Since ancient times, the population heated stoves with coal and wood to heat their homes. However, progress does not stand still and humanity has come a long way in all spheres of its life. The synthesis of scientific developments and modern, high-tech production has made it possible to create a new type of solid fuel - briquettes for heating.

For their production, various raw materials are used - peat, waste from the wood processing industry (sawdust, shavings), agriculture (straw, husks), residues from coal production. The scope of application of briquetted fuel is quite large and varied: heating saunas, industrial and residential premises, heating greenhouses, heating coolant in boiler rooms.

Classification of briquetted products

In accordance with the listed technologies and equipment used for production, three types of briquettes are distinguished:

- In the form of a brick, obtained by hydropressing under pressure up to 400 bar (about 4 kgf/cm2).

- Cylindrical - about 50 cm long, 10 cm in diameter, using hydro- or mechanical pressing methods with pressure from 400 to 600 bar (4-6 kgf/cm 2 ).

- Piney-key - with radial holes, obtained by processing on screw (extruder) presses, while simultaneously exposed to high pressure (up to 110 bar) and high temperature (250-350 o C). They differ in combustion duration, increased heat transfer, density and resistance to impact.

The density of briquettes is a fundamental value that directly affects calorie content, mechanical resistance, and resistance to moisture.

Briquetted products warehouse

The higher the density, the higher the listed indicators accompanying it. Which fuel briquettes are better is up to consumers to decide, in accordance with their own needs and preferences.

Fuel briquettes RUF

This fuel resembles white or wood-colored bricks in appearance (the shade varies widely). RUF briquettes are made from dry sawdust by pressing under high pressure. As a result, Euro-firewood is born, which can be used in any type of stove. Their distinctive feature is the inscription RUF, embossed on both sides.

Eurobriquettes PINI KAY

An interesting feature of these Eurobriquettes is their unusual shape - they resemble square pencils from which someone has taken the lead. That's why they are called "pencils". In order for it to burn with the release of a large amount of heat, a hole is made in it, increasing the draft. The “pencils” themselves look dark, as they were fired. This procedure makes them more durable and removes excess moisture.

The disadvantage of PINI KAY fuel briquettes for heating stoves is that they are more expensive than firewood and even more expensive than any other types of fuel. But they burn well, releasing a large amount of heat. They are also convenient to transport and store. Thanks to their shape, they are ideal for lighting fireplaces. Some people take them with them into the wild to use PINI KAY bars instead of wood for a fire.

Fuel briquettes from coal and peat

Peat and coal fuel briquettes for heating stoves are made from peat and coal, respectively. The starting materials are formed into small cylinders. The fuel can be used to light stoves and solid fuel boilers. Coal products give a high combustion temperature, but are characterized by high ash content. As for peat fuel, it is ideally suited for long-burning stoves, but it also produces a lot of ash.

Simple cylindrical briquettes

The simplest fuel briquettes for heating stoves are also on sale - in the form of cylinders. They are made from pressed sawdust and small wood waste. All this is pressed under slight pressure using a non-toxic adhesive base, after which the finished bars are sent to consumers. This fuel is cheap, but has one distinct drawback - low strength. It easily disintegrates and crumbles and does not withstand exposure to moisture.

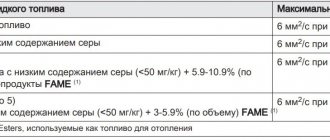

Basic parameters of pellets

Pellets for heating are granules of white or shades of brown, with a length from 10.00 to 30.00 mm, a diameter of 6.00 and 8.00 mm, less common fuel with a diameter of 10.00 mm, the maximum diameter of the granules is 25.00 mm. The darkening of pellets is associated with the presence in the structure of the material of various non-combustible residues (dust, earth, and a number of others).

The main parameters of pellets are:

- ash content (the lower, the better and the less ash, so the boiler will have to be cleaned much less often);

- humidity;

- calorific value (ENPlus-A1 – 18.0 MJ/kg, ENPlus-A2 – 18.0 MJ/kg, EN-B – 15.0 MJ/kg).

