close ×

An excellent alternative to solid fuel boilers is a pyrolysis furnace. This is a long-burning stove that operates on a special principle and allows significant fuel savings. Compared to other types of heating devices fueled with wood, such a stove can work much longer, while being in no way inferior in the efficiency of heat supply. Let's take a closer look at how such a stove works, as well as what features of its operation and construction you need to know.

What is a pyrolysis oven

Such a furnace operates on the principle of pyrolysis - organic substances during heat treatment in the absence of a sufficient amount of oxygen are decomposed into solid residues and gases, which in a conventional furnace exit through the chimney, and in a pyrolysis furnace they become the main source of heat. The more the fuel heats up with a minimum amount of oxygen, the greater the percentage of gas evolution.

This technology is developed specifically for the oil refining industry. In this way, fuel for cars is obtained through the processing of petroleum products. In domestic conditions, the pyrolysis process for heating residential premises began to be used recently, but many users have already confirmed its effectiveness and efficiency. The difference is the temperature required for processing. Petroleum products are processed at 800-900 C, while 500 C is sufficient for wood.

Connection diagram of the pyrolysis furnace to the heating network

The gas extracted from wood fuel has excellent flammability, and during prolonged combustion it releases a sufficient amount of heat for heating.

Classification by material

There are a large number of types of pyrolysis boilers.

According to the material from which the boiler is made, stone and metal are distinguished.

Stone stoves today are in fairly low demand and are installed extremely rarely.

A metal pyrolysis combustion boiler is used much more often, because it is more efficient than its predecessor. This unit is also easy to assemble and, if desired, can be moved from one room to another.

Among metal pyrolysis boilers there are:

- Potbelly stove. Perhaps the pyrolysis stove is the most convenient and multifunctional heating system. It can be used for cooking, for baths and saunas, and is also often used for heating both residential and non-residential buildings.

- Buleryan stove. One of the most versatile and frequently installed types of pyrolysis boilers. Provides heating for both residential and non-residential premises.

- Bubafonya stove. The design of such a boiler is extremely simple and understandable to any non-professional welder. In most cases, it is used to warm up non-residential premises.

- Furnace using waste oil (waste oil). It is also not used for heating residential buildings, but is actively installed in non-residential premises. It is very easy to manufacture and is a fairly economical model.

Among brick structures, it is customary to single out only the Kuznetsov stove, which can be installed both in a residential area and in a bathhouse.

In addition, it is possible to cook food on such stoves. Their main advantage is that the heat generated in them is softer, and such stoves retain heat longer.

The main disadvantages are the large dimensions of the oven and its immobility. They are more problematic to install and install. Brick pyrolysis furnaces, most often, look more aesthetically pleasing than metal ones.

How the oven works

Long-burning pyrolysis furnaces are designed according to a special principle. A combustion chamber with a burner is built into the body, where firewood is placed. The main condition for the combustion chamber is tightness. It is designed so that the air flow inside is minimal. The firebox must have a tight door and a reliable valve, and there must also be a supply and exhaust fan. After laying and igniting firewood, the combustion chamber is limited in the access of oxygen.

After the firewood has charred and released gas, it rises through a separate air duct into the second combustion chamber, where it is mixed in the required proportion with secondary air and burned. This process generates heat.

The second chamber, as a rule, is combined with an air duct or the beginning of a chimney. Air is provided by a supply and exhaust fan or a separate fan. If the chimney system is well thought out, then ordinary draft with sealed dampers will be sufficient.

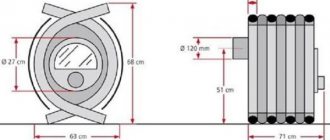

Scheme and dimensions of the furnace

The body also provides a retort - a round part for extracting solid residues of burnt logs. A special feature of the pyrolysis furnace is that the fuel is burned almost completely, with only a small residue of ash, which is removed every few days.

Video

Stove heating in Ukraine, as they say, is experiencing a rebirth. The reasons for this phenomenon are clear without any explanation.

