The market for thermal insulation materials is replete with offers for every taste. Mineral wool, polystyrene foam and polyurethane foam have long established themselves as reliable and safe thermal insulators. However, science does not stand still, and manufacturers are always striving to expand their market share with new products.

A relatively “young” thermal insulation material is XPS (eXtruded PoliStyrene) insulation. This is the name given to extruded polystyrene foam. Thanks to its unique combination of characteristics, the material has gained recognition among a large number of buyers.

Extruded, or extruded polystyrene foam, is expanded polystyrene foam that is produced by extrusion. Essentially it is plastic with a uniform fine-mesh (0.1-0.2 mm) closed structure. The fundamental difference lies in the more advanced technology of foaming polystyrene granules, as a result of which the resulting material is fundamentally different from the usual ball foam. Despite the fact that these two insulation materials are made from the same raw materials, the set of properties of the finished products has significant differences.

A line of materials based on mineral components

Mineral wool differs in fiber depending on the initial component underlying it.

The structure can be spatial, corrugated, the layers are divided horizontally or vertically. The manufacturer designates products depending on the raw material composition:

- Fiberglass products are marked with the Geo prefix. The products fall into the category of materials that are safe for humans and environmentally friendly.

- A product with the PureOne index is created on the basis of glass threads. The composition contains acrylic components. This type of insulation is installed to protect against cold in children's institutions and hospitals.

- The non-flammable Terra material is ideal for insulating wooden buildings. The composition includes natural components, the insulation does not harm the environment and humans.

- Thermal insulation based on extruded polystyrene foam is marked with the prefix XPS and is a durable and reliable insulating option for insulation.

Ursa GEO

Material marked Geo is environmentally friendly and does not emit harmful combustion products.

The heat insulator is allowed for use in rooms with a high risk of fire, since the material does not emit harmful components when heated.

Ursa Geo products are available in the following range:

- Light;

- Pitched roof;

- Frame P;

- Mini;

- Facade;

- Noise protection%

- Universal plates.

Mats with one foil side are designated M-11F and M-11, double-sided - M-25F, M-25, M-15. The slabs are marked P-60, P-15, P-45, P-20, P-30.

Ursa PureOne

Pure One material does not emit dust during installation

The characteristics of Ursa insulation show that the material consists of 95% natural substances, which underwent quality control during the production process. The material is produced in accordance with sanitary international standards and is included in the class of environmentally friendly insulators.

Line names:

- 35QN rolls measuring 1200 mm x 3900 mm;

- slabs 34PN with dimensions 1250 mm x 600 mm);

- rolls 37RN size 1200 mm x 100 mm).

The products are flexible when installed in curved structures due to the thinned fibrous elements in the structure. The material does not emit dust or odor during installation. The white color is obtained through the use of quartz sand.

Ursa TERRA

Terra material is available in the form of slabs

The products were developed for private buildings, but also meet the requirements of professional construction. Plates of this type are distinguished by their small size and rigidity with sufficient elasticity and flexibility.

The following range of Terra brand insulation is produced:

- slabs 34 PN;

- mats for insulation of highways and ventilation ducts 34 RN.

Penoplex

American made insulation. Made from expanded polystyrene. When extruded, closed cells filled with air are formed in polystyrene foam. This structure ensures the strength of the material.

Several types are available, depending on the purpose of use:

- Penoplex Wall (Penoplex 31 with fire retardant). It is used when arranging the basement, internal and external walls.

- Penoplex Foundation (Penoplex 35 without fire retardant). Used for thermal insulation of the base and foundation.

- Penoplex Roofing (Penoplex 35). Insulation used in the construction of roofs of various configurations. Due to its strength, it is used in the construction of inversion (flat functional) roofs.

- Penoplex Comfort (Penoplex 31C). Universal coverage. It is used for thermal insulation of any part of the building.

Types and characteristics of Ursa mineral wool insulation

Ursa mineral wool insulation, the characteristics of which make it possible to call it the most environmentally friendly thermal insulation among all its competitors, is represented in three positions in the line. Each of them has its own characteristics, so they need to be considered separately.

Mineral wool Ursa Geo

Produced in the form of rolls and slabs. This is a fiberglass material based on quartz sand. A special production technology eliminates the use of harmful substances, including formaldehyde. Ursa insulation, technical characteristics:

- thermal conductivity lambda 0.035-0.044 W/m*C;

- vapor permeability 0.51-0.64 mg/m*h*Pa;

- moisture absorption no more than 1 kg/m. kv;

- does not burn;

- operating mode from -60 to +300 degrees.

