- Buleryan

Every home during the cold season needs high-quality, reliable and highly efficient heating. In conditions of high energy prices, many buyers are trying to save money. Therefore, despite the abundance of modern solar systems, “warm electric and water floors,” gas and electric boilers, owners of private and commercial real estate are increasingly returning to a long-burning wood-burning heating stove for their home. It is a useful aid in the autumn-winter period and a wonderful interior decoration. In our article we will look at the operating features of such devices, their varieties, and tell you what to look for when choosing.

Design

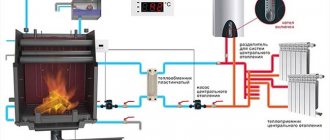

Structurally, devices with slow combustion of fuel are divided into two types - with a built-in water circuit and without it. In the first case, the installations are used to heat buildings with a fairly impressive area. They are connected to a heating system with installed radiators, heating tanks and pipe distribution. Such a purchasing decision will cost much more than installing a contourless product. However, the investment pays off over time - the house will be heated from the device, which provides autonomy for up to 12 hours on one load of fuel briquettes.

Stoves that are not equipped with a water outlet are also capable of heating large volumes, but within the same room. The manufacturer always describes the physical and operational capabilities of the equipment in the technical documentation. Therefore, before purchasing, you need to carefully study it to ensure it meets your requirements.

Types of solid fuel for pyrolysis stoves

Of course, dry wood is considered the best choice of fuel for such a heating unit. But since one of the main reasons for installing long-burning appliances is to save money on heating the home, other types of combustible materials that are constantly at hand by the owners are also suitable.

You can replace logs with inexpensive fuel granules - pellets, which are made from pressed waste wood and agricultural crops; they can be wood chips, sawdust, onion or sunflower seed peels and other environmentally friendly raw materials.

Operating principle

Devices with long fuel combustion, when compared with conventional traditional designs, are more economical and efficient. This is due to the peculiarities of their functioning. For such units, one fill of fuel lasts much longer. To understand how a slow-burning stove for a home differs from a classic firebox, it is necessary to consider their components in more detail.

The process during which wood burns slowly is called pyrolysis. To describe this in simple terms, they say that there is “active smoldering” of the fuel in the combustion chamber, since a minimum oxygen concentration is ensured there. Under such conditions, a fairly large volume of pyrolysis gas is released, which has enormous energy potential.

After the wood is placed in the stove, ignition is performed. The damper plays a significant role in this procedure. While the wood is burning, the door is required to be open, then, after 35-45 minutes, when the house warms up, it is closed. The first step is to heat the unit and dry the wood. Then heat transfer begins and the release of a flammable gas mixture. The latter goes into a special afterburning chamber, where it burns. Thus, the stored fuel burns out, doubling the efficiency, while minimizing the consumption of firewood. In long-burning stoves for the home, all combustion products of wood briquettes are emitted directly through the chimney into the atmosphere.

Principle of operation

Gas air boilers operate on the following principle:

- First of all, the boiler heat exchanger is heated;

- Then the cold air from the room enters the heat exchanger, passing through special filters;

- Purified heated air is forced into the air channels using forced-action fans.

The heating process is cyclical. It involves not only cold, but also previously heated air masses.

Evacuation of fuel combustion products is carried out through the chimney. Exhaust gases do not come into contact with the room air. The chimney is usually vented through the roof of the building. But for a number of high-performance modern models, the chimney is positioned horizontally, for which a hole is punched in the wall of the house.

With the air heating method, you can use inexpensive plastic chimney pipes. This is due to the fact that in modern highly efficient models of units with an efficiency of 95%, the temperature of the fuel combustion products at the outlet of the boiler is approximately 40°C.

These models include Goodman gas boilers manufactured in the USA of the GMS/GDS and GMP series.

Other section materials:

Description of the operation of gas boilers that do not depend on the supply of electrical energy.

Air-type heating is one of the types of heating systems in buildings. Their main element is air heating boilers. and the coolant is air. Such systems can be used both in public institutions and for heating private housing, the area of which is 100 square meters or more. The most remarkable thing is that the air heating system can be installed both at the construction stage and in an already constructed facility.

