of a mixture of crystalline magnesium oxides.

After the body is filled with filler, it is pressed and bent to give the required shape. All insulators are coated with an organosilicon moisture-proofing compound.

Such a device can be installed in any type of radiator: copper, cast iron, bimetallic, etc. The device is capable of generating up to 2.5 kW of power. Models intended for industrial use produce up to 6 kW.

The design of the electric heating element is such that the device completely converts all incoming electrical energy into heat, with virtually no losses.

The operating principle of the device is extremely simple. When activated, it begins to heat up quickly, warming up the coolant located in its immediate vicinity. According to the laws of physics, a heated liquid is lighter than a cold liquid, so it begins to move upward.

A cooler coolant is lowered in its place. Having risen to the top of the radiator, the heated liquid gives off its heat there, cools down and falls down.

The main enemy of heating elements of any type is limescale. It inevitably forms on the heating element and gradually leads to the device failing

The cycle is repeated many times. Thus, the electrical device creates a unidirectional flow of liquid inside the battery. The higher the power of the device, the higher its speed.

Based on practice, transformer oil is considered one of the best types of coolant. The liquid heats up quickly and does not cool down for a long time, gradually giving up its heat to the radiator body.

TOP 7: HAJDU AQ PT 1000 C

Description

The buffer design, in addition to storing excess heat generated by a solid fuel boiler or any other alternative energy source, can redirect it to a heat accumulator.

Their advantage is that they supply practically free heat all year round, even with little lighting. Even in cloudy weather, the heating system can receive tens of kilowatts of energy from them.

Design

Inside the Hajdu AQ PT 1000 C tank there is a heat exchanger in the form of a spiral. Its area is 4.2 square meters. The coolant heated by the sun's rays, flowing through the coil, gives off its heat, which is directed to the heating system for heating.

The dimensions of the device allow it to function in tandem with a solid fuel boiler, whose power is 25-35 kW.

Important: the system that ensures the accumulation of heat by a buffer capacity is only capable of functioning in a heating system with a forced cycle, and is not suitable for a gravity system. The designers of the Hoidu brand did not limit themselves to the described function of the device, i.e.

the ability to accumulate heat. Therefore, they provided a technological hole that makes it possible to install 2, 3, 6, 9 - kilowatt heating elements. The importance of this solution is the ability to increase the time between downloads. This was appreciated by those living in country cottages and dachas

The designers of the Hoidu brand did not limit themselves to the described function of the device, i.e. the ability to accumulate heat. Therefore, they provided a technological hole that makes it possible to install 2, 3, 6, 9 - kilowatt heating elements

The importance of this solution is the ability to increase the time between downloads. This was appreciated by those living in country cottages and dachas

We recommend:

- Portable phone chargers: advantages, features, price - TOP 7

- Thermal accumulators: purpose, features, price - TOP-6

- TOP 6: inexpensive solar collectors for heating and heating swimming pools, prices and where to buy

Now they can load cheap heat, i.e. load the energy storage device at a discounted rate. There is no need to insert an electric boiler into the heating system, because the heating elements heat the storage tank directly, releasing the heat accumulated during the night into the system during the day.

Inner surface

On the inside, the walls do not have an enamel coating, like boilers with indirectly heated water heaters, so heat accumulators are not recommended for use in hot water supply.

Buy

| Where can I buy | Price in rubles |

| https://avangardteplo.ru/products/name/teplonakopitelj_hajdu_aq_pt_1000_c?_openstat=bWFya2V0LnlhbmRleC5ydTv/ | 40030 |

| https://xn—-7sbcqc4aneonsmco5krb.xn--p1ai/products/bufer-emkost-hajdu-aq-pt-1000-c | on call |

| https://vsegdateplo.ru/vodonagrevateli/teploakkumulyatory/hajdu/hajdu-aq-pt-1000-c-bez-izolyatsii / | 42725 |

| https://nasos-kotel.ru/bufernyy-nakopitel-hajdu-aq-pt-1000-c/ | 40030 |

| https://mrklimat.ru/teploakkumulyatory/teploakkumulyator-hajdu-aq-pt-1000-c.html | 40030 |

Pros and cons of radiator heating elements

Tubular-type electric heaters make it possible to assemble a practical and fairly efficient heating system for main or additional heating.

The advantages of the devices include:

- Extreme ease of installation . Every novice master can handle this job.

