Few residents of apartment buildings are well aware of the rules for flushing heating pipelines. Meanwhile, this operation can extend the service life of the entire system, and, what is important for each of the residents of the house, improve the efficiency of its operation. After all, everyone wants their apartment to be warm and cozy in winter! And the temperature in the apartment in the winter cold directly depends on timely and high-quality washing.

With the onset of cold weather, many note that the heating in the apartment does not work very well, to put it mildly. Utility workers, in turn, assure that everything on their part complies with the standards, the temperature of the coolant is sufficient to keep the house warm. Everything is correct, everything corresponds - but in the bedroom no higher than +17! Residents buy heaters and curse in their hearts both careless utility workers and standards that do not correspond to the real climate.

However, the problem often lies elsewhere. Simply, the pipes are clogged, the passage of coolant is difficult, and the bulk of the heat goes to heating solid deposits in the pipes, and not the radiators in the rooms. It's time to flush your home heating system! Naturally, residents cannot do this on their own. And they shouldn't!

COST OF HEATING PRESS TEST

The COST of heating pressure testing is calculated individually, after visiting the site. The survey to submit a commercial proposal is free, call!

TABLE with examples of the cost of heating maintenance (pressure testing, related work and delivery to MOEK)

| Name | Work carried out | Cost of maintenance of one separate building up to 3000m2 | |

| 18000 rub. | |||

| SET OF WORK No. 1 Preparation for delivery to MOEK for new heating systems* | 1. Replacement of pressure gauge - 4 pcs. 2. Pressure testing of the heating system | ||

| SET OF WORK No. 2 Preparation for delivery to MOEK with system restoration** | 1. Replacement of pressure gauge - 4 pcs. 2. Washing the dirt filter - 2 pcs. 3. Restoration of the anti-corrosion coating of the elevator 4. Restoration of the thermal insulation coating of the elevator 5. Restoration of markings and designations of the elevator 6. Pressure testing of the heating system | 22000 rub. | |

| COMPLEX OF WORK No. 3 Preparation for the heating season with delivery to MOEK*** | 1. Organization of acceptance at MOEK 2. Replacement of the pressure gauge - 4 pcs. 3. Washing of the dirt trap filter - 2 pcs. 4. Restoration of the anti-corrosion coating of the elevator 5. Restoration of the thermal insulation coating of the elevator 6. Restoration of the markings and designations of the elevator 7. Pressure testing of heating 8. Registration of a certificate of readiness of the energy recipient equipment for the heating season. | 45,000 rub. | |

The following are checked: heating devices, pipelines, dirt traps, shut-off and control valves, instrumentation of the heating system

* It is assumed that the anti-corrosion and heat-insulating coatings of pipelines are in satisfactory condition, that shut-off and control valves, tags and designations on pipelines are in satisfactory condition.

** The complex includes work to restore the anti-corrosion and heat-insulating coatings of pipelines to a satisfactory condition, repair of shut-off and control valves, washing of dirt filters, restoration of markings and designations on pipelines and shut-off and control valves, pressure testing of the heating system.

*** Work on organizing the acceptance of the readiness of energy-receiving equipment for the heating season, pressure testing of the heating system. It is assumed that the anti-corrosion and heat-insulating coatings of pipelines are in satisfactory condition, that shut-off and control valves, tags and designations on pipelines are in satisfactory condition.

Contract for flushing and pressure testing of heating, delivery of results to MOEK.

MOEK (Moscow United Energy Company) requires all owners of Moscow buildings to carry out work to prepare the heating system for the heating season every year. This requires the following actions: Carrying out preparatory measures, replacing and repairing heating units (if necessary), handing over the prepared heating system to the MOEK inspector with the signing of the “accumulation sheet”. One of the preparatory measures for such preparation is pressure testing of the heating system. Pressure testing is a deliberate and most important thing - a controlled increase in pressure in the heating system above the working one (the value is determined by regulatory documents), turning off the booster pump and subsequent monitoring for 30 minutes. During this time, the system is inspected for leaks and deformations. If pressure drop, leaks and deformations are not detected, then the heating system is considered to have passed the test.