That is why Kharkov innovator Oleg Petrik proposed using pulverized-coal thermal power plant technologies to increase the efficiency of home stoves, and for this it is not at all necessary to have the skills of an experienced mechanic. How can you increase the efficiency of a coal (wood-burning) stove or solid fuel boiler without the use of additional energy resources. The principle of operation of the technology is quite simple : water from the reservoir (steam generator) turns into steam at a high temperature (400 - 500 C) and is supplied directly to the flame, acting as a kind of combustion catalyst that increases the performance of the heating installation. To create an innovation system, you will need: a steam generator, which is made from improvised means ( A canister or pan is suitable, preferably made of stainless steel; even an old moonshine still can be used). A nipple from a car tire is cut into the container. You will also need about half a meter of oxygen hose and about one and a half meters of tube, preferably made of thin-walled stainless steel with an internal diameter of 8 mm, from which the superheater is made.

According to the superheater, steam in a heated state enters through a hole in the stove onto the grate. A steam divider is mounted at the end of the tube to neutralize noise: the tube is cut into slightly less than half with a grinder, in increments of approximately 10 mm, 7 - 10 cuts are made, then the holes are wrapped with a mesh with a 20-30 micron stainless steel window in two or three layers, and it is attached to the tube with a wire with a diameter of 1-1.5 mm.

The rubber tube above the stove must be raised 20-30 centimeters (it is not raised in the photo shown). Although some cooling of the oxygen hose occurs due to water vapor, this must be done for fire safety reasons.

On the subject: Ukrainian craftsman designed an energy-efficient solid fuel boiler and abandoned natural gas

In order, in turn, to speed up the production of steam by the steam generator, when lighting firewood, it is necessary to pour no more than 200 ml of water into the container, it will boil in 5-8 minutes and the device will begin to operate at full power. After this, the steam generator can be completely filled with water for long-term operation of the furnace. The increase in productivity is approximately 50% compared to conventional devices.

Tests of the device showed that the stove's output to operating mode was reduced by half, that is, from 2 to 4 hours. This means that half as much firewood will be needed to heat the stove. The completeness of fuel combustion has improved, the smoke coming out of the chimney is practically invisible, and the amount of ash has decreased significantly. Due to the rise in prices for energy resources, in particular natural gas, such modernization will become relevant for many homeowners. Of course, the proposed solution requires significant improvements: it is necessary to automate the water supply process, optimize the design itself, etc.

However, the option of inexpensive and quick “pumping” of the stove using basic means that can be found in every home will help many people save a lot, and may also be an impetus for the development of new technologies and the birth of new ideas. Read also: Water as a fuel: scientists have found an effective a method of splitting water into hydrogen and oxygen. The craftsman from Kharkov also has a windowed experimental installation for burning coal or wood in a steam atmosphere, or, as he calls it, a “hydrogen potbelly stove.” Help. Superheated steam is widely used to improve the efficiency of turbines in thermal power plants, with the beginning of the last century was used on steam locomotives of all types. Moreover, nuclear reactor designs have been developed in which part of the process channels should be used to superheat steam before feeding it into turbines. It is known that the use of a superheater can significantly increase the efficiency of a steam installation and reduce the wear of its components. Source: ecotown.com.ua Did you like the article?

Share it and you will be happy! A pyrolysis furnace is a virtually waste-free production device that runs both on standard fuel - wood or coal - and uses a by-product of previous processing cycles - gases - to produce thermal energy. Thus, this type of furnace performs the function of a gas generator. Such a stove is almost the only source of heat in cold areas of the planet that are difficult for civilization to reach, where there is no possibility of installing a gas pipeline or a central heating line. On what principle does a pyrolysis stove operate, and the main points in creating it yourself should be considered in the article presented below .This is what a pyrolysis oven looks like

Advantages and disadvantages

Based on their functional features, pyrolysis stoves for heating a home have many advantages, but they also have disadvantages. Let's take a closer look at what the operating principle of a pyrolysis furnace is based on.