- The low cost of the device , however, refers to the price of one heating element, without additional equipment.

- Greater reliability compared to oil radiators. In addition, batteries with heating elements are repairable. If the equipment fails, it will be enough to replace the heater.

- Availability of additional options and functionality.

- Possibility of automatic control of the heating system, but this will require additional equipment.

We have listed the main advantages of radiator heating elements; we will consider their significant disadvantages. There are quite a lot of them. First of all, these are impressive operating costs, which is explained by the high cost of electricity. They can be reduced if the heating system control is fully automated.

In this case, the heating elements will be switched on only after the room temperature drops to a certain minimum value. And turn off when the temperature defined as comfortable is reached. Working in this mode is as economical as possible.

The simplest radiator heating elements in design are not equipped with automatic control. To automate such a system, you will need to purchase additional equipment

However, automation equipment will require financial investment. If we consider purchasing a heating element complete with a radiator and automation, the cost of such a kit will be much higher than the price of an electric convector or an oil radiator.

But at the same time, in terms of the level of comfort provided, the latter are in no way inferior, and in some ways even superior to radiators with heating elements. For example, the latter require permanent installation, while electric convectors and oil radiators are more mobile and compact.

In addition, like any other electrical device, heating elements generate a magnetic field during operation. Its danger to the body has not been proven, nor has its safety. Therefore, it is worth attributing the presence of such a field to the negative qualities of devices, because they are mounted in radiators, that is, they are in close proximity to people.

In other heating systems powered by electricity, this disadvantage is to some extent leveled out. For example, electric boilers are located in non-residential premises where human presence is short-term.

One of the most significant disadvantages of radiator heating elements is their relatively low efficiency. If we compare it with the efficiency of traditional systems operating with liquid coolant, it will be significantly lower.

This is due to the fact that in the first case the coolant moves at a fairly high speed. Thanks to this, the radiator warms up quickly and completely.

To increase the heat transfer of radiators equipped with heating elements, you can cover the wall on which the device is mounted with a reflective screen made of foil. Thermal radiation will only move into the room

The functioning of the heating element is not able to provide such a high speed. As a result, the heating of the battery case will be uneven. The temperature at the bottom will be much higher than at the top.

Considering that, for safety reasons, the battery should not be allowed to heat up above +70ºС, such a temperature will only be present in the lower part of the radiator, where the heating element is located. Consequently, in order to prevent overheating of the equipment, it will be necessary to reduce its power by about a third.

How does a boiler work with electricity or with solid fuel?

Mixed heating boilers for solid fuel and electricity operate on the principle of using a backup heat source. In practice, this means that after the coolant stops heating from burning wood, coal, etc., the electric heating element turns on, continuing to maintain the required temperature in the heating system.

A hybrid combined solid fuel boiler with electric heating, heats the coolant through a “water jacket” and has a special technological hole for installing a tubular heating element. In the basic configuration, the hole is covered with a plug. At the request of the customer, the boiler is equipped with a heating unit.

How does energy carrier switching occur?

There are two ways to switch from one type of fuel to another, differing in the degree of automation:

- Manual switching - in a solid fuel boiler with an electric heating element that uses manual switching between types of fuel, there is no thermostat or temperature sensor. In the basic configuration, almost all models of dual-fuel units have exactly this method of turning on the electric heating element. This solution is extremely inconvenient and does not solve the main problem. After the flame in the boiler has died down, the user’s personal participation will be required to turn on the heating of the coolant.

Modern universal heating boilers using solid fuel and electricity, in addition to sensors installed on the coolant return, are connected to temperature sensors located in the rooms and controlling the heating of the rooms. The automation ensures operation in several modes, including “anti-freeze”, maintaining the minimum permissible heating of the coolant, preventing it from freezing.

Is it possible to install a heating element in a HT boiler yourself?

In most modern boilers, a hole is provided in the heat exchanger for installing an electric heating element. Connecting a tubular heating element, in this case, is quite simple. The water is drained from the boiler and the heating element is installed using a special threaded connection. For sealing, use heat-resistant silicone.

If a hole is not provided in the structure, the possibility of installing a heating element depends on the design, or more precisely, the material of the heat exchanger:

- Cast iron boilers - drilling a hole for the heating element is quite problematic. During cutting or subsequent operation, cracks may occur, leading to a violation of the tightness of the structure. The damage cannot be repaired; the damaged section will need to be replaced.