OUR SERVICES

| Flushing the heating system | Boiler washing | Flushing heat exchangers | Heating pressure testing |

An engineer’s visit to calculate the cost of work is free of charge.

To contents

Regulatory rules for conducting hydropneumatic tests

The rules for carrying out such work are determined by regulatory documents - SNiP (building codes and regulations).

These standards regulate certain technological schemes and instructions, taking into account the specifics of work from the point of view of compliance with safety regulations, and also define equipment for pressure testing of the heating system.

These standards regulate certain technological schemes and instructions, taking into account the specifics of work from the point of view of compliance with safety regulations, and also define equipment for pressure testing of the heating system.

Hydraulic tests must be preceded by flushing and preparation of the main pipeline of the heating system. Flushing is carried out in various ways and aims to remove scale and deposits of various salts and other chemical compounds from the internal walls of pipes in the system. A compressor is used for this.

Composition of deposits on the walls of pipes of heating systems (in decreasing order):

- ferrous oxide;

- magnesium oxide;

- calcium oxide;

- copper oxide;

- zinc oxide;

- trivalent sulfur oxide.

Important! Flushing should be carried out every 5-7 years of operation of the heating system. This will make the operation of the entire system more reliable and of higher quality.

What is the practical meaning of such a flush? During operation, heating efficiency is significantly reduced due to plaque and deposits on the pipes.

The flow diameter of pipes is reduced by almost half due to deposits and scale. This all leads to breakdowns and disruptions to proper operation. Due to scale and deposits, the quality of water circulation decreases.

The flow diameter of pipes is reduced by almost half due to deposits and scale. This all leads to breakdowns and disruptions to proper operation.

The procedure for carrying out work when performing pressure testing of the heating system:

— agreement on the availability of access at the time of work to ALL premises of the building and the presence of the minimum possible number of people; — checking that the system is filled with coolant (water) and that there is no air in the system (de-airing); — installation of plugs on safety valves; — shutting off shut-off valves on the lines of expansion tanks;

— shutting off the shut-off valves on the inlet pipelines (disconnection from the city) or from the boiler (for autonomous heating systems); — connection to the system of a booster pump and control pressure gauge; — raising the pressure in the heating system to the required (1.5 operating pressure of the system, usually from 6 to 10 Bar); — turning off the pump (press) and maintaining a technological pause (15 min); — inspection of the system for leaks, leaks, ruptures, monitoring of pressure drop (no more than 0.2 atm in the absence of leaks); — pressure release to working level; — registration of a pressure test certificate for the heating system;

When carrying out crimping there are several points that you should pay special attention to:— the scale mark on the control pressure gauge should be no more than 0.01 MPa (0.1 Bar); — the increase in pressure and its release should be carried out smoothly without the formation of “water hammer”; — when carrying out pressure testing of a heat supply system, including various types of heating equipment, it is necessary to ensure that the test pressure for one equipment does not exceed the maximum permissible for another. Otherwise, damage is inevitable; — all general rooms with equipment must be equipped with artificial lighting; — all floor spaces and passages must be cleared of foreign objects; — it is advisable to carry out disinsection and deratization measures in all general premises; — rooms with equipment must be dry. |

To contents

Necessity

Despite the fact that most consumers who have a centralized heating system in their homes are accustomed to the fact that pressure testing is carried out in the summer, it is recommended to carry it out twice a year.

In addition, crimping is carried out in the following cases:

- Do-it-yourself pressure testing can be carried out at any time if there are suspicions about the integrity of the system, for example, rust on the pipes, their bending, etc.

- According to the rules of SNIP, pressure testing of the heating system is necessary when putting it into operation, for example, in new buildings or after major repairs with the replacement of pipes.

