Installation of fireplaces with a water circuit

Different designs of stoves and fireplaces also require different designs of the built-in water circuit (heat exchanger).

Stoves and fireplaces

The optimal solid fuel device for heating a house using water heating can be a fireplace stove. It may be less efficient than a boiler, but it is more presentable and functional. In addition, it is quite possible to build it with your own hands.

We are talking about the construction of a brick stove-fireplace, in which the heat exchanger is also prepared independently (or with the help of a welder). The shape and size of the water circuit may vary. The installation location is also different: directly in the firebox, behind it or on the side.

The design of the heat exchanger must correspond to the functional purpose of the unit and ensure rapid and uniform heating of the coolant. Tubular models - coil and register - cope best with this. It is, of course, easier to make capacitive circuits from steel sheets.

If the heat exchanger is installed in the combustion chamber, then the thickness and grade of steel matters, since it will be exposed to open fire. For these purposes, it is better to use boiler steel with a thickness of 4 mm.

The water circuit can also be located in different ways in the firebox. If the fireplace stove is equipped with a hob, then the heat exchanger should not interfere with cooking.

Fireplaces

A fireplace with a heating system will work with fireplace inserts in which a water circuit is installed. As in fireplace stoves, it can be tube, capacitive or combined, but with some features.

A spiral of copper tube bent in a special way is placed around the smoke collector. The selected shape allows you to quickly heat the coolant and maintain its parameters in the system. Circulation can occur by gravity or forced.

- Another type of pipe circuit is a “snake”, a pipe that is curved in several places, like a heated towel rail. Placed behind the wall of the smoke box.

- The combined version consists of two containers located on the sides of the smoke collector and connected by pipes. Since there is direct contact with flue gases, boiler steel is used. A very effective option, but not wear-resistant.

The simplest type is capacitive, also called “water jacket”, since the coolant is filled between the double walls of the housing. It is heated by the firebox casing, therefore it is the most inert.

Most fireplace inserts with a water circuit are made closed, but open ones are also found. In addition, fireplace inserts differ in appearance, power and connection diagram.

Pellet fireplaces

The solid fuel pellet fireplace stands apart in this category; it has also begun to be produced with a water circuit. Almost all of these units are of the same type: a closed firebox with a burner, a capacitive heat exchanger located behind the firebox, a pellet hopper, and a control unit.

Fuel is supplied automatically using a screw drive, the air is moved by one or two fans. An ash pit is also provided. Connection to the heating main, as in all fireplaces

Manufacturers are paying attention to the use of stainless steel pipes as chimneys, including do-it-yourself stainless steel chimneys.

The big advantage of pellet fireplaces is the automation of the work process. You can load 15-20 kg of pellets into the bunker and this will be enough for one and a half to two days of burning at moderate mode. When operating at maximum power, the consumption will double.

Two bold minuses spoil the reputation of these devices. Firstly, for operation you cannot do without electricity, as is the case with conventional electric fireplaces. Secondly, it is necessary to clean the burner regularly, and if you add low-quality granules (a fairly common occurrence), it may stop working altogether.

DIY fireplace

The fireplaces discussed above represent factory-produced models. Is it possible to make a fireplace with water heating with your own hands? Many people have already done this - respect is due to them.

A description of how to build a brick fireplace yourself is in the article “Do-it-yourself fireplace: notes at the portal.” You can order a heat exchanger from a welder. Most likely, it will be a register of several rows of tubes spaced apart. The heat exchanger must be checked for the quality of welds. To do this, water is poured in, preferably under pressure.

Well, then the fireplace is built to the level of the smoke collector and a circuit is installed on the fireplace stove. The register tubes will be located in the cavity, and the housing will be laid down, leaving fittings for connection to the system.

It should be noted that such a fireplace is unprofitable for heating, but it will cope with the task of hot water supply.

What would you like to change in the aqua fireplace?

During the week of using the aqua fireplace, one of its shortcomings was revealed: a bag of pellets in a standard 15 kg package does not fit completely into the aqua fireplace bunker, so you have to leave 1/3 of the bag nearby and add more while the aqua fireplace is operating. This is a small thing, but it is very strange that the bunker was not designed to fit the standard bag capacity. Moreover, this implementation would not significantly affect the dimensions of the fireplace: 10 cm in height and 5 in width - it would not scare away potential buyers. Or in Europe, pellets are packaged in 10 kg bags?