Types of tubular heaters for radiators

Despite the simplicity of the design, you can find various variations of radiator heating elements on sale. First of all, the power of heating devices varies. Models with a minimum power “produce” about 0.3 kW, with a maximum – 6 kW.

The devices differ in the design of the housing. Considering that the configuration and location of radiators can be different, there are heating elements with left-hand or right-hand threads.

The diameter of the device may also vary. This is due to the cross-section of the radiator plug plug, in the place of which the device is mounted. Standard size is 40 mm.

There is no fundamental difference between devices intended for installation in radiators made of different materials. Their design is similar, only the diameter may differ. You can find single and double heating elements on sale.

Double heating elements are more convenient to use. They allow you to significantly increase the rate of heating of the coolant, but at the same time they differ from single analogs at a higher price

The latter is more convenient to use. At the moment of switching on, both elements are activated at once, due to which the coolant heats up as quickly as possible. After this, one of the elements is turned off, which allows you to save energy resources. Some models are equipped with additional functionality.

The manufacturer uses only two functions:

- Turbo heating . Makes it possible to maximize the increase in temperature in the room. A thermostat is necessarily built into the device, which allows you to change the heating intensity.

- Antifreeze . This mode allows you to prevent possible defrosting of the entire system when the temperature drops to negative values. The heating element automatically maintains the minimum permissible temperature, while consuming a small amount of electricity.

In addition, radiator heaters vary in length and the presence or absence of a thermostat.

Internal structure of electric heaters

It is convenient to consider the device using the example of a tubular model. An electric heater is a ceramic or metal tube filled with a thermal conductor with a spiral located inside. In the place where the tube is fixed to the flange there are insulating bushings that make it impossible for the conductive spiral to contact the heating element body.

Most models of heating elements use similar components, but their durability may vary depending on the build quality

The electric heater is mounted primarily with a flange connection, which allows the internal environment of the heating device to be sealed from the external space. The disadvantage of this design is the impossibility of replacing the spiral if it burns out internally.

How not to make a mistake in choosing

Radiators for heating elements are quite simple to choose, since they do not require a special variety of designs and technical characteristics. Please consider the following points before purchasing.

Electric heating element power calculation

In order to correctly determine the required power of the device, it is advisable to know the thermal standards in force in the given area. As a last resort, you can use the average indicator, which can be used in central Russia and make some adjustments if necessary.

Based on this, for 10 sq. meters of heated area, provided that the heating element will be used as the main heating, 1 kW of its power is required.

If heating elements for radiators are chosen as the main heating for the home, it is highly advisable to purchase models with a thermostat. In this way, it will be possible to regulate the power of the device and thereby reduce energy costs

If the device is used as additional heating, the required power will be 3-4 times lower. In addition, when choosing a device, you should take into account the specifics of the radiator heating element.

Due to its design features, it will be able to operate uninterruptedly only at 75% of the heat transfer from the radiator. With higher power, the device will overheat and it will constantly turn off.

Based on this, the power of the device is calculated. The exact heat transfer values of a particular radiator can be found in its technical documentation. However, on average, one section of an aluminum battery has a heat output of 180 W, and a cast iron battery has a heat output of 140 W.

Let us calculate, as an example, which heating element is suitable for a 10-section radiator. We multiply the data by 10 and we get that for an aluminum battery it is worth taking a heating element with a power of up to 1.35 kW, for a cast iron battery - up to 1 kW.

Design features of the device

For each radiator, you should select a heating element that is suitable for it in size and thread direction. The equipment has different shaft lengths, which may affect its performance.

If the length of the heating element is insufficient, the equipment is not able to provide a sufficiently high circulation rate of the coolant, as a result of which the heating of the radiator will be uneven and insufficient.

The length of the device is perhaps one of its most important characteristics, which directly affects its efficiency. Before purchasing, you should measure the radiator and calculate the required length of the built-in heating element

The optimal option is when the heating element rod does not reach the inner wall of the opposite edge of the radiator by 60-100 mm. It is also important to choose the right body shape and diameter of the device.

The material of the plug may vary between models. To make the right choice, you should study the manufacturer’s recommendations, where he describes the types of heating devices suitable for using a particular heating element.

