Innovative technologies and materials make it possible to improve the basic elements that create comfort in the home, in particular the heating system. Today, the consumer is able to increase its functionality and reliability. But some of the innovations that are being introduced to improve the performance of the heating system are associated with risks. Even basic things can threaten her work. For example, water. Some homeowners choose non-freezing liquids for heating systems, and this, as practice has shown, is much more rational.

Antifreeze for living quarters

Non-freezing liquid for the heating system - antifreeze, antifreeze, but having a completely different composition than products for cars. The main property of this household product is that it does not transform into ice when the temperature drops even to -60 °C (the substance simply thickens).

Any antifreeze for heating systems, for example, Warm House, is produced according to the same principle. The product contains:

- alcohol or glycol;

- base active ingredient;

- inhibitory components that protect against rust;

- additives that are responsible for the properties of antifreeze.

Anti-freeze for the heating system of a country house - an alcohol-based product. The glycol alcohol substance is not dangerous, but other components of the liquid can harm people:

- glycerol;

- ethylene;

- propylene.

The area of application of the product for the home heating system depends on the constituent substances. It is not recommended to use a product containing ethylene.

Liquid containing ethylene should not be allowed into the heating system of a building where people live permanently. This product is very poisonous, and if it gets on the skin, it will cause tissue burns. When an ethylene-based antifreeze liquid gets inside the body (both in liquid and gaseous states), severe complications develop, including death.

A low-quality antifreeze product and the familiar antifreeze for cars, which sometimes unknowing people pour into the heating line of a building, is produced precisely with ethylene glycol. If there is even an insignificant risk of people coming into contact with ethylene, it is correct to refuse its use in systems:

- vapors from an open expansion tank;

- leak;

- mixing into the DHW circuit in 2-circuit boilers.

It is prohibited to use ethylene antifreeze for systems where a 2-circuit boiler is used as a heating element.

Antifreeze based on propylene is absolutely non-toxic - it can be safely used for heating systems. This does not mean that if it gets on the skin or even inside the body, no problems will arise. Still, this is a chemical substance and it is alien to the body. But it will not lead to death or severe damage to internal organs. This non-freezing liquid can be safely poured into the home heating system.

Antifreeze based on glycerin has been used in circuits since the 50s of the 20th century and is used today. Unlike the two heating compounds listed above, glycerin liquid does not dry out the rubber, but, on the contrary, promotes restoration and renewal. Therefore, the rubber seals of the system will not deteriorate.

Reasons why boiler manufacturers refuse to use antifreeze

(Slovakia) declares that it is not responsible for the consequences caused by the use of antifreeze. Cast iron boilers manufactured by the company are not designed to interact with non-freezing liquids. Vaillant (Germany) is even more categorical, declaring that non-freezing liquids cannot be used in wall-mounted boilers! As for other manufacturers, everything is more confusing here. Some of them inform about the use of special paronite gaskets in the design of boilers, which are suitable for many types of antifreeze. However, the other side of the coin is not advertised: difficulties with seals are not the only problem when using antifreeze.

Characteristics of anti-freeze

The behavior of the product in the heating system is affected by the quality of the additive elements and the conditions of use. Regardless of which base material is included in the glycol base, all fluids protect against corrosive formation and foaming.

If there are no additives, it is harmful to use an antifreeze product for home use. Such antifreezes foam, especially those based on glycerin. Foam is a substance containing air. Oxygen causes circulation problems, forms air pockets, and can also cause water hammer in the heating network.

Additives have a time resource. When a certain period of time passes, they disintegrate into molecules. A precipitate forms and acid is released. This means that nothing can neutralize the aggressiveness of the antifreeze liquid for the heating system of the building. In addition, the situation is worsened by the formation of acid. The terms of application of the compositions in years are as follows:

- ethylene based – 5;

- propylene – 5;

- on glycerin – 10.

Temperature matters. When the temperature of the coolant increases to 90 °C, the non-freezing liquid for the heating system begins to split and lose its qualities. This happens if the boiler is not started correctly after a long period of inactivity, as well as due to errors when installing equipment.

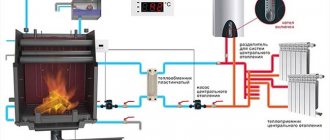

For example, when a heat exchanger is installed in a standard stove. Often homeowners arrange it so that it is in contact with open fire. Do not use antifreeze in the oven - this is strictly prohibited. It is necessary that there is a layer of brick between the exchanger and the fire. This way the heat will dissipate efficiently, and the non-freezing liquid for the heating system will not heat up too much.