- If necessary, sewer risers can be pressure tested to identify defects. Considering that the sewer system is usually gravity-fed, a small leak does not cause problems until the riser becomes clogged or the water intake level is exceeded.

- In some cases, control pressure testing is carried out to resolve controversial issues, for example, when filing a civil lawsuit against neighbors who flooded as a result of burst pipes. In this case, a pressure test certificate for the heating system is issued, the form of which is certified by specialists and handed over to the judicial commission.

Pressure testing of heating systems

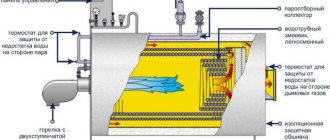

The heating system is a high-tech engineering system that allows you to maintain conditions of thermal comfort in the premises. In our country, where temperatures in winter drop below zero, the issue of reliable and uninterrupted functioning of the heating system is extremely important.

Unfortunately, even the best installed system can fail. Due to harsh operating conditions, over time, pipes become corroded, may suffer mechanical damage, and in rare cases, there may be manufacturing defects.

Also, one of the dangers for the heating system is water hammer - a sharp short-term increase in pressure in the system caused by a change in the speed of water flow, which can result in serious damage to the system, including destruction of the pipeline.

To prevent emergency situations, a control method is used using pressure testing, and if the system does not leak under excess pressure, it can be reliably operated in normal mode.

Pressure testing or hydropneumatic testing is one of the types of testing the tightness and operability of a pipeline system, heat exchangers, pumps and other equipment. To do this, in a small section of the network to be checked, excess pressure is created using water, which renders it unusable and makes it possible to see emergency sections of the system.

Washing and pressure testing are mandatory activities in preparation for the heating season. In addition, hydraulic tests (pressure testing) are carried out:

• before commissioning a new pipeline or heating system (primary pressure testing). Any solder or connection is a potential leak point and the weakest points of the structure; crimping helps to diagnose the build quality of a new mechanism and identify all its problem areas, and evaluate the strength of the case. • after completing a major renovation of a house or building, after carrying out preventive or repair work on the heating system. • after reconstruction or modernization of the heating unit. • annual regular inspection of heating systems before the start of the heating season; • as a diagnostic method in case of emergencies, malfunctions and problems in the operation of heating systems.

To contents

Working and pressure testing in the heating system

During the entire heating season, a certain constant pressure, called working pressure, is maintained in the heating system. During pressure testing, excess pressure is injected into the system, the magnitude of which is determined by SNiP standards.

The pressure test during hydrodynamic tests depends on the type of heating equipment and the number of floors of the building. Failure to comply with established standards can lead to damage to the system, so special attention should be paid to factors such as:

1. Type of building (residential, warehouse, administrative, industrial, etc.; 2. Number of floors; 3. Type of heating radiators used.

Table. Operating and testing pressure in the heating system (approximate data)

| Radiators and convectors | Operating pressure | Crimping |

| cast iron radiators | 9 kg/cm2 | 9 kg/cm2 |

| steel radiators and convectors | 8.5 kg/cm2 | 13 kg/cm2 |

| bimetallic radiators and convectors | 5.5 kg/cm2 | 7 kg/cm2 |

| Building | Operating pressure | Crimping |

| low-rise buildings (no higher than 3 floors) | 1.9 kg/cm2 | 3-4 kg/cm2 |

| low-rise buildings (4-5 floors) | 3-6 kg/cm2 | 6-8 kg/cm2 |

| buildings from 7 floors and above | 7-10 kg/cm2 | up to 12 kg/cm2 |

In low non-residential and residential buildings (no higher than 3 floors), the usual pressure is not higher than 1.9 atmospheres. It is regulated by a special emergency valve located in the boiler room, which is activated, preventing accidents, whenever the pressure exceeds the norm.