Availability of automatic control

Devices are available for sale with or without built-in automatic control. The first variation is as convenient as possible and does not require the purchase of additional equipment. In this case, a thermostat with a sensor that measures the temperature of the coolant is built into the lower part of the heating element housing.

If there is no built-in automation, the electrical appliance does not have a thermostat. In this case, it is advisable to connect using a detector that measures the air temperature in the room.

It must be admitted that this equipment is not so popular and in demand for large European companies to start producing it.

In stores you can find radiator heating elements made by Turkish, Polish and Ukrainian brands. In terms of quality and functionality, they are approximately similar.

It is difficult to say which company's products should be preferred. But you need to be wary of Chinese heating elements, since you can often get a low-quality product.

Additional information on choosing a heating element for heating is provided in this article.

TOP 10: Nibe BU – 500.8

Application

This type of heat accumulator is used for heating boilers with different heat sources, be it a heat pump or a boiler, a solar collector or another, and also, as an alternative supplier, effective when the centralized supply is turned off.

Important: when operating with boilers using solid fuel, overheating of heat accumulators is eliminated, the efficiency increases and the service life of the boiler equipment is extended. Additionally, it is possible to reduce the frequency of loading it with fuel

Peculiarities

For this heat accumulator model they are as follows:

- attractive design;

- effective polystyrene foam thermal insulation up to 140 mm thick. It was easy to remove it in order to reduce the size of the device if it was impossible to pass through doorways. It is similar in appearance to molded panels, the outer side of which is covered with white PVC;

- allows connection of more than one electric heater;

- use as an alternative source, in the absence of centralized heating;

- the ability to consume cheap energy (night tariff) when working with two-tariff meters and electric boilers;

- the presence of additional coils for individual modifications installed in the lower part. Thanks to them, you can connect additional heat sources;

- there are flanges for connecting heating elements and a thermometer;

- the ability to distribute the coolant along the entire height of the device, thanks to the vertical bar available at the inlet of the heat storage tank (on the left);

- suitability for organizing the most complex heating systems, including those for which the heat load is quite large.

Technical indicators

- Type – floor;

- Tank capacity - 500 liters;

- The maximum pressure in the external tank is 6 bar;

- Maximum heating temperature - 95 Cº;

- Device weight – 106 kg;

- Diameter – 750 mm;

- Height – 1757 mm.

Buy

Features of installation of radiator heating elements

Installing the device is quite simple. In order for the operation to take place without any difficulties, you should familiarize yourself with its equipment in the store. Ideally, together with the heating element, all the elements and fasteners necessary for a safe connection will be placed in the box. If any parts are missing, you need to purchase them immediately.

Heating elements with thermostats are more functional than their standard counterparts. At the same time, their installation is essentially no different and is just as simple and quick.

Another important point: before starting installation, you should make sure that the system is free of water. For this reason, in apartment buildings it is optimal to carry out work in the summer, when the central heating is turned off.

The actual installation consists of removing the plug located at the bottom of the radiator and then installing a heating device in its place. To make the joint airtight, a rubber gasket must be installed. It would not be superfluous to pre-treat the joint area with sealant.

The heating element can only be installed in the lower part of the radiator so that liquid circulation can occur unhindered. The part is inserted into the battery strictly horizontally, otherwise problems with operation may occur.

To connect the heating element, it is allowed to use a grounded socket. It is advisable to install a voltage stabilizer to protect the device from network surges.

You can connect the device to the network only after filling the radiator with liquid, otherwise the device will fail. The design with a heating element is repairable. If necessary, the device can be easily removed and repaired, and more often replaced with a new one.

Considering the hardness of process water, experts recommend regularly descaling the heater. To do this, the device is removed from the battery, after which it is cleaned.

A radiator with a built-in heating element will serve for a long time and without problems, if you do not forget to service it regularly, namely, remove the heater and carefully descale it

You can use a mechanical method, when the scale is carefully removed with sandpaper or a stiff metal brush. This should be done very carefully, since heating elements are very sensitive to mechanical damage and can fail.

In addition, you can use the chemical method. In this case, the device is treated with special substances. It is very important not to damage the rubber gasket.

Operating principle of heating elements

The heating element works according to the following principle. When connected to the network, the internal spiral is heated and energy is transferred to the thermal conductor and the outer shell. The heat is then transferred to the surrounding fluid, air or solid material.

When heating a heating element immersed in oil or water, convection currents are created around the tube, which mix the coolant and contribute to its uniform heating.