The manufacturer provides three options for roll widths: 600 mm, 610 mm and 1200 mm. Thickness can be 10, 50, 75, 100 and 200 mm. Such a variety of dimensions of Ursa insulation, according to reviews, allows you to select thermal insulation as accurately as possible for any type of work. The line also includes universal thermal insulation boards with a thickness of 50 and 100 mm. Ursa slab insulation, dimensions:

- standard width 600 mm;

- length 1000 or 1250 mm.

They can be used on all surfaces, both outside and inside. The exception is the insulation of the bathhouse.

You can read about which vapor barrier is best for the floor here.

Mineral wool Ursa Terra

Quartz sand slabs made using new technology.

This type of thermal insulation is also available in rolls and slabs. This can be read by the markings:

- PN – plates, from the English word plates;

- RN – rolls, from the English word rolls.

Ursa insulation characteristics:

- thermal conductivity lambda 0.034-0.039 W/m*C;

- flammability class G1;

- water absorption no more than 1 kg/m. kv;

- temperature range from -60 to +220 degrees.

The thickness of the slabs is 50 and 100 mm, the standard width is 600 mm, and the length is 1000 and 1250 mm. Sound insulation in slabs 610 mm wide and 1000 mm long has a thickness of 50 mm. Thermal insulation in rolls is available in widths of 1200 mm and thicknesses of 50 and 100 mm.

Ursa Terra is used mainly for wall insulation. This includes laying thermal insulation in the inter-wall voids of frame houses, and installation outside using ventilated facade technology. To protect the material, windproof films and waterproofing are additionally used.

Extra pure mineral wool Ursa PureOne

Ursa PureOne is the most environmentally friendly material in the line, soft like cotton.

Ursa PureOne roll insulation is positioned by the manufacturer as the most environmentally friendly material in the line. It is made from quartz sand, without the use of formaldehyde, components of plant origin and recycled materials. The acrylic-based binding component makes the thermal insulation absolutely harmless to humans. This material is white, looks like natural cotton, does not irritate the skin and does not generate dust. PureOne is recommended for use in children's rooms.

The Ursa insulation material (seen in the photo) is very elastic and has shape memory. Thanks to this, it completely restores its volume after opening the polymer packaging. Installation between the guides can be carried out without adhesives, just by surprise. Available in mats and slabs. The thickness of the mats is 50, 100 and 150 mm. The dimensions of the slabs are 600x1250 mm, and the thickness is 50 and 100 mm. Thermal conductivity is indicated on the label. For example, Ursa PureOne 37RN means that the insulation is in rolls with a thermal conductivity of 0.037 W/m*C.

The correct calculation of liquefied gas consumption for heating is outlined here.

Weight and density

There is an opinion that reliable and durable thermal insulation must have a high density, which is designated as weight per m³. Modern experts consider this to be erroneous. Most manufacturers use low-density extruded polystyrene foam, while maintaining the quality of the material. This is due to the cost of the main XPS raw material - polystyrene, which is more than 70%.

In order to save raw materials (stabilizers, foaming agents, dyes, etc.), manufacturers deliberately make the boards denser to create the illusion of quality.

Outdated equipment does not make it possible to produce durable XPS insulation, the density of which is less than 32-33 kg/m³. This indicator is unable to increase thermal insulation properties and does not improve performance characteristics in any way. On the contrary, excess pressure is created on the structure.

If the material was made from carefully selected raw materials using innovative equipment, then even with low weight it will have high density and excellent thermal conductivity. To achieve this result, it is necessary to follow the production technology.

Comparison with other insulation materials

Other materials are also used as insulation. They all have certain features and disadvantages that are worth remembering.

Below we compare Penoplex and:

Expanded polystyrene. It is produced using a non-press method, due to which the strength and density are reduced. Almost all technical characteristics of polystyrene foam are lower in comparison with Penoplex. The exception is vapor permeability: it is much higher, and therefore it is better to use insulation in rooms with high humidity.

Styrofoam. Its characteristics are similar to expanded polystyrene.

Foam insulationSource tildacdn.com

Styrex. Stirex and Penoplex have almost identical characteristics.

Mineral wool. Made from mineral raw materials by heat treatment. It has different densities (up to 300 kg/cubic meter) and high vapor permeability, can absorb up to 1% moisture. At the same time, mineral wool can withstand temperatures up to +450 degrees. It is best used in rooms with high humidity and in fire hazardous places (workshops, garages, industrial facilities).

Extrol. It has the same characteristics as Penoplex, but is produced not only in the form of slabs, but also in the form of cylinders or semicircular segments. It is convenient to use for thermal insulation of pipes.

When choosing a material, it is important to pay attention not only to the properties of the insulation, but also to the form of release and the ease of working with them. This video shows a comparison of other insulation materials:

This video shows a comparison of other insulation materials:

Advantages of materials

The popularity of both types of heat insulators is ensured by their positive properties. In addition to the main quality - low thermal conductivity, Penoplex and Ursa have the following similar positive characteristics:

- Easy to use. Each cover is easy to cut alone.

- Ursa is prickly and dusty. Penoplex does not have such an unpleasant quality. Fragments of any type are cut out of it.

- Coatings are inert to various building mixtures.

- Immune to pests.

- Environmentally friendly.

- Same service life. Manufacturers promise up to 40 years of service, but in practice, after 15-20 years, the properties weaken.

Remember that insulation materials become flammable under certain conditions. Of course, the latest technology reduces the possibility of fire. However, the materials cannot be considered absolutely safe.

If we talk about price, then both insulation options are available. But Ursa is more profitable. It began to be used much later than expanded polystyrene, but its demand is due to its low cost, 3-4 times lower than the price of its competitor.

Briefly about the main thing

Insulation plays an important role in construction and renovation. You can find a huge number of insulation materials on the market, each of which has its own characteristics and disadvantages.

“Technoplex” and “Penoplex” are similar in technical characteristics. Both materials have high density and can withstand significant weight, and are characterized by low vapor permeability and thermal conductivity. They also have similar disadvantages. Both insulation materials ignite easily and release hazardous substances.

The choice is most often made in favor of Penoplex. This is due to the low price and the ability to use sheets for external insulation.

Other materials can be used for insulation: mineral wool, polystyrene foam and others. Each of them has its own characteristics.

Ursa insulation and its types

The manufacturer of this insulation is the German company Ursa, and several branches of the company are located in Russia. The insulation is mineral wool, which is based on durable stamped glass fiber. It can be used to insulate any part of the house structure. This insulation has soundproofing properties and resistance to mechanical loads. The company's specialists have developed several series of insulation.

The following types of Ursa insulation can be distinguished, each of which has its own purpose:

- Ursa M 11 is a lightweight insulation material made from fiberglass. The mats are soft, pleasant to the touch, elastic, environmentally friendly, and resistant to various vibrations. Anyone will be pleased with its price. But there are small disadvantages: they are not entirely durable and flexible. And when installing M 11 insulation, you should use gloves and a respirator to avoid small particles of fiberglass getting on your body and to avoid further unpleasant irritation.

- Ursa M 11 F is a roll that is covered on one side with vapor barrier aluminum foil. This coating prevents the penetration of steam and prevents the formation of condensation. In this regard, it can be used in rooms with high humidity and can safely insulate places that have contact with water. This room can be a bathhouse, sauna, attic, basement.

- Ursa M 15 has good elasticity and compressibility. Insulation is mainly used to insulate floors, pitched roofs, and partitions.

- Ursa M 25 is a lightweight roll that offers good flexibility and thermal insulation. It can only be used indoors, it is not suitable for use outdoors, in pipes or in the ground. Insulation M 25 prevents heat loss in pipelines with a diameter of 32.5 cm. Capable of absorbing the sound of industrial units, for example, boilers and tanks. It would also be appropriate to use it on pitched, attic and mansard roofs, and plasterboard partitions.

- Ursa P 15 - its main application is to insulate pitched roofs, frame walls and partitions. One person can handle the installation of this insulation. P 15 is a very light and, at the same time, elastic material.

- Ursa P 20 is intended for insulating an external wall. The insulation is installed either outside or in the middle layer of the wall. P 20 has good heat and sound insulation.

- Ursa P 30 has high elasticity and flexibility, due to which the insulation is tightly mounted on the surface. Designed for use in air ducts and gas outlets (preferably rectangular in shape), insulation of a pipeline with a large diameter.

- Ursa P 35 is insulation in the form of plates. It is vapor-proof and resistant to various vibrations. Some slabs can be treated with fiberglass or a water repellent. You can find out about this as follows: in the first case, the letter C will be added to the insulation brand, and in the second - the letter G. This insulation is mainly used in railway, water and road transport to preserve heat and suppress noise.

- Ursa P 60 is intended for use under flooring (tiles, laminate

etc.). This insulation has very high sound-absorbing properties.

- Ursa Light is a fairly popular insulation material, which is light, elastic, durable, non-flammable material. In addition, it does not react to chemical influences and changes in ambient temperature.

- Ursa Pitched roof consists of yellow mats that have sound and heat insulation and elasticity. When installing insulation, virtually no waste is generated.

- Ursa The facade is covered with black fiberglass, which is very durable. It is used for insulating systems that have ventilated gaps. It has sound and heat insulation and holds its shape well.

- Ursa Partition is used for installation on frame partitions. The insulation is light, elastic, noise-absorbing and heat-insulating.

- Ursa XPS is used to protect the foundations of buildings and road construction.

Characteristics of the technoplex

The slabs are made using similar technology and have been produced in Russia since 2006. They do not shrink, are resistant to chemical influences, but are resistant to gasoline and solvents, and are also used inside buildings. Let's compare several parameters:

| Penoplex | Technoplex | |

| Use of buildings | roofs, facades, roads | inner part |

| Density, kg/m3 | 25-47 | 26-35 |

| Flammability group | G4 | G4 |

| Water absorption,% | 0,2-0,4 | 0.2 |

| Vapor permeability | 0,012 | 0.01 |

| Price, rub/m2 | 90-250 | 100-290 |

Thermal insulation Ursa XPS-N-III-L G4 1250x600x40 mm 10 slabs per pack

Extruded polystyrene foam Ursa XPS N-III-L-G4 1250x600x40mm

Thermal insulation Ursa XPS-N-III-L G4 1250x600x40mm - rigid slabs made of extruded polystyrene foam with a smooth surface and a stepped edge shape. Due to the semi-overlapping of the seams, there are no leaks in the joints of adjacent slabs. Ursa XPS-N-III-L G4 is the ideal solution for thermal insulation of large surfaces in one layer.

Ursa XPS-N-III-L G4 is a high-quality thermal insulation material that has one of the best thermal conductivity indicators among insulation materials widely used in construction. The boards are resistant to temperature changes and moisture, so they can be used in structures in direct contact with water, soil or vegetation.

Ursa XPS is a high-quality thermal insulation material made from extruded polystyrene foam, which has one of the lowest thermal conductivity coefficients among insulation materials widely used in construction. The high strength, rigidity and durability of Ursa XPS slabs allow them to be used for insulating underground parts of buildings, ground floors, flat roofs, plaster facades, foundations for highways, railway embankments and airfield runways.

Ursa XPS is an ideal product for applications where operating conditions are extreme - high humidity, high loads, direct contact with the ground.

Thanks to its closed cell structure, Ursa XPS has excellent thermal insulation properties, does not absorb moisture and has high compressive strength. It is these characteristics that allow Ursa XPS to be used as an effective thermal insulation solution in most building structures where a combination of these properties is required. The high deformation-strength characteristics of Ursa XPS slabs allow them to withstand distributed loads of up to 50 tons per 1 square meter. m. Having high flexural strength, Ursa XPS slabs can be installed directly on sand preparation without the risk of damage to the material.

In the production of Ursa XPS, exclusively carbon dioxide (CO2) is used, a natural gas that is involved in the respiration of living organisms. The production of Ursa XPS does not use freons, which complies with the standards of the Kyoto Protocol (addition to the UN Framework Convention on Climate Change) and allows us to present on the market environmentally friendly extruded polystyrene foams that do not harm the ozone layer of the atmosphere. Thus, Ursa XPS and its production technology are safe for humans and the environment.

Ursa XPS boards are resistant to aging. When used correctly, the material retains stable physical and mechanical properties, shape and dimensions for more than 50 years. In addition, Ursa XPS materials are highly resistant to biological influences, so they can be used in structures in direct contact with soil and vegetation.

The accuracy of geometric dimensions and low weight of Ursa XPS slabs allow achieving maximum labor productivity during installation without the use of special mechanisms. Ursa XPS boards can be easily machined using the most affordable cutting tools. Ursa XPS slabs can be installed in any weather conditions.

URSA XPS or penoplex which is better

Penoplex is essentially the same extruded polystyrene foam, but only from a different manufacturer. Which is better - penoplex or URSA XPS depends on the cost of insulation in your city, the cost of delivery, and in terms of their thermal conductivity characteristics in practice they differ little from each other. As for cost, URSA XPS boards are considered a more expensive material.

As you can see, the characteristics of URSA are the optimal solution for a private developer. The slabs are lightweight, easy to cut with a utility knife and easy to install. To insulate your home yourself with URSA XPS slabs, you do not need any special skills or tools. At the same time, you will receive reliable protection from the cold with high mechanical strength and moisture resistance.

What are the disadvantages of Ursa wall insulation?

One of the main disadvantages of installing fiberglass insulation is that loose particles can irritate human skin during Ursa installation. Protective clothing is the main method of protection: long trousers and sleeves, collar and cuffs must be buttoned. Buy a respirator specifically designed to filter out fiberglass particles. Thin leather gloves will block irritation and at the same time allow you to easily work with the tool. Once you have finished installing the Ursa wall insulation, you need to shower using cool water to close the pores of the skin, so the fibers will not penetrate your skin.

Another way to avoid discomfort is to choose high-quality thermal insulation for walls, rather than cheap Chinese fakes. If the product contains a lot of small twisted fibers, then they will be less irritating to the skin during installation.

Performance properties of extruded thermal insulation Penoplex

Extruded polystyrene foam panels are produced using special technology. The insulation compares favorably with polystyrene foam due to its perfect structure, increased strength, unique moisture and frost resistance and a long fifty-year service life.

Unlike the granular structure of polystyrene foam, the composition of extruded insulation is a homogeneous closed-cell structure that can withstand high compressive loads without consequences.

Naturally, the more complex and energy-intensive production of extruded material has resulted in an increase in its cost.

- A popular insulation material that makes it suitable for use in large-scale projects, it is in demand for thermal insulation of flat roofing structures and thin concrete screeds used in the installation of floor tiles.

- Extruded panels, which are focused on efficient and high-quality installation, are an excellent option for thermal insulation of foundations and blind areas, as well as underground structures for a wide variety of purposes.

Do you want to buy Penoplex at a dealer price with an official guarantee from the manufacturer? The time to do this is now!

Comparison of Ursa and Penoplex

These two materials differ from each other not only in their scope of application (although there are also “intersections”) and the basis of their composition. Let's compare Ursa and Penoplex insulation materials:

Fiberglass, mineral wool. Polystyrene in the XPS series

Laying on a specially mounted frame, closing with another frame after that

Simply placed on glue

Texture to the touch

Similar to an elastic sponge

The need for vapor barrier

Eat. Some types are already foil-lined, others require preliminary installation of a vapor barrier layer

Five series of several types

Possibility of insulating ceilings

No. It crumbles, mineral dust can get into the eyes and lungs

Precautions during operation

You can’t work without a respirator, it’s very dangerous

Basic protection is enough

Possibility of use with building mixtures

Resistant to any mixtures, chemically inert

Thanks to modern technologies, high-quality and affordable home insulation has turned from a dream into a completely solvable task. There are many reviews that it is better to choose polyspen or penoplex (penoplex). We will understand this by evaluating the properties of these materials.

Penoplex

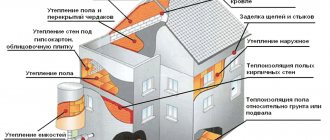

Due to excellent thermal insulation, zero water absorption, strength, resistance to biodegradation, durability, lightness of the material and ease of installation, it is used for thermal insulation:

- Basements and socles. Insulation of shallow and deep foundations.

- Floors on the ground, on a concrete slab, when installing heated floors.

- Walls outside and inside. Thermal insulation of concrete and brick walls, multilayer walls, walls of frame houses, additional thermal insulation and internal.

- Septic tanks pipelines, drainage systems.

- Pitched roof and attic floors.

Ursa and Penoplex are modern thermal insulation coatings . The first appeared relatively recently, and polystyrene foam has been used for a long time. Both materials have similar qualities. Light weight, easy to install, biodegradable. But on several points Penoplex is more attractive than Ursa. It is moisture-resistant, vapor-tight, and does not require special protective devices during installation. Ursa is superior only in price, but the characteristics are sufficient to maintain the demand for coverage at a high level.

Repair and constructionComment

Installation of extruded polystyrene foam

XPS slabs have a stepped edge, allowing the slabs to be joined together without gaps. This is an ideal option for thermal insulation of a surface in one layer. This brand of extruded polystyrene foam is very popular among developers, despite cheaper Russian extrusion analogues, for example, Technoplex from the Russian corporation TechnoNIKOL.

To attach the slabs to a horizontal surface, use mastic, polystyrene foam glue or polyurethane foam. When finishing vertical structures (for thermal insulation of house facades, plinths, basement walls, etc.), dowel mushrooms are used for additional fastening. After laying the slabs, they should be protected from possible mechanical damage by plaster or siding.

Classification of Ursa insulation materials

The well-known brand produces several types of products that differ in size, functionality and technical characteristics.

URSA GEO

This product line offers a wide selection of environmentally friendly building products that are made from fiberglass, which is a mineral raw material. The manufacturer strictly follows the requirements of environmental friendliness, so this insulator can be used in so-called “green” construction.

The series took its name from a unique technology based on natural ingredients and a special recipe. Thanks to the interaction of raw materials and production methods, consumers have the opportunity to create a healthy microclimate in their premises, in which clean air reigns.

The URSA GEO assortment group includes about twenty product items that are intended for certain operating conditions. On the Russian market, the most popular material is the M-11 series, as it is universal and suitable for most objects. Its release form is rolls 50 or 100 mm thick. Thermal conductivity indicators vary from 0.03 to 0.04 W/MK, the vapor permeability coefficient does not exceed 0.64 Mg/MCPA.

You can also often find material from the GEO series, the name of which contains the following markings:

- "Mini";

- "Universal plate";

- "A private house";

- "Pitched roof";

- "Noise protection";

- "Light";

- "Framework".

URSA Pure On

A new product on the construction market that visually resembles layered cotton or wool fabric. Just like the previous sample, the insulation is made from mineral fiberglass. Insulation is an environmentally friendly building material, does not cause allergic reactions and does not irritate the skin and mucous membranes. With the help of Pure On, you can efficiently treat premises of any purpose, as well as those buildings that require special environmental control.

The material does not contain formaldehydes and phenols, it is soft to the touch. On the territory of Russia, URSA Pure On insulation is represented by three samples (34 PN, 25 QN, 37 RN), the vapor permeability of which is at the same level (0.51 Mg/MCPA), and the thermal conductivity coefficient ranges from 0.034 to 0.037 W/MK. The material is available in three thicknesses: 50, 100 and 150 mm.

URSA Terra

In most cases, such insulation is used when treating private houses, although in terms of its technical characteristics it is in no way inferior to professional material. The Terra series product is ideal for processing industrial facilities, sloping roofs, facades, cladding and various partitions. The mats do not ignite and do not absorb moisture, and are also characterized by increased elasticity.

The Terra series range includes three insulation options:

- "Noise protection";

- "Technical mat";

- "34 PN".

The height of the slabs is 1 m, thickness - 50 and 100 mm, thermal conductivity varies from 0.034 to 0.037 W/MK, fire safety class - KMO, operating temperature from - 60 to + 220 ºС.

URSA Seko

The insulation is available in rolls of different lengths and thicknesses. It reliably protects the building from wind, high humidity and evaporation. Can be installed on sloping roofs, facades, ceilings and ceilings. This line includes 4 products:

- "AM";

- "A";

- "IN";

- "D".

The material can withstand 1000 mm of water column, its density corresponds to 65 g/m2.

URSA XPS

The insulation of this series is made on the basis of extruded polystyrene foam and does not contain harmful toxic substances. Recommended for installation on roofs of any configuration, ceilings, walls, foundations and basements. Loggias and balconies are often insulated with the help of such products. URSA XPS is presented in three samples:

- "NV";

- "N-III-G4";

- "N-III".

The thickness of the plates ranges from 30 to 100 mm, thermal conductivity is 0.032 W/MK, vapor permeability is 0.004 Mg/MCPA, moisture absorption is 0.3%.

Each label supplied with the mats contains information about the following parameters:

- fire safety class;

- degree of moisture permeability;

- flammability;

- recommended operating temperature, etc.

The world of XPS penoplex insulation and analogues

Modern construction of buildings and structures for various purposes is not possible without the use of effective insulation materials, which make it possible to create reliable thermal protection of buildings and structures. Extruded polystyrene foam used for these purposes makes it possible to create reliable thermal insulation of premises, which helps to increase living comfort. The available opportunity to purchase technoplex penoplex in Kirishi and analogues produced by other manufacturers allows the buyer to make a choice based on financial capabilities and region of residence.

Huge selection of extruded polystyrene foam insulation

Insulation materials made from extruded polystyrene foam (XPS) are represented on the Russian market by products manufactured by a variety of companies. Most of them offer insulation materials that are similar in physical and technical characteristics to insulating boards produced at. If the original penoplex is not available for sale, the buyer has the opportunity to purchase modern insulation made from foamed polystyrene obtained by extrusion, produced under various trade names. Here are just a few of them:

The product line of well-known brands that produce extruded polystyrene foam includes an analogue of Penoplex 35 (Stirodur 4000 C) and analogues of Penoplex 45 (Greenplex type 45, Primaplex 45 Standart, Expol M 50). Similar technical and operational characteristics of insulation from different manufacturers are explained by the use of one material to create modern insulation - extruded polystyrene foam.

The scope of application of insulation from various manufacturers is as wide as the products of PENOPLEX SPb LLC. Using insulating boards of various densities, the consumer has the opportunity to insulate a private house, floors or walls. Just like Penoplex insulation, insulating materials from other manufacturers are used in road construction and for insulating roofs, foundations, and basements. If you need Penoplex 35, an analogue of TechnoNIKOL (Technoplex 30-250 standard) is also used for insulating balconies and loggias. And the analogue of the Penoplex 45 brand in the TechnoNIKOL line - Technoplex 35-250, has proven itself well in insulating loaded floors and creating inversion roofs.

Which insulation to choose?

The wide range of insulation products offered based on extruded polystyrene foam allows the consumer to choose a material that corresponds to his idea of the required level of thermal protection, at an affordable price for the client. You can choose, for example, the Chinese analogue of Penoplex (fiberglass insulation “Uteplit” or “Phoenix”) or purchase the German analogue of Penoplex35 (Styrodur BASF 4000 C). Naturally, the cost of polystyrene foam produced by extrusion, made in China, will be significantly less than products of German quality.

Or maybe it’s enough to feed foreign companies that offer their own, albeit sometimes inexpensive, analogues? After all, the Russian market's need for XPS materials can be satisfied by domestic manufacturers. Moreover, they work on imported equipment, using time-tested technologies for the production of insulation from extruded polystyrene foam. The successful experience of PENOPLEX SPb LLC, whose factories are located in many regions of Russia, allows us to confidently declare an effectively operating system that ensures consumer availability of penoplex insulation.

Features and application of URSA insulation

High-quality URSA insulation is one of the most successfully used thermal insulation materials today. Compared to other thermal insulation elements used in the construction industry, URSA insulation is distinguished by its low thermal conductivity.

URSA slabs, which are made from extruded polystyrene foam, are characterized by high strength and low susceptibility to external influences, which makes it possible to use them for insulating a wide variety of structures, from underground elements of buildings to airfield runways.

Extruded polystyrene foam URSA XPS

Advantages of URSA XPS material:

- zero hygroscopicity;

- frost resistance;

- non-susceptibility to deformation;

- environmental friendliness;

- ease of installation.

In the production of insulation, clean technologies are used (use of carbon dioxide without the use of freons), which ensures the safety of the material itself and its manufacturing process for the environment.

The unique structure of extruded polystyrene foam URSA XPS determines its thermal insulation ability and resistance to high mechanical loads (compression), and prevents moisture penetration. Thus, this material can be successfully used for insulating structures that require a combination of these properties.

Types and features of installation of URSA XPS insulation

Due to its properties, URSA extruded polystyrene foam is ideal for insulating parts of structures exposed to extreme operating conditions, such as high humidity, contact with soil or groundwater. An important feature of expanded polystyrene is that it does not require additional hydro- and vapor barrier. The temperature range for use of the material is from -50 to +75 ⁰С.

URSA XPS insulation is available in several modifications. For private use, type N-III-G4 is recommended: slabs of different thicknesses and light weights, easy to cut and not requiring special installation skills. In the professional construction of roads and other structures, the NV type is used, which has increased strength (up to 50 t/sq. m).

URSA XPS expanded polystyrene boards are manufactured with a stepped edge, which allows them to be laid without the risk of loose fit or gaps. The slabs can be easily processed with conventional cutting tools. Installation can be done in any weather.

Application area of XPS boards

Manufacturers and sellers talk about the versatility of XPS, but based on the main results of certification tests, the following possible applications can be identified.

Insulation of foundations, basement and semi-basement premises. The material does not rot under the aggressive influence of the soil, ideally protects the structure from the forces of underground heaving of soils of any complexity. It is both an insulator and a waterproofing agent. The main habitat in the Russian Federation is located on wet and swampy soils, so XPS insulation is especially popular for this type of work. The only “competitor” of the material in foundation insulation is polyurethane foam, but it seriously loses in cost, and due to its manufacturability, it cannot be installed by hand. Here extruded polystyrene foam is the undisputed market leader.

Thermal insulation of floors of the first floors in private and industrial construction. Insulating the floor of the first floor has two main goals - insulation of the floor and its hydro-vapor barrier from moisture flows rising from the ground or basement. With the use of XPS, the insulated floor will achieve maximum strength.

Insulation of the facade. External thermal insulation of walls can be performed using the “wet” method, as well as using the method of ventilated frame construction for siding cladding.

Technical characteristics of URSA mineral wool

Technical characteristics of URSA mineral wool The mineral wool is based on glass fiber, in the manufacture of which dolomite, sand and other additives are used.

All components are melted and drawn into thin threads. Next, the fibers are glued together with a special adhesive with anti-feathers. Due to its structure, URSA mineral wool is suitable for heat and sound insulation of house facades, interior partitions, etc. But in the line of insulation from this manufacturer there is not only glass wool, but also extruded polystyrene foam URSA XPS, a direct competitor of Penoplex. Let us further consider the thermal insulation brands URSA GEO, URSA TERRA, URSA PureOne and extrusion URSA XPS that are common today. Let's take a closer look at the technical characteristics of the materials and their possible applications.

Characteristics of URSA XPS and its purpose

Extruded polystyrene foam retains heat well when wet, unlike basalt wool, since it practically does not absorb water. The fact is that extrusion in its structure consists of closed polystyrene foam cells filled with air. Thanks to this, URSA XPS boards are highly resistant to deformation and can withstand high compressive and bending loads.

Summarize. URSA XPS insulation is extruded polystyrene foam with low thermal conductivity and vapor permeability. Due to its high strength and moisture resistance characteristics, URSA XPS extrusion should be used for thermal insulation of foundations and basements, as well as for insulation of facades, flats and roofs of houses.

Characteristics of URSA GEO, purpose

URSA GEO thermal insulation does not contain harmful components, since it is made from natural materials. The characteristics are no different from glass wool, since it is fiberglass. The material is produced in mats and slabs. The slabs are denser and are intended for vertical structures, while mats are used for horizontal structures.

Summarize. According to the manufacturer, URSA GEO insulation will serve you for about 50 years. All materials from this line are fiberglass, which has its pros and cons. The thermal conductivity coefficient of this fiberglass is up to 0.045 watts per meter per Kelvin. In terms of noise absorption, URSA GEO mineral wool belongs to class “A” or “B”.

Characteristics of URSA TERRA, purpose

URSA TERRA thermal insulation is available in the form of slabs 125 by 60 cm, 50 or 100 millimeters thick, as well as in mats 61 cm wide, 10 meters long and 50 millimeters thick. Mineral wool belongs to the NG class - non-combustible materials, the temperature range of use is from -60 to +220 degrees, but, like any mineral wool, protection from moisture and wetting is required during installation.

Summarize. Mineral insulation URSA TERRA will protect your home from the cold and will reduce the noise level in the room. Moreover, the material is environmentally friendly and non-flammable, and therefore has no restrictions on use in residential premises. It easily fits on horizontal and vertical structures, creating a continuous layer.

Characteristics of URSA PureOne, purpose

According to laboratory tests, URSA PureOne thermal insulation in slabs has a sound absorption class of “A”. Plates and mats of this brand are tightly fixed between the guides, and the original dimensions and shape of the slabs do not change over time. Technical characteristics distinguish it from analogues; the material is pleasant to the touch and resembles natural cotton or wool.

>