Advantages:

- Saving. Fuel burns longer and with better quality, so a heating device operating on the principle of pyrolysis requires less fuel consumption than a conventional stove.

- Ecology. Pyrolysis furnaces do not harm the environment because they practically do not emit harmful carcinogens and other chemicals. The combustion products leaving the chimney contain a very small percentage of CO.

- Fast heating. Due to the lack of oxygen, the combustion process begins quite quickly.

- Efficiency The high temperature is maintained for a long time in autonomous mode due to the massive volume of the firebox. The efficiency of a properly designed pyrolysis furnace can reach 85%.

- Power. The thermal power interval range can vary from 5 to 100%.

- Possibilities. Allows you to connect almost any circuit. It can be used not only for heating, but also for extracting hot water, as well as installing circuits with natural and forced circulation.

- Fuel. Even though it is recommended to use at least 70% wood of the total mass of fuel materials, you can burn almost any waste, from rubber and construction waste to polymer plastics.

- Easy to use. The operation of the furnace requires minimal human supervision; it is enough to load fuel once a day and unload ash every few days.

- Soot. It is produced in minimal quantities due to the fact that the fuel processes the material several times. You don’t have to worry about contamination and the need for constant cleaning of the chimney.

Operating principle of a pyrolysis furnace

Disadvantages:

- Price. Despite the subsequent savings in fuel consumption, the purchase of such a unit will cost a tidy sum, so a do-it-yourself pyrolysis oven will be much more profitable.

- Massiveness. Such stoves have rather large dimensions compared to other heating structures, so the unit is not suitable for a small room. In addition, we should not forget about the fuel storage area.

- Smells. Even taking into account the absence of harmful substances, odors will be present when burning waste, so a good ventilation system must be provided.

- Electricity. For the fan to operate correctly, an uninterrupted power supply is required. If a pyrolysis stove is installed for a bathhouse or other non-residential premises, access to the network must be provided.

- Condensate. At the outlet, the exhaust gases have a fairly low temperature, so condensation will accumulate in the chimney and outlet channel. The design must include a storage tank, and the outlet pipe with the chimney must be large in size with insulation from the outside of the room, otherwise condensation may freeze in cold weather.

- Humidity. The fuel for the stove must be dry, otherwise the pyrolysis process will not take place. Under the influence of heat, moisture will evaporate and dilute the pyrolysis gases.

Approximate diagram of a pyrolysis furnace

Assembly

It is necessary to assemble the structure with your own hands according to the drawings and at the site of operation. After laying the foundation, the internal walls and ash compartment are installed. Structural elements are assembled using welding.

Pyrolysis oven in nature

The heat exchanger, chambers, and grates are being assembled. External stiffeners and walls and a top plate are installed. Water tanks are being installed. Sand is poured between the walls (it is pre-calcined to get rid of organic components), which will accumulate heat and prevent overheating of the structure.

Primitive design of a pyrolysis furnace

The chamber doors are installed. Connection is made to the circuits of the water container. The metal structure, made by hand, is ready for use.

Scheme of a pyrolysis furnace

What types of pyrolysis ovens are there?

Quite a variety of designs can operate on the basis of pyrolysis; their construction largely depends on the type of fuel that will be used in the future. Therefore, before planning a design for your needs, you need to understand what types exist.

Material

- Brick pyrolysis oven

- Metal pyrolysis furnace

Purpose and method of use

- Periodic action. The stove is built taking into account heat-accumulating materials and can release energy for a long time after the end of the combustion process.

- Constant action. The design is characterized by comparative lightness and thin walls, there is no array for heat accumulation, and fuel is burned continuously.

Heat transfer method:

- There is a water circuit.

- Heat exchangers for heating air.

- Without heat exchangers. Heating will be carried out through thermal radiation and convective heating of air in contact with the hot surfaces of the device.

Relative arrangement of chambers and type of traction:

- There is a gasification chamber on top, and a pyrolysis gas afterburning chamber on the bottom. This furnace operates on forced draft, so blowing fans and smoke exhausters are used.