Advantages and disadvantages

The stove has not only advantages, but also significant disadvantages, which are important to know about at the purchase stage. The advantages include:

- Ultra-fast heating of rooms, provided that the walls of the building are well insulated.

- High efficiency. A heater with correctly calculated power is capable of heating large areas.

- With properly set controller parameters, the system is fully autonomous for 8-12 hours (no need to constantly add firewood).

- There is no need for complex installation - its compact dimensions make it possible to place it in the smallest rooms.

- Modern design that will not only not spoil, but also decorate the interior of the room.

- Unpretentiousness and ease of maintenance and management.

- Complete safety (subject to high-quality installation work).

- Long period of operation - the unit is guaranteed to last at least 10 years.

- Economical.

Long-burning stoves also have some disadvantages:

- High efficiency will be ensured only with the correct settings of the device. Wood briquettes must completely decompose when smoldering; if this does not happen, then pyrolysis gases will not be released in sufficient volumes. Also, they may not “burn out”, simply going into the chimney without igniting.

- Slow combustion devices require high-quality, well-dried firewood - otherwise pyrolysis will be incomplete. The exception is models with bottom ignition - their ascending heat flows dry out the wood. However, in both the first and second options it is better to choose and use dry briquettes.

- A well-insulated chimney is required - if it is not enough, condensation will form on the walls of the pipes, which strongly attracts soot. Over time, deposits will begin to increase and reduce the throughput of the smoker.

- High price tag - automatic control offerings, made of durable cast iron, with beautiful exterior finishes can cost quite a lot. However, this price is completely justified and is compensated by excellent physical and operational characteristics.

Air heating boilers

Boilers for air heating - a type of heating equipment

Air heating boilers occupy a fairly significant niche in the Russian markets.

This is not a new, but quite effective way to heat any room (private house, garage, greenhouse, cafe, construction site, etc.). Air boilers for heating systems

Unlike standard systems (where hot water or steam acts as a coolant), these devices use ordinary air. This greatly simplifies the design of the system, and also reduces the required number of additional components (batteries, radiators, pipes, etc.).-

These devices operate on the following principle:

In the air heating boiler, the heat exchanger is heated;

Next, the air enters this heat exchanger through special filters;

After heating, the purified air is transported through air channels using forced-air fans;

This is a cyclical process in which previously heated air also enters with fresh air.

Let's consider the advantages and negative features of these systems:

Advantages:-

Due to the presence of ventilation air ducts, in the summer they can be used as cooling systems (when an air conditioning system is connected to them);

Lack of a water circuit (at low temperatures, the system does not freeze);

Saving gas (since the entire beneficial effect goes to heating the air, and not radiators and batteries);

Possibility to install outdoors (Roof-top);

Ventilation and air humidification functions.

Flaws:-

Poor efficiency at very low temperatures (since the air cools down very quickly and the system cannot cope with the task);

Rapid cooling of the system (due to the properties of air);

Now think about whether it is worth installing an air heating boiler. although everyone decides for himself what is best for him.

In recent years, air heating of a country house has been chosen by an increasing number of owners of private houses. This choice is due to a number of positive factors.

- Aesthetic potential (by choosing air heating, you can design your home in almost any style, without having to think about where to hide the radiators or convector). You can make the most of the overall appearance of the room.

- Relatively low cost (for a middle-income family this is the best option for a heating system that will pay for itself in the shortest possible time).

- Sufficiently high efficiency (up to 90%) with a complete absence of intermediate carriers and low energy consumption.

- Easy to operate (the system is fully automated.

- High heating rate (no more than 20-40 minutes after starting the house is completely heated, which is especially in demand in winter)

- Durability (with proper installation and proper design, air heating in a private house can last about 20 years, but if it is repaired in a timely manner, regularly inspected and used carefully, it can last much longer).

- User safety (operating equipment is blocked by the system at the slightest sign of danger).

But along with the obvious advantages, these systems also have their disadvantages, which must be taken into account especially for those who plan to install air heating at home with their own hands.

- Such a system can only be installed at the stage of building a house; moreover, this issue must be worked out during the design process.

- This type of heating system will require periodic maintenance.