To contents

Similar materials on the company website

JSC "Teplokontrol" - Temperature regulators LLC DESIGN PRESTIGE Heating water supply boiler room 8(495)744-67-74 Heating repair Repair of water supply...

Cyclone BC-259-(6×8) - Ash catchers Technical characteristics Cyclone BC-259-(6×8 ) Type: Ash catchers Operating pressure, MPa: 32 Dimensions,…

Veer-2M No. 2 - Flat-spray nozzles of the “Veer-2M” type Technical characteristics of Veer-2M No. 2 Type: Flat-spray nozzles of the “Veer-2M” type Nozzle performance,…

Water hammer in heating networks and its consequences

Timely tests make it possible to identify weak points in communications and prevent a possible accident. The usual operating pressure in the heating main is 12 atmospheres. A sudden increase in permissible pressure causes a situation called water hammer.

What are the consequences of water hammer in a heating network? The moment of occurrence and spread of water hammer cannot be tracked: having suddenly formed in the heating network, it is instantly transmitted to the general heating system, including intra-house communications that are not designed for this pressure. As a result, cracks and leaks occur; in the most serious cases, an accident occurs - a rupture of a weak part in the pipeline, flooding of premises with hot water, which leads to damage to valuable property, furniture, equipment, etc. Subsequently, fungus and mold may spread on the walls and ceiling. Since the pressure in heating systems is high, an area of several tens of meters around can be flooded with boiling water. If a room is flooded with boiling water, people can also be harmed. Regular hydraulic checks and professional maintenance of the heating system help to successfully avoid such unpleasant and dangerous moments.

To contents

How is heating pressure testing carried out?

Pressure testing is carried out using water (hydraulic testing of pipelines) or using air or inert gas (pneumatic testing of pipelines). For testing pipelines, the hydraulic method is most desirable; this simplifies the detection of cracks and defects based on pressure gauge readings, and does not contribute to rapid ruptures at the test pressure level. The testing stages are always standard.

Initially, the area to be pressure tested is sealed and closed, completely disconnected from the rest of the network. A pressure increasing device (pump) is connected to the system, with its help the pressure is increased to the operating value, and a visual inspection is carried out to identify defects in the system. After this, the pressure increases to the test value according to the control pressure gauge. If the heating system is successfully tested, the pressure does not drop after a certain time, and no ruptures are recorded.

If a leak is detected, the defect is eliminated and the procedure is repeated until a successful result. The operating pressure in the heating system depends on the number of floors in the building, its type and the properties of the heating devices. The operating pressure in private houses no higher than three floors, as a rule, does not exceed 2 atmospheres and is regulated artificially; when the pressure increases, the relief valve is activated.

For multi-storey buildings with 5 floors, the operating pressure level is 3-6 atmospheres, from 9 floors it is about 7-10 atmospheres. The minimum value of the test pressure during hydraulic pressure testing should be at least 20-30% greater than the working pressure, while the maximum pressure is calculated based on the type of pipe.

The importance of pressure testing a heating system

Sometimes clients neglect flushing systems and hydraulic tests, believing that such measures are not very necessary. At the same time, carrying out these measures is quite sufficient to ensure the correct operation of important equipment for a sufficiently long time. The exact cost of a hydraulic inspection service depends on the nature of each individual object, its architecture, normal loads, and the need to use special equipment for research and washing. Much depends on how the client uses the installed system. For some, it can work around the clock, others turn it on only at night or only during the day, and some clients use the devices only during the season.

It should be noted that the low price of crimp testing usually means that the package includes a minimum of services and does not include eliminating problems when they are detected. And, for eliminating the problem or replacing any elements of the system and additional visits by specialized specialists, you have to make an additional payment. We exclude such cases by informing our clients in advance that the provided price list for hydraulic testing includes only general prices, without taking into account the individual characteristics of a particular situation.

In order to avoid client confusion regarding the cost of services, before voicing them, we send our experienced specialist to the site, who, having carried out all the necessary examinations and taking into account all the features, will prepare a package with the optimal range of services.