- Furnaces with a reverse chamber arrangement operate on natural draft, gasification occurs from below, and afterburning occurs from above.

Furnace components

Design

Power determines the dimensions of the structure. The DIY creation procedure includes the following operations:

- welding of two chambers and a steel body;

- creating a brick foundation;

- creating holes, organizing air supply into the chambers;

- cutting out a cell window, installing a door;

- a fan is inserted into the outlet pipe;

- the boiler walls are cut out of sheet steel and profiled pipe (for stiffeners) using a grinder;

- a hole is created in the front wall, taking into account the dimensions of the door;

- Stainless steel sheet is used to create a water container;

- The heat exchanger is made by hand from a set of water pipes.

Self-made pyrolysis boiler

Fuel

The optimal raw material for pyrolysis is hardwood, but other types of organic raw materials are also successfully used as fuel.

- wood shavings and wood chips;

- pellet granules;

- straw or cake;

- fuel briquettes;

- coal, coke

If combustible waste is disposed of in a pyrolysis furnace, it is important that at least 70% organic fuel is present in the deposit.

Diagram of the pyrolysis furnace

The physical characteristics of the wood are also important. Thick bark or rot can have a negative effect on the pyrolysis process, reducing the yield of gas emissions several times. Large logs will significantly increase the duration of the process, but will also reduce energy efficiency.

Service Features

An important point is to always keep the fuel dry - the recommended humidity is 12-20%. This is necessary not only for combustion efficiency, but also affects the service life of the stove. Water vapor released during drying and some gases during condensation form tars and acids that corrode equipment. Due to the fact that the calorific value of wood decreases along with humidity, its consumption increases. Burning raw fuel can reduce the life of furnaces by half.

The pyrolysis furnace does not require constant filling with fuel

During pyrolysis combustion, less ash is produced than during conventional combustion. In practice, this means that gasification furnaces require less care to remove heavy ash residues. But fly ash can be deposited in significant quantities on the ceramic fittings of the combustion chamber, leaving less and less space for combustion. The latter can lead to overheating and equipment failure. Therefore, it is necessary to clean the fan blades and chimneys at least once a year.

Almost all types of pyrolysis furnaces require such maintenance.

In addition to high efficiency, saving time on preparing firewood and kindling, pyrolysis stoves, compared to conventional ones, have another serious advantage - the ability to continuously adjust power. This property, together with efficiency, environmental friendliness and automation of combustion processes, makes pyrolysis furnaces the best alternative to traditional heating methods for country houses.

How to make a pyrolysis miracle oven:

Do it yourself

Making your own wood-burning pyrolysis oven is also quite an expensive undertaking, because you only need expensive materials. Despite the high cost, this method will be much cheaper when compared with purchasing a ready-made pyrolysis boiler.

Metal stove

The body of the future design should be made of particularly durable material; the ideal choice in this case would be alloy steel. You will also need tools:

- welding machine;

- refractory bricks - 15 pcs;

- electrodes - 5 packs;

- drill;

- angle grinder - diameter 230;

- metal sheet - thickness - 4mm, size - 7.5 sq. m;

- sensor for measuring temperature;

- grate;

- wheels for a grinding machine - 10 pcs;

- fan;

- doors - 2 pcs.;

- pipes: section 57×3.5 mm, length - 8 m, section - 15.9×4.5 mm, length - 0.5 m, section - section -32×3.2 mm and length - 1 m;

- profiled pipes: section - 2.0×30×60 mm 1.5 m, section -2.0×40×80 mm and length - 1 m;

- steel strips: section 80×5 mm 1 m, section 20×4 mm 7.5 m, section 30×4 mm 1.5 m.

Schemes for metal pyrolysis furnaces are developed taking into account the individual characteristics of the room and the needs of the owners, but the general provisions are the same for everyone.

Subtleties and useful tips:

- It is necessary to weld the body from alloy steel. If another metal is used, it is better to make the structure two-layer.