- total length;

- degree of density;

- diameter;

- bulk mass;

- abrasion class.

Production

The production process, as we have already said, is quite simple, even though it takes place at home.

To make briquettes for heating stoves with your own hands you need:

- Prepare high-quality raw materials, grind them to the desired consistency, and dry them. In order to improve the quality of combustion, paper can be added to any raw material.

- If necessary, add a binding element (clay, lignin), add water, and load it into the press machine.

- Press the product into a suitable shape at high pressure and preferably high temperature.

- Dry the finished product and, if possible, package it to protect it from external factors. When drying, you can use rags and paper that can draw out any remaining moisture from the briquette.

Having carried out all this work, you will receive excellent fuel, which can be used to easily and quickly heat a bathhouse and heat a house. At the same time, over a long period of time, you will experience the benefits and cost savings from using such eco-drives.

Note that during operation you should try to achieve a briquette moisture content of no more than 10-12% so that they burn well. Industrially produced briquettes have a moisture content of less than 10%.

To make sure of the excellent characteristics of this type of fuel, you can buy yourself some Euro briquettes to try in any store. At the same time, to create a suitable atmosphere, you can sometimes light a fireplace or stove with ordinary wood, because the use of different types of fuel is not mutually exclusive.

Pellet cost

Let's take the initial data:

- the average cost of industrial pellets in the Krasnoyarsk Territory as of December 2015 is 3,500 rubles per ton (3.50 per kilogram);

- the price of birch firewood is 1,300 rubles per cubic meter, in terms of tons (a cubic meter of dry birch firewood equals 650 kg of weight) is 1,846 rubles per ton (1.85 rubles per kilogram);

- the calorific value of birch firewood is 10 MJ/kg;

- The calorific value of wood industrial pellets is 18 MJ/kg.

In order to obtain 100 MJ of thermal energy, you need 10 kg of firewood (100/10), that is, 18.50 rubles, or 5.5 kg of pellets (100/18), that is, 19.44 rubles. The difference in cost is 1 ruble per 100 MJ. Moreover, it is necessary to note the undoubted advantages of pellets with an ash content of 1.5% over firewood with an ash content of 10%, the difference is obvious. It should be taken into account that the pellet market is growing dynamically, and with an increase in supply, the price will undoubtedly decrease.

Pros and cons of homemade briquettes

Advantages of homemade sawdust fuel briquettes:

- much less carbon dioxide is released than when burning wood or coal;

- compact product requiring little storage space;

- the material does not rot due to its high density;

- burns smoothly and beautifully;

- there will be no garbage and dust in the house;

- cost savings, subject to the availability of raw materials and equipment for manufacturing;

- briquettes burn for a long time - up to four hours;

- little smoke is produced;

- No harmful substances are released into the air;

- chimney cleaning can be done three times less often;

- environmentally friendly and safe;

- boiler power increases by 50%;

- burning coal gives an ash content of 20%, and briquettes 1-1.5%;

- A cubic meter of sawdust briquettes in terms of heat transfer is equal to 4-6 cubic meters of firewood.

Disadvantages of homemade sawdust briquettes:

- if the press force is insufficient, the briquettes may crumble;

- At home, ready-made briquettes are difficult to dry well. In the summer, they can be dried in the sun, and at other times of the year - only indoors, which does not significantly reduce humidity. Accordingly, they will burn worse.

- making and drying briquettes requires a lot of space;

- The manufacturing process is extremely labor-intensive and requires great physical effort.

Briquettes must be stored in a dry place. The shelf life of sawdust briquettes made at home does not exceed a year. The ash obtained from the combustion of the product is an excellent fertilizer.

Homemade sawdust briquettes are a cheap and safe fuel. If you have the opportunity to make them yourself, then briquettes will make the process of heating your home profitable and environmentally friendly.

