To control water heating using a heating element, a special small device is used - a thermostat. It may have a different design, but the principle of operation will be very similar for all assembly options. In the article we will learn how to connect a thermostat to the heating element of a water heater and what subtleties should be remembered during installation.

How to connect a thermostat

Heating element device

A tubular electric heater (TEH) is an electrical device in the form of a multilayer metal tube that allows you to convert electrical energy into heat. Typically, heating element devices are installed in water heating systems (for example, in boilers or boilers), which makes it possible to obtain hot water for domestic needs or room heating. Depending on the design, there are several types of heating elements, but most devices have a three-layer tubular design:

- The outer shell of the heating element is a thin-walled metal tube, which is usually made of copper, brass or carbon steel. The metal tube receives heat from the heating rod through a layer of insulator (they are located inside the tube). From the outside, the metal comes into contact with air or water, which causes it to heat up.

- Inside a thin-walled metal tube there is a dry filler, which is quartz sand, corundum or magnesium oxide. The filler has electrical insulating properties, so it does not allow the electrical current generated by the inner rod to pass through. The filler also allows heat to pass through well, which heats the outer tube of the heating element.

- Inside the filler there is a thin metal spiral, which is usually made on the basis of nichrome. The spiral has high electrical resistance, so when an electric current passes it becomes very hot. From the outside, the spiral is connected through wires to a source of electric current, and at the ends of the spiral there are silicon insulating flaps.

The operating principle of a tubular electric heater is simple. When connected to a current source, electricity passes through the coil, causing it to heat up. Heat is transferred to the dry filler, which, due to its insulating properties, does not allow electrical current to pass into the surrounding space. The heat heats the outer metal tube, which warms the external environment (water or air).

Note! To heat the air, heating elements with a ribbed corrugated tube are often used, which increases the heat transfer and efficiency of the device.

Heating elements for heating batteries and radiators

The devices are designed to warm up the coolant and maintain a given heating mode within a set time. Electric heating elements are installed in any devices filled with liquid, including batteries, boilers, and are used as the main or additional heat source. The power of the device is selected depending on the area of the room, but it is recommended to use the units as a temporary heating source.

Advice! When installing a heater in a stand-alone device, attention is paid to the battery material and the power of the device. For example, you can buy a heating element for a cast iron battery, which is used to heat the basement, utility room or garage.

Thermal electric heaters are convenient to use because they are placed in a battery that is not included in the common line. The radiator is filled with liquid only to the volume of the housing. Experts advise changing the water to technical oil so that when the heater is turned off, the device does not freeze. A battery with a thermal heater has increased power and greater heat transfer, which is beneficial for quickly heating small rooms and country houses.

Advice! If you plan to use an electrical appliance in an apartment, a heating element in the battery is installed on each heating unit, into which water can be poured provided that the system is constantly operating.

Types of devices advantages and disadvantages

Manufacturers offer several types of devices:

- Tubular heaters. Tubular sections are convenient for installation in household heating appliances; transmission is organized by convection or infrared radiation.

- Finned devices. Convenient and practical devices with an increased heat transfer area. The plates are located throughout the entire plane of the device, so the room warms up faster. Finned heaters work best in air-type systems equipped with fans.

- Cartridge devices. These are units with one free end, which dictates the installation rules. The polished steel coating enhances contact with the coolant, the device can be inserted into the hole of the boiler, batteries, fixed to flanges.

Advantages of heaters:

- simplicity, ease of installation;

- you can find devices of low cost;

- reliability;

- maintainability.

There are devices on sale with turbo heating and anti-freezing properties. The circuit can also be equipped with additional devices for automatic startup and shutdown.

Flaws:

Gas heating convectors for home and their design

- Increased maintenance costs. Electric heating elements will increase your electricity bills. Payments can be reduced by creating an automatic start-up and shutdown scheme when the specified temperature parameters are reached.

- Reduced efficiency. Compared to a conventional heating system, batteries provide significantly less heat due to the reduced coolant circulation rate.

Advice! When choosing between oil heaters and electric thermal heaters, the latter will become more profitable, provided that automatic control devices are installed on the batteries with heating elements.

Rules for choosing a heating element for a battery

The main characteristics of devices that you need to pay attention to:

- Power. To heat an apartment with high-quality thermal insulation, an indicator of 20 W/m3 is sufficient; for private buildings with an area of 25-30 m2, a device with a power of 30 W/m3 is suitable; for an old house with insufficient thermal insulation, heating elements for heating radiators with a power of 50 W/m3 are suitable. The devices are produced with operating rates of 800-2000 watts.

- View. To determine the desired shape, material, thickness and cross-section of electric heater plugs, you should first carefully study the characteristics of the battery or buy both devices together. Characteristics and dimensions are indicated in the technical data sheet of the devices.