In liquid-free heating devices, the heating temperature is usually limited so as not to damage surrounding parts or cause a fire.

To speed up heat transfer, they often use a fan, which circulates air both inside the device and in the room surrounding it.

Electrical connection diagram

As for ensuring safety when connecting voltage, the entire circuit must be powered only through an RCD or differential circuit breaker with a leakage current of 30 mA.

Mistake #14

A simple modular machine is not suitable for this.

Otherwise, you will have to move around this miracle only in rubber boots and gloves. The water shadows are destroyed over time and the heating coil, initially protected by the shell, is exposed.

Upon contact with water, current leaks to the metal body of the heater. As soon as you touch any of the sections, you will find yourself energized. Something similar happens in electric titans or boilers, when the water from the tap begins to “pinch” and “shock”. RCD saves you from all this. True, it will only work on its own when the battery is grounded. Otherwise, the RCD will wait until you touch the battery with your hand. The RCD starts to knock out - immediately change the heating element.

The thermostat itself is connected with a flexible PVA wire 3*2.5mm2.

A Euro plug is mounted on one side of the wire, which is plugged into the nearest socket.

Do not clamp a stranded wire without lugs under the screws of the thermostat. This is especially true for powerful heating elements of 1.5-2.0 kW. To ensure reliable contact, the ends of the cores must be crimped with NShVI sleeves.

Mistake #15

Another problem is exposed contacts on the thermal relay.

If there are small children and pets in the house, this is very dangerous. Some craftsmen advise covering the top of the thermostat with a plastic case from the socket box. It's just the right diameter.

Benefits of the latest technology

Infrared film is used not only for heating window sills; it is used in systems of heated floors and baseboards. Installation of this device is simple, and no special tools or skills are required.

The heating film has the following qualities:

It heats up in a very short time: one or two minutes, and it is in the operating temperature range. It warms up efficiently, evenly, affecting the entire area. Electricity consumption is striking in its economy - 20 W. Three window sill plates - three 20 W each - the energy consumption is equal to one incandescent light bulb. Excellent aesthetic appearance. It does not damage the base at all, since it does not require either a cement screed or an adhesive solution for installation: it is applied to the surface using a dry method

This is very important: if it fails, there is no need to do “dirty” work. Replacement will require about an hour of free time

Sold in kits that include all the necessary accessories and elements for its installation: special tape, mounting wires, an insulating block, several clamps. To control such a heating system, a convenient electronic control has been created

There are both simple hand-held devices and programmable ones with an LCD display. Invisible to prying eyes. It is more convenient to measure thickness not in millimeters, but in microns.

Circulation without expander

What role do air pockets play? As it warms up, the liquid inside the battery expands and the pressure increases.

Without air pockets there will simply be no compensation for thermal expansion. There is no expansion tank provided in the design.

These pockets do just that. Homemade expanders only spoil the appearance and help evaporate the liquid from the heater.

This is especially dangerous with anti-freeze agents and their mixtures (50% antifreeze or antifreeze + 50% dissolved).

Also, a closed system without an expander, due to the creation of pressure, helps reduce noise when the heater operates. Noise is a phenomenon of cavitation, when microbubbles of gas are separated when the heating element is heated, and their appearance directly depends on external pressure.

Even 1.5-2 bar will make the battery much quieter.

However, the air inside the sections also poses a hidden threat. If the battery overheats (the heating element does not turn off, the relay contacts are stuck), the pressure will increase more and more.

Having reached a critical point, the radiator will burst. A sharp piece may fly off from it, or you will simply be scalded by hot steam.

What happens if the battery is filled up to the neck, without any remaining air at all? In this case, the pressure will increase much faster, and one of the sections will crack at one “wonderful” moment.

As a rule, this is not accompanied by any explosion. But due to the lack of an expander, we need air pockets in any case.

Mayevsky tap or valve?

You can get by with a Mayevsky crane, but then you will need one more protection. An external emergency thermostat with an operating temperature in the region of 80-90C is mounted on the first section of the battery (counting from the heating element). Moreover, it is connected to the power supply of the heating element itself.

When the heating element’s original thermostat does not work and the water begins to approach the boiling point, the emergency temperature sensor operates. It interrupts the voltage supply and saves the battery from explosion.

Which is better - an emergency valve or an external thermostat? It is still preferable to have a valve. The design is simpler and more reliable.