Quality requirements

The main requirements for the quality of fuel pellets are:

- The granule should be even and smooth.

- No cracks in the granules, no warping or shedding.

- The granule should be tightly compressed.

- The finished product must have the correct percentage of moisture (it should not exceed 15%).

- It is desirable that the pellets be the same size (mainly manufacturers make fuel pellets from 5 mm to 70 mm in length, and from 6 mm to 10 mm in diameter) regardless of the type of fuel pellet.

- The absence or minimum content of impurities (dust, sand) in the finished product, which deteriorate the quality of pellets.

- Color. For wood fuel pellets, it should be light (lighter is higher quality), since the fewer dark or brown inclusions in the pellet, the less bark and impurities it contains. In peat and plant granules it is dark gray or black.

- There should be no fungus or mold on the pellets.

- There should be no chemicals.

We recommend: Why do we need a heat exchanger in a heating system?

How to store peat briquettes?

Pressed peat briquettes do not crumble and look beautiful. Therefore, they can be stored at home. In general, they are stored in ventilated areas, avoiding their direct contact with moisture (including condensation). Condensation is formed from temperature changes in a humid room or outdoors. If drops of water fall directly on peat wood, they will lose their properties at the point where the water hits and begin to crumble.

Briquettekin stores briquettes for sale in ideal conditions. All briquettes are checked before shipment. Defects, if any, are removed from the batch and replaced with high-quality briquettes. We work for reputation.

The cheaper way to heat your home

The price of fuel for heating a private home is of great importance, but it is pointless to consider it in isolation from heat transfer. We will calculate the cost of heating taking into account both parameters.

Combustion of peat fuel 3 hours after laying

In the area where our expert lives, the following prices are asked for proven types of fuel:

- Freshly cut firewood – 20 USD. e. for 1 m³. Let's tie the price to the weight: 20 dollars for 600 kg or 33 cu. e. for 1 ton.

- Briquettes made from pressed sunflower husks – $57 per ton.

- Peat briquette – 84 USD. e./1 t.

It is easy to calculate that 10 kg of wood will cost 33 cents, the rest of the fuel - 57 and 84 cents, respectively. Then 1 hour of heating on wooden logs costs 33 / 1.5 = 22 cents (remember, the wood burned out in an hour and a half).

In a similar way, we determine the hourly rate for burning briquettes:

- pressed husk: 57 / 2.17 (2 hours 10 minutes) = 26 cents;

- briquetted peat: 84 / 3 = 28 cents.

Burning briquetted sunflower seed husks

Interesting result, right? In our case, heating up an absolutely cold building costs 5.28 USD. e. per day for wood, 6.24 dollars for pressed husks and 6.72 cu. e. - on peat “bricks”.

Please note that we took the cost of raw wood (and it will decay sooner) and divided it by the time of full combustion of dry wood. That is, the difference between traditional fuel and briquettes is minimized. We invite you to track the progress of the experiment on video and listen to an expert’s opinion on this matter.

Prices:

| From 1 to 10 tons | Over 10 tons | up to 1 ton | Up to 500 kg. |

| 6500 rub./ton | 5000 rub. | 200 rub./bag | 200 rub./bag |

We put it in 35kg bags or 1t pallets.

You can buy or place an order by phone, or use the “send request” form on the website.

Pros and cons of using fuel briquettes

The advantages of the new fuel are clearly revealed when it is compared with classic firewood. First, it’s worth discussing the benefits received:

- High calorific value. When burning, pressed sawdust releases 2–3 times more heat per unit weight.

- Increased burning time. Compared to ordinary wood, fuel briquettes last 1.5–2 times longer, which, coupled with the first advantage, allows you to save on heating.

- Environmentally friendly and harmless. No chemical reagents are used during creation; the production of European firewood itself utilizes part of the waste from wood processing factories.

- Low resin release. The chimney needs to be cleaned 2 times less often than when burning wood.