Usage and operational capabilities

Fireplaces and stoves with a water circuit are intended for installation both in country houses and in private multi-storey buildings. Due to their high efficiency, such fireplaces can serve as the main source of heating. Also, the presence of a water jacket allows you to make a connection in such a way that the house has hot water and a boiler for its regular heating.

A fireplace stove with a water circuit does not depend on the availability of gas and electricity, and thus can be installed even in towns and villages, where interruptions and shutdowns of these resources often occur.

The main features and positive qualities of such installations include:

- Possibility of connection to almost any type of heating system;

- Wide range of prices, brands, models and manufacturers;

- To kindle and operate the structure, you need dried and prepared logs or purchased briquettes;

- The working process is fully streamlined, and the furnace itself can operate in an autonomous and economical mode;

- Each model has its own unique and inimitable style;

- For small rooms, you can choose a corner heating unit;

- Due to the presence of a heat exchanger and a water jacket, heating of the premises occurs very quickly and evenly.

This article presents a large number of photos of various models and installation schemes that will help you make a melting choice and determine the visual qualities of the hearth you need.

Criterias of choice

A fireplace stove with a water circuit can have different characteristics and operational capabilities

Before purchasing, pay special attention to the following criteria:

- Determine the required power of the heating unit. You can visually recognize it based on the size, shape, and location of the hearth. The most powerful are massive cast iron structures that have a wall or island arrangement. You can learn more about this parameter by studying the instructions included with the model. Keep in mind that to heat 10 square meters, you will need about 1 kilowatt;

Steel model, with sidewalls finished with fire-resistant materials

Steel model, with sidewalls trimmed with fire-resistant materials, a hob and firebox equipped with transparent fire-resistant glass

The principle of heating using the example of a two-story house

The principle of heating using the example of a two-story house

- Fireplace stoves with a water circuit can be of both domestic and foreign origin. When choosing, give preference to a proven, well-known brand, the quality of which has been tested by time;

- The installation must be of high quality and durability. As a base material, give preference to cast iron or sheet steel, which is additionally painted with a special protective paint. Such fireplaces are suitable for both regular heating and periodic heating; they can be located in rooms that do not have other heat sources;

- Long-burning fireplace stoves with a water circuit are more suitable for installation in rooms where you live permanently, as well as for houses with a large area and several floors.

Diagram showing the passage of air masses and heated air

Diagram showing the passage of air masses and heated air

Some steel models with a water circuit have average efficiency

Some steel models with a water circuit have average efficiency with small dimensions

What are pellets?

Pellets are a granular type of fuel. For their production, environmentally friendly plant material is used:

- branches of bushes and trees obtained during spring and autumn pruning;

- stem cobs;

- peat consisting of grass residues, etc.

Photo 2 Pellet granules have a small diameter of 5-10 mm and a length of up to 5-7 cm.

The production process for natural fuels is quite simple. The initially prepared material is crushed to a dusty state. Next, it is dried and sent to a special granulator, which presses the raw material into granules.

Such briquettes are an excellent alternative to large firewood, which must be chopped before placing it in the firebox. In addition, an aqua fireplace running on such fuel can serve as the main source of heat in a house, even with a large cubic capacity. The environmentally friendly side is also an important aspect. The autonomous unit can independently supply fuel.

Advantages of fireplace stoves

Fireplace stoves combine the positive qualities of these heating devices, while they are devoid of their inherent disadvantages. What are the main differences between a traditional stove and a fireplace?

- The oven takes a long time to heat up, but is able to accumulate heat and radiate radiant energy from the walls of the oven into the surrounding space for a long time. The heat from the fireplace immediately spreads throughout the room in which it is installed, but after the fire stops, it quickly cools down and the temperature in the house decreases.

- The heating furnace is usually fired with a small blind door, this reduces the likelihood of smoke and helps improve draft. The firebox is open and occupies about half the area of its façade. If the chimney is not installed correctly or bad weather conditions, reverse draft and smoke may enter the room, which leads to an unpleasant odor, deposition of soot and soot on household items.