- The system cannot be upgraded.

- Constant need for electricity (it is advisable to install a backup power supply).

How to choose a heating device

If you intend to purchase equipment of this type, you need to decide on the following important nuances:

- How will the installation work - as the only source of heating or as an addition to a gas or electric boiler.

- Whether cooking is required - many models are equipped with this function.

- The volume of the heated room must be taken into account. The power, material of the firebox and its dimensions depend on this parameter.

- Location and battery life are also important factors.

- Availability of water connection.

Budget options made of steel are usually installed in country houses and garages. In buildings with large areas it is better to use cast iron units.

Device

The air heating furnace consists of the following elements:

- Housing made of cast iron or sheet steel.

- Primary combustion chamber.

- Convection circuit.

- Ash pit.

- Secondary afterburner.

- Chimney.

- Exhaust for secondary air intake.

- Traction regulator.

The equipment in question can be externally designed in different variations, which depends on the modification and configuration, but they work the same.

Types of stoves for heating a country house and other buildings

Compact, highly efficient devices with a beautiful design are very popular among the population. Manufacturers are trying to satisfy the demand for this type of equipment, so they are developing entire lines of devices that have a diverse set of adjustments. Thanks to the wide range, everyone can choose the model that best suits their needs.

Wood burning stoves

Such products, profitable from an economic point of view, will not only become a highlight of the interior of the room, but will also last for a long period of time. Ignition and heating of buildings (even quite voluminous and large in area) occurs in the shortest possible time. Some units on the market are additionally equipped with a hob. The latter quality makes the devices universal.

The process of servicing the unit will not cause difficulties even for an inexperienced stove operator - the ash can be removed while the fireplace is operating. However, with all the positive properties of the device, it also has negative aspects:

- Heat is not distributed well enough - the air masses at the top of the room are much warmer than at the bottom.

- The rapid formation of soot deposits in the chimney is a phenomenon due to abundant condensation of excessively hot smoke. With regular use, pipes need to be cleaned of deposits between seasons.

Ovens with built-in hob

This auxiliary function of the heater is pleasantly combined with its reliability and operating efficiency. Thanks to the huge variety of options, the device will fit into any interior design and can even become its main accent. It is easy to install, easy to operate and maintain. Manufacturers recommend using only high-quality wood as fuel. If this rule is neglected, the efficiency of the device decreases. Difficulties may also arise when it is necessary to reduce the temperature of the steel plane. When choosing equipment, take this fact into account and give preference to the one that is equipped with additional doors to reduce the temperature. Food cooked on such a surface has a special aroma and taste.

Reviews of air heating stoves

Judging by the mixed responses from users, the choice of air heating equipment depends on many factors. Considering the required power, type of fuel and additional functionality, there is no particular problem in choosing a product for specific purposes. In any case, all modifications of the configuration in question are based on the three main systems listed above.

Some versions have an attractive design and high efficiency, while other models are distinguished by the ability to connect air ducts and related devices. The owners note that with proper maintenance and care, this equipment is not only effective, but also profitable to operate.

Models and manufacturers

Selecting a quality product is a troublesome and difficult task. You can buy an inexpensive long-burning wood stove for heating and use it with pleasure for decades. It is important to clearly understand what you need and why, accurately calculate the power of the installation, find out its autonomy and other technical features. Then the purchase will 100% please you and bring maximum benefit. Below are the most popular types of units from leading industry manufacturers.

Buleryan

Heaters with a colorful name originate from distant Canada. They are distinguished by reliability and high heat dissipation. They are a cylindrical steel firebox with a wall thickness of 6 mm. The loading chamber door is located on the end side, which simplifies the loading of firewood. There are pipes along the body for convection of warm air masses.

Structurally, the device is divided into two parts; fuel briquettes are loaded into the first half, and the released pyrolysis gas mixture is burned in the second. The hole for connecting the smoker is on the side opposite the loading flap.

Butakov furnaces

Such heat generators are intended not only for heating residential buildings in severe frosts, but also for heating baths.