- Less noise, smoke and embers flying to the sides. Sawdust briquettes burn evenly, less smoke is released during the process, and after that there is not as much ash left as from ordinary firewood.

- Ease of storage and use. The shape of the briquettes allows for a minimum of space for storing them, and it is also optimally suited for use in boilers with automatic fuel supply.

- High density. This means that with the same volume, the mass of fuel will be on average 3 times higher than that of firewood. Convenient for transportation, the truck will transport more payload at a time.

- Low moisture content. Such sawdust fuel has a moisture content of about 10%, while dry firewood has a moisture content in the range of 20 to 25%. Euro-firewood has less useless water in weight, and less heat is used to evaporate it.

Comparison of Eurowood with other types of fuel Disadvantages:

- Relatively high cost. Buying sawdust in briquettes will cost more than the same volume of firewood.

- Be afraid of interaction with water. When storing, it is necessary to ensure that fuel blocks are protected from moisture.

- Limited shelf life. Some manufacturers indicate a maximum shelf life of 1–3 years. During this period, fuel must be used;

- Distribution problems. In some regions, compressed sawdust is not used for heating due to the lack of a supplier.

- Fragility. Fuel briquettes are not very durable and can crumble under mechanical stress, especially for low-quality products, which, unfortunately, are now widely represented on the market.

- The smell is from ash. Ash from burnt fuel briquettes has an unpleasant, tart odor.

- No clicking. For some, this may be a disadvantage, because people associate this sound with warmth and comfort, it’s just a psychological feature.

The use of long-burning furnaces and boilers will increase the economic effect of using fuel blocks by approximately 2 times. It is possible to provide a burning time of more than 12 hours with one load of fuel. From here it became possible to smoothly move on to the next question: “How to properly heat with pressed sawdust?”

Material selection

The determining factor in the quality of European firewood is the raw materials for production. Most briquettes for heating with your own hands are characterized by low heat transfer precisely because of incorrectly selected and prepared manufacturing materials.

The most popular waste products currently used are wood processing industry waste – sawdust, shavings, etc.

Wooden briquettes for heating

In reviews of briquettes for heating, the most controversial opinions are expressed about wood models. This can be explained by the characteristics of the original manufacturing material. Unlike coal briquettes for heating, European firewood made from wood waste has one significant drawback - moisture absorption.

This can lead to artificial weight gain due to increased water content. Alas, there are no regulatory documents for the production of Euro-firewood. Therefore, manufacturers most often introduce internal standards, which may not always meet customer expectations. If the technology was followed during the production of wood briquettes for heating, then the product must meet the requirements from the table.

| Characteristic | Meaning |

| Bulk mass, kg/m³ | 125 |

| Briquette density, kg/m³ | 1150 |

| Humidity, % | 6-10 |

| Calorific value, MJ/kg | 25 |

| Ash content, % | 0,5-1,3 |

How to distinguish a quality product from a dubious one? The first one must have a number of qualities:

- Uniform surface firing or correct shape of RUF cubes;

- No condensation on the surface or water stains;

- All briquettes from the same batch have the same shape and size.

But besides this, you need to ensure the correct storage location. To do this, it is recommended to use a separate room with normal ventilation and room temperature. When organizing heating with sawdust briquettes, the fuel is most often stored in an adjacent room.

Peat and coal briquettes for heating

The use of peat and brown coal to make heating briquettes with your own hands is due to large reserves of raw materials. This helps reduce production costs, and as a result, reduce heating costs.

The main problem with peat and coal heating briquettes is the initially high humidity. To solve this problem, it is necessary to perform a drying procedure in special sealed thermal chambers. However, the high cost will not allow most manufacturing enterprises to include them in the technological process.

