Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

The Bullerjan stove (bullerjan, buller, buller, breneran) was not invented by ordinary Canadian guys, as some claim, but by fairly competent heating specialists. The rest of the history of the buller is true: it was actually invented in Canada for the needs of lumberjacks and more on a whim, without further ado. It turned out well, it looks impressive, and there are more than enough people who want to make the buller themselves. This article is written about some of the obstacles and subtleties that may be encountered along this path.

A little history

In Canada, forests are felled not in blocks, but selectively, and teams of lumberjacks lead a nomadic lifestyle. Logging is carried out more in the cold season, when the vegetation does not vegetate, life in the forest comes to a standstill and the damage to forest biocenoses from logging is minimal.

The climate in the Canadian taiga is even harsher than the Siberian one, and even with a 4-hour shift, workers froze into icicles. Comfort and civilization in general in the wilderness is zero. Therefore, lumberjacks needed a heating stove that could be carried with them without cluttering the body, and could be carried into a residential trailer by hand. And this stove was supposed to heat up a housing of 20-30 cubic meters in a maximum of 20 minutes. Waste fuel: branches, wood chips. The firebox is large enough to fit pieces of thick, gnarled logs into it. Operating time from one fill of fuel is at least 8 hours. Where to get up at night and heat it up, when during the day your bones have been broken to the point of pain.

Depending on the weather and season, the heating power must be adjusted. The adjustment should be simple so that it can be performed by an untrained person or after a one-time introductory briefing.

At the same time, the stove had to be inexpensive and quite technologically advanced. Electronics requiring power supply, and automation in general, were excluded: the slightest breakdown in the taiga could cost the lives of an entire brigade. The use of expensive and special equipment-requiring special alloys was also excluded: Buleryan had to be available for production in any mechanical repair shop.

Additional requirements were put forward for operational safety. Firstly, the formation of waste must be excluded under any combustion mode and under any regulations of regulatory authorities. Secondly, the body temperature of the stove should not exceed 60-70 degrees, so that if you accidentally bump into it while asleep and “out of a hangover,” you will not get burned to the point of losing your ability to work. They say that Canadian lumberjacks know how to distill moonshine from pine cones. It's called sterno.

Buller device

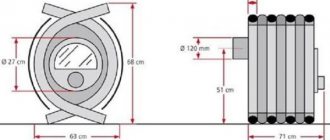

Scheme of the Buleryan stove

Canadian engineers took as a basis the long-known and well-proven design of a slow-burning steel convection-tube air boiler; in common parlance - a heater oven. This is how the design appeared, the diagram of which is shown in Fig. The wide sealed firebox door is equipped with a blower in the form of a pipe with a rotary damper - a throttle. The throttle regulates the furnace power. Sometimes its handle is equipped with a scale, graduated in degrees of outside temperature, and a movable stop-limiter. At the same time, the throttle can be closed tightly if it is necessary to turn off the stove or stop the draft so that the room does not get cold.

Next comes an extensive firebox with curved walls. The batteries of heat exchanger pipes are recessed into them by 2/3 of the diameter. These 2/3 are the first highlight of the buller. With this ratio, 70% of the heat released in the firebox in smoldering mode is released to the air in the pipes. Another 10% spreads over the metal welded body of the furnace and heats the air in addition to them. At a room temperature of 20-25 degrees and a thermal power of 10-20 kW, this requires a temperature gradient of 40-45 degrees, i.e. the body of the furnace will be heated to 60-65 degrees. 5 degrees will give some margin of safety.

At 1/4 of the height of the firebox from the bottom there is a horizontal grate made of thick, at least 4 mm, steel, or a grate made of cast iron grates. At the top, also 1/4 of the height of the firebox, but already from the top, a horizontal partition that is not full in length is welded into the firebox, not reaching its front wall by 1/4-1/5 of the length of the firebox. Holes are made in the partition, precisely calibrated in diameter, location and total area (approximately 7% of the hearth area).