- Heating tube length. This part must be long to maintain uniform coolant circulation in all sections of the battery. The standard size of the tube length is calculated by the length of the radiator minus 10 cm.

- Manufacturer. Devices from Polish, Italian, and Russian manufacturers have proven themselves well. Manufacturers from the Russian Federation offer products adapted for different regions. Chinese devices should be taken with caution, require certificates and be checked for strength and quality.

Technology for installing a heater in a radiator

To install the heater into the battery, you need to unscrew the radiator plug, insert the heating element, tighten the thread and seal the joint area with a rubber seal. Installation is carried out similarly in any radiators. If you are installing a heating element for heating with a thermostat, you need to pay attention to the installation diagram in the technical data sheet of the product. The manufacturer gives clear recommendations.

On a note! A shut-off valve and bypass must be installed on the battery with heating element. In the absence of shut-off valves, heat will go to neighboring radiators; a bypass reduces the risk of disrupting the circulation of coolant in the heating main throughout the riser.

The device must be screwed on carefully, without applying much force, so that the locknut and heater fasteners do not burst. It is recommended to install a small expansion tank behind the shut-off valve, which is designed for 10% of the volume of the total coolant. This is necessary to discharge excess liquid when it is heated.

Schemes for connecting heating elements to a single-phase network

Many homes use a single-phase electrical network. Heating elements can have different levels of operating voltage, but for home use it is recommended to buy devices with a voltage of 220 volts. There are the following options for connecting the heating element to a single-phase network:

- Direct plug-in. If you bought a low-power heating element with a power level of up to 1 kilowatt, then you can safely connect it to a working outlet directly. You can also connect several heaters (series or parallel), but their total power should not exceed 1 kilowatt, and it is recommended to use a more reliable plug for connection. Such heating elements are not suitable for heating systems, since they generate little heat, but boilers and electric kettles are often made on their basis.

- Connection via auto switch . If you want to install a more powerful heating element at home, it is recommended to connect it directly to the electrical panel using a switch. The simplest option would be to use a single-way switch that is connected to the phase. To improve the operation of the heater, you can use a two-way device, which is connected to phase and zero on the panel. There are also three-circuit systems with grounding that automatically drain current and de-energize the machine in the event of a short circuit or overload. This allows you to avoid electric shock and also protects equipment during an emergency.

- Connection via temperature controlled circuit . In this case, the installation of the heating element is carried out through various thermostatic devices that allow you to keep the heating temperature within certain limits. The main devices in this category are relays, starters, contactors and others. Most of these devices work on a similar principle - they are built into a circuit and monitor the temperature level, and if there is excessive heat, they open the circuit. They can also perform auxiliary functions - they multiply contacts, redistribute the load level, act as a fuse when closed, and so on.

Device and connection diagrams for heating elements video

What is a thermostat

A thermostat (thermostat) is a mechanical or electronic device that is built into the electronic circuit that serves the heating device. The thermostat is compact in size, and its main function is to regulate the heating level. The thermostat is based on a sensitive element, which changes its properties under the influence of ambient temperature.

These properties can be of different nature:

- Geometric shape (metal regulators).

- Liquid level (capillary devices).

- Photosensitivity (infrared sensors).

- Voltage level (electric thermostats).

Purpose

The purpose of the thermostat is to maintain the heat level in the heating circuit within certain limits. The regulator can operate with water, atmospheric air, and also with solids. Typically, regulators are connected to the water heating system in heating systems. They are also connected to home boilers to produce hot water and in systems of the “Warm Floor” category.

Thermostats can operate on a variety of circuits, from single appliances to large multi-story buildings. When choosing a device, you should take into account not only its operating mode, but also temperature sensitivity, and this issue is especially critical in the case of heating large circuits. The main categories of devices according to the level of temperature sensitivity:

- With low sensitivity. In this case, the operating error of the device is 2-5 degrees, and it is recommended to use such devices in small heating circuits, for which accuracy is not of great importance. For example, these could be shops, technical buildings, small offices, and so on.

- With medium sensitivity . In this case, the accuracy of the device is within 0.5-2 degrees, and such installations are suitable for residential buildings, individual heating circuits in private apartments, as well as for technical buildings.

- With high sensitivity . With this option, the sensitivity is 0.01-0.5 degrees. Such devices are usually used for heating special warehouses that contain objects sensitive to temperature changes, as well as in washing machines, electric ovens, and cars.

Attention! Devices with high sensitivity can be installed in ordinary houses or apartments, but such accuracy is of little practical use. Therefore, devices with medium sensitivity are most often installed in residential buildings.

Operating principle

The operating principle of the thermostat is based on various physical principles depending on the category of the device. The thermostat monitors the heating level of the thermal circuit, and it is installed in the open circuit of the phase cable. The device may have a fixed operating temperature (most mechanical installations) or a floating temperature (electronic devices). However, they work according to an identical scenario:

- The heating element heats the heating circuit, and the thermostat monitors the heating level with a certain sensitivity.