As a result, peat heating briquettes are characterized by slightly worse parameters than those made from sawdust.

| Characteristic | Meaning |

| Bulk mass, kg/m³ | 280-400 |

| Briquette density, kg/m³ | 500-600 |

| Humidity, % | 12-18 |

| Calorific value, MJ/kg | 16-18 |

| Ash content, % | 3-5 |

Also, unlike European sawdust firewood, ash from peat or coal analogues is practically not used as a fertilizer for the soil. In addition, most often they are made by pressing without additional surface firing. This leads to a decrease in the strength and shelf life of coal heating briquettes.

Technology

The most suitable raw material for the production of peat briquettes is low-lying peat, which does not contain any by-products and consists of fine particles. Fuel bricks from such low-lying peat are high-calorie and the most dense, dark brown, almost black in color. It is important to remember: fuel briquettes made from peat are used exclusively for boilers operating on solid fuel. The technology for producing peat fuel is quite simple and is as follows:

- peat chips are extracted by milling the upper layer of caustobiolite;

- using drying and turning, the crushed raw materials are brought to the required moisture content;

- Then the dried products are stored in piles.

The next production stage is drying the semi-finished product to 9-12 percent humidity. Then the raw materials are separated and sent to the press for briquetting. High pressure and temperature conditions of 200-350 degrees Celsius contribute to the melting of workpieces, increasing their strength.

The result is a peat briquette with certain parameters:

- briquette size – 150 x 70 x 60 mm;

- mass fraction of sulfur – within 0.2%;

- content of ash impurities – no more than 15%;

- standard humidity – within 18%;

- calorific value – from 4500 Kcal/kg.

This briquetted fuel is popular among private owners and is used in furnaces and boilers with controlled air supply. And the ash obtained from the combustion of peat briquettes, according to reviews from amateur gardeners, is an ideal mineral fertilizer with a high content of potassium and phosphorus.

You may be interested in an article on how to connect a gas boiler. You can read about the boiler room in a private house in this article.

In addition to the milling method of extracting peat raw materials, there is also a less expensive and simple method for harvesting sod peat. With the help of special attachments to the tractor, compaction takes place in areas where high-moor peat is being developed.

The completed briquettes are extruded directly onto the field and dried under natural conditions. This type of briquette is called “peat firewood”. The disadvantages of peat fields include low heat transfer and variability of consumer criteria. In most cases, boiler houses operating on solid fuel use peat firewood.

Application of husks

To create fuel briquettes, it is permissible to use even materials that, it would seem, are no longer good for anything. Oat waste, buckwheat husks, sunflower husks - all this is used to produce compressed fuel. Such products have increased heat transfer and minimal combustion time .

Husks for pressing have a moisture content of no more than 8%. There are no harmful impurities in such products, and they themselves are affordable. Briquettes burn for a long time. They are made in such a way that they are convenient to store and transport from place to place.

How to make briquettes yourself?

It is problematic to use fine-grained wood waste (tyrasa, sawdust) as fuel in its “natural” form - due to its low density, it quickly burns out, releasing a small amount of heat, and is poured from the grate into the ash pan, which increases consumption.

If you have free access to an unlimited amount of sawdust and a desire to make it suitable for burning in a stove or heating boiler, you can make sawdust briquettes with your own hands.

What you should immediately pay attention to:

- Only expensive industrial equipment can compress raw materials until lignin is released; for handicraft production, a binder will have to be added to the raw material;

- The formed briquettes must be dried in air and stored somewhere, i.e., it is necessary to take care of a suitable spacious room, a canopy in case of bad weather.

To make briquettes from sawdust, you will need the following equipment

:

- grinder (the finer the fraction of raw materials, the higher the density of the final product), you can use a device that grinds plant materials to prepare compost;

- manual or hydraulic press + suitable containers for molding;

- a container for manually mixing raw materials, a construction mixer or a compact electric concrete mixer.

Features of briquetting

The production of fuel briquettes from sawdust begins with the preparation of raw materials. The sawdust is crushed (if possible) and soaked in water.