Air intake for afterburning is carried out from the combustion space. There are no separate vents for secondary air. The proportion of air taken by the afterburner from the firebox automatically changes depending on the properties of the fuel and the firebox mode. This is the second difference between the buller and classic designs with combined or separate air flows.

The space fenced off by the upper partition forms an afterburning chamber when operating in smoldering mode. Flue gases from the afterburner exit into the “hog” or “pig” - a horizontal part of the chimney 0.8-1 m long. The hog is mandatory for the buleryan; it somewhat slows down the combustion of the exhaust gases. Why this is necessary will be discussed below.

Immediately after the chimney is turned up, a damper (smoke choke) is installed in it, which switches the combustion mode. Because The heat capacity of the buller body, unlike a brick stove, is small and has almost no effect on heat transfer to the room; there is no view that completely blocks the chimney (and creates the danger of burning out if used carelessly or unskilledly).

Buller gate

The diameter of the chimney is equal to or 10-20% larger than that of the blower pipe, and a quarter is cut out in the damper damper (see figure). Therefore, no matter how you twist the throttle with the damper, the draft will not stop and fumes, even if it is formed, will not enter the room will go, but will fly out into the chimney. With the specified ratio of the diameters of the blower to the chimney and 25% of the area of the idle hole in the damper, the buller is safe, even if you forget to close the firebox door. True, in this case almost all the heat will fly out.

Above the gate is the third most important element of the buller - the economizer. In general, an economizer is a device that heats the working fluid entering the boiler with the residual heat of flue gases - water, air. But in this case, the role of the economizer is different.

The buller economizer is a vertical section of the chimney 1.5-3 m long, well insulated for heat: 40-50 mm of asbestos or basalt cardboard, or 30-40 mm of basalt wool, or 10-15 mm of expanded vermiculite. In the economizer, the flue gases finally burn out: the core of the gas jet in the hog does not have time to cool down too much, the IR reflected from the walls of the economizer increases the concentration of thermal energy in the jet, and the gas flares up. Firefighters are familiar with this effect as flame jumping.

The gas that flares up in the economizer tends to expand, but in a limited volume it has nowhere to go. A gas plug is formed, which is also well known to builders and owners of poorly designed stoves. The combustion in the firebox subsides, the plug cools down, slips through, the combustion intensifies again - the Buleryan, puffing sometimes more often, sometimes less often, automatically adjusts to the quality of the fuel and the position of the air throttle.

They say that this idea dawned on one of the developers while looking at a colleague puffing heavily on his pipe. The design team tried to solve the problem of stability of the combustion mode at low temperatures in the firebox. It was not possible to stay on the verge of smoldering and flame until a self-oscillatory combustion mode was introduced. So a canoe, if rowed alternately with one oar, from one side to the other, moves in a straight line. An overall buller efficiency of 80% is achieved only with an economizer. Without it - at most 60% something.

Sometimes, even often, due to some features of the buller (which will be discussed later), it is operated without an economizer, increasing combustion and putting up with a reduced, but still quite good efficiency. But then a good branded stove only lasts 2-3 years. Why? This will also be discussed further in the course of the presentation.

Step-by-step instruction

Materials:

- Pipes;

- 4mm. 50x50 – 27 m;

- 2mm. 30x20 – 0.76m;

- 2mm. 40x25 – 2 m;

- Diameter 15mm – 0.6m;

- Diameter 95mm. (5mm.) – 1m;

- Steel – 5mm. – 3m2;

- Sheet metal – 100mm. – 0.1m2;

- Wire with a diameter of 10mm – 0.5m;

- Garage hinges – 2 pcs.

Step-by-step instructions for making Buleryan:

- We cut the pipe, which is 27 meters long, into 18 one and a half meter sections, from which we make pipes characteristic of Buleryan (two bends of 120 each).

- 15mm nozzles are welded into 4 of them. tubes (tube length – 15 cm).

- The pipes are folded together in the shape of the future Buleryan and secured by welding. Parts with nozzles are placed two on both sides (later they will act as a blower). Everything is finally boiled down.

- To make the gas afterburning chamber we use 5 mm. steel. We cut out 2 blanks (370x700 mm with a jagged edge 50x60mm to fit the pipe size).

- The parts are welded inside the contour formed by the pipes. Pipes with nozzles should be located in front of the partitions.

- Frame. From the same metal as for the afterburning chamber, we cut plates that will close the gaps between the pipes: 18 pieces for the middle part (400mm x 50mm). 36 pieces for all lower and upper spaces (350mm x 50mm).

- We cover the ends with two 6-carbon plates from the same 5 mm. metal (side 40cm). We make a hole in one of the plates for the chimney. It should be 85 mm in diameter. and located in the afterburning chamber.

- And a hole for the door is cut in the front plate. Approximately 25x25cm. We weld both plates into place.

- The chimney will be a 95 mm pipe, 50 cm long. A valve is installed in the pipe on a wire axis (similar to a throttle valve in a carburetor), with a quarter cut out.

- A pipe frame (40 x 25mm) is made around the perimeter of the door opening.

- We cut out two squares from 10mm metal. The first is 330mm, the second is 246mm. We weld the smaller square with a profiled pipe (40x25), so that it fits into the frame onto the hole for the door (see points 8, 10).

- The blower will be similar to the chimney, only the valve in it will not have a selected quarter. Pipe for 95, 140 m long.

- A 95 mm hole is made in the finished lid, and a blower is welded there.

- Canopies. The door is fixed (by welding) and at a distance of 40 mm from its top and bottom, 2 professional pipes with a length of 380 mm are welded horizontally. Where there will be awnings, the ends of the pipes should protrude 5 cm beyond the hatch. Garage hinges are welded to them.

- Constipation. You can make the lock yourself, or you can order it from a turner. After welding it to the door, the fixing welding is removed.

- All welds are ground.

- You can weld the legs.

Don't be tempted by narrow water pipes. For efficient operation of Buleryan, pipes of 50-70 cm are better suited.

About pipe batteries

With a thermal power of up to 20-25 kW, the pipes in the batteries are made in the form of technologically simple semicircles, as on the left in Fig. In this case, the diameter of the pipes is 60-100 mm, and their number is 3-4 per battery.

Buleryan stoves of low and high power

With a higher thermal power, it is impossible to increase the diameter of the pipes proportionally; due to the low thermal conductivity of the air, the efficiency will decrease. It is necessary to increase the “tube” of the batteries. But with batteries of 6 or more pipes, the efficiency also drops; this is where the square-cube law applies to fuel loading.

Up to a power of 100-120 kW, designers get out of the situation by making pipes curved in the form of sinusoidal arcs and slightly inclined with the top of the arc downward. In this case, the firebox acquires a drop-shaped or ovoid cross-section, as on the right in Fig. With even greater power, computer modeling of the Buleryan with optimization is required, and a positive result of long, complex and expensive work is not guaranteed.

Advantages of the Buleryan stove

Of course, this device has its pros and cons, and there are still more of the former, otherwise the device would hardly have become so popular.

The positive aspects include:

- High performance;

- Device mobility;

- Ease of operation;

- Possibility of using several types of fuel;

- Independence from communications;

- Safety – it is almost impossible to get burned by a buller operating in gasification mode;

- Cost-effective - one device can replace three: a conventional oven, a gas generator and a heater.

Based on reviews of the Buleryan stove, it is clear that users include the following as disadvantages:

- The need to use dry fuel;

- Formation of highly toxic condensate inside the chimney;

- The inevitable presence of a burning smell;

- The need to construct chimneys with a height of 5 to 7.5 meters.

How Buleryan is heated

At first, when it is necessary to quickly warm up the room, dry and fast-burning fuel, such as paper or cardboard, is placed in the firebox. Since pellets went on sale, Canadians, going on their next logging voyage, take 2-3 bags with them; enough for the season.

The throttle and gate are fully opened, the fuel is ignited, and the firebox door is closed. The combustion is fiery, with a “bourgeois” efficiency of 20-40% (and not 5-7%, as advertisers of Buleryans write for comparison). At the same time, 4-6 cubic meters of air per minute, heated to 130-140 degrees, pour out from 4 pipe batteries, and the room quickly warms up.

The accelerating fuel load is given such that it burns down to coals 3-4 minutes before the end of warming up; some experience is needed here. If heat-resistant glass is built into the buller door, combustion can be monitored through it. But it is possible, only inconveniently, to do this by simply peeping into the ash pit.

As soon as the coals have burned down, large logs are placed on them. The bigger the better. You can have one, as long as it fits into the firebox. You can use peat briquettes or the same pellets, they are universal fuel. The blower throttle is now closed to the desired position, or until it stops at the movable power scale limiter. The gate is closed all the way, i.e. at 3/4.

The buller then goes into smoldering mode with partial pyrolysis and gasification. The air leaves the batteries at a temperature of 60-70 degrees, and the furnace body cools down to 50-55. Even if you fall on a bully at night in an Adam costume, you will swear, but you will not get burned.

Calling a buller a pyrolysis or gas generator oven, as is often done, is incorrect. The ratio of heat transferred to the air directly from the smoldering mass of fuel and afterburning pyrolysis gases continuously changes during the combustion of one charge with the throttle and gate position unchanged.

Firebox features

The first is that the thermal conductivity of air is small even compared to its, also small, heat capacity. Therefore, there is no point in “heating up” the buller: the air will not have time to absorb the excess heat, and it will have no choice but to fly out into the chimney.

The optimal temperature in the smoldering mass of the buller is 550-650 degrees. This ensures a fairly high durability of the furnace, welded from ordinary structural steel with a thickness of 4-10 mm, depending on the power. But pyrolysis at this temperature is weak and not complete, which leads to some unnecessary and unpleasant effects. Next we will talk about them in more detail.

If you raise the temperature in the furnace to 800 degrees or higher, then not only the efficiency will drop. And the steel of the housing will not only burn out, but will also undergo thermochemical corrosion due to the presence of hydrocarbon radicals and nitrogen oxides in the flue gases. You can avoid their formation by supplying air separately to the firebox and afterburner, but this will no longer be a buller, but another furnace. Difficult to operate and can be dangerous.

That is why manufacturers of buleryans categorically prohibit burning them with coal and coke. Carbon does not burn if it cools below 800-900 degrees. And if you give more air so that it doesn’t go out, not only will the efficiency drop, but an expensive special steel stove will burn out to holes in a season or two. The claim will not be accepted, the case is not covered by warranty.

Kindling technology

To use the stove, no specialized knowledge or skills are required. The boiler is easy to heat and maintain.

You can melt Buleryan as follows:

- Fuel is loaded into the firebox. First, firewood of small thickness is used. The fuel should be dry, this will minimize the amount of condensation that forms and allow the fire to start quickly.

- The wood is set on fire. The dampers that regulate the draft and the amount of air supplied are fully open.

- After hot coals have formed in the firebox, thicker firewood is loaded through the door. The dampers are installed in the desired position to ensure long-lasting combustion.

Should I do it myself?

Properly made homemade buller

Before moving on to the features of installing and operating bulleryans, their improvements and varieties, you need to dwell on the question: is it worth making a buller with your own hands? The reason is primarily the selling price of ready-made factory ones. Bullers are very technologically advanced: the zero cycle of their production comes down to the manufacture of a couple of bending templates and welding jigs. The material of the product is even scrap metal.

A very good 10-15 kW Buleryan can be purchased for $200-250. At the same time, equipment that is usual for a camp repair shop is not kept at home, in a garage or on a summer cottage, if only because of the lack of suitable space. And ordering piece-by-piece rather large parts made of thick metal will cost much more.

Perhaps the only exception is if a self-made master works at a remote provincial factory, where most of the technological equipment is still idle. And the “Soviet-style” management will allow him to use the machine park in his free time, and will even allow him to rummage through the landfill and pick up workpieces. Although at current prices for scrap metal this is unlikely.