- At the locations of the ash and combustion chamber, openings for doors are cut.

- The ash pan must be separated with a cast iron grate.

- An air supply section with a damper is installed in the gasification chamber. The passage channel for pyrolysis gases and the air supply system must be placed at the maximum distance from each other.

- Doors made of heat-resistant steel, reinforced with angles or cast iron are installed in previously made openings.

- The inside of the chambers is lined with fireclay bricks.

- To regulate the draft, a damper is installed in the chimney. The chimney must be made from an insulated pipe.

Brick oven

For a 30 kW furnace you will need:

- ceramic bricks - 400pcs;

- fireclay bricks - 100 pcs;

- steel sheet measuring 6x1.5 m, with a wall thickness of at least 4 mm;

- cast iron grates - 3 pcs;

- fan - power of at least 300 W;

- lever thermostat;

- doors for blowing and combustion - 2 pcs;

- welding machine;

- drill;

- grinders with different circle diameters;

- pipes of different diameters;

- profile pipe - 80×40;

- electrodes;

- temperature sensor.

Preparation

First of all, the installation site is prepared. In the selected area, it is necessary to dismantle the floors and dig a hole for laying the foundation, at least a meter deep. To avoid distortion of the structure, the foundation must have a larger area than the furnace. First, layers of sand and crushed stone, 10 cm each, are laid. They are tightly compacted and leveled, and filled with concrete. The height of the foundation is 8-10 cm above the floor level.

The heating system is being installed in the rooms. If water will be used as a coolant, then the project provides for the presence of a reservoir.

The bricks also need to be prepared by soaking them in water for a couple of hours in advance. This will prevent deformation of the fastening solution in the future. The seams will be rubbed with a solution of creamy consistency made from clay diluted with water. If sand is added to the clay, it must first be sifted, so that large fractions will not get into the solution. The proportion of sand in the solution should not be higher than 30%.

Order

The perimeter of the furnace is lined with ceramic bricks, the internal partitions are lined with fireclay.

- The first row is laid over the entire area of the foundation.

- The next row is laid under the stove area.

- Then the rows are laid out according to the prepared drawing. After every 2-3 rows, daily breaks are taken to consolidate the solution.

- Metal parts are installed immediately when laying the corresponding row. The gaps between the masonry and the parts must be well sealed, because when heated, the metal will expand and can damage the seams.

- A cast iron grate is installed in the firebox, which is placed with a small gap.

- The firebox is equipped with a fan.

- After arranging the firebox, the stove is laid out to the end, according to the chosen scheme.

- Particular attention must be paid to the layout of the chimney. It is calculated in advance and laid out in compliance with the parameters. Violation can lead to deterioration of traction.

There is no single mechanism for laying out pyrolysis furnaces; all proportions must be calculated taking into account the space of a particular room. We have prepared several diagrams of different furnaces, but it is better to contact a furnace specialist when designing a future structure and carrying out calculations.

Self-production

It is quite difficult to construct a heating boiler with your own hands. The slightest inaccuracy and it will not work correctly, which can lead to tragedy. Therefore, it is necessary to carefully study the technology of their manufacture and carry out all activities very efficiently.

Shaft-type heating devices

You can create a mine or pyrolysis boiler yourself. The first operates not only on wood, but also on coal, peat or sawdust. You can immediately load up to 50 kg of firewood into its chamber.

When the chamber is fully loaded with fuel and high power, such a device will work continuously for up to 5 hours, at the lowest power (15-20 kW) - up to a day. Its efficiency is 75%. The power of such models can be adjusted automatically.

Pyrolysis model

Yellow or colorless wood gas, released under high temperature, is the heat source in the pyrolysis boiler. For such a heating device, you can only use completely dried firewood, otherwise it will not start. The pyrolysis design can also operate on pellets. Their automatic feeding into the furnace (using special augers) will be an additional advantage of the boiler. The operating time of a model of this type when fully loaded is 12 hours.

Disadvantages - high cost (you can reduce it if you make it yourself), energy dependence (the fan runs using electricity), large size. To make such a device you need:

- pipe and sheet of steel 4 mm thick;

- professional pipes, metal rods with a cross-section of 2 cm;

- electrodes;

- fan;

- fire bricks;

- automatic temperature controller;

- fasteners.

They first draw up a diagram of the future boiler with all the calculations. The most successful design of a homemade boiler in this regard, developed by engineer Belyaev, is taken as a basis. Adjustments are made to it according to the wishes of the home owner. For example, heating can be made more efficient by increasing the volume of the heat exchanger jacket.

Homemade pyrolysis devices must be installed on fireclay brick platforms specially equipped for them. After this, they are connected to the water circuit.

During the first test switch-on, they find out whether there were any errors in the boiler design. If everything was done correctly, the device can quickly switch to gas generator mode. The room will become much warmer within half an hour.

Tools and materials

A wood heating device is the safest design. Its autonomy, ease of operation, minimal risk of explosion, and the possibility of self-production are its main advantages. Its disadvantage is the regularity of adding fuel.

Homemade wood-burning boiler models can be made from the following materials and parts:

- metal barrel (volume – 200 l);

- steel sheet 3-5 mm thick (to create a firebox);

- metal pipe with a diameter of 20 mm and a wall thickness of 3 mm;

- L-shaped pipe (diameter – 20 mm);

- grate;

- doors for the vent and firebox.

Homemade models of wood-burning boilers are made using gas welding equipment and an angle grinder.

Sequence of work

Before starting work, you must carefully consider the design of the device, purchase all the necessary materials and tools.

Cut 3 circles (diameter of each 57 cm): this is the bottom, the top cover and the partition between the ash pit and the firebox. Make a hole with a diameter of 20 mm in two of them.

A strip 400 mm wide and 3600 mm long was cut from a sheet of steel, holes were cut in it for the firebox door, and below it for the ash pan. Weld the sheet together into a circle.

Weld a circle with a hole on top and without one on the bottom. Install a partition with a grate between them.

Weld the pipe and the barrel together according to the “one inside the other” principle. Install a firebox with a blower underneath. Connect all elements by welding.

Attach an L-shaped piece of pipe to the top of the barrel: it will connect the heating container and the chimney. When water heats up in a barrel, it forms steam, which will freely escape into the chimney, thereby preventing the pressure in the boiler from increasing.

Install pipes at the top and bottom for cold water inlet and hot water outlet.

Hang the doors on the firebox and vent.

Install the structure on a foundation made of refractory bricks.

Such a device heats using firewood, pellets or peat, tightly packed inside the firebox.

Even the simplest model of a wood-burning boiler requires care and attention when making it yourself

Criterias of choice

When choosing a heating unit, it is necessary to take into account all the features of the stove.

The advantages of choosing pyrolysis boilers are their high efficiency (up to 85%). This indicator is ensured precisely due to the combustion of gas released in the furnace (pyrolysis gas).

Combustion products do not contain harmful substances and are environmentally friendly. Also, when operating a pyrolysis boiler, it is possible to use a wide range of fuels. There is no need to constantly monitor such a device, unlike conventional ovens. When choosing a pyrolysis oven, you should pay attention to a large number of factors.

For example:

- Purposes of use. For heating non-residential premises, it is better to use metal stoves, because... they are more compact and easier to install.

- Oven location. An important factor in choosing a stove is its location. In the garage, metal pyrolysis ovens are usually used, while at home you can often see stone structures.

- Room volume. To heat a small garage or house, in order to save space in the room, they often resort to using small structures. Often these are metal pyrolysis boilers. Since stone stoves often occupy a larger area than metal products.

- Fuel used. As mentioned earlier, most pyrolysis furnaces are capable of operating on various types of solid fuel. Therefore, this is rarely a limiting factor when choosing a pyrolysis boiler.

Also, there is the possibility of independently designing and manufacturing a pyrolysis boiler, which is a big advantage for many, even non-professional, welders.