Properties affected by the quality of filler components:

- viscosity;

- fluidity;

- heat conductivity;

- thermal expansion;

- density.

The better the additive elements of the non-freezing liquid for the heating system, the higher these properties are. This means that they are as close to the characteristics of water as possible. The level of thermal expansion should be low. The volumetric expansion of non-freezing heating fluid is higher than that of water - this is important to take into account when filling the system.

The thermal conductivity of antifreeze is less than that of water. For glycerin products it is the lowest - 85%, for other antifreeze products - 90%. The difference is insignificant.

Antifreeze is 50% more dense and viscous than water. These properties negatively affect circulation. To improve the movement of the coolant along the circuit, powerful pumping equipment is required. It would be nice to assemble a heating network from pipes with a large diameter. For example, when it comes to polypropylene pipes, section 32 is suitable.

Circulation pump

Antifreeze liquid for the heating system is more compacted and viscous, but it has a high level of fluidity. Thanks to this, it is able to move where water cannot pass due to surface tension. Therefore, if there are microscopic cracks and even micro-holes, then antifreeze will leak in this place.

Therefore, often, after water has circulated in the circuit and antifreeze has been poured into it, leaks are found. Most often, micro-holes or cracks are found in the following places:

- pipeline joints;

- areas between radiators;

- areas for connecting additional components;

- directly the boiler tank.

Water as a coolant for the heating system of a private house

Water is the most accessible coolant, but it cannot always be used. In terms of technical parameters, it is superior to any antifreeze, but for many homeowners its disadvantages cancel out all its advantages.

Advantages of water as a coolant

- Compatible with heating equipment. Condensing boilers are designed to operate on water. All parameters are valid only when working with this coolant. Boiler heat exchangers have a small tube diameter, so when using antifreeze, over time they can become clogged with additives and other decomposition products of liquid components. For this reason, adding antifreeze will void the equipment warranty of most boiler manufacturers.

Some boiler manufacturers allow the use of antifreeze while maintaining warranty service, but in this case only recommended brands of coolants can be used.

- Power of heating devices. For radiators, this parameter depends on the heat capacity of the coolant. With water it turns out to be 15 - 20% higher compared to antifreeze.

The power of the radiator can be calculated using the formula W=c*Q*(t2-t1), where c is the heat capacity of the medium, Q is the liquid flow rate in liters per hour, t2 and t1 are the temperature difference. Also, when calculating the number of radiators per room, it is important to take into account that the power parameter of the device on the packaging is indicated for operation on water.

- Water does not require replacement. Non-freezing coolants require replacement every 5 years. Some manufacturers produce compounds that can last up to 10 years. Replacing antifreeze and flushing the system is a labor-intensive procedure that will require the involvement of specialists and significant costs. At the same time, it is almost impossible to completely remove the antifreeze carrier.

This fragility of antifreeze is due to the additives that are present in their composition. These additives reduce corrosiveness so that substances do not harm heating equipment. Over time, the additives decompose and precipitate, after which ethylene glycol and propylene glycol begin to react with the metal.

- Water cannot be faked. The likelihood of purchasing counterfeit products when using water tends to zero. There is only a possibility of purchasing ordinary water under the guise of distilled. When using antifreeze, the possibility of filling with counterfeit liquid is higher.

- Safety. Water does not belong to the group of toxic substances, does not emit harmful fumes and is disposed of without great expense. Its harmlessness to humans makes water the only possible coolant for open gravity flow systems.

Disadvantages of water

The main disadvantage of water is that it freezes at 0 degrees. When the liquid turns to ice, it increases in volume by 10% and can burst pipes. This means that in any building where the temperature drops below freezing, water cannot be used as a heating medium. Such buildings include dachas, tourist centers, campsites, etc. There are many situations when the owner is not at home and he cannot control the operation of his heating system.

Also, improperly prepared water can lead to damage to heating equipment: corrosion, salt deposits.

What kind of water can be used for heating systems?

Water for heating systems must meet the requirements for two parameters: hardness and acidity, and it must not contain sand or other large particles. The pH indicator is responsible for acidity; normally it should be 7 units. Values from 1 to 6 correspond to acid, and from 8 to 13 to alkali. An acidic or weakly acidic liquid in a closed system tends to increase its pH to normal, for this it absorbs metals from the environment. This leads to destruction of pipes and boiler elements.

