Russian stove makers mastered the technology of Dutch oven laying more than two hundred years ago. During this time, the stove has established itself as a reliable, economical and efficient heating unit. At the same time, the Dutch woman has an extremely simple design. After studying the following guide, you can post it yourself.

DIY Dutch oven

What is a Dutch oven

The first Dutch ovens appeared in the 15th century. The appearance and size have changed a little, but the concept remains the same: this is a compact heating and cooking device that can fit into a room of any size and will do its job perfectly.

The small dimensions of the structure are explained by the small size of houses in the Netherlands. Sometimes it was necessary to install a stove in rooms up to 10 square meters. m. Cities in northern Holland are densely populated, the local climate is cold and harsh. Therefore, the stoves here were of the highest quality.

High taxes on land plots forced local residents to build narrow and tall houses. Such projects require special furnace designs. This is exactly what Dutch women look like: stretched upward to a great height. One stove can heat two or three floors of a household. The main thing is to correctly draw up or choose a project for a house with a stove. The very first models did not yet have a grate and ash pan, and they did not install hobs either. All these attributes appeared over time. Thus, the efficiency has become significantly higher.

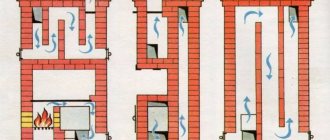

Hot gases in a Dutch oven flow through six lines: three up and three down. The bell system accumulates hot air and increases heat transfer.

A distinctive feature of the first designs was the arched vault, which was then replaced by the standard rectangular shape of the firebox.

There are many varieties of Dutch oven designs with a stove, which are equipped with chambers for baking bread, benches, a tank for heating water and other useful attributes.

But the most popular are Dutch ovens with a stove.

Varieties

As already noted, in addition to the classic version used for heating, there are other varieties.

Dutch fireplace

. It differs from the classic version in that instead of a fuel damper, heat-resistant glass is installed, through which the fire is visible. It looks aesthetically pleasing and is suitable for country houses and cottages.

Dutch oven with oven

. The oven is located above the fuel compartment, which allows you to cook food and baked goods. Dishes from the oven have a special taste and aroma.

Dutch woman with stove

. The hob is also installed above the fuel compartment and is used for cooking or heating any food.

Principle of operation

The special feature of the Dutch oven is its six-channel chimney, inside which heated gas circulates. When smoke comes out of the firebox, it goes up, warming up the walls. It goes through all the channels in stages and goes out into the street through the chimney pipe. Heat is distributed evenly over the entire surface of the furnace walls.

The main design elements are as follows:

- combustion chamber;

- chimney pipe;

- six chimney channels.

Regardless of the dimensions of the furnace, the fuel chamber is always large and rectangular in shape. The appearance of the stove can be anything: semicircular, triangular, square.

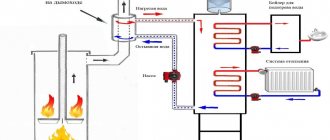

Since the stove always has a large combustion chamber, it can be connected to a water heating circuit.

The chimney is connected on one side to the chimney; a steel pipe acts as a connecting link. The heating level of the oven is controlled using a conventional damper.

DIY Dutch oven construction

The construction of the stove is carried out in the following sequence:

- preparatory work (arrangement of the foundation and preparation of materials for masonry);

- furnace masonry;

- chimney masonry;

- cladding of the structure.

Now let's take a closer look at each item separately.

Preparation

At the preparatory stage, the foundation is constructed and the walls are protected from heat. Since the oven is heavy, formwork will be needed.

When cooking, it is important to maintain the proportion of ingredients

Foundation installation

Work at this stage is carried out according to step-by-step instructions:

- mark the floor taking into account the location of window and door openings;

- using a grinder, cut and dismantle the boards at the marked place;

- build a foundation and fill the mortar;

- lay roofing felt.

After this, a short break is taken until the solution completely hardens.

Substrate preparation and waterproofing

The height of the foundation is such that it is possible to lay two rows of bricks. At the same time, do not forget about bandaging. Waterproofing is laid on top, consisting of several layers, securely attached to the base.

Since most of the heat goes down, you need to approach waterproofing carefully. Experts additionally recommend laying a layer of thermal insulation. Basalt cardboard can be used together with roofing felt.

Before starting laying, you need to pull plumb lines from a strong thread. Thanks to the plumb lines, they prevent the rows from moving during laying. Otherwise, you need to periodically check the evenness of the structure. Any deviations will cause the stove to work ineffectively.