There are several varieties of this equipment that differ in performance characteristics. The model with the loud name “Student” has a power reserve of 9 kW with a weight of 70 kg and provides excellent heating of up to 150 cubic meters of space. The most powerful device is named “Akademik” - with a mass of 300 kg, it perfectly heats rooms up to 1200 m3. Intermediate lines have also been developed - “Associate Professor”, “Engineer” and “Professor”, which are capable of heating buildings with a volume of 250 to 1 thousand m3.

Breneran

A long-burning wood-burning stove from a domestic manufacturer is an improved analogue of Canadian equipment with a similar name. It is manufactured on modern high-tech production lines, in accordance with all existing international quality and safety standards. The model range is referred to by the abbreviation AOT with a numerical serial number. The lower the index, the lower the weight of the unit and its functionality. The spatial volume that it can heat directly depends on the power of the device. Thus, a 6 kW installation copes with heating an area of 56 m2, and a 35 kW installation can warm up to 260 m2.

Some models are equipped with outlets with a water circuit connection and beautiful doors made of fireproof glass. The disadvantage of "Breneran" is the high probability of moisture getting into the room where the stove is located. This is due to insufficient tightness of the chimney connecting unit.

Teplodar

An excellent quality stove from a Russian manufacturer is designed for heating a home in our harsh winters. Devices from this brand are distinguished by their compact size, excellent efficiency and relatively low weight.

The line includes many different format variations:

- “Vertical” is a heater equipped with a surface for cooking food.

- “Matrix-200” is capable of heating rooms up to 200 m2.

- "Siberia" - warms up a much smaller space, but much faster than its analogues.

Vesuvius

A good, compact, Russian-made installation is intended for a summer house, garage, bathhouse, and other outbuildings and residential buildings. The heat exchanger is selected based on the technical parameters of the heated premises.

Termofor

The design development of the domestic company includes several products with very colorful names. Compactness and high performance with economical fuel consumption make the device popular among the population. Depending on the type, the unit is capable of heating a space with a volume of 55 to 255 m3.

Ermak

The reliable installation features miniature dimensions, light weight, and excellent heat output. The boilers have proven themselves well and can be installed in both commercial and residential buildings.

Bakhta

This is a heating and cooking stove-fireplace made of durable and heat-resistant cast iron of the ChH-1 brand. The high quality of the heating device, versatility, wear resistance and visual appeal are its main advantages.

Criterias of choice

You can choose air heating stoves for your home according to several criteria. Pay attention to the following parameters:

- Performance and power rating.

- Dimensions.

- Type of chimney installation.

- Possibility of connecting air ducts.

- Material of manufacture of the body part.

Also, the choice of equipment when purchasing is influenced by the modification of the device:

- Furnaces of the "Buleryan" type.

- Models "Breneran".

- Butakov's heater.

These versions are the basis for all other options. Modern and foreign manufacturers only improve and complete existing developments, releasing their own series.

How to increase the efficiency of a long-burning wood-burning stove

To achieve maximum heat transfer with minimal fuel consumption, many are trying to increase the efficiency. This can be achieved in several ways. The first involves the forced supply of air masses using a fan mounted next to the firebox (it improves air circulation). The second involves placing an additional water circuit directly on the chimney. When performing these procedures, it is worth understanding that efficiency will never increase if you use wet fuel.

Operating principle of air boilers

Heating of residential, industrial or public premises is carried out with warm air heated using an air heater. The heater is connected to a system of air ducts that are routed to each room of the building. Low-temperature (160 degrees or less) combustion gases are discharged outside.

Using an air heater allows you not only to quickly warm up a room, but also to do so throughout the entire volume of the room, that is, evenly. After cooling, the air flows back into the heat generator through return air ducts. Thus, the operating principle of the system is based on the recirculation of air masses, to which fresh street air is mixed.

To maintain the desired temperature in the rooms, a thermostat (thermostat) is used. A special additional electronic unit allows you to very finely tune any climatic air parameters. The main electronic unit (processor) is used to control the air heater. It tracks the following parameters:

- Availability and pressure of gas in the system;

- State of security elements;

- Power options.

In addition, the processor is involved in controlling the humidifier, air conditioner, electronic filter and other equipment. All of the above functions can be added modularly to the basic heating system if desired by the user.

Installation of the device

Installing a long-burning wood-burning stove is not particularly difficult. A flat surface and proper organization of the chimney are sufficient. The latter may pose some difficulties. It is important that the diameter of the heater pipe clearly coincides with the smoker pipe. The connection must be completely sealed. If combustion products are discharged through a wall, then the passage must be insulated with non-combustible materials. Due to the large mass of the heater, measures to transport it to the place of operation are carried out with the help of assistants.

Self-assembly

Diesel units are very popular, as they run on diesel fuel and waste fuel. In addition, creating them yourself is very simple.

Any type of metal is prepared for the creative process. The fuel is undoubtedly diesel fuel: the stove does not stop working on it and provides high-quality heating. True, the work gives off an unpleasant aroma; not every dacha can install this. Due to this, it is better not to use such a model in residential premises.

Often the creation of a diesel stove is caused by its subsequent appearance in the garage. There are direct and indirect heat versions of garage ovens. The first ones do not have a smoke exhaust and are very uncomfortable for the intended purposes. The latter have this kind of fuel tank and combustion department, which function in a simple way: the liquid goes through the spray device of the tank and ends up in the combustion department. There it is burned thanks to the air sent by the fan. Air flows in transit through the heat exchanger go from the nozzle into the room space. A similar model using diesel fuel may have a similar composition:

- adjustment screw,

- frame,

- burner,

- removable tank,

- lattice,

- removable block,

- reflector.

To all this, a valve is attached to the removable tank in the stove, and a wick is attached to the replaceable block.

Characteristics of diesel equipment

Modern diesel modifications have a flame control procedure. It turns off the device when it overheats. As already noted, these stoves can heat small rooms. The same garage stoves are also very useful for heating emergency rooms. Actually, diesel ones can be taken outdoors. They are especially necessary when it rains during a hike and there is no opportunity to make a fire.

Small details of making your own diesel stove

As we have already said, a diesel stove can be made with your own hands from any metal. It must be leafy. You will also need:

- corners (their material is steel),

- pipe (metal),

- welding equipment,

- electrical tools.

The thickness of the listed corners can vary by 4-5 mm. Pipe thickness range: 2.5 – 3 cm.

The suburban apparatus can be built in the form of a rectangle; why it is necessary to cut the sheets and weld them.

Required components: top side, bottom, wall at the back, walls on both sides.

The outer panel is necessary to place the door on it for the combustion chamber and the blower.

The working stages of making a stove for a home are as follows:

- Welding the walls on the sides. Their mandatory position is vertical. To check, use a square or level.

- Parts are stuck in some places. We need to make sure that they are in the right positions.

- The wall at the back is being cooked.

- Splitting the entire formed space inside into three parts. It turns out: an ash pan, a firebox and a smoke circulation.

- It is necessary to attach corners to the sides inside.

- Stripes are being prepared. They are needed for the grid. The distance between the plates is 5 cm.

- Metal rods need to be connected from above by welding.

- A reflector is placed on the metal rods. Its format is sheet metal. This element is removable.

Before welding the cover, you need to make a hole for the pipe. Then you can weld the lid. At the next stage, the upper jumper for the furnaces is cut out and attached (by welding). Its correct position is at the level of the grid.

The issue with door parameters does not have to be very burdensome. The entire structure should be placed on legs. An iron tube is suitable for creating legs. Its diameter is 100 cm.

To create a chimney, a 15-centimeter pipe is required. It is brought out. To do this, a hole is made in the wall a little larger than its diameter.

Horizontal sections are not allowed here. A suitable transition angle is 45 degrees.

Creation of a diesel version - dropper

When you need to independently heat a car garage, it is possible to organize a diesel model there - a dripper. In this room it is most harmless. An unused gas cylinder is suitable for its creation. An iron pipe with an impressive diameter will also work.

A bowl is placed at the bottom of this stove. Fuel will be burned into it. And through a perforated pipe, arranged in a vertical position, oxygen will be supplied, due to which the vapors will burn primarily and the gas generator gases will be burned. The fuel will end up in the bowl in transit through a metal pipe. For such a task, the fuel tank must be located at a higher height and slightly to the side. This way you will prevent a fire situation.