To do this, you need to leave a request on our website to receive detailed advice and proposals for crimping, and a company manager will contact you within no more than half an hour.

To contents

Hydropneumatic testing process

How to pressurize a heating system? The following procedure for pressure testing and flushing primarily applies to the prevention and testing of heating systems in residential apartment buildings.

Pressure testing of heating systems is carried out after completion of heating operation at the end of the heating season. As a rule, in our area the heating season ends in April. At the same time, the condition of shut-off valves, riser pipelines, thermal and elevator units is checked.

To eliminate problematic blockages in risers, flushing is carried out. Before this, the following preparatory work is performed:

- checking the elevator, risers and main pipeline;

- inspection of all elements of the heating system to identify leaks and eliminate them;

- checking thermal insulation on risers, highways and basements.

Important! At the thermal unit, preparatory work should be carried out after the system has been prepared, since hydrotesting of the thermal unit is carried out at a pressure higher than in the system.

Important! At the thermal unit, preparatory work should be carried out after the system has been prepared, since hydrotesting of the thermal unit is carried out at a pressure higher than in the system.

Sequence of hydropneumatic tests:

- filling the system with water;

- a press is connected for crimping heating systems;

- checking the pressure gauge readings.

If within half an hour after the pump for pressure testing heating systems has been connected, the pressure readings do not change, this means that the system is sealed and can be considered pressure tested. If the pressure reading on the pressure gauge decreases, there is a leak in the system. It is searched for, eliminated, and the process repeats.

Crimping of the input unit is carried out separately under a pressure of 1 MPa. Pumps for pressure testing heating systems can be manual or electric.

Crimping of the input unit is carried out separately under a pressure of 1 MPa. Pumps for pressure testing heating systems can be manual or electric.

After this, a representative of the organization that provides heat supply and a representative of heating networks fills out the report form. A representative of the heating service has a sample of the heating system pressure test report.

After this, a representative of the organization that provides heat supply and a representative of heating networks fills out the report form. A representative of the heating service has a sample of the heating system pressure test report.

The inspector also checks the system for rigidity. To do this, a sample of network water is taken from any tap and the content of magnesium and calcium salts in it is determined in a laboratory method. The standard water hardness is 75-95 units. If all parameters are normal, this means that the system is ready for operation.

When is it necessary to check and pressure test heating systems?

Hydraulic checks and pressure testing are required:

• When putting the system into operation, upon completion of installation and all necessary commissioning work. • When preparing systems for the next cold season. Seasonal pressure testing is simply necessary to eliminate leaks and prevent possible subsequent accidents; • Flushing and pressure testing of heating systems is required both upon completion of repair work and after local replacement of pipes, valves, shut-off valves and other components;

Timely testing and control is necessary at any facility, be it a residential, warehouse or industrial building. If you do not carry out regular checks, this can lead to such unpleasant consequences as a breakdown of communications, flooding of premises, malfunctions of the heating system and the vital functions of the entire building. Regular hydraulic testing of heating systems and air conditioning systems in multi-storey residential buildings and other facilities with social purposes, large entertainment or shopping centers is reflected in SNiP.

To contents

Conclusions and useful video on the topic

Video #1. The effectiveness of using hydropneumatic radiator flushing can be assessed by the amount of dirt thrown out:

Video #2. The subtleties of performing a chemical type of flushing of the heating system are outlined in the following story provided by the owner of a private household:

Any of the considered options for flushing heating systems does not represent an overly complicated procedure. If you have some experience in plumbing work and, in some cases, special equipment that can be rented, you can perform this operation yourself.

Would you like to talk about the effectiveness of flushing or tell us how you flushed the heating circuit in your home? Do you have valuable recommendations or important nuances that you would like to share with site visitors? Please write comments in the block form below.

sovet-ingenera.com

Flushing the heating system (cleaning from the inside)

The purpose of flushing the heating is to clean the system of various types of contaminants, deposits and rust.