Then the binder is added

:

- clay (an affordable and cheap option, added in a ratio of 1:10, but after such briquettes a large amount of ash remains, since clay does not burn);

- wallpaper glue (increases production costs);

- crushed soaked cardboard, waste paper (proportion 1:10, the additive is safe, burns almost completely, but during production it will be necessary to increase the time for drying the formed briquettes).

After mixing manually or mechanically, the raw materials are placed in a mold for sawdust briquetting. This is a rectangular or cylindrical metal container with a perforated bottom and walls. Small diameter holes are needed to drain excess moisture during pressing.

A homemade briquette press can be floor or wall mounted. It consists of a powerful steel frame welded from a profile and a working part. The rod moves by twisting or by pressing on the lever. A manual press with a screw rod squeezes better, but it takes a lot of time to make one briquette. A self-made press with a lever can be equipped with two rods to increase productivity.

You can see the design of the described machine in this video:

Squeezing moisture out of briquettes using muscular effort is difficult and ineffective. The blanks have to be dried for a long time; when finished, they crumble easily and burn quickly due to their low density. To improve product quality, the press for making homemade briquettes is equipped with a hydraulic car jack, securing it upside down on the top beam of the frame. The hydraulic force depends on the characteristics of the jack.

Sawdust fuel briquettes, removed from the mold, are laid out to dry in the sun or in a well-heated room. You should achieve a humidity level comparable to at least that of wet firewood (up to 25%). The drier the fuel, the higher its heat transfer. Solid fuel and pyrolysis boilers are designed to use fuel whose humidity does not exceed 30%.

Extraction of raw materials

I would also like to dwell on peat extraction. This is one of the important stages in the production of fuel pellets. In addition, after peat extraction, huge fields of empty land are formed that need to be restored. Often this area is swamped again, this reduces the risk of fires and eliminates the dustiness of the areas.

Large investments in equipment, development of peat bogs, delivery of raw materials to the production site, all this makes this type of business not very easy and simple. Unlike wood or straw pellets, processing and extraction is a much more labor-intensive technology. When organized, it requires large labor reserves and monetary costs. And in order for it to be profitable, you need to extract raw materials on your own.

How raw materials are extracted and the land restored after mining can be seen in the video below.

Advantages and disadvantages of fuel briquettes

Let's see what good fuel briquettes are for heating stoves, and what are their main pros and cons. Let's start with the positive features:

You are unlikely to have any problems with storing and storing European firewood.

- Ease of storage – thanks to its neat shape, Euro firewood and other briquettes can be stacked in neat, even stacks;

- High calorific value of fuel briquettes - if we compare them with ordinary firewood, they provide one and a half to two times more heat. Due to this, you can save on fuel when firing stoves and boilers;

- Briquettes are a long-burning fuel for any type of stove. Pressed sawdust burns one and a half to two times longer, reducing the number of approaches for adding new portions of fuel. If there is a regular stove in the room that burns with wood for 2-3 hours, then with fuel briquettes this time will increase to 4-5 hours;

- Uniform burning, without unnecessary noise and embers shooting in all directions. In addition, fuel briquettes used to fire stoves emit less smoke and produce less ash, reducing labor costs for cleaning;

- Low formation of resins - this reduces chimney clogging;

- The storage duration of fuel briquettes for heating stoves varies from 1 year to 5 years - it all depends on the manufacturing technology;

- High environmental friendliness - no chemicals are used in the production of briquettes;

- The volume of briquetted fuel consumed during one heating season is 1.5-2 times less than the volume of firewood used during the same time period.

Fuel briquettes intended for heating stoves burn smoothly and softly, releasing a large amount of heat. They do not clog stoves and chimneys and burn almost 99%.

If your home has a long-burning stove or boiler, then you will experience an additional benefit from using briquetted fuel - the combustion duration will increase by another 1.5-2 times, reaching 12-16 hours or more (depending on the model of equipment used).

Unfortunately, it was not without certain disadvantages:

We do not recommend storing briquettes outdoors; they can become damp and spoil.

- Fuel briquettes used to fire stoves are not afraid of dampness. However, they still do not like direct contact with water;

- Some types of briquetted fuel do not tolerate long-term storage - their shelf life is limited to one year from the date of manufacture;

- The cost of purchasing fuel may be higher than purchasing regular firewood - it all depends on the manufacturer;

- In some regions and localities, purchasing fuel briquettes for heating boilers and stoves is more difficult than buying a truckload of ordinary firewood;

- The cost is slightly higher than the cost of ordinary firewood. But due to the high calorific value and long combustion, you can save a little.

Despite all this, briquetted fuel continues to gain popularity.

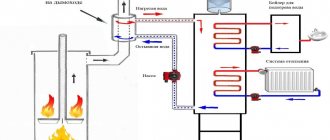

House heating

Fuel briquettes are probably ideal for heating a home. The ability to light the stove once and maintain the fire and heat for a long time without additional tossing allows us to talk about the good characteristics of Eurobriquettes. Let's look at how to heat a brick stove with fuel briquettes within the house.

Of course, pressed bricks will not burn immediately, so let’s figure out how to light fuel briquettes. This is quite simple to do; first of all, you should put tree bark, wood chips, and some dry newspapers in the oven, and then place alternative firewood on top. During kindling, while the wood chips are actively igniting, we adjust the airflow. As soon as the fire starts on the first briquettes, you can add the rest.

Another option is to heat the stove with fuel briquettes after the first batch of wood has burned and decent coals have appeared. In such a firebox, the fire can quickly be caught on Eurobriquettes.

Depending on your needs, we choose the tactics for filling the stove with fuel:

- If you stack the fuel briquettes loosely, at a short distance from each other, the fire in the stove will be quite intense and will generate a lot of heat, which will allow you to quickly heat the house.

- If you stack alternative firewood tightly to each other and cover the vent, the firewood will smolder for a longer time, which is perfect for heating a house at night. At the same time, the consumption of fuel briquettes per day will be several times less than firewood.

In order to roughly understand how many eurobriquettes will be required to heat a house, you should conduct several experiments, each time finding out this parameter in practice. There are too many nuances in this matter.

It is worth noting that fuel briquettes have a specific purpose - to create heat, while firewood can be considered for the purpose of creating a comfortable and cozy environment. For example, is it possible to light a fireplace with fuel briquettes - well, of course, yes, but they will not create the same atmosphere as firewood with its pleasant crackling and uneven fire. By the way, the smell from burning wood is stronger and more pleasant.

In conclusion, I would like to say a little about the storage of Eurobriquettes and compare it with the preparation and storage of firewood. Fuel briquettes are sold in separate packages wrapped in cellophane. In this state, they are not afraid of moisture, which means they can be placed in a utility room, attic, basement or shed. Eurobriquettes look like bricks or tubes, all of the same shape, which is very convenient for storage. In addition, they take up much less space, since for the winter they will be needed several times less than firewood.

If we remember what difficulties await us when collecting firewood, there is food for thought when choosing the appropriate fuel. Eurobriquettes do not need to be sawed, split, stored and dried throughout the year; they are already ready for use.

Since ancient times, the population heated stoves with coal and wood to heat their homes. However, progress does not stand still and humanity has come a long way in all spheres of its life.

The synthesis of scientific developments and modern, high-tech production has made it possible to create a new type of solid fuel - briquettes for heating.

For their production, various raw materials are used - peat, waste from the wood processing industry (sawdust, shavings), agriculture (straw, husks), residues from coal production. The scope of application of briquetted fuel is quite large and varied: heating saunas, industrial and residential premises, heating greenhouses, heating coolant in boiler rooms.

How to make fuel briquettes with your own hands: selection of raw materials and equipment, description of the process

To provide your household with solid environmentally friendly fuel, you do not have to buy it.

It is enough to acquire a constantly renewable source of biological waste, special equipment for processing it, and also study the technology for producing briquettes for heating.

As a result, you will solve two problems at once: you will recycle waste and obtain a source of home-produced energy.

