Installing a fireplace insert is not an easy task. I warn you right away that if you lack experience and confidence in the result, it is better to entrust the implementation of the project to professionals. But, regardless of your decision, the following information will be useful in choosing a practical and safe way to install a fireplace in your home or apartment. Let's consider the most popular of them, paying attention to ensuring reliability, installation of the base, primary cladding and insulation of the installed firebox.

Important: I would like to note right away that auxiliary materials for installation, as well as the main materials for intermediate and final finishing, are determined strictly by the design and characteristics of the firebox and smoke exhaust system, materials of the walls and floor of the room, fuel for combustion, combustion temperature, and other indirect indicators. The materials indicated in the article may not correspond to the type of fireplace you decide to install. Therefore, I ask you to consider the information provided not as a mandatory guide to action, but as an article to familiarize yourself with the basics!

Indeed, it is quite difficult to navigate the preparation of instructions and recommendations for it. To do this, it is worth working strictly with a specific manufacturer, only with a cast iron or steel firebox of a certain type, determining the technical characteristics, the type of wood to be burned, the floor in your house and walls, the chimney and many other criteria. If you dive deeper, it might look like this:

- There are at least 60 licensed and certified fireplace manufacturers on the Russian market, as well as small companies that are just starting to operate;

- Each manufacturer presents several lines, and within them there are 5-6 different fireplaces;

- There is a serious variety in standard sizes: square, rectangular, round and other shaped fireplace inserts of a standard open type, with glass doors or stops... corner and wall, hanging and built-in fireboxes with different thicknesses of the base and walls;

- The type of wood is taken into account, which affects average temperatures, and, accordingly, the choice of protective and decorative cladding materials. I’m ready to immediately provide examples: the burning temperature of oak and ash is about 1040°C, acacia – 700°C, pine – 620°C, poplar – 470°C. The difference is quite dramatic;

- It is necessary to pay attention to the material of production of walls and floors, as well as floors in the house where the fireplace is installed - wood, panels or panels based on natural wood, SIP panels and sandwich panels, stone, brick, foam blocks and expanded clay concrete, other materials;

- An important part of a safe system is the chimney. There are many different offers on the market: standard steel and brick, stainless double-walled sandwich chimneys, more expensive and high-quality ceramic ones!

As you can see, in order to compose specific instructions, it is necessary to cross over many concepts, which is impossible at this stage. Therefore, I will shorten the information part somewhat and present the two main types of installation of fireplace inserts, which are most common!

Features and types of fireplace inserts

It is important to remember that the fireplace insert will work as efficiently as possible if certain conditions are met:

- the chimney must work reliably;

- the fuel used to light the fireplace must be of high quality and not contain any harmful impurities;

- Skill in operating a fireplace is welcome.

High-quality operation of the chimney is extremely important so that the draft is continuous, and all harmful combustion products formed during the combustion of fuel are freely discharged outside. Therefore, the installation of a chimney for a fireplace must be performed impeccably. The chimney is also subject to certain requirements due to the fact that during the operation of the firebox the following features of the chimney must be taken into account:

- the height of the chimney is directly proportional to the draft forces, therefore, in order to strengthen this parameter, a longer chimney system should be equipped;

- A decrease in draft is facilitated by many small nuances that are not always immediately noticeable: various cracks and chips in the pipe body, structural elements that do not fit well together, an open fire door, etc.

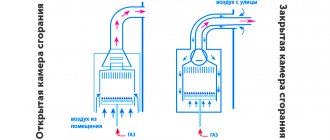

If we talk about the types of fireboxes, it is customary to distinguish between two main categories: the most common open fireboxes and closed fireboxes. Each of these designs has both its advantages and disadvantages, which should be discussed in more detail. A fireplace with an open firebox is distinguished by the fact that the owners can easily see the fire burning in it, which is often quite impressive.

According to the type of construction, such a firebox is a niche in the surface of the wall, for the arrangement of which it is first necessary to strengthen the fireplace foundation. Fireplaces with a closed firebox have a higher heat output compared to units with an open firebox, since the heated air does not escape outside as much as it does in models without a door, but the aesthetic indicators are certainly higher for an open fireplace. A fireplace with a closed firebox has a number of undeniable advantages:

- the entire structure is very easy to use due to its compactness;

- installation of such equipment does not involve any difficulty;

- it is much easier to regulate the fuel combustion process in such a design than with open-type systems;

- thanks to the heat-resistant glass included in the design of such a firebox, any fire due to the emission of sparks and other unpleasant situations is excluded;

- The performance of fireplaces with a closed firebox is very high (as a rule, the efficiency is more than 80%).

It is important to remember that to equip a closed firebox you will need a fireplace with very impressive parameters, while for an open firebox a standard size fireplace will be sufficient.

In addition, all installation work, which includes both the lining of the fireplace insert and the external design, for a closed firebox is more expensive and more complex.