During operation of the heating system, various deposits arise and accumulate inside it.

This is mainly scale, which is formed due to the precipitation of mineral salts, primarily calcium and magnesium. In addition, small and large particles of rust get into the salt build-up. Over the course of many years, all these various contaminants settle on the walls of the pipeline and other elements of the heating system, reducing its performance and increasing the hydraulic resistance to coolant circulation. They also cause deterioration in heat transfer of heat exchangers, reduce operating efficiency and increase thermal energy consumption, and at the same time, naturally, the cost of servicing heating systems increases. Ultimately, the situation is fraught with an increased risk of failure of the entire heating system. The layer of contaminants and deposits can be up to 50% of the pipe cross-section.

It is not uncommon that in systems where flushing has not been done for more than 10 years, the layer of contaminants and mineral deposits makes up about 50% of the pipe cross-section, significantly reducing the functionality of the system.

Heating systems are usually flushed before pressure testing. The purpose of flushing is to clean the system of various types of contaminants: construction debris, deposits and rust. Flushing should be carried out annually, after the end of the heating season or installation work.

To thoroughly and effectively flush even an old heating system, our specialists use the following methods:

• Chemical flushing of the heating system

When chemically flushing heating, a specialist selects a cleaning agent depending on the type of contamination and pipe material. An acidic, alkaline or gentle neutral base can be used. In addition, anti-corrosion reagents are added. A special flushing liquid with chemically active substances is pumped and circulated through the heating system, dissolving internal contaminants and deposits. Its chemical composition forms a special protective layer on the internal surfaces of pipes and heat exchangers that prevents corrosion and protects against possible contamination in the future.

This method allows you to effectively get rid of scale and rust in hard-to-reach places in the heating system - heat exchangers, pipes, radiators - without disassembling the system. With annual chemical flushing, the heating system can operate for approximately 20 years without major repairs or replacement of elements. Heat consumption is reduced by 30-40%.

Professionals must pay attention to the following points:

— Correct selection of cleaning agent and reagents. Do not use acids or alkalis to flush aluminum radiators. — Taking into account the toxic properties of the flushing liquid. Work in a ventilated area, use personal protective equipment, follow safety rules. — Correct washing duration according to instructions to complete the reaction. — Rinsing with clean water and connecting the system for further operation.

• Hydropneumatic flushing of the heating system

The essence of flushing is to supply water and compressed air to the heating system using a special compressor. The water-air mixture under a pressure of 6 kgf/cm2 passes through the heating system and is discharged into the sewer system using a hose connected to the valve. Flushing is carried out first from the supply point to the return, and then in the opposite direction. The process is repeated until the outlet water is completely clarified. This method is slightly less effective, but also allows you to clean the heating system of foreign matter;

• Flushing the heating system using water hammer

In this case, a special device is connected to the system, which forces the pressure so much that the water speed reaches up to 1.5 km/sec. The resulting hydraulic shock is capable of tearing off foreign fractions and contaminants from the inner surface of the pipes and bringing them out. This method is quite effective only for small systems, since the device is capable of throwing a strong jet up to a maximum of 60 meters.

• Hydraulic flushing of the heating system

Simply, rinse with running water. Typically used in private homes as a gentle and cost-effective cleaning of heating system elements. This washing can remove dirt and pulp, but if there is a large amount of solid deposits, more effective methods will be required.

All of the above methods have their own subtleties and features, knowing which you can further increase the effect of washing. Our company has developed and applies environmentally friendly technologies that allow us to clean the internal surfaces of pipes, boilers, heat exchangers and other heat supply elements from contaminants.

The work performed by the craftsmen and engineers of our company provides guarantees of high quality flushing and confidence that the system will operate flawlessly for all the necessary time, throughout the heating season, providing homes and residents with heat and hot water all year round.

How we are working

Order service

To contents