- The smoke exhaust system of the furnace has a complex design: the smoke in them passes through numerous channels, giving off most of the heat to the body of the furnace. It comes out of the pipe almost cooled down. The chimney in the fireplace is almost straight, the smoke is retained only under the arch, so its outlet temperature is much higher, and the heat removal is worse.

- The efficiency of heating stoves is on average 60-80%, for fireplaces - no more than 50%.

- The stove is not very decorative, and it can only be given an aesthetic appearance with the help of finishing. The fireplace itself is a decoration of the interior, and the flames decorate it even more.

Industrial production models take into account all the features of these heating devices, eliminate the most significant disadvantages and emphasize the advantages. As a result, modern fireplace stoves have a number of advantages:

high efficiency - up to 80%, and when connecting a heating water circuit - up to 92%; a sealed firebox with a large glass that allows you to observe the flames, but does not allow smoke to enter the room; smoke channels with smoke circulation and heat exchanger, which improves heat removal and transfer to the room; aesthetic appearance, there are models decorated with ceramic panels or metal forging; light weight - they can be installed even on wooden floors laid on joists, without constructing a foundation; small dimensions with high power - fireplace stoves do not take up space, which is very important for small houses; the ability to connect a water circuit allows you to heat all rooms of the house and retain heat for a long time, as well as avoid daily temperature fluctuations; low price compared to the cost of materials and work for the construction of brick stoves or fireplaces; Simple and quick installation that you can do yourself.

In addition, modern fireplace stoves may have a number of other useful functions:

- hob;

- a glass cleaning system that prevents it from darkening, as well as a long-burning mode that is very popular among consumers.

Feedback from the owners of such stoves is clear: the stoves can heat a residential building for a long time and efficiently, without causing problems or hassle for the owners.

Technological description of the device

The appearance of these installations differs little from standard fireplaces, although in terms of technological characteristics they have a more complex system.

* The first difference is related to the type of fuel; ordinary firewood is not used here, but special pellets are used. A special feature is the automatic supply of fuel to the compartment, which is very convenient for the consistency of the process and long-term combustion.

The second feature is associated with a closed firebox, which allows you to set the temperature yourself.

Inside the structure there is a heat exchange chamber filled with water. And along the walls from the fireplace there are steel pipes that transfer the coolant to the rest of the rooms.

Boiler design

- So, any boiler you can buy consists of:

- combustion chamber

- grate

- chambers for collecting combustion products (ash chamber)

- heat exchanger (water circuit)

The combustion chamber is the heart of a wood-burning boiler, or fireplace. Wood combustion occurs in it and heat is released. Volatile combustion products enter the combustion chamber into the chimney, which leads them outside. The air required for combustion enters the combustion chamber through the lower ash pan (ash pan), or through adjustable blinds in the combustion door. The combustion chamber is also equipped with a door for loading fuel. It can be made both from the materials of the boiler body and from glass, such as, for example, near a fireplace.

At the bottom of the combustion chamber there is a grate. Through it, the coals and ash remaining from the combustion of wood enter the chamber for collecting solid combustion products.

The ash chamber is equipped with a door, which is used to clean it from unburned residues and to regulate the intensity of combustion by increasing or decreasing the flow of fresh air into the lower part of the combustion chamber. You can do this with your own hands or with the help of a special mechanical thermostat that regulates the flow of fresh air into the combustion chamber depending on the achievement of the specified fluid temperature in the water circuit.

The heat exchanger can be a water circuit, which is like a second body of the combustion chamber. In this embodiment, the liquid heated by the boiler circulates around the firebox, isolating it from the outer casing of the wood-burning heating boiler. Such a heat exchanger is very effective in terms of quickly warming up the liquid and reducing unnecessary heat losses, but if it is damaged for any reason, repairing this circuit can be very difficult.

Also, a system of pipes passing through the internal space of the boiler in the places of the most efficient heat transfer from the combustion chamber can be used as a heat exchanger. Such a system is more convenient to repair than a continuous water jacket system, because each pipe, or the entire pipe system, can be easily pulled out and replaced with a serviceable one.

Boiler interior

The combustion chamber, a system of heat exchangers, is insulated from the outer casing with non-combustible materials with a low thermal conductivity coefficient. This could be asbestos, mineral wool, fireclay clay, ceramic filler, etc. materials.

Such thermal insulation has two goals: - firstly, by reducing the heat transfer of the boiler body into the surrounding space, the efficiency of the boiler itself significantly increases, in terms of the efficiency of heating the working fluid; - secondly, the operating safety of the boiler itself increases when it is installed in a room with fire-prone building materials.

Principle of operation

A pellet stove operating on granules consists of the following components:

- Frame.

- Burner.

- Firebox.

- Heat exchanger.

- Fuel bunker.

- Fan.

- Chimney.

The main element of the design is the burner, controlled by an automatic system. Burners are divided into 2 types:

Flare. This is a pipe that is the combustion chamber. In it, on one side, pellets are fed by an auger with a stream of air, and on the other there is a stream of flame.

Retor. The burner is bowl shaped. Fuel is supplied from below by a screw. Air is blown in from the side by a fan. There are holes in the bowl for this purpose. The flame is directed vertically upward.

The burner design has a built-in fan and auger. Electric ignition and combustion process is provided by a photosensor, an incandescent element and a control board.

On command, the screw transfers a portion of granules into the combustion chamber. According to the program, the fan turns on and the incandescent element starts working. A flame appears. As soon as the photosensor detects stable combustion, the control unit stops the incandescent element. Subsequently, the cycles continue according to the specified program.

Diagram of a pellet stove inside

The combustion chamber is made of steel or cast iron. The oven has a built-in heat exchanger. It consists of pipes through which smoke and hot gases pass, heating the water. From the heat exchanger there are pipes for connection to the heating system.

Rational assessment is important

It is important to choose the right boiler

All automatic pellet boilers show good results. However, it is always worth remembering that the lower the degree of user participation in their work, the higher the price of the engineering solution. It is growing literally exponentially. Therefore, an automatic household pellet boiler must be chosen rationally.

Inexpensive units will require daily cleaning, reloading and ignition in a semi-automatic mode, but will be able to operate on fuel of any quality with a stable efficiency indicator. At the opposite end of the scale are fully automated systems. They clean, load, maintain and manage themselves. However, their cost is very high.

Types of pellet boilers

Solid fuel heating equipment can be partially or fully automated.

Manufacturers produce 2 types of devices:

- Pellet.

- Combined.

In the second case, in addition to the main type of fuel, it is allowed to use additional fuel: firewood, sawdust. According to the design of the burner, retor or torch devices are distinguished. The latter are used in combined models. Fuel is supplied to the bunker automatically or completely manually.

Fuel benefits

Going through all stages of production, this type of fuel not only increases its density, but also reduces humidity to 8-12%. The latter indicator plays an important role in the combustion process. Fuel with low humidity releases more thermal energy, hence the high efficiency. More complete combustion occurs with low ash content.

For comparison, we present the amount of heat released during the combustion of 1 ton of different types of fuel.

- 3500 kW/h - pellets;

- 7000 kW/h - hard coal;

- 2000 kW/h - firewood;

- 10,000 kW/h - gas and diesel fuel.

In fact, inexpensive pellets are better than firewood, but produce less heat compared to other types of energy sources. But here price comes into play.

Initial data of a frame house

I have a frame house with a total area of 157 m2, two full floors, floor-to-ceiling windows on the first and second floors. The thickness of the floor insulation is 20 cm, the external walls are 20 cm, the ceiling is 30 cm. All windows face south. Three-chamber double-glazed windows, rehau profile. Two entrance doors with thermal break, insulated.

Design of a water-heated fireplace stove

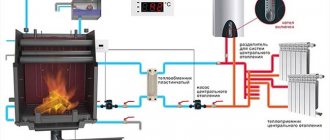

Heating and heating of liquid in this design is carried out using a fireplace stove. Pipes radiate from the fireplace stove and are connected to the radiators.

The water circuit looks like a tank in which the process of heating the liquid takes place. Using a special circulation pump, hot water moves through the pipes. In a system with natural circulation of coolant, a pump is not required. Radiators in the rooms will evenly distribute heat and transfer heat to the rooms.

Stove-fireplace design

The design of the fireplace stove is made in such a way that the owner does not need to purchase additional devices to ensure a comfortable microclimate in the home at any time of the year.