- In case of excessive heating, the thermostat opens the electrical circuit, which leads to the heating element stopping operation.

- When the temperature drops below the minimum level, the thermostat closes the circuit again, which starts the heater.

- The heating-cooling cycle lasts as long as the heating element with thermostat is connected to the electrical network, and the user can often set temperature thresholds.

Thermostat and water heaters video

Heating elements for heating boilers

Manufacturers offer heaters for domestic use and powerful equipment for use in industrial heating systems. Household units are convenient for integration into boilers for autonomous systems; industrial circuits are equipped with devices with high power and specific requirements.

Types of devices, their advantages and disadvantages

Cartridge and block elements are used for heating boilers. Block heaters are a bundle of tubes placed on one platform. Products are used to increase the power of the heating boiler. Block heating elements accelerate heat transfer, while the load on each individual element is reduced. Block devices can be installed in domestic boilers or additional heating devices. The power of electric heating elements for water heating is 5-15 kW, connection to a separate cable, standard wiring may not withstand the load.

Devices are distinguished by type of connection and structure:

Types of radiators and batteries - water heating convectors

- smooth with a flat surface of the heating element;

- ribbed with fixation on clamping nuts, washers, ribs of the device are made of durable metal tape with an additional protective coating;

- single-ended, similar to a boiler, with water contacts on one side;

- double-ended, equipped with water contacts on both sides.

On a note! A single-end heating element for a heating boiler is considered the best for electrical devices of equal heating power.

More than one heater can be installed on one boiler, subject to preliminary calculation of the equipment power. The minimum power of heaters is 1 kW, the maximum limit is determined by the manufacturer. Technical parameters - length 20-600 cm, tube cross-section 6-18.5 mm.

Advantages of the devices:

- Economical energy consumption. By installing a staged or block heater for your boiler, you can reduce maintenance costs by 30%.

- During operation, the equipment does not emit harmful gases or combustion products.

- The weight of the products is insignificant, so there is no danger of making wall-mounted boilers heavier.

- Compact heating elements for heating water can be installed in devices of any size, receiving additional benefits from low-power boilers. Retrofitting does not require permits; installation is carried out independently.

Important! As when working with any electrical appliances, the socket for heaters must be grounded and other requirements must be met for the safe operation of the device.

The disadvantages include:

- accelerated scale formation;

- to adjust the heating power of the coolant, you need to turn off all heaters;

- fragile devices require care when cleaning so that the contact rods are not damaged and the seal of the external terminal is not broken.

You cannot turn on devices without filling the container with coolant; this will lead to the devices burning out. When equipping boilers with built-in equipment with heating elements, you should check the control of automatic shutdown and the ease of replacing the heating element.

Types of thermostats

Depending on the design, the following types of thermostats are distinguished:

- Metal rod . As the temperature rises, the rod heats up, which leads to an increase in its size. When a certain length is reached, the device opens the circuit and the heating device stops working.

- Thermocouple. The device consists of a V-shaped metal bracket and a control relay. An electric current passes through the bracket, the resistance of which can vary depending on the ambient temperature. When the heat is too high, the bracket transmits a signal to a relay, which stops the heater from operating.

- Flask with liquid . The role of a thermostat is performed by a small flask with liquid, which expands when heated, as well as a control relay. With strong heating, excessive expansion of the liquid occurs, which triggers a relay that opens the circuit.

- Infrared sensor . The device is a photocell with thermal sensitivity in the infrared spectrum, as well as a relay. When excessive heating occurs, a photocell is triggered, which sends a signal to the relay, which opens the circuit.

Attention! There are also metal thermostats that work on a different principle. Such devices are made in the form of a plate made of two different alloys. When heated/cooled, the metal bends at a certain angle, which leads to the opening/closing of the electrical circuit.

Areas of application of thermostats

Many devices today are equipped with heating elements - heating boilers, washing machines, vehicles, electric furnaces. Thermostats on such devices allow you to turn the heating element on or off to either prevent excessive overheating. Thermostats on such devices are often connected to a special unit that controls the device in an integrated mode (monitors temperature, humidity, and signals breakdowns). And you can set the threshold value for temperatures using the control panel.

What are electric heating elements?

A heating element is a tubular electric heater. It is essentially a hollow tube made of stainless or carbon steel. Inside there is a wire spiral, which has a high resistance value. For installation, a brass nut is provided, which is screwed into the heating device. The heating element is installed in any radiators, suitable for both old cast iron batteries and modern aluminum and bimetallic ones.

The best option is a heating element equipped with a thermostat. This device will allow you to control the temperature and protect the heating element from overheating. Considering that the device will be installed in a heating radiator, water will play the role of coolant.

Electric heating elements work quite simply. After connecting to the home network, the coil installed inside the tube begins to heat up, transferring energy to the coolant. If the device is equipped with a thermostat, the required temperature mode is set. After the batteries reach the set temperature, the electrical circuit will open and the heating element will turn off. When the liquid in the batteries begins to cool, the device will turn on automatically.

The heating element with a thermostat has several additional modes:

- Turbo. In this mode, the heater turns on for a short period of time, but uses maximum power. Turbo mode is used to quickly warm up the room.

- Antifreeze. This function is relevant mainly for non-residential premises. The heating element operates at minimum power, preventing the system from freezing in emergency situations.

An electric heater for a battery allows you to turn a heating device into an autonomous system with minimal cost, time and effort.

Options for connecting and installing the thermostat

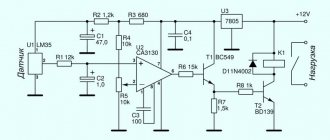

To assemble the heating circuit using a heating element, single-core cables are used. In this scenario, the thermostat is installed in the open phase wire leading to the positive terminal of the heating element. The device analyzes the heating level, and in case of excessive temperature, it opens the circuit, which leads to de-energization of the heating element until the temperature normalizes.

It is recommended to connect the thermostat via a magnetic starter. This is due to the fact that most heating elements have high power, which can cause an overload in the electrical network, and the starter will allow you to adapt the device to the needs of your home. It is also recommended to install a spare protective thermostat-fuse at the input, which can de-energize the network in the event of failure of the main thermostat.

Attention! Systems based on a two-core cable are also used to install the thermostat. However, such systems are more suitable for operating radiators or heated floors. If you have a heating element, then it is better to use a single-core cable.

connection diagram

Step-by-step instructions for connecting the thermostat to the heating element

The method of installing the thermostat depends on the category of the device and the dimensions of the heating element. Regardless of the type of heating element, the thermostat must be attached to a phase wire in the electrical network. If you are working with a home boiler, then most likely there will be a metal regulator-rod, which is located inside the heating element in a special hole. The regulator connection in this case will look like this:

- Disconnect the heating device (boiler) from the electrical network, and also turn off the water supply (via the riser or using the supply tap, if available). Disassemble the device according to the instructions, find the heating element, unscrew the mounting fasteners and remove the heating element.

- Most modern heating elements have the form of a tubular device, to the base of which current is supplied (phase and zero). A protective casing (based on metal or plastic) is attached to the base - loosen the bolts and the casing is carefully removed.

- Remove the electrical contacts, and then carefully inspect the heating element. In the center of the base of the heater you will find a hole into which a thin metal strip is inserted - this is an old thermostat. Carefully pull the regulator out of the hole using pliers or a similar tool.

- Reconnect the electrical wires. With a high degree of probability, you will work with 6 contacts - in this case, connect three wires to zero, and the other three to phase. Insert a new thermostat into the open circuit into the special hole.

- Using the tester, adjust the temperature conditions under which the assembled circuit will operate. Place the device back on the boiler in the reverse order - install the plastic/metal cover, secure the retaining bolts, place the device in the boiler, and so on.

How to connect the Ten video block

Installation Tips

To avoid installation errors, use the following tips:

- If you are installing another thermostat (not in the form of a metal rod), then its installation will be carried out using a similar method - the thermostat is built into the electrical circuit break on the phase wire that goes to the heating element. More detailed installation instructions can be found on the packaging.

- Before purchasing, be sure to check the operating voltage of the thermostat. There are devices on sale that work not only with 220 V, but with other voltage levels (24, 127, 380 and others). You can also check the technical parameters with the seller or look at the packaging.

- Do not rush to buy a device with maximum sensitivity. For most everyday tasks, a sensitivity of 0.5-2 degrees will be sufficient. Of course, no one will forbid you to buy more accurate devices, but they usually cost several times more, and they will be of little practical use.

Requirements for operation and maintenance of heating heating elements

Regular preventive maintenance of devices comes down to a visual inspection of the equipment, descaling and updating when defects appear on the equipment.

The rules of use are also not complicated:

- Purified or settled water and technical oil are used as a coolant.

- Before putting into operation a heating element for heating with a thermostat, a safety group with an automatic start/shutdown system is installed on the equipment.

- Frequent switching on and off of devices reduces their service life. In order to prevent the units from failing, the optimal operating mode is selected with a difference in heating temperature of the coolant of 10 degrees. In this case, the device will not start and turn off every minute to maintain heating.

- Checking the tightness of the system will reduce the risk of static electricity forming in the battery and reduce the possibility of an accident.

Heating elements can be a good replacement for all types of radiators and heat guns. To increase the thermal efficiency of appliances and reduce heating costs, you need to pre-insulate the premises.