Hardness reflects the amount of salts dissolved in the liquid and is expressed by the total mineralization of the solution. When the temperature rises, these substances precipitate in the form of scale. The accumulation of deposits on the internal parts of the equipment can cause equipment failure.

If the heating system is closed and no new liquid enters it, then the initial amount of water will contain too few salts to clog the heat exchanger.

- Tap water – has a normal pH, but in some regions contains high levels of salts. Over several cycles of passage through the heating system, the hardness decreases, as some of the salts precipitate and are deposited on the heat exchanger. This will not cause any harm during startup, but it is not recommended to add water from a water supply or well to such a system, as there may be more deposits.

- Boiled water differs from ordinary tap water in the lower mineralization of the solution. At the same time, boiling large volumes is problematic.

- Bottled drinking water has normal acidity and a level of mineralization acceptable for humans. Thanks to this, it does not leave scale and is safe when topping up the system.

- Distilled water does not contain mineral impurities, but has a pH level of 5.4 to 6.6, which is not normal acidity. Some boiler manufacturers do not recommend using distilled water due to the potential for corrosion.

Which antifreeze to choose

If the user wants to use an antifreeze liquid, then when choosing it, you should not focus only on cost. Antifreeze for the home is a product presented on market shelves in a large assortment.

The “Warm Home” product, produced by a Russian manufacturer, is popular. Some homeowners use this type of anti-freeze. Its cost is reasonable. The main advantage is that it has improved operating properties. It can not be changed in the heating system for 5-10 seasons.

Antifreeze “Warm Floor” is the most popular on the Russian market

Prices for antifreeze liquids vary, so each homeowner can choose the right one. The assortment expands every year. They are made from high-quality raw materials and are safe for the body. The non-freezing liquid Warme Hydro has proven itself well, as well as Galan, Thermagent ECO -30, BOILER -65 oC. A specialist from a specialized store will always help you with your choice.

It is forbidden to fill the heating network of the house with car antifreeze. It contains components that are not suitable for residential use.

How to choose a coolant for heating

Drawing up a wiring project and installing heating in a private house should be carried out together with the choice of the type of coolant. The type of liquid selected depends on the boiler power rating and the performance of heating devices, the selection of such an important unit as a circulation pump and the purchase of other materials and components.

If a two-pipe heating system with bottom wiring will be used throughout the winter, then water is considered the ideal choice. At the moment, such a liquid is considered the main coolant. Water can be collected from a well or borehole, and it is absolutely free.

When the coolant is not used

Antifreeze sometimes cannot be used. Recommendations:

- When the heating network of a building is based on a 2-circuit boiler, no antifreeze is used. The substance may penetrate into the building's water supply circuit.

- Antifreeze is prohibited in open heating networks. The coolant will steam and the homeowner will have to top it up regularly.

- It is forbidden to pour the product into a system that consists of a galvanized pipeline. This provokes a change in the chemical composition of the antifreeze and its loss of its performance qualities.

- Antifreeze, when compared to water, has a lower heat capacity. If it is to be used as a heat carrier, then powerful radiator elements must be used when organizing the heating network.

- The antifreeze composition is viscous, so you cannot do without a strong circulation pump.

If the homeowner 100% decides to add antifreeze, then it is better to prefer products based on propylene or glycerin. The former are expensive, the latter have the lowest thermal conductivity and weigh more. Propylene glycol products are more innovative, which is why many people purchase them. Ethylene glycol liquids are prohibited for the home, since the risk of contact with residents is high, and maintaining a network with a toxic substance is a big problem.

Advantages and disadvantages

Compared to water, the coolant for the heating system has both advantages and disadvantages. The advantages include:

- the liquid is resistant to low temperatures, so the pipes will be in good condition even in severe frosts;

- heats more efficiently than water;

- there is no need to drain the non-freezing coolant when spring comes;

- when used correctly, does not cause allergic reactions and is not harmful to health;

- the cost of insulating heating pipes is lower;

- slow evaporation, so refueling the system is required less often, 1-2 times a season.

The antifreeze composition cannot be heated above 170 °C, it will begin to decompose.