In this case, we will give advice: do not be tempted by narrow water pipes for batteries. The minimum diameter of air ducts is 60 mm; it is determined by the ratio of heat capacity and viscosity of air. A buller with a “picket fence” is unlikely to be more economical than any other slow-burning stove, but it is more difficult to make. A drawing of a design that is unsuccessful in this regard is shown in Fig. below, and an example of a correctly executed homemade buller is in Fig. on the right at the beginning of the section.

Drawing of an erroneously designed buller

Video: review of homemade buleryan

Manufacturing principles

It is quite understandable to want to try to make a buleryan oven with your own hands. You should immediately take into account that trying to build a furnace without experience in welding and plumbing is pointless. Even though a detailed description and drawing of the Buleryan stove can be easily found on the Internet.

If such a decision is nevertheless made, it is worth remembering that in a buleryan one of the most complex elements is the front wall with the door: the latter must ensure complete sealing, and its production will have to be ordered, otherwise you will not have to count on high-quality operation of the stove.

A list of necessary materials and tools can also be found on a specialized website or forum for stove makers.

Ready-to-purchase

Installing a buller in a heated room also has some features. Look at fig. On the left - the option is not entirely successful. And not only because it is necessary to chisel concrete floors, which requires a project with permission, load-bearing structures.

Options for installing a buller indoors

Firstly, to install a chimney passing through the attic and roof, you will need to collect a lot of paperwork in order to obtain permission from the fire department. And then also to comply with all fire safety requirements, which will not be easy or cheap.

Secondly, the condensate that settles from the flue gases of the buller (sludge condensate) has amazing physical and chemical properties. A special section will be devoted to them, but for now we note the following: although there are no separate sanitary rules for this substance, it is better for yourself to stay away from it. And in this case, the sludge condensate remains in the room.

The option on the right is good because you need to drill not into a concrete wall, but into a brick wall. It is, of course, also load-bearing, but it is loaded with less than the ceiling. Control authorities turn a blind eye to an opening in it up to 150 mm in diameter. And the standard diameter of the buller chimney is 100 mm. And getting a fire permit for an external chimney is much easier. And the sludge condensate will be outside.

In both cases, a foundation for the buleryan is not needed; a fireproof stand is sufficient. Other general conditions are as follows:

- The distance from a regular wall is at least 1000 mm.

- If the wall is covered with fire-resistant plaster (for example, vermiculite) with a layer of at least 25 mm, the buller can be moved 800 mm towards it.

- Within a radius of 1200 mm from the center of the firebox door there is a fire-resistant flooring, as for other stoves: steel from 1.5 mm on an asbestos cushion.

- The extension of the stand beyond the contour of the stove is at least 300 mm in all directions.

- If the buller is certified by the fire department for operation without a stand, is equipped with standard non-removable fireproof legs and a pocket-catcher in front of the ash pit door, you can place it without a stand directly on the floor, except for plank wood or plywood. You can use laminate or marmoleum.

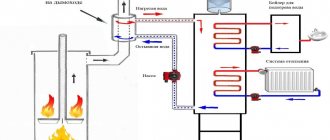

Water bullers

Buleryan water boiler

Is it possible to adapt such a really good stove for water heating? It is possible, and water buleryans are produced by industry. But, looking at this (see figure), one inevitably recalls the statement of an outstanding Soviet submarine builder about the project of a giant nuclear-powered missile submarine of the Akula type, also known as the Typhoon: “This is a vivid example of the victory of technology over common sense.”

The authors of “water bullers” forget, or ignore, based on market demands, that buleryan was originally created as an air furnace. And the heat capacity of water is 800 times greater than that of air. In order for the exhaust gases to transfer their heat to it, they need to be entangled in the labyrinth of the water heating register. But in a buleryan with its side-heated heat exchanger, this is basically impossible, otherwise you will have to create a completely different furnace.

The only way to heat water for heating with a boiler is to intensify the combustion in the firebox. But at the same time, as discussed above, the efficiency will inevitably drop.

However, it is very simple to adapt any Buleryan for hot water supply. Let's say we have 2 batteries with 4 pipes each, and the whole furnace is 10 kW. As can be seen in the thermal image (see the figure on the left below), even with intensive heating for rapid heating, the air temperature in the battery nozzles is not higher than 160 degrees.

Thermal image of the Buleryan stove

Now let’s put the most ordinary metal hoses on two pipes and connect them to the pipes passing through the DHW boiler. Horizontally, vertically – it doesn’t matter. 2.5 kW will go into the water. If an 80-100 liter tank is insulated with 40-50 mm thick EPS, then in half an hour the water in it will heat up to 60-70 degrees, and then this temperature will be maintained. For comparison: 3.5-5 kW heating elements are installed in household 100-liter electric boilers.

This system is also good because without any automation, boiling of water is absolutely excluded. Let's remember the school physics problem for the especially (without quotes) gifted and savvy: how to heat water exactly to 100 degrees without letting it boil?

The answer is: take a pan and put wooden blocks in it for thermal insulation. Place another, smaller pan on them. Pour water into both pans and put on fire. The water in the outer pan will boil, but its temperature will not rise above 100 degrees, because... the heat of the fire will be used to transfer the latent heat of evaporation of water to the water.

The water in the inner pan will also heat up to 100 degrees, but there will be no temperature difference between it and the outside, and the heat required to evaporate the water will not be able to transfer to the inner pan. The water in it will heat up to exactly 100 degrees without any signs of boiling.

In the case of a “water buller”, in air with a temperature of 140 degrees there is no reserve of heat to ensure boiling of water. When its temperature approaches 100 degrees, the air in the heat exchanger will rapidly cool, the temperature gradient will approach 0, and the water will never boil.

Tips and rules of operation

For the Buleryan heating system, it is necessary to comply with operating conditions, which makes it possible to increase the efficiency of the installation and extend its service life. Comments from numerous stove users show that the most pressing questions are:

- measures to prevent freezing of the coolant when the heating system is turned off;

- reasons for low productivity;

- rules and features of the firebox;

- Is it possible to install the structure outdoors?

How to prevent the circuit from freezing?

When operating the furnace, care should be taken to ensure that the coolant does not freeze. For this purpose, the boilers have a built-in 1 kW heating element. The system is equipped with a sensor that constantly monitors the coolant temperature and turns on additional heating when it drops to a minimum level.

A method of protection is also the complete drainage of water when the system is turned off. In this case, the pipes and housing will withstand frosts down to -50 degrees.

Why does Buleryan start to heat up poorly?

Why can water boilers not heat a room well? The reasons may be as follows:

- incorrect installation/connection (insufficient height of the chimney pipe, poor gas outlet);

- improper installation of the stove with a violation of the height (a distance from the floor of 40-50 cm is allowed, in other cases the performance of the system decreases);

- the wood-burning stove has too low power (the actual power is 10% lower than that indicated in the documentation, which is due to the peculiarities of the installation);

- too many connected radiators.

Firebox features

The Buleryan boiler with a water circuit is heated using the smoldering mode; wood chips, firewood, and paper are used for ignition. Intense combustion is observed only in the first half hour, then the stove should switch to normal mode.

Attention: The stove should not operate at its maximum, the thermal conductivity of the body is limited and the heat will go to nowhere. The efficiency of the design during strong acceleration will be extremely low; this is a waste of fuel.

The principle of kindling Bullerjan will be as follows:

The principle of kindling Bullerjan will be as follows:

- the gasifier and special regulator open completely;

- light a fire (it is best to use paper and small wood chips);

- after the fire ignites, the chamber is filled to 80%;

- it is necessary to heat until the sensor shows a value of 180-200 degrees (the heating time is no more than 20-30 minutes);

- then the gasifier must be closed at 45 degrees.

Wood fuel is used for the firebox; logs with a size corresponding to the length of the chamber that are not split into pieces are best suited. The firebox door must close tightly; no gaps are allowed. The ash of the heating furnace is not removed; it remains in the chamber throughout its operation.

Outdoor installation

Is it possible to install Buleryan water boilers outdoors? Theoretically, it is allowed, but in practice it is not recommended, since the presence of a “water” jacket will greatly limit the possibility of the device under such conditions.

About heating a private house

Okay, the reader may say, but you need to warm up! Yes, but stove heating is used mainly in private households, and there water heating is pure prejudice, a stereotype of “centralized” thinking. For the efficiency of a central thermal power plant, indeed, the heat capacity of the coolant is of paramount importance, otherwise it will cool down before it reaches subscribers.

What about in a private house? What, should we run a line from the kitchen or furnace around the entire area to the living room/bedroom? Isn’t it easier to disperse the warm air through the rooms, which the bubbler gives, as they say, from the top? Judge for yourself:

- Air ducts can be made with a simple tool from cheap materials: tin, plasterboard, plywood, just cardboard, but pipes are expensive, they need to be bent, boiled, soldered.

- No registers, expansion tank, fittings, or automation are needed.

- You can forget about fistulas and leaks once and for all.

- Ductwork with fans and louvers does not require a design or permit. It is enough to calculate for yourself which section should go into which room.

- Heat transfer into the walls (and this is up to 15% of heat loss through water) is zero; here the poor thermal conductivity of the air works to our advantage.

- Install adjustable blinds at the exits - here you have easy, quick temperature control in rooms. It’s better not to compare it with setting up water heating.

- If you place the exit blinds on the walls farthest from the window above the floor, then the air will give up its heat to the room by the time it gets to where it can heat the street. And everyone knows how batteries in window sills increase the entropy of the Universe.

- The same technique will also provide a warm floor without any additional costs or work.

- The walls are straight, there are no deformities in sight - design the interior as you please.

Video: Buleryan and garage heating

Bullers without pipes

Professor Innokenty Nikolaevich Butakov (not to be confused with Alexander Vladimirovich Butakov, also a professor, but a lawyer) actually invented the Buleryan back in the 20s of the last century, attaching an afterburner to the top of a potbelly stove with a heat shield. Nowadays, stoves such as “Butakov”, “Professor Butakov”, “Student” in modern design (see figure) successfully compete with Buleryans on the domestic market. Their technical characteristics and principle of operation are similar, like identical twins, but making “Butakov” yourself is much easier, as can be seen from the figure.

Convection oven Butakov

Computer buleryan

The first buller was calculated almost on a slide rule. Oddly enough, they were the first to figure out how to properly simulate it on a computer and optimize it in Novosibirsk, at Termofor. Now their “Fire-battery” stoves of various sizes are one of the hits on the market. And it’s not surprising: having carefully calculated all the processes, it was possible to place a hot water circuit for DHW and a hob with a burner in the same tank, see fig.

Stove “Fire battery”

The “Fire-Battery” stoves immediately drew a volley of criticism. But here the complaints of the classics of literature come to mind: “All the same petty attacks on the font, vignettes, typos...”

“It doesn’t correspond to my idea of stoves...” Sorry, sir, there’s no arguing about tastes. “Metal stoves are harmful to health.” By whom, when and where was it proven or at least noticed? “Not a stove, but some kind of boiler for a destroyer.” Sir, you flatter the developers. The best minds in heating engineering worked on boilers for destroyers and cruisers. 70,000 kW in a volume of 8 cubic meters. m. with an efficiency of 97% - if this is not perfection, then what is perfection at all?

What's bad about it?

Yes, the bullers have no visible flaws. That’s what they call it: a stove without flaws. But there is still one hidden one, and a serious one.

Any organic fuel burns, releasing the so-called. reaction water. It is a complete analogue of metabolic water formed in living organisms: it is released during the breakdown of organic molecules. Due to the low temperature in the furnace, there is more reaction water in the exhaust of Buleryan than other slow-burning furnaces; in them this water partially participates in pyrolysis.

The second point is the mineral components of wood. Buller sellers present as an advantage the fact that the wood in the buller burns without even leaving ash. But there is ash in the wood initially, and in bullers, ash particles fly out into the chimney.

The third is hydrocarbon radicals. These are chemically very active remnants of organic molecules that have not completely decomposed. All this taken together reduces the efficiency of the buller by only 5-7% and by volume constitutes the same share of its exhaust. But for household Buleryans, these percentages turn out to be truly lethal.

Let's remember Carnot's formula. If you take a pyrolysis boiler with 1500 degrees in the combustion chamber and 300 in the exhaust, it will show an efficiency of 80%. For Buleryan, the same 80% is obtained at 600 and 120, respectively.

The reaction water from the pyrolysis boiler does not have time to condense in the chimney and dissipates without a trace in the atmosphere. The ash settles under the firebox. From where it has to be raked out from time to time. It contains purely mineral salts suitable for fertilizer. The boiler also produces organic radicals in small quantities, but already 1-2 m from the mouth of the chimney they are oxidized by atmospheric oxygen to carbon dioxide and water, because they were formed at high temperatures and are very light, of low molecular weight

Not so in a buller. The reaction water immediately after the economizer falls into condensate. Each drop of it is a thin film rolled into a lump, and the physical chemistry of thin films is strikingly different from that of massive aggregates of matter. And then there are ash particles, heavy organic radicals. As a result, not just dirty water settles into the sump, but a cocktail of monstrous toxicity, carcinogenicity and God knows what else.

This crap (without quotes) needs to go somewhere. Leaving the end of the “pipe that goes to the ground” open will gradually undermine the foundation, and you won’t be able to eat vegetables from the garden. Slowly take it out and pour it out - the properties of the Buleryan sludge condensate are such that it cannot be hidden from the SES and environmentalists, with all that it implies.

That’s why bullers are also called greenhouse stoves. They are most often installed in greenhouses without an economizer (see figure). Flowers, early and all-season vegetables are highly profitable products; it will not be expensive not only to put up with worse efficiency, but also to change the entire stove in a year or two or three.

Installing a buller without an economizer

True, the exhaust from such a buller still smells, but greenhouses themselves emit methane, ethylene, and so on in the same spirit. Therefore, according to sanitary rules, they cannot be built near residential buildings, so the smoke from the buller does not even require a separate “solution to the issue.”

Some cunning flower growers, especially in places poor in water, judging that tulips, roses and carnations are not eaten, and many plants with luxurious flowers are poisonous in themselves, install bullers according to the full scheme, and the sludge condensate, after slightly filtering, is put into drip irrigation systems. However, tomato and strawberry experiments of this kind always end in resuscitation of buyers, investigation and loud scandals with sanctions, or even prison.

The combustion process and the mechanism of pyrolysis

The main physical phenomenon, without which it is impossible to imagine the operation of any furnace, is the oxidation of various substances by oxygen contained in the air.

Fire, tamed by our ancestors millions of years ago, has become so familiar today that we don’t even think about how combustion occurs, with which each of us has been familiar since childhood. The seemingly simple question “how does wood burn?”, in fact, requires a separate explanation. After all, without understanding the basics, we will not be able to understand how economical pyrolysis furnaces work and why they are so good and economical. Actually, the formation of a flame occurs in several stages:

- First, the wood heats up and dries, releasing water vapor into the environment, which prevents fire from starting. This requires an external source of energy, which is usually flammable paper, kindling liquid, or a pile of small burning wood chips.

- Firewood, which from a chemical point of view is a complex organic structure, consists of three main elements: carbon, hydrogen and oxygen. When heated, wood disintegrates, and these components, in the form of various simple gaseous compounds, begin to be released into the surrounding space. The general name for all substances formed during fuel heating is pyrolysis gases, and for the process itself is pyrolysis.

- At the next stage, the wood decomposition products ignite and accelerate the pyrolysis of the remaining logs more and more, providing the fire with fresh fuel.

- In the end, the tree burns, leaving behind some of the coals that did not have time to react with the oxidizing agent.

How combustion occurs

Actually, the idea that made it possible to build long-burning furnaces is to ensure the most complete decomposition of fuel in such a way that after its use there is practically no unburned waste left. To do this, it was necessary to slow down the pyrolysis as much as possible so that the entire volume of firewood would gradually and completely disintegrate into pyrolysis gases.