Advantages and disadvantages of briquettes for heating

This type of fuel is used for solid fuel boilers, fireplaces, stoves, and barbecues.

In industrial production, briquettes are made from waste:

- wood processing enterprises - sawdust, wood chips, shavings;

- agriculture - straw, husks, corn, sunflower, buckwheat;

- peat;

- charcoal.

All of the above refers to renewable natural sources.

The main advantage of fuel briquettes in comparison with traditional types of fuel is environmental friendliness and higher heat transfer and efficiency.

]Unlike wood, briquettes flare up quickly and smoke less, which is facilitated by the low moisture content in the material.

When burning, they maintain a constant temperature and do not spark, and the correct geometric shape of the briquettes is convenient for storing fuel.

Disadvantages include poor moisture resistance and susceptibility to mechanical damage during transportation.

Raw materials for homemade briquettes

Wood sawdust

Almost any combustible organic combustible material is suitable for fuel production, including:

- sawdust, straw;

- fallen leaves;

- crop waste (seed husks, dry stems, walnut shells, etc.);

- paper, cardboard.

Any potentially flammable material in a crushed state will do. Give preference to raw materials that are not suitable for use on the farm and must be disposed of.

As a binding component, you can use ordinary clay in a ratio of 1 to 10: one kilogram of clay for every ten kilograms of dry crushed raw materials.

Necessary equipment

There are many enterprises specializing in the development and sale of equipment and technological lines for the production of fuel briquettes. As a rule, manufacturers additionally provide installation and commissioning services. In some cases, they teach how to use the equipment.

You can also buy equipment from companies specializing in the sale of pellets, fuel briquettes and lines for their production.

Granulator for pressing wood chips

To make fuel briquettes with your own hands you will need:

- device for crushing and grinding base raw materials;

- briquetting press (impact-mechanical, hydraulic or screw);

- drying complex.

In the home production of fuel briquettes, you can do without a drying complex if it is possible to dry the briquettes in the open air. And if you decide to make briquettes from sawdust, you won’t need a crusher either.

There is an alternative option: briquetting equipment can be made independently in a home workshop.

Premises requirements

The choice of premises should include the possibility of placing a pressing area, a drying complex, a place for placing finished products and storing raw materials.

The size of the required area depends on the volume of expected production. On average, at least 50-60 square meters should be allocated for the pressing area. m.

When preparing the premises, it is necessary to pay special attention to ensuring good ventilation of the pressing area, reliability of electrical networks and fire extinguishing systems

Description of the briquette manufacturing process

The whole process comes down to the sequential execution of the following operations:

Briquetting process flow diagram

Features of industrial production

In industrial production, 3 technologies for pressing fuel briquettes are used:

- under high pressure on hydraulic presses - the output briquettes are obtained in the form of small bricks;

- under high pressure on shock-mechanical and hydraulic presses - at the exit the briquettes are obtained in the form of a cylinder;

- pressing under the influence of heat treatment and high pressure on screw (mechanical) presses - the output briquettes are obtained in the form of a hollow polyhedron.

As a result of pressing, lignin is released from wood, which acts as a binding component for the formation of a dense, uniform briquette structure.

Origin of biofuels

Peat is a useful fossil fuel that is formed due to the accumulation of plant remains that have undergone partial decomposition in moist soil conditions. In the soil of our planet, peat covers more than 3% of the total dry area. And Russia ranks 2nd in reserves of this mineral after Canada.

Peat can be used as a combustible fuel in 3 types:

- Shredded.

- Lump, low degree of pressing.

- Peat briquette.

New generation peat briquettes are high-calorie products that are obtained through the use of modern technological equipment and have maximum beneficial properties, like biologically clean fuel.

Today, the small-scale thermal power industry of the Russian Federation uses approximately 700 thousand tons of crushed biological clean fuel, 200 thousand tons in the form of briquettes and 100 thousand tons of lump fuel.