Despite the advantages, home heating fluid has a number of disadvantages compared to water:

- installation of powerful equipment and a pump for the heating system;

- heat capacity is 15% lower;

- the volume of the heating radiator should be 50% larger;

- use only a closed tank.

Fluid deficiencies can be mitigated if heating communications are planned in advance, at the construction stage.

Methods and methods of water preparation

Water preparation for the heating system can be done in the following ways:

- adding additives, chemical reagents that change the composition of the liquid;

- cleaning using filter equipment;

- catalytic oxidation technique to eliminate excess iron by removing it into sediment;

- softening during treatment with electromagnetic waves;

- heat treatment - distillation, freezing, boiling;

- settling the liquid to eliminate sedimentary inclusions;

- deaeration to remove excess oxygen and carbon dioxide.

Types of boilers and filling of a closed heating system

The choice depends on the component composition of the coolant, but filters are always installed. For flows with a large inclusion of mechanical particles, powerful devices with an increased number of layers of quartz sand, activated carbon or expanded clay are required. And water with inconspicuous suspensions (soft) is passed through filters with washable or replaceable cartridges.

Important! Long-term heat treatment can remove carbon monoxide and soften water, but boiling does not get rid of calcium carbonate, which contributes to scale formation.

Rating of the best non-freezing liquids

TOP 5 antifreezes for the home will allow you to easily choose what you need. If problems arise, you can always contact the manager of a specialized store.

Knowing the advantages and disadvantages, it is important to buy a good heating fluid. The following brands of antifreeze are the most popular among users.

DIXIS-65

Ideal for use in gas and electric boiler equipment of any type of installation. Excellent transfer of heat at external temperatures from -65 °C to +9 °C.

This antifreeze composition is ideal for cast iron, copper, aluminum, and brass heating pipes. Does not damage joints, does not harm pipelines and plastic tanks. Together with the anti-freeze system, a sticker is issued for the heating boiler, where you can see fields for entering the fill date, volume and other details - this is indispensable when maintaining the system.

Experts gave the leading position in the rating to this particular non-freezing liquid, since its crystallization occurs only at -66 °C. This is the best substance for heating lines in northern regions - it will survive severe frosts and keep the pipeline and radiators intact.

When used in regions where the temperature in winter is not lower than -20 °C, the antifreeze liquid is diluted with water 1 to 1 - this is a serious money saving.

Pros:

- fire resistant;

- increased antifreeze rate;

- five-year warranty;

- protection of containers from burglary.

Minuses:

- liquid heat capacity is 10% lower;

- high viscosity;

- cannot be used in galvanized heating pipelines;

- prohibited in boiler equipment with electrodes.

THERMAGENT-65

Domestic liquid produced from German raw materials. The unique technology of Organic Technology is used in production. The antifreeze substance does not contain amines or other toxins. It is poured into boiler systems operating on liquid fuel, gas and current.

According to consumers, the drug does not spoil rubber, sealants and parasites. The manufacturer included additives that prevent the growth of bacteria and foaming, so the heating pipes will remain clean and with high-quality permeability.

The non-freezing coolant is included in the TOP 5, as it has a low level of crystallization at a temperature of -65 ° C, as well as a long service life. It protects against rust for up to ten years and is used for up to twenty seasons without losing its properties. This is more than economical.

Pros:

- raw materials for the production of antifreeze composition for heating are imported from Germany;

- the liquid does not freeze at low temperatures;

- can be bred;

- contains no toxins.

Minuses:

- ethylene is present;

- cannot be used in Galan type heating equipment;

- when combined with water, the quality of rust protection is reduced;

- functions poorly with wood-burning boilers due to overheating.

RODA

Antifreeze liquid from a well-known brand that creates boiler equipment from neighboring countries. The manufacturer also took care of the careful handling of heating systems.

Glycerin-based coolant is one of the safest. Contains an anti-foaming additive. The liquid does not freeze even at -30 °C. It boils after +105 °C, so it is suitable for a larger number of heating lines and equipment.

Contains a fluorescent dye for rapid detection of leaks in pipes and heating radiators. Non-freezing liquid is produced in containers of 10 and 20 kg. It is poured into the system in proportions of 113 kg per 100 liters.

Experts recommend this liquid for heating networks with open circuits, where the expansion tank is not equipped with a sealed lid. The organic antifreeze composition is not dangerous when evaporated. Therefore, this type of heating fluid can be used even in food industry enterprises. The advantage of the coolant is that it is allowed to be used in galvanized pipelines.