Several continuous rows of bricks are laid in the base

Design features

The Dutch woman does not have a grate. Unlike many other stove models, it has several smoke channels. There is no blower. This feature prevents the fuel from burning intensely. Therefore, firewood burns slowly, evenly and releases heat energy to the room for a long time. That is, the design of the stove is suitable in its operational characteristics for long-burning stoves. Oxygen for combustion enters through the firebox door.

The shape of the Dutchman is elongated upward. The firebox has a rectangular shape. In the classic version, the function of the Dutch oven is heating. The hob, oven and benches were added by craftsmen later. Thus, over time, the standard look of the Dutch woman has changed.

The stove has very thin walls—half a brick. This feature allows the structure to quickly warm up. Combustion products, passing through a long chimney, give off heat to the walls and go out into the street. The design of the furnace can be changed, the main thing is to maintain the basic proportions and maintain the principle of operation.

The principle of operation of the Dutch oven is not to make the logs burn with a strong flame, they should smolder intensely. If the fire is strong, the flue gases will escape through the chimney ducts into the street very quickly and will not have time to transfer thermal energy to the walls. Therefore, small logs, shavings, sawdust and other types of fuel that burn through quickly should not be loaded into the combustion chamber. If the stove is fired correctly, it will warm up quickly and will transfer heat to the room for a long time. The temperature of the outer surface of the wall is usually about 60 degrees.

How to drown a Dutch oven correctly? First, make sure that there is no ash in the fuel chamber and ash pan. Fuel should be placed on the grate. The fuel must be dry. Before setting fire to the logs, cover the ash pit. The logs are laid out horizontally in even rows. Then the firebox door needs to be closed and the ash pan opened.

In order for the stove to distribute heat evenly and intensively over the entire surface, the combustion process should be adjusted. The air supply is regulated using the blower door, which must be opened or closed if necessary.

Operating principle and design of the Swedish oven

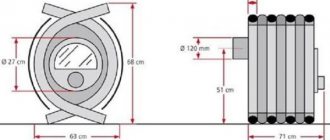

The compact dimensions of the stove (1020x885x2030mm) allow it to be placed in a small country house or dacha. But despite its small size, these dimensions of a Swedish stove are enough to effectively heat a room of 30-35 square meters.

Depending on the type and type of Swede, the designs will vary. So, for example, to equip a Swede with a sunbed, it is necessary to equip horizontal channels with a winter/summer mode. Thanks to a special valve, which is installed in a straight vertical channel, it is possible to block the latter.

In winter, such a valve closes, and the heat moves in a large circle, warming up the entire stove along with the sunbed. And in the summer, the damper opens a direct outlet for warm air into a vertical pipe through which the gases escape outside. This makes it possible to use only the hob and oven without heating the room.

Swedish stove

The “Dutch” design was taken as the basis for the Swedish stove. This model was already very popular, but it did not allow for effective heating of the room, and the fuel consumption was too high.

Taking into account the harsh climate of Scandinavia, the developers improved the “Dutch” model and added a hob with an oven. Thus, elements were added not only for cooking, but also for heating water and drying clothes.

Whatever the design of the stove - with a sunbed, with an oven or just a stove - the principle of its operation will be the same: channel, like the “Dutch”.

Swedish: scheme

The metal oven is located on the side of the firebox and is designed to directly transfer heat into the room. But cooking and baking is not the main function of the oven.

After lighting the wood, it warms up in literally 5 minutes. The figure shows why the oven heats up so quickly.

Swedish design

Before going down, combustion products heat the oven in the top and sides. On the other hand, the stove is heated by the firebox. The stove warms up from the firebox, heating the room itself.

The upper part was originally designed for the purpose of drying clothes; it is heated by the stove and the ducts running behind it. The channels, going around the entire oven, go into vertical channels and transfer heat to things that are hung out to dry.

How the Swedish oven works

The design of the Swedish stove is the result of improved engineering. Unlike Russian and Dutch stoves, it has a more complex device with high efficiency. It has significantly greater thermal power and heat transfer.

If we take the same amount of material and fold the “Dutch”, we will get a power of 2500 kcal/hour, while the Swede will produce all 3500 kcal/hour. In this case, it will be enough to lay only 2 portions of firewood per day to keep the house warm.

Swedish woman in a modern interior

If in Scandinavia the Swedes were traditionally installed between the kitchen and the bedroom so that on a cold winter night it would warm the room, today in stylish and modern houses you can increasingly find a stone structure that stands between the living room and the kitchen.

At the same time, it performs a double function: it serves for cooking and is the main decorative decoration of the living room. On one side it can be equipped with an oven, and on the other with an open fireplace, decorated with an openwork forged damper.

Swede with fireplace

The high efficiency and efficiency of the stove is due to a complex smoke exhaust system, which allows rational use of the heat generated by burning wood. One of the undeniable advantages of the design is the ability to create winter and summer versions of the stove.

The fact is that each type has its own smoke path. This makes it possible to cook food in summer without heating the room.

Many summer residents are familiar with the situation when, at the beginning of the heating season, when lighting the stove, the room begins to smoke. There is also a separate smoke exhaust system, which allows you to effectively use the stove with different functions in both winter and summer.

Advantages and disadvantages

Any stove has advantages and disadvantages. The Dutch oven is no exception. The design is not complicated. Compared to a traditional Russian stove, the advantage of a Dutch stove is that it gets hot much faster, and its compact dimensions allow it to be built in any room. Dutch is more economical when it comes to calculating the costs of building materials. If a small Russian stove is made of 1200-1300 bricks, then a Dutch stove needs only 700 pieces. That is, if it is necessary to build an economical stove, the choice will be in favor of the Dutch oven.

For those who need a stove for a country house, where they need to warm up the room in a short time, the Dutch oven will be indispensable. In a Russian stove, the fuel must burn for several hours before the room becomes warm. A Dutch oven for a summer house can be lit in half an hour. You can load the firebox immediately “to the fullest extent” and get maximum efficiency.

The advantages of the Dutch woman are as follows:

- The stove can be modified by adding useful options - a water tank, an oven, a fireplace insert, a stove bench.

- Compactness, small dimensions. A normal good oven with high thermal characteristics occupies an area of 50x50 cm.

- Warms up the room very quickly. Heat is distributed evenly to the upper floors.

- The costs of constructing the structure are minimal. Expensive refractory bricks are used only for the combustion chamber. For the rest of the stove, you can use used building material.

The Dutch oven also has disadvantages:

- When compared with a Russian stove, the efficiency is not high - 40-45 percent, if operated correctly.

- There is a possibility that the chimney ducts will draw in cold from the street.

- Heat the oven frequently, at least twice a day.

- Fuel consumption is high. If you do not monitor the view and leave it open, the Dutch oven will quickly begin to cool down.

- If you heat a Dutch oven excessively, carbon monoxide can escape into the room.

Dutch models that are currently popular:

- with fireplace function;

- with baking oven and hob;

- with a tank for heating water;

- stoves with a stove bench.

The compactness of the Dutch oven outweighs all the disadvantages when you need a small oven. If the house has many windows, doors, rooms, and a large area, then other designs will benefit: a Russian stove, a bell stove or a Swedish one.

Tips and tricks

For a room with an area of 40 sq. meters, you can calculate the required dimensions of the furnace. With a furnace height of 210 mm, the optimal size is 780 x 580 mm.

To improve the quality of the masonry, before using the bricks, experts advise immersing each of them in water for several minutes, which helps remove air bubbles from them.

Thanks to this procedure, the brick will not absorb the mortar, which will improve the quality of the masonry.

Since the door frames installed during the masonry process are subject to temperature effects, before installing them in a Dutch oven, they must be wrapped with asbestos cord or coated with varnish that has fire-resistant properties.

The most common problem that requires repairs to a previously used furnace is chipping of bricks at the ends and corners of the furnace. To prevent this, during the masonry process they finish with specialized plates of various shapes.

Another important indicator of the quality and long-term operation of a Dutch oven, according to experienced stove makers, is the distance between the chimney pipe and the roof slabs. Ideally, it should be at least 15 cm.

Experts recommend building walls one brick thick for small structures, and two bricks thick for more massive structures. Only this thickness can ensure maximum heat transfer with minimal fuel consumption, characteristic of a Dutch oven.

Rules for constructing a Dutch oven

Any modification of the Dutch woman requires compliance with certain rules:

- It is necessary to install a foundation separate from the house. Therefore, you need to think about the construction of a Dutch house at the stage of building a house. You need to find a specific place for the stove so that the chimney ducts do not fall under the beams or roofing. If you do not plan for the construction of the Dutch house in advance, you will need to dismantle the floors. The foundation must be done, since the stove has a lot of weight. If you connect the base to the foundation of the house, cracks will appear due to the difference in loads. The stove will shrink, become deformed, and the chimney will move. As a result of depressurization of the seams, the stove will become a fire hazard, and carbon monoxide smoke will penetrate into the house.

- The foundation must be covered with a waterproofing agent.

- At the stage of constructing the combustion chamber, high quality refractory bricks should be used. You can't tie it with a regular one. The mortar for masonry must be special - clay, fireproof. You can purchase a ready-made mixture or make it yourself.

- It is important to maintain the thickness of the seam - the combustion chamber, no more than 5 mm, the entire rest of the structure - from 5 to 8 mm.

On a note. To ensure that the seams are even, use a wooden strip between the masonry.

Historical facts

A game of contrasts in modern kitchen design

In fact, Dutch ovens are still in use today, although they have been replaced by various heating boilers. Previously, people were simply deprived of alternatives. Dutch stoves were installed in houses, or rather huts and towers, as a more modern alternative to Russian stoves. Their cardinal difference from their predecessors was one characteristic feature - the presence of a chimney, which was completely absent in Russian stoves and the smoke formed during the combustion process either filled the home or was released through a special hole in the nearest wall, the so-called dormer window.

The initiative to introduce new heating structures at that time was taken by the Russian Tsar Peter the Great, who arrived from Europe. The problem for local residents was that there were no detailed instructions, recommendations and technologies for laying such stoves. At the same time, there was a set of certain principles that made it possible to create similar designs. Despite their absolute external similarity, they could have completely different internal structures, and only later could they be standardized, unified and modified in such a way that they could be easily created according to a set of schemes without lengthy training of the stove maker.

Dutch is extremely simple to construct

Beautiful interior in country style

Magnificent mosaic finishing of the Dutch oven

Some well-known designers even managed to create models that were popular and quite effective in terms of heating homes. As a result, they acquired a whole set of advantages, which attracted special attention to them.

Fire safety measures

Dutch is considered a fire-resistant structure.

However, as with the construction of any furnace, certain rules must be followed:

- An asbestos sheet is placed in front of the stove to protect against accidental ignition of fallen coals or sparks from the firebox.

- Systematic cleaning of the chimney to remove soot accumulation is required.

- There should be no furniture or household items within half a meter from the stove.

- The fewer metal elements used in the construction of the Dutch house, the safer it will be. However, when constructing an arch, the opening above the cooking zone must be blocked with a steel corner.

- At the junctions of metal elements with brick, a 0.5 cm layer of building mixture and an asbestos cord are laid.

- When laying a hob on a brick, you need to apply a clay layer to protect it from overheating.

Materials and tools for construction

Before laying out the Dutch oven, you need to select a good clay solution. The mixture includes sand, red clay and plain water. The ratio is selected for the specific quality of the clay.

The fewer grains of sand natural clay contains, the less of it goes into the solution:

- 1:2.5 - clay to sand ratio for oily clay;

- 1:1.5 - ratio of components for clay of medium fat content;

- 1:1 - equal proportions for thin clay.

On a note. Cement should not be used for laying the furnace; such a solution will crack due to temperature changes, and cracks will appear along the walls of the furnace.

In order to lay out a Dutch oven for a brick cottage, you should stock up on the following materials:

- fireclay brick for firebox;

- ordinary ceramic brick;

- concrete mortar for the foundation made of cement, sand, gravel and water;

- mortar for laying the main part of the furnace;

- the required amount of roofing felt for waterproofing the foundation;

- boards (boards) for formwork;

- grate;

- blower;

- steel firebox door;

- gate;

- steel rods and reinforcing wire;

- steel wire for dressing;

- asbestos cord;

- hob.

You will need the following tools:

- construction trowel;

- level, corner, plumb line, tape measure);

- construction stapler;

- rule;

- Bulgarian;

- two shovels - scoop and bayonet;

- construction trough for mixing mortar;

- bucket;

- rubber hammer for bricklaying;

- an ordinary hammer and nails for constructing formwork.

Furnace laying

Before you start laying, you need to prepare a solution and perform a few simple steps to prepare the foundation.

Preparation of the solution

Sift the sand and break up large pieces of clay. The crushed clay also needs to be sifted. The mesh from an armored bed will perfectly cope with the functions of a sieve. If this is not available, use a simple sieve with cells of similar sizes.

Soak the clay in water for several hours. Drain off any excess water not absorbed by the clay.

Important! You need to soak not only the clay, but also the bricks. To do this, just immerse them in water for about a minute. Thanks to this treatment, the bricks will not absorb water from the clay mortar.

Let the clay swell and mix it with sand in equal quantities. Add about 1/8 of clean water to the same mixture. Carry out the calculation in accordance with the resulting volume of sand-clay mixture.

Preparatory work

The weight of the stove is considerable, so they make a full-fledged concrete foundation using formwork:

- Mark the location of the furnace. It is necessary to ensure that the door and window are not on the same line and provide a chimney outlet. The size of the foundation will be 15-20 cm larger than the dimensions of the stove. Using a grinder, dismantle the wooden floor covering.

- Formwork is arranged and the foundation is poured with concrete (the upper level should not reach the floor surface by 2 bricks). Concrete is reinforced not only around the perimeter, but also in depth. To save on materials when constructing a foundation, it is sometimes made of rubble (broken stone, brick or any large construction waste is used).

- Next, they take a break from work for 20 to 25 days to allow the concrete to set.

- Lay a layer of roofing felt folded several times for waterproofing. The layers of roofing felt are connected with a stapler. This is a very important stage, since the Dutch oven is capable of transferring some of the heat to the floor. On a note. If climatic conditions are such that the soil freezes up to one and a half meters, it is recommended to use a layer of basalt cardboard for thermal insulation.

- Plumb lines are arranged to ensure that the oven is strictly vertical. To do this, strings or ropes are pulled, which will act as beacons. If this is not done, each row will need to be monitored not only horizontally, but also with a protractor with a vertical plumb line. If the design “goes to the side,” the performance characteristics of the stove will deteriorate.

- Bricks are selected for masonry and dry masonry is carried out. Mix the clay-based solution in an amount sufficient to use it at a time. On the second day, this solution will lose its quality. Clay is placed in a trough, filled with water and allowed to soak for about 2 days. The solution is stirred, breaking up lumps. The required plasticity is achieved using sand. To improve the quality, the mixture is kneaded with a construction mixer.

On a note. If the stove is being built in winter, the bricks must be brought from the street into the room in advance.

How to lay out a high-quality Dutch oven if you have no experience as a mason? There is one trick: before laying out the stove on the mortar, you should practice “dry”.

Plaster, cladding and décor design

Not every craftsman can tile it like a real Dutch woman. The design of the tiles and the method of their installation makes this a difficult task. However, if during the process the space of the boxes behind the tile is filled with fireclay sand, the thermal inertia will increase manifold. It should be taken into account that in this case its weight will become significantly greater. I would recommend tiling for old surfaces.

Preliminary plaster will help seal microcracks, and the tile will increase heat transfer. It is imperative to lay a reinforcing mesh into the plaster. And for tiles use a special heat-resistant adhesive. After this, there is still no guarantee that the tiles will not begin to sag after accidental overheating. Therefore, they are most often plastered if the masonry is sloppy.

For plastering you will need a composition slightly thinner than that used for masonry. To do this, you can add a tenth of sand to it. A binder should be added to the plaster composition. This could be asbestos fiber, glass fiber; people often used chaff formed during threshing of grain. This greatly increases the integrity of the layer when drying. Plaster with warm plaster, cutting out cracks and seams, cleaning from dust and thoroughly moistening with water.

Nowadays it is easy to purchase fine mesh metal mesh. Secure it to the surface of the masonry with nails, driving them into the seams at an angle and the plaster will not crack. The applied layers should be thin, about 3 mm. First comes a thinner layer, then a thicker one. After setting, while the surface is still soft, you should rub it with a grater, smoothing out minor flaws.

After complete hardening, the surface is covered with lime milk. The corners can be decorated with tiles imitating artificial stone, glued with heat-resistant glue. If new ceramic bricks were used, the stove can be carefully “embroidered” and coated with heat-resistant varnish.

Detailed order diagram

Before starting laying, you need to immerse a batch of bricks in water. This measure will further prevent moisture from being drawn out of the solution and provide better adhesion. The first two rows, which are laid out to the level of the finished floor, are not included in the diagram.

Description of the arrangement of a Dutch oven with a stove:

- 1 row is laid in a continuous layer, at the level of the floor surface. You should fold it as carefully as possible so that the entire further structure comes out smooth.

- Rows 2 and 3 are also laid out in a continuous layer, and the masonry is checked horizontally.

- In the 4th row, a blower is laid, maintaining a gap of 0.5 cm, and an asbestos cord is placed in it. It is needed to ensure that the metal element does not split the bricks during thermal expansion. To strengthen the door between the bricks, rods are placed in the mortar. Laying is done from right to left. The suture dressing is performed in half a brick.

- In rows 5 and 6, part of the blower and ash pan should be covered. For this purpose, the brick is sawed lengthwise and a metal plate measuring 0.35 x 0.4 cm is passed under the masonry.

- In the 7th row, a firebox is formed from refractory bricks and a firebox door is installed. The grate is laid, the gap at the seam is left at 0.3-05 cm. The brick of the rear wall of the firebox is laid at an angle. The gap must be filled with sand.

- In the 8th row, the blower door is closed, forming an ash pit.

- From rows 9 to 14, the fuel chamber is lined with refractory bricks.

- In the 10th row, the combustion chamber is covered with bricks. The next step will be to lay the hob; to do this, prepare the bricks. 0.5 cm grooves are cut into them, which will allow the metal to expand and not destroy the oven. The edges of the hob are secured with a steel corner.

- Rows 11-13 - lay out the area above the stove.

- The 14th row is laid out like 13th, but grooves are cut in the bricks into which a steel corner is inserted. It will be necessary to place bricks of the next row on it.

- The 16th and 17th rows are laid out like the 15th, but a door is installed in it for cleaning the chimney. They also provide gaps and lay asbestos.

- Rows 18-22 - laying the smoke return channel and covering it.

- In row 23, a damper is installed in the chimney. The bricks are adjusted to size, and asbestos is laid between the metal and the brick.

- In rows 24 and 25, the lowering and lifting channels are combined.

- In row 26, the formation of the chimney begins. At this stage, it is important that the surface inside the chimney is as smooth as possible. The solution is immediately cleaned off so that it does not worsen traction in the future.

- In rows 27 and 28, the chimney is being laid; the brick is moved by 40 mm to narrow the structure.

- Rows 29-30 continue laying the chimney and install a slide damper to adjust the draft. A gap of 0.5 cm leaves room for metal expansion. Laying asbestos.

- In row 31, the size of the chimney is reduced to the original size.

- From the 32nd row the chimney is being laid. Not reaching the 3rd row to the roof, the pipes are “fluffed” to protect the wooden structure from fire. The thickness of the pipe is one and a half bricks.

Installation of a Dutch oven on a foundation

One of the main advantages of a Dutch oven is the ability to fit it into any design while providing high-quality room heating. The shapes and designs of these stoves are varied, and you can choose a model according to the desired size and function. The compactness of the Dutch ovens and the fact that both the stove and its service area take up very little room area speak in favor of these heating units. It is possible to build a stove designed by Utermark - it is perfect for heating a country house or a private house. A brick stove lined with tiles, majolica or tiles will not only heat, but also serve as an additional decoration for the house.

All brick ovens are massive and require a solid, reliable foundation. A reinforced concrete foundation is most suitable for this purpose. Reinforcement must be done not with flat meshes and frames, but with a three-dimensional frame. Reinforcement, concreting and maintenance of concrete are carried out using standard technology; full strength gains occur after 28 days. It is possible to start masonry work earlier, when the strength has reached 75% of the brand strength. Before masonry is carried out, the foundation is waterproofed, vertically and horizontally. You can use both coating and roll materials.

Basic materials for laying the furnace:

- A clay-sand mortar mixture in an approximate proportion of 1:1 (the ratio is unstable and must change to adjust the fat content of the solution. It all depends on the fat content of the clay used; the higher it is, the greater the proportion of sand in the solution required).

- Brick for the combustion chamber - fireclay or red ceramic refractory; brick for chimney ducts and furnace walls - ordinary ceramic brick, it is possible to use slotted and hollow bricks. Sand-lime bricks and dry-pressed products - adobe bricks, slip bricks, etc. - are not used.

The specificity of Dutch ovens is their special elongated vertical design, so the height of the combustion chamber from the level of the foundation edge can be greater than that of other models of ovens. But the fireboxes are usually located no higher than 250 mm above the floor level so that the stove heats up more evenly.

Laying order (example - a small stove 52*52 cm)

- Sand is poured onto the foundation waterproofing in a layer of up to 50 mm, leveled horizontally and carefully poured with water until the layer is completely wetted.

- A feature of the stove masonry of many stove models is that the first rows are laid dry - without bonding with mortar. For a small oven, 12-14 bricks are needed to lay rows along the base. The first row of bricks is laid as a bed.

- The second and third row of bricks are placed on the bed, but already on the mortar.

- The fourth and fifth row will be the beginning of the internal partition of the chimney channel. For future cleanings of the chimney, it is necessary to leave holes; for this, bricks are laid dry in these rows, they will be “knocked out”. Masonry, even without mortar, retains heat much better than a built-in metal door; for this reason, they prefer not doors, but knock-out bricks laid without mortar.

- The firebox door is installed, but the height of its installation depends on the overall height of the stove, and can be installed not in the sixth row, but much higher.

- In the seventh row, the bricks are laid flat (in a bed), except for the back ones - they are placed edge-on. Then all the rows are laid on the bed, and in the eighth row (or in the row closing the firebox door) the laying is done as in fireplaces - with bevels.

- Along the ninth row, an offset is made to the inner surface of the combustion chamber. Heat-resistant material is laid out on the shelf under the hob - kaolin wool, asbestos cords. Then install the slab.

- In this example, chimney channels are formed from the tenth row. In small stoves, it is more rational to make chimneys from metal rather than brick, so as not to burden the structure.

- The view, or stove valve, is installed in this example in the eleventh row, then the chimney pipe is installed.

- The sand, which serves as a shock-absorbing layer, should not spill out along the contour, so it is protected with a plank or plinth, installing them on the upper edge of the foundation up to the first brick row or slightly higher.

- They finish the stove - jointing, plastering or tiling, tiles and so on.

The stove dries out and the clay mortar in the seams sets only naturally, and the first firebox is made no earlier than two weeks later - after the stove masonry has completely dried.

Read with this

Pipe arrangement

If you think about the chimney design in advance when building a house, then laying the pipe will not be a problem. But it often happens that a stove is built in an already built house.

When the place for the chimney is not prepared in advance, additional preparatory work must be carried out. Remove the roofing and install lintels at a short distance from the ventilation ducts. If it is impossible to partially dismantle the roof, use a grinder or jigsaw. Asbestos sheets are laid between the pipe and the wooden roof elements. They are attached to the rafters using self-tapping screws or construction staples. Carrying out fire prevention measures at this stage is a very important point in the construction of the furnace.

When erecting a pipe on the roof, the craftsman should be careful. This is especially true for installing a chimney in old houses.

To enhance traction, the corners of the bricks are rounded. If this is not done, the draft will be weakened by turbulence, and the efficiency of the furnace will significantly decrease.

The pipe should rise 0.6 m above the roof. The penultimate 2 or 3 rows slightly expand the pipe. This is necessary to protect the roof from water. In the last row, the chimney is narrowed to its original size. Be sure to install a protective metal cap against rain and snow.

To correctly calculate the height of the pipes, they are guided by the height of the ridge. When the pipe passes through the hole in a well-insulated attic, you can do without additional thermal insulation.

The opening between the pipe and the roof should be carefully closed. All cracks are clogged with heat insulation. The best material for this is stone wool or foam glass.

Advantages and disadvantages

Each stove has its advantages and disadvantages, and the Dutch oven is no exception. Thanks to its thin walls, it is more efficient than a Russian stove. Due to its fairly compact size, it can be installed in any room or building. Savings are also important. The construction will require half as much brick as a Russian stove.

In addition, the Dutch woman has the following advantages:

- if necessary, the design can be modified and supplemented with functional elements;

- the design can have different sizes and shapes (round, rectangular);

- the room warms up very quickly;

- the height of the structure does not in any way affect productivity;

- To build a Dutch oven, you need to spend a little money; previously used bricks will do just fine.

The operating principle of the oven is very simple

Dutch is ideal for cottages and other buildings used for a certain period of time. It will take a little time to warm up, and the room temperature will reach a comfortable level after a few hours. If necessary, load the firebox as much as possible, which will speed up heating.

Before building a furnace, you should familiarize yourself with some of the disadvantages of the device:

- even proper construction and operation does not ensure high furnace productivity;

- the channels are designed in such a way that there is a risk of drawing in cold air from the environment;

- the stove needs to be heated regularly;

- despite the savings, a lot of fuel is spent on heating;

- the view must be constantly monitored, otherwise the structure will quickly cool down;

- It is unacceptable to heat the oven to the maximum temperature.

A modern Dutch woman is equipped with the following elements:

- fireplace;

- oven;

- hot water tank;

- sunbed;

- heating and cooking surface.

First of all, the Dutchwoman is chosen due to its simplicity of design, operational efficiency and cost-effectiveness.

During construction it is worth considering many nuances

Finish stage

Finishing work is the creative stage in the construction of the Dutchman. If the stove is laid using new red ceramic bricks, then cladding is not required.

For Dutch cladding, clinker or tile tiles and decorative plaster are used. The Dutch woman looks great in the interior. In color it can either merge with the interior or contrast. A stove lined with mosaics or decorative stone looks very good.

In past centuries, the outer parts of the first Dutch ovens were decorated with tiles. The ordinary stove looked like a work of art.

The classic rectangular stove, lined with ceramic bricks, is widely used. Round-shaped Dutch women have a number of disadvantages during operation, so they are less common.

On a note. The stove can be whitewashed or painted using heat-resistant decorative coatings.

After veneering, take a break for two weeks. The structure must dry. The firebox door is left open during this time.

After the Dutch oven has dried, you can light the stove for the first time. There is no need to rush things. If the first firebox is made with a damp stove, the structure will crack and all the work will be lost.

For the first burning, take a fifth of the full portion of fuel. It is good to use wood chips or shavings for firing in test mode. You need to take the smallest logs.

Open all valves and dampers. In gentle mode, the oven is operated for approximately 7 days. The oven temperature should not exceed 600 degrees.

When burning low-quality, high-ash fuel, a large amount of soot quickly appears in the chimney of a Dutch oven. Therefore, it will have to be cleaned often, but it is better to select good fuel. The most suitable logs for heating a stove are made from wood from not very old oak, alder, linden, and fruit trees.

On a note. If you use aspen logs as fuel from time to time, the chimney will clean naturally.

The first Dutch firebox with stove

The first firing of the furnace can be done after 10-14 days - this time is necessary to completely dry the structure. The firebox door must be left in the open position. If construction work was carried out during the cold season, then a lamp can be placed inside the Dutch oven to speed up the drying process. Do not heat a damp oven prematurely, otherwise it may crack.

First of all, you should check the draft; to do this, set fire to a sheet of paper in the fuel compartment. If the smoke goes away normally, then you can start testing the furnace. The Dutch firebox is filled 20% with brushwood or sawdust and ignited, while all dampers must be completely open. The firebox in this mode will completely dry the structure. During the first week, it is necessary to ensure that the temperature inside the oven does not exceed 600°C.

Recommended Posts

Water heating at home

Installing a metal stove in a bathhouse

Wood-burning potbelly stoves for the garden

DIY chimney draft amplifier

Cast iron stoves for baths

The best sauna stoves for a Russian bath

Results

It is quite possible to build a compact and effective Dutch oven with your own hands. You need to strictly follow the order, take your time, and take the necessary technical breaks. Comfort and warmth in a house with such a stove are guaranteed.

Dutch ovens are almost the only heating devices that can be used by home craftsmen who do not have the skill to build ovens.

Large material costs for the construction of a Dutch house are not required. It can be built from a small number of bricks, and this will not affect its heating function.

When constructing a furnace, you can use hollow bricks or its halves. Fireclay brick is needed only for the firebox.

The main thing in this work is to make a clay solution of good quality and not make mistakes in the order. Such a stove will immediately begin to release thermal energy and will not create problems in the future.

In order not to doubt the quality of the solution, you can use ready-made oven mixtures. The cost of such building material is small and will hardly increase the cost of constructing a furnace.

Types of Swedes

There are several popular types of Swedish oven.

- The stove in the form of a fireplace is designed in such a way that the hob opens into the kitchen, and the decorative part with the firebox and fireplace portal opens into the living room.

- Swedish, equipped with a sun lounger. This stove design is quite complex, but in winter it functions as a very cozy and warm bed.

- Swedish, equipped with a hob and oven. The back part of such a stove heats the room, and the functional front part is located in the kitchen.

The choice of stove design depends on the area of the room and the functional tasks that it must solve. If the stove is needed exclusively for cooking in the country and is not intended to heat the house in winter, then you can opt for a compact design.

Swede with one plate

If the stove is installed as the main heating device, then it is better to choose a model that can heat several rooms at once.

It should be said that the Swedish stove design is an ideal option for a small country house, in which the owners live not only in the summer.

Of course, it is also suitable for a small cottage. But the Swede gets damp quickly enough, which means it requires constant use. Otherwise, it will have to be dried for a long time each time before putting it into operation, and this significantly reduces its efficiency.

With regular use, such a stove, equipped with a comfortable hob and a functional oven, will become an indispensable household assistant and will give warmth and comfort to the house.