Installation of a pellet fireplace

The structure is installed independently, in accordance with the technical parameters specified in the passport. Think in advance about the necessary materials, calculate and plan the layout of the water system.

The equipment instructions describe in detail the installation process and important characteristics, including power indicators and operational requirements.

- The pellet system can also be installed in an old fireplace, dismantling the unnecessary firebox in advance, while the old chimney can be successfully used for efficient operation of the equipment.

In conclusion, we can say that with the advent of pellet fireplaces we are one step closer to a comfortable and safe life. They are gaining popularity due to their combination of high efficiency and aesthetic design.

Advantages and disadvantages of pellet boilers

The popularity of pellet boilers is growing due to a series of advantages. Among them:

- efficient heat transfer; The efficiency of such devices is comparable to the efficiency of gas heating devices and is significantly higher than the efficiency of wood-burning stoves;

- fuel efficiency;

- complete environmental friendliness; absence of any harmful substances in the granules;

- autonomy; provided there is an automated system, the user is deprived of the need to control the combustion process - the automation does almost everything for the person;

- independence from main power systems;

- almost complete non-waste - when burned, the granules leave a very small amount of ash; cleaning the ash pit is rarely required;

- equipment safety and no need to coordinate installation with the relevant services;

- aesthetic design of boiler-fireplaces - the ability to “fit” the unit into any interior.

It is not without its drawbacks. These include:

- the need for electricity, without which ignition of fuel, operation of the auger and control unit are impossible;

- high cost of equipment; average price range – 100,000-1,000,000 rubles;

- dependence of European models on Russian energy systems and pellet quality; devices can be sensitive to power surges and require fuel; When choosing a stove, you should definitely consider protection against voltage surges and the possibility of purchasing pellets suitable for a specific model.

Advantages and disadvantages

Solid fuel boilers compete with gas heating equipment.

Pellet units have high efficiency and have the following advantages:

- safety of use;

- ease of installation and maintenance;

- process automation;

- burning duration;

- compact dimensions;

- possibility of remote control via a mobile application, GSM module;

- small volume of combustion products;

- the presence of a low-noise, energy-saving fan for air injection;

- heat resistance of the case (it does not heat up).

The disadvantages include the high cost of 1 kW of thermal energy.

When installing a long-burning pellet boiler in a country house where there is no centralized power grid, you will need a generator and additional technical equipment. The fuel must meet the specified parameters of humidity, quality, and size. The unit itself is expensive.

Features of the structure of the pellet device

A pellet fireplace looks like a regular wood-burning fireplace insert. But in terms of its internal design and operation, such equipment is a higher technological device, which allows using pellets to completely automate the heat transfer process.

The fireplace is closed with a special transparent door made of durable glass. This solution allows you to admire the view of an open fire. There are small holes on both sides of the device through which heat passes into the room.

Form factor

Pellet fireplaces come in two types:

- Built-in. Such a device is completely built into the opening in the wall. The pellet container can be located in an additional room or hidden using cladding. A firebox similar to a wood-burning fireplace remains visible.

- Separate. The fireplace already has its own cladding in the form of a steel body and ceramic panels, which allow it to retain heat for a long time. At the top of the equipment there is a container for pellets. The type of heating device is selected depending on the characteristics of the room.

Firebox

The container for burning pellets is made of cast iron or strong, high-density steel. The ribbed surface of the firebox significantly increases convection heat transfer.

Unlike free-standing fireplaces, devices built into the wall can have a large firebox, which allows you to load not only pellets, but also firewood. Burner

In the lower zone of the fireplace there is a burner, to which fuel and heated air are supplied. Dosing of granular raw materials and oxygen ensures complete combustion of pellets, which significantly increases the productivity and efficiency of the heating process. Some manufacturers equip fireplaces with burners with automatic ignition.

Automation

The fireplaces are equipped with an automatic control system. The presence of temperature sensors, controllers, and electric motors makes it easy to control the entire heating process. The auto control panel can be located on the body. In more expensive models, the fireplace can be controlled remotely.

Thanks to the automatic control in the pellet fireplace, it is very convenient to control the heating process

Container for ash and fuel

The fuel compartment is located at the rear of the fireplace. The pellets are accessed into the firebox using a screw drive. A separate chamber for ash is installed under the firebox. It is a small drawer that can be easily pulled out for cleaning.

Fan

To allow air to pass through special openings between the walls and the body of the fireplace, a ventilation device is built into the system. It allows you to fill the room with warm air masses.

Models with two fans are also produced. The first is for the release of air masses to the channels, and the second is for access of oxygen to the firebox.

Pellet fireplaces with water circuit

The operating principle of such equipment is similar to a single-circuit boiler. Pipes through which the coolant circulates are connected to the heating system. Pellet fireplaces with a water circuit are an autonomous device with high power. The device allows you to warm up the entire house. This model provides for the connection of cold water and the outlet of already heated liquid. Heating is organized using pipe junctions and radiators.

Main characteristics

Firebox for a pellet fireplace

Pellet-type fireplaces are similar in appearance to traditional ones, but have a number of differences. The firebox for them is always closed, made of heat-resistant glass. The operation is controlled by software, the display is located on the cover of the device. With its help, you can set a specific operating mode, the desired air temperature, automatic switching on and off.

The external design is varied, you can choose the desired option for any interior style. All pellet fireplaces are made of stainless steel with elements of heat-resistant glass. Manufacturers offer one-piece boilers or separate fireboxes that can be built into any portals, even those made by yourself.

A pellet stove requires a vertical or horizontal chimney. You can connect the furnace outlet pipe to the ventilation shaft, but make sure that it does not become clogged and provides good draft. Often such options are installed in the dining room or kitchen, due to the proximity of ventilation ducts.

Manually firing the stove with pellets

One of the simplest and cheapest formats for using such pellets involves manually adding fuel to the stove. For many people, this process seems unnecessarily complicated and incomprehensible, since the first time it is not possible to calculate the exact amount of fuel and the time of its addition.

After just a few times, you will be able to understand the features of the process and will easily control the flame power and the “operating” combustion temperature.

You can heat a stove with pellets in a conventional stove without significant modifications:

- The easiest way is to install a specialized basket in the oven. It has a fine-mesh structure, which prevents burnt pellets from falling into the ash pit. The cost of such products is extremely affordable, so every stove owner can afford it.

- If you want to do the work yourself without purchasing additional products, you should manually reduce the gaps between the grates. To do this, you need to re-weld the grate with a decrease in clearance or install a special mesh, which is made of thickened wire.

Using a pellet burner for a stove

Modernization of a wood-burning pellet stove by installing a burner device is optimally suited for heat generators operating using long-burning principles. After installing the burner, it is possible to achieve maximum heat transfer and economical consumption of pellets.

Converting the stove from wood to pellets is carried out by installing a mounted or built-in burner connected to a screw transmission and a fuel hopper. The design of the burner device consists of several important elements:

- The operation of an automatic pellet burner is controlled by a microprocessor chip. The controller selects the feed rate of granules and, in the event of an emergency, turns off the operation of the equipment.

- Transport feed – the equipment for organizing the supply of pellets includes: a screw feed, an electric motor. The nodes are connected to a controller that regulates their operation.

- Ignition and flame control system. Ignition is carried out as soon as the system starts. When the flame dies out, the pellets are re-ignited automatically.

A long-burning wood stove converted to pellets is economical. Given the availability of pressed pellets, heating costs are reduced by 30-40%.

The burner has a removable design.

A long-burning heating stove operating on pellets and wood can be converted from one type of fuel to another within 10-15 minutes. For modification, there is no need for qualified assistance. It is enough to remove the burner and install the firebox door back. Date: September 25, 2022

Ash after pellets

Another important detail is ash. After combustion, the pellets turn into ash, and although I bought pellets stated in the offer as DIN+ with an ash content of 0.3%, more ash remains after their combustion. I would say 5 percent for sure. And you can’t determine this when purchasing. In addition, their humidity also did not correspond to the offer.

When burning two bags of pellets, the fireplace must be cleaned of ash. Ash in the ash pan and in the burner. A regular or special vacuum cleaner is used. But since the ash needs to be removed from the fireplace, you need to stop the fireplace and perform actions that the automation cannot do. Therefore, the aqua fireplace is not designed to operate autonomously for more than one day.