Our advantages

| Experienced craftsmen All installers are constantly trained and know the rules and regulations of installation. Work experience of at least 5-10 years. You don’t have to calculate the estimate yourself, go for materials and overpay for them. Prices do not change after signing the estimate. By entrusting the installation to a professional, you can live and sleep in your home in peace. | For designers and architects Special conditions for designers, architects and builders. | Finishing work In addition to installing fireplaces, we will also carry out external cladding of the fireplace in accordance with your wishes. |

| Fireplace selection We will help you choose a fireplace according to your requirements and financial capabilities. You will be truly pleasantly surprised by our managers with the volume and quality of knowledge. | Work guarantee We provide a 1 year guarantee on all types of work provided. We will come and fix it free of charge in a warranty case at the expense of the installation company. | Promotions and discounts When ordering turnkey, you will definitely receive a discount on installation work, and you can always find products on sale with us. |

Rules for installing a fireplace insert

The quality of the fireplace's operation largely depends on how correctly all instructions were followed during installation. Thus, professional craftsmen recommend following the following rules:

- when determining the location where the fireplace will be located, it is important to ensure that the adjacent walls and ceiling surface can withstand high temperatures;

- the arrangement of the fireplace requires the presence of a smooth stone or ceramic base;

- as a safety measure, the base of the firebox should be equipped with a sheet of steel, the thickness of which should be more than 2 mm;

- The role of thermal insulation material will be perfectly fulfilled by basalt-based cotton wool, which must be laid between the surfaces of the floor and ceiling. This type of cotton wool is highly heat resistant (heating to 900°C will not cause any harm to it);

- one of the features of laying the firebox is the need for its gradual rounding, for which each of the subsequent bricks must be laid 6 cm closer to the beginning of the previous brick;

- the remaining mortar mixture formed after laying a row of bricks must be removed with a sponge;

- speaking about such a parameter as the thickness of the firebox walls, it should be remembered that at the side walls this parameter should be 20 cm, and at the rear edge - 10 cm;

- provided that if the fireplace is installed in a structure made of stone, then its arrangement can be done near any desired wall. But if the main structural element of the house is wood, then before installation it is necessary to build a special layer of protection. For these purposes, you can use either standard bricks or building blocks;

- the diameter of the gratings mounted in the decompression chamber must correspond to the power of the firebox used;

- in order to prevent the surface from being damaged during the operation of the fireplace, it is important to extend the chimney pipe beyond the roof by at least 1 meter;

- those sections of the chimney that cross the attic must be treated with a layer of thermal insulation;

- the joint between the fireplace insert and the chimney pipe must be completely sealed;

- in order for the air necessary for ventilation to flow to the gas outlet channel, a gap of 5 cm must be provided at the fireplace outlet area;

- the minimum height of the firebox above the floor surface is 20 cm;

- control over the air supply to the firebox will be improved by installing a special throttle-type damper mounted in the ashpit;

- Excess condensate can harm the system, so it is important to provide for the possibility of its drainage from the pipe.

Functional purpose of individual parts

Fuel is loaded into the firebox and ignited. The combustion activity and intensity of heat release are directly related to the damper - with a larger opening, maximum air enters the firebox and the wood burns better. If the design involves an open firebox, the intensity of the fire does not need to be adjusted.

To regulate the air supply you need a grate. An important point is the timely removal of ash, which collects through the grate into the ash pan. Usually it is raked out or shaken out, depending on the presence of a built-in or retractable system.

The fireplace chimney removes the accumulated combustion products to the street. To prevent gases from spreading inside the house, the chimney is often equipped with forced draft force. It is a fan. For the construction of a chimney, it is allowed to use only heat-resistant bases: brick, ceramics, heat-resistant steel.

Preparatory work for installing a fireplace insert

Before talking about the process of installing a fireplace insert, you should initially consider which design would be most appropriate to give preference to. Despite the prevailing stereotype regarding the old-fashioned nature of cast iron, many experts recommend choosing this material, since its reliability indicators are ideal for arranging a firebox. Having purchased the desired model, you should take care of the so-called foundation and equip a high-quality base for the fireplace.

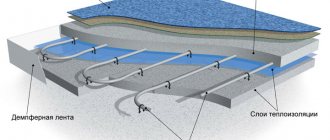

It is best to carry out all the preparatory activities while building the house, but you can carry out the installation in an already finished structure. Here you need to remember that when installing a closed firebox, the floor under it must be equipped with a reliable coating and a heat-insulating layer must be laid.

Both fireplace inserts with a heat exchanger and any other systems require that the base be non-flammable, since high temperatures certainly carry a certain risk. The structure of the foundation for the fireplace must be strong, so it should be filled with a cement-based screed so that the final layer thickness is 15 mm. The base itself may include heat-resistant bricks or aerated concrete blocks - both of these materials withstand temperature influences and last a very long time.

For beauty in the home

If there is no need to heat your home, you just want to decorate it with an original stove, you can choose a decorative fireplace for this purpose. It does not require either a chimney or a complex internal structure; in fact, it is simply a portal inside which an artistic composition or an electrical imitation of smoldering coals is installed. At the same time, it’s easy to make a portal with your own hands, even for those who have never in their life thought about how to build a fireplace.

You can install it directly on the floor, without any foundation; the frame is made of wood or metal profiles, and covered with plasterboard on top.

A corner decorative stove will fit even in a small room, decorating it and creating an additional surface - a mantelpiece. An antique-style living room will greatly benefit from such decoration. An openwork fireplace grate will complement the composition.

You can draw fireplace designs yourself or enlist the help of specialists. This is what a project for a decorative stove for home decoration looks like.

Decorative fireplace project

Decorative stove project

Furnace lining process

After assembling the base, you should move on to work such as lining the fireplace insert (for more details: “How to veneer a fireplace - tips on cladding”). Panels intended for this purpose must be fixed to plasterboard sheets, maintaining a gap of about 1 - 2 cm between the cladding material and the fireplace to prevent the accumulation of excess hot air. Installing a ventilation hole in the case will also help get rid of it. Read also: “How to cladding a fireplace - finishing with stone, tiles.”

Heat supply and removal are very important aspects in the operation of any fireplace, so it is important to remember that in cast iron samples, about 30% of the heated air leaves through the base, and the rest leaves the firebox through the walls of the body. To equalize all indicators, a special pipe should be connected to the firebox, designed to remove air. For these purposes, a pipe made of PVC with a minimum cross-section of 150 mm is quite suitable. Next, the firebox must be equipped with a door on the back side of the entire structure for more convenient access to the fireplace and removal of combustion products. Upon completion of installation of the combustion chamber, it is necessary to take a responsible approach to the installation of the chimney.

Introduction

Before starting work, carefully read the instructions for assembling the fireplace insert. The stove manufacturer does not accept any responsibility for any damage that may occur as a result of failure to follow the instructions in their manual, which will void the warranty. Damage to components may occur if assembly procedures are not followed. The manual for professional installation and assembly of the firebox must contain all local rules and regulations regarding national and European standards. Keep this manual in a safe place.

Installing a chimney for a fireplace

To fix the chimney pipe to the fireplace, you must use specially designed fasteners and mechanisms, for example, a radiator equipped with a grille and pipes, the main material for which can be stainless steel 1 or 2 mm thick (it all depends on the type of steel used).

Equipping them with layers of thermal insulation will help extend the service life of these materials. Absolutely all connection elements must be located inside the pipe to avoid the negative impact of condensate that periodically occurs in the system.

Experts do not recommend making the chimney straight and advise placing its components at an angle of about 5 cm. To protect yourself from potentially uneven installation, you can place bars under the fireplace firebox to level it, which can be removed after all work is completed.

Dimensions: instructions for calculation

You can determine the size of the fireplace using the following calculations.

Note: The parameters of the firebox depend on the size of the room: the area of the firebox hole corresponds to 2% of the area of the room. For example, for a room of 30 m2, the area of the combustion opening will be 0.6 m2 - that’s 6000 cm2.

The standard ratio of the dimensions of the firebox height to its width is 2:3. In our case, it is 95 cm by 62 cm (95*62=5952, almost 6000 cm2).

Next we look for the size of the hole depth. Traditionally it is equal to 2/3 of the height. In our example, the best depth would be 620/3*2=413 mm. Why exactly so much? At greater depths, heat will fly out into the chimney without heating the room. If it is less, smoke will begin to enter the room.

The size of the fireplace also depends on the material chosen. Stone fireplaces look bulky and massive; they are suitable for a spacious home. Metal finished with tiles or plaster will look much more compact with the same firebox parameters. The size of the portal also matters.

Fireplace operating standards

In order for the fireplace system to last as long as possible, it is important not only to study photo and video materials on installation, but also to adhere to a number of requirements, namely:

- replacing wood as the main fuel with something else during the operation of the fireplace is highly not recommended, since such a desire to increase the burning rate can negatively affect its functioning;

- using water as a fire extinguisher is strictly prohibited;

- It is necessary to carry out fireplace cleaning and other maintenance at least once every two months.

To make the fireplace work better, you should always leave a layer of burnt wood about 1 cm thick on its bottom. The outer surface can be cleaned with a rag and regular soap solution. If the fireplace firebox is closed, then carbon deposits usually form on its glass from the combustion of wood, which can be easily removed with a regular glass cleaner. It is recommended to clean the inner walls with a special hard brush, which will help get rid of plaque and ash.

Base

Some models of freestanding gas fireplaces or electric fireplace kits do not require reinforcement of the floor covering. Due to their low weight, they can be installed in multi-storey buildings. It is necessary to first calculate the load per unit area and familiarize yourself with the technical characteristics of the floor of the house.

The cast-iron firebox will be built into a brick body, which means that the mass of our structure will require a reliable foundation. Ideally, the foundation for the fireplace is built simultaneously with the construction of the house, but few people have such foresight.

- The first step is to dismantle the floor covering. The floors are raised to such an area that it is convenient to carry out work. It is necessary to dig a pit, the dimensions of which will be 30 cm larger than the fireplace body on each side, except adjacent to the wall.

- The foundation is poured using reinforcing elements. If the soil is wet, it is recommended to use a stone rubble. Filling the foundation layer by layer, bring it to the floor level. After the mortar has hardened, the surface of the foundation is covered with waterproofing material and two rows of brick base for the future fireplace are laid. Its level must be brought to a strictly horizontal state.

Concrete screed construction work