Pros:

- service life eight to ten years;

- fire resistance;

- will not harm circulation pumping equipment;

- When switching to this type, there is no need to flush the heating line.

Minuses:

- relatively high price for 10 kg;

- it is forbidden to overheat the liquid;

- cannot be used with non-polar plastic materials.

AMT-300

Antifreeze heating agent from a domestic manufacturer, supplied to the market in barrels weighing 20, 30 or 180 kg. This makes it possible to immediately buy the required volume for your home at an affordable price. It is based on an oily substance with flavorings. Products must undergo catalysis and adsorption for a higher level of purification.

Not suitable for open communication systems. The density of the oil substance is 940 kg/m3, therefore it is suitable for relatively warm climates. Antifreeze from this manufacturer is mainly used in southern regions, where it rarely gets colder than -15 °C.

Antifreeze for heating entered the TOP due to its increased thermal stability when heated and the impossibility of ignition under the influence of high temperatures. The boiling point of the oil is almost +300 oC. Therefore, it is even poured into equipment that runs on solid fuel, but only with powerful pumping units to increase circulation so that the non-freezing coolant does not overheat in the exchanger.

Pros:

- almost zero acidity is gentle on heating system components, rubber, plastic, metal, sealant;

- high-quality fluidity in a heated state;

- high anti-corrosion properties, regardless of the period of use;

- does not accumulate condensation and does not form plaque.

Flaws:

- antifreeze composition is prohibited for open boilers;

- crystallizes at -15°C;

- it is necessary to use powerful pumping equipment.

Ethylene glycol based coolant

Most likely, due to its simple preparation and low cost, the group of antifreezes that contain ethylene glycol is the most common among others. As we noted, the coolant is found in the form of a concentrate or in a ready-made solution, usually with a crystallization threshold at -30º C. Antifreeze is red, supplied in cans from 10 to 50 liters. The declared characteristics in a concentrated state are capable of serving a temperature range from – 65º to + 110º C.

If necessary, guided by climatic realities, you can always bring the coolant to the required crystallization value. The requirement for antifreeze concentration is regulated by the service center of your boiler and pumping equipment. It is recommended to mix the concentrate with distilled water according to the table below. The red color of antifreeze warns of the need to adhere to the strictest safety measures.

| Water percentage | Concentrate percentage | Freezing threshold | Boiling threshold |

| 87,5% | 12,5% | -7 | 100 |

| 75% | 25% | -15 | 100 |

| 50% | 50% | -40; -45 | +130; +140 |

| 40% | 60% | -50; -60 | +150; +160 |

| 25% | 75% | -70 | +170 |

Disadvantages of Ethylene Glycol

- Ethylene glycol foams when exposed to high temperatures, forming air pockets in the system. Manufacturers solve the problem by adding special additives. Additives help prevent foam formation, including preventing corrosion processes in metal structural elements. Galvanized elements should be avoided - they are susceptible to the negative effects of ethylene glycol, despite the additives.

- The negative point is the irreversible process of decomposition of ethylene glycol when the boiling point is reached. During the degradation of antifreeze, a hard, insoluble precipitate is formed, which settles in the pipeline or heat exchanger. The liquid residue takes on the character of aggressive acids that promote corrosion processes. Additives lose their positive properties and no longer prevent foaming of the coolant.

Thus, ethylene glycol antifreeze can be used only when boiler equipment is equipped with a control and adjustment system that maintains specified temperatures.

- Ethylene glycol is a highly toxic product. Penetration of a substance into a heated living space (liquid or vapor phase) seriously threatens the health of residents. Contact of ethylene glycol-based coolant on exposed skin is unacceptable. That is why the use of ethylene glycol antifreeze is allowed only in “closed” heating systems, with a closed expansion tank equipped with a membrane. The use of ethylene glycol in a double-circuit boiler is not allowed.

As we can see, there are a lot of shortcomings, and quite significant ones at that. The only attractive aspect is the low cost of the product. The price of ready-made formulations does not exceed 60 rubles per liter, the cost of concentrated products stops at 90 rubles per liter in 2022 prices.

A significant limitation to the use of ethylene glycol as a coolant is the manufacturers of wall-mounted gas boiler equipment. Companies strictly prohibit the injection of ethylene glycol-based antifreeze into systems using their devices and withdraw them from warranty service if the rules are ignored by the consumer.