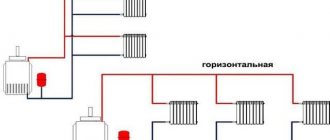

A circulation pump is most often installed in autonomous heating systems to ensure constant circulation of coolant through the pipes. This allows thermal energy to be evenly distributed throughout all rooms and used efficiently. Using a circulation pump in a private home allows you to warm up all the rooms in a short time, and then constantly maintain a comfortable temperature by adjusting the performance.

The correct choice of a circulation pump allows you to reduce energy costs by almost a third. Therefore, when purchasing equipment, you should either pre-calculate the required operating parameters or seek help from specialists.

- Design and operating principle

- Types of circulation pumps

- How to choose the right pump

- Marking of circulation pumps

Two main characteristics of a circulation pump

With a long list of technical characteristics of heat pumps, there are two main ones. This is the diameter of the connection pipes and the power of the “accelerator”. These two numbers are considered decisive and are indicated in the name.

Connection pipe diameter

The most important parameter for pump installation, especially with already installed heating systems. This is a numerical value indicated in millimeters and indicating the diameter of the heating pipes that can be connected to the inlet/outlet pipes.

Please note that for connection to the body pipes, taps are made with threaded threads.

Power

Power in heating systems is the ability to raise water to a certain height or pump pressure.

In the marking of Grundfos pumps, the power is indicated in meters multiplied by 10 or atmospheres multiplied by 100. That is, Grundfos with the ability to raise water by 5 meters (pressure 5 meters), the marking will receive the figure 50 or 0.5 atm. (atmospheres).

Example: Circulation pump Wilo Star 30/2, means that the diameter of the connection pipes is 30 mm, the pressure is 2 meters.

In Wilo markings, power is indicated simply in meters.

Example: Grundfos UPS 25 40 (130 mm), means that the diameter of the connection pipes is 25 mm (1/2 inch), the pressure is 4 meters. 130 is the installation length.

Types of submersible pumps depending on the intended purpose ↑

Submersible pumps can be used in everyday life for various purposes - pumping clean, dirty water, chemically active liquids, sewage. They are capable of operating at high fluid temperatures. The design features, materials of manufacture, and principle of operation depend on the purpose. Depending on the intended use, the following types of household devices are distinguished:

Mermen. These are submersible models designed for pumping clean water from hydraulic structures. Pumps for wells and boreholes are similar in design and operating principle, but differ in size. Devices designed for wells usually have a larger body diameter than borehole ones.

Drainage The equipment is designed for pumping dirty water with solid inclusions. Pumps are used for draining pits, wells, basements, technical tanks, swimming pools, and small reservoirs. A design feature is the presence of a filter grid at the inlet. It allows solid particles of a certain size to pass through, but traps larger ones.

Fecal. Used in sewer systems. Many models are equipped with cutting mechanisms that crush solid inclusions - plastic, foil, thin tin. Fecal pumps are similar in operating principle to drainage pumps, and in some cases can be used for the same purposes. The devices operate in chemically aggressive liquids at high temperatures. The permissible temperature maximum is indicated in the technical documentation.

Modifications of drainage pumps of different power and performance

What is a BP/BP connection?

The detachable connection BP/BP of the heating system is a set of adapters that allows you to connect the pipe to the pump body.

- BP/BP means nut/nut;

- BP/HP means nut/thread.

BP/BP adapters are used to connect circulation pumps. Here is an example: Photo of an adapter for connecting a BP/BP pump (1 1/2″ - 1″). This means that the pump nut has a diameter of one and a half inches (32 mm), and the pipe connection nut has an inch (25 mm) diameter.

On the nameplate of the pump and in its description, the diameter G is often indicated; this is the diameter of the union nut for the pump. Pumps are sold complete with connection adapters.

Note: Threaded connection of circulation pumps is typical for low-power household pumps. More powerful pumps are connected via flange connections.

Design and operating principle

The circulation pump, regardless of its type, consists of the following components:

- housing made of corrosion-resistant materials;

- an electric motor consisting of a stator winding and a rotating rotor;

- wheels with blades (impellers) connected to the drive shaft.

When power is applied to the stator winding, the rotor begins to rotate and transmits torque to the impeller. The latter, rotating in the working chamber, creates a vacuum in the heating main, which leads to the suction of water from the pipeline. The coolant that enters inside creates excess pressure and is pushed into the discharge pipe of the heating system. Thanks to the pressure, hot water enters the pipes and radiators and circulates freely through them, overcoming the force of friction.

Grundfos circulation pump markings

Decoding the brand (Type) of the grundfos pump:

- UP – circulation;

- S – there is a power (rotation speed) switching;

- D – twin;

- 30 – diameter (mm dn) of the suction pipe and pressure pipe;

- 60 – max. pressure (meters×10);

- F – connection of pipes through a flange (the letter is missing when threaded);

- N – body material (cast iron body – no letter, letter N – stainless steel body);

- B – bronze body;

- A – the housing has an air outlet;

- K – housing for working with antifreeze (special version).

Letter designations in technical documentation ↑

The pump type, depending on its purpose and design, is indicated in capital letters and their combinations with lowercase letters:

- artesian - A;

- gasoline - B;

- household - Bt;

- vertical – B;

- vortex - Bx;

- horizontal two-way entrance - Gd;

- horizontal sectional - Гс;

- horizontal network - GSE;

- dosage – D;

- condensate – Ks;

- console – K;

- console circulation - Kts;

- oil pumps – Mn;

- mass – Ms;

- marine – Mr;

- pumps for suspended solids – Вз;

- oil - N;

- axial – O;

- steam piston – Pp;

- sand, soil, slurry - Pgsh;

- nutritious – Fri;

- submersible – Pg;

- drive-piston – Pr;

- special – Sp;

- fecal – Φ;

- chemical – X.

Depending on the regulatory documentation that the manufacturer used when labeling products, the letters B, C, X may appear, indicating “high-pressure”, “medium-pressure”, “chemical”, respectively. The letters A and B indicate the first and second options for turning the impeller.

Well pump "Aquarius"

Standards

- RF: GOST 26349-84, GOST 356-80, GOST R 54432-2011

- EU: DIN EN 1092-1-2008

- USA: ANSI/ASME B16.5-2009, ANSI/ASME B16.47-2006

©Obotoplenii.ru

Articles on the topic

- Heating system flushing technology

- Heating system with solid fuel boiler for houses over 25 kW

- Hydropneumatic flushing of heating systems, instructions

- Flushing the heating system: methods for flushing heating

- Baseboard heating: description, application

Tips for choosing a device for a heated floor system in your home

How to choose a pump for underfloor heating? Today, the market mainly offers CO pumps with a standard flow rate of about 40 l/min (about 2.5 cubic meters/hour) and a pressure of up to six meters. The flow rate is directly proportional to the pressure value.

When purchasing, you should understand that the flow rate of 40 l/min indicated on the pump will not always correspond to the actual flow rate. Because the latter depends on what the throughput of the floor assembly or the system itself is. A large number of long circuits reduces consumption.

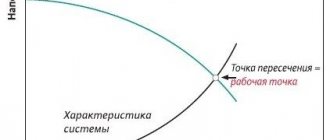

It’s easy to understand this using two graphs: theoretical (for all similar pumps) - No. 1, and real for the 2.5 cubic meter pump considered in the example. with a pressure of six meters - No. 2.

The higher the throughput capabilities of your system, the weaker the pressure on all connected circuits. Those. The more circuits are closed to one mixing unit, the greater the flow rate.

Advantages and disadvantages of CN

If we compare centrifugal pumps with other pumping equipment, we can note several positive qualities unique to them. In most pumps, as the pressure increases, the flow decreases. In centrifugal pumps, flow rates are maintained within the widest ranges. That is why they are mainly used in autonomous water supply systems fed from deep water intakes. So:

- A distinctive feature of central heating pumps is their high shaft rotation speed. This fact allows the use of turbines and electric motors as drives.

- Another undeniable advantage is the ability to smoothly change power. Thanks to this, the pump can be started even with the outlet valve closed.

- When pumps are combined into a group to work on one pipeline, the flow and pressure indicators also increase. And in general, the design of the centrifugal pump itself is simple, like everything ingenious. Therefore, the price of such equipment is an order of magnitude lower than the cost of units of other designs with similar characteristics.

- There are also some drawbacks. Centrifugal pumps require priming before starting; they do not tolerate interaction with viscous and contaminated liquids. Most pumps of this type are susceptible to cavitation.

- The air that is formed in this case creates vibration, and this, in turn, complicates the operation of the mechanism and leads to rapid wear of bearings and components. To remove air, special plungers are provided on the casing.

It should be borne in mind that several specific factors influence the suction of the pump:

| Main problems | Eliminating them |

| Clogged suction line | Replacing the filter |

| Higher temperature of the pumped liquid than regulated by the manufacturer | Pausing the pump until the liquid cools down |

| Long pipeline route, with its small diameter | These are system design errors that need to be corrected. |

| Depressurization of connections on flanges and shut-off valves | Find the cause and update the seal |

- It is not difficult to install a centrifugal pump with your own hands; it is important to understand what the problems in its operation may be. As we know, there are no mechanisms without problems. If you use such a pump, carefully monitor its operation.

At the first sign of unstable water supply from the pump, look for the problem yourself, or consult with specialists. Measures taken in time will allow you to do without repairs for a long time, and will extend the life of the pump as a whole.

Alphanumeric designations of pipelines

GOST 21.205-93 establishes the letter designation of sewer and water pipelines of the following categories:

B – water supply; digital symbols show its purpose, the movement of the working fluid in the system and the quality (source) of water.

K - sewerage pipeline, digital symbols characterize the purpose of the sewerage system and the chemical composition of the discharged wastewater.

T - heat pipes, the numbers show the purpose of the pipeline, the direction of circulation and the type of working fluid.

Rice. 12 Alphanumeric marking of pipelines according to GOST 21.205-93

—

CONDITION 1

RESULTS ¾Ð»ÑÑинÑÑве ÑÑÑеÑÑвÑÑÑÐ¸Ñ Ñимволик окÑÑжноÑÑи. RESULTS, RESULTS RESULTS ° RESULTS. RESULTS ÑÑ Ð¾ÑÑием жиÑной ÑÑÑелки, помеÑенной внÑÑ Ñи конÑÑÑа Ñимвола, а ÑегÑлиÑÑемоÑÑÑ Ð¿Ð¾Ð´Ð°Ñи — дР»Ð¸Ð½Ð½Ð¾Ð¹ Ñонкой ÑÑÑелкой, пеÑеÑекаÑÑей ÑÑÐ¾Ñ Ð ºÐ¾Ð½ÑÑS под ÑгÐ" ом. â

RESULTS 1) 3000 rs / 3000 rs. â

ROOM 1/2 У - опÑÑкаеÑÑÑ. â

бознаÑение наÑоÑа вклÑÑÐ°ÐµÑ ÑÑи бÑквÑ: Ц — ÑеР½ÑÑобежнÑй, Ð — наÑоÑ, С — ÑекÑионнÑй и двР° ÑиÑла, пеÑвое из коÑоÑÑÑ — подаÑа наÑоÑа Q, м3 / Ñ, вÑоÑое - Ð½Ð°Ð¿Ð¾Ñ Ð, м ÑÑ. жидкоÑÑи. â

RESULTS дÑÑÑим обÑазом: а) ЦР— ÑенÑÑобежнÑй, геÑмеÑиÑнÑй; б) дÑобÑ: ÑиÑлиÑелÑно-миналÑÐ½Ð°Ñ Ð¿Ð¾Ð´Ð°Ñа в м3 / Ñ, знаменаÑÐµÐ»С — номиналÑнÑй Ð½Ð°Ð¿Ð¾Ñ Ð² м ÑÑ. жидкоÑÑи; 1) SYSTEM; - ¾ÑÑÑ ÑлекÑÑодвигаÑелÑ, кÐÑ; д) поÑледнÑÑÑиÑÑа - обознаÑение конÑÑÑÑкÑиР› влениÑ. â

RESULTS дÑÑÑим обÑазом: а) ЦР— ÑенÑÑобежнÑй, геÑмеÑиÑнÑй; б) дÑобÑ: ÑиÑлиÑелÑно-миналÑÐ½Ð°Ñ Ð¿Ð¾Ð´Ð°Ñа в м3 / Ñ, знаменаÑÐµÐ»С — номиналÑнÑй Ð½Ð°Ð¿Ð¾Ñ Ð² м ÑÑ. жидкоÑÑи; 1) SYSTEM; - ¾ÑÑÑ ÑлекÑÑодвигаÑелÑ, кÐÑ; д) поÑледнÑÑÑиÑÑа - обознаÑение конÑÑÑÑкÑиР› влениÑ. â

ROOM RESEARCH - ( Ð), Ð¥Ð. â

| конÑолÑнÑй наÑÐ¾Ñ 4Ð - 8. â |

registry That's it. RESULTS ½Ð¾Ð³Ð¾ паÑÑÑбка в мм, ÑменÑÑеннÑй в 25 Ѱз, а ÑиÑÑÑ Ð¿Ð¾Ñле бÑкв — коÑÑÑиÑÐ¸ÐµÐ½Ñ Ð±ÑÑÑÑоÑодноÑÑ 10 points ROOM . â

| бÑий вид. â |

registry I'm sorry. RESULTS 15150 - 69) ¸Ðµ ÐÐСТа. ÐÑабÐ". 2.2 RESULTS оÑов Ñипа Ð. â

| RESULTS а ÑекÑионного Ñипа.| OPTIONAL RESEARCH RESULTS. â |

RESULTS . â

RESULTS . â

ROOM 25 Ñаз; бÑква - Ñип наÑоÑа; коÑÑиÑÐ¸ÐµÐ½Ñ Ð±ÑÑÑÑоÑодноÑÑÐ ¸ наÑоÑа, ÑменÑÑеннÑй в 10 Ñаз и окÑÑгленнÑй. â

Model range of SCL units

In the “Pumps” category of the company’s product catalog you can find the following units: ASCL, pumps SCL 20/24, 00A, SCL 00 pump, SCN 75/70, etc. Let’s look at the most popular models and their technical characteristics.

Main characteristics

SCL-00 is a left-hand rotation unit with two stages, the first of which provides suction of water (gasoline), the second creates pressure. The centrifugal vortex pump is installed on a fuel tanker and water dispensing installations. The centrifugal wheel of the SCL-00 pump is made of cast iron. The pressure reaches 30 m, self-priming - 6 m. Productivity indicators are high - 30 cubic meters / hour.

The shaft rotates at a speed of 1500 rpm. It is equipped with a gearbox on agricultural machines for watering livestock, pumping water when extinguishing fires and irrigation machines. The purpose of the SCL-00 pump gearbox is to drive the unit from the power shaft of a tractor vehicle, increasing the gear ratio by 3.22 times.

Spare parts for the SCL pump

00A is a self-priming two-stage mechanism installed on diesel tankers and tanker chassis. The horizontal cantilever pump is developed in two versions: the first version is left rotation (mounted on ZIL, GAZ trucks, MTZ tractors, the second version is right rotation for installation on KamAZ, KrAZ trucks). The rotation speed is 1500 rpm. Flow is 21.6 cubic meters/h, head is 30 m, suction height is 4.5 m.

The pump is driven by a machine (tractor) engine, through a power take-off box, and an intermediate transmission. For a stationary installation, an explosion-proof electric motor is used, the power of which is close to 5.5 kW. Flow precision material: body made of cast iron, blade wheel made of aluminum alloys, centrifugal wheel made of cast iron.

Self-priming electric pump 1SCL-20-24G is a device that pumps neutral liquids with a viscosity not exceeding 2 ∙ 10-5 sq.m. m/s and temperature value – from -40 to +50 degrees. The operation of the 1SCL 20 24G pump occurs in a temperate climate. Available in left-right rotation.

Suction duration – 50 s. Power varies in the range of 16-24 kW. The efficiency is 33%. Pressure length – from 45 m at 1700 rpm. up to 54 m at a rotation speed of 1450 rpm. Feed – 32-45 cubic meters/hour. The self-priming height exceeds 5 m.

SCL 20/24 pumps are horizontal, two-stage, centrifugal-vortex units used for pumping clean liquids. 1st stage – centrifugal mechanism equipped with a closed impeller and a spiral outlet of circular cross-section. It provides high cavitation qualities. Stage 2 is a vortex mechanism with a closed wheel and an open channel, thanks to which high pressure arises.

The pump is aggregated with an electric motor into the ASCL-20 device. Suitable for use in tropical or temperate climates. Liquid supply – 35-45 cubic meters/min. The pressure ranges from 45 to 54 m. The self-priming height is 5.5 m. The power of the SCL 20/24 pump is 15.5-24 kW. Rotation – “according to customer’s order”, left/right. Drive – electric. Max. flow rate – 32 cubic meters/hour.

Areas of application

The Wilo brand produces pumps designed for different purposes and therefore having different characteristics.

With the help of such a pump, you can water the beds directly from a well, borehole or the nearest body of water.

The scope of their application is wide and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in wells for water extraction.

- Such pumps are also suitable for pumping out groundwater when creating basements and cellars.

- They are also used on construction sites when working with contaminated water.

- Owners of private suburban areas have found good use for them, in particular those who grow plants on their plots.

The Vilo pump can operate in the most difficult conditions, and it does not matter what the temperature of the water circulated through the pipes will be or what the pressure will be.

You can connect the device yourself without any problems. For this purpose, it is equipped with special spring terminals. It does not have a fan, so there is virtually no noise during operation.

Designation of centrifugal pumps

The designation of centrifugal pumps often indicates information about the characteristics - flow and pressure of the pump.

What do the numbers 60/35, 70/50 mean in the pump brand?

The designation of the Jumbo pump 60/35 indicates that the nominal flow is 60 l/min and the maximum head is 35 meters.

The Jumbo 70/50 brand indicates that the nominal pump flow is 70 l/min, and the maximum pressure reaches 50 meters.

Source of the article: https://hydro-pnevmo.ru/topic.php?ID=96

What do plumbing diagrams indicate?

According to GOST 21.601-79, which defines the equipment and rules for drawing up working drawings for internal water supply and sewerage systems of buildings and structures, the water supply diagrams show:

- inlet openings with the application of diameters, axial levels of pipelines at the points of intersection with the axes of the walls of equipped construction sites;

- the pipelines used, their dimensions and slope;

- levels of pipeline axes;

- the length of horizontal pipe sections when they break;

- non-standard fasteners with markings on the remote shelf according to GOST and below the line an indication of the corresponding document;

- shut-off and control valves, fire extinguishing and irrigation taps.

- risers and their schematic representation;

- electromechanical equipment, measuring and control instruments, other system elements.

Rice. 13 Designation of pumps and fans according to the operating principle (GOST 2.782-96 ESKD)

Internal water supply of buildings - designations of elements

Graphic symbols on drawings of water supply and sewerage of various elements used in sanitary systems are regulated by GOST 21.205-93. They are accepted for use in design schemes of various types of engineering networks of construction sites.

Basic provisions of GOST 21.205-93:

- The dimensions of schematic graphic images are set without respect to scale.

- In an axonometric projection, a simplified schematic representation of system parts, assemblies and equipment in the form of outlined contours is allowed.

- GOST 21.205-93 regulates the designations of elements divided into the following categories:

- General purpose, these include heaters, filters, coolers, dehumidifiers and humidifiers, condensate drains.

- Plumbing fixtures and drainage devices, main elements - sinks, sinks and washbasins, toilets, bidets and urinals, bathtub bowls, drainage devices: drains, funnel drains.

- Elements of heating, ventilation and climate control systems, these include pipes, radiators, air ducts, grilles, dampers and valves.

- Direction of air and hydraulic flows, lines of communication, adjustment, types of drives.

- Expansion and storage tanks, pumps, fans.

- Pipeline elements and their supports, revisions, siphons and compensators.

- Pipeline shut-off and control valves include the designation of a check valve in the diagram, valve, gate valve, faucet and mixer.

Rice. 7 Elements of pipeline lines according to GOST 21.205-93 - schematic representation

Classification

The internal water supply of any buildings and structures is conditionally divided into the following components:

A). Cold water supply, consisting of three systems with letter and digital designations in accordance with GOST 21.205-93:

- B1 - for household and drinking purposes;

- B2 - for fire extinguishing;

- B3 - general purpose (production).

b). Heat line T0:

- General pipeline for supplying hot water, heating fluid, transporting the working fluid in ventilation and air conditioning systems: - T1 - supply line; - T2 - return circuit.

- Pipeline for transporting hot water: — T3 – supply; — T4 – circulating.

Rice. 8 Display of plumbing fixtures and drains

Pipeline

The symbols of pipelines and their elements are indicated in accordance with GOST 21.205-93, simplified images are also used in accordance with GOST 21.206.

Internal water supply pipes are made of polymers (polyethylene PE, polypropylene PP), metal-plastics, galvanized steel and corrosion-resistant metals - stainless steel, copper. Their standard internal diameter is 15 (16) - 20 - 25 - 32 - 40 mm.

The pipeline must withstand the maximum pressure in the water main with a margin of at least one and a half times. Since in communal apartment buildings the maximum pressure standards are up to 6 atmospheres for cold water and 4.5 for hot water, it is clear that any pipe in the water supply system must withstand a pressure of 10 atmospheres.

Regarding temperature parameters in systems with hot water or coolant, the lower threshold of heat resistance of the pipeline material should not fall below 90 °C; in underfloor heating circuits, the limit is considered to be 60 °C.

Rice. 9 Elements of heating, ventilation and climate control systems - schematic representation

Types of schemes

A diagram in design documentation is a document that graphically shows the symbols of the main elements of communications or parts of products, equipment, as well as the connection (connection) between them. Their distinctive feature in comparison with drawings is the lack of image scale and correspondence to the real spatial arrangement of elements.

The types and types of schemes are regulated by GOST 2.701-84, the most famous of them, usually used in individual housing construction:

- Electrical.

- Hydraulic.

- Energy.

- Gas.

- Combined.

According to their purpose, schemes are divided into the following categories:

Structural . A structural or block diagram shows the main components of the product, their purpose and mutual connections, and reveals the functioning algorithm. Parts of a system or device are depicted inscribed in rectangles, diamonds or other shapes, connected by indicating relationships with lines with arrows.

Developed at the initial stage of designing a product or system, they are useful for studying its operating principle.

Functional . They reveal the processes occurring in the system, a specific product or its individual components. Necessary for determining the principle of operation, technical parameters of products, used in adjustment, adjustment, repair, monitoring of the physical parameters of the working environment and equipment.

Rice. 4 Sewerage diagrams in drawings according to GOST 21.601-79 - examples

Principled. These are detailed diagrams with a graphical indication of all elements, their main technical parameters and connections between them. They give a detailed idea of the structural design of a system or equipment and are the main document when carrying out repair work with the replacement of parts or assemblies.

Connections. Wiring diagrams show connections between individual units or parts of systems, simple products, and complex technical equipment. Laying methods and methods of connecting system elements, connection points are established, indicating the input and output points of the joined fragments.

Connections. The diagrams show the connection of external communications, products, and equipment to system devices. The type of connections is disclosed, indicating their technical characteristics.

Are common. They show the main system components and connections between them in relation to specific installation conditions and are linked to equipped objects of various types.

Locations. They specifically show the placement of various communication nodes and equipment relative to objects and each other, indicating distances in length units.

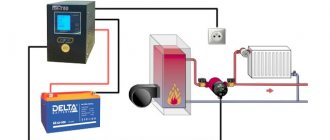

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system increases significantly. In this case, thin pipes can be used, which, in turn, helps reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is released into the atmosphere is reduced, and the daily consumption of electrical energy is no more than 250 W.

Of course, such a device is not cheap. You will have to pay a large amount for its purchase, but the cost will certainly pay off later when used due to energy savings and durability. The device will not require repair for a long time.

Vilo pumps have many positive properties.

The most important of them are the following:

- After water evaporates, there is no heat loss.

- The operation of the system can be controlled automatically. The device has a liquid crystal screen, a built-in thermostat and other elements that allow control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent failure due to sudden surges in voltage in the electrical network.

- The motor operates silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms of several hundred square meters. The selection is carried out according to such parameters as power, volume of circulated water, room area and pressure height. The last parameter is the most important.

You can see how to distinguish an original pump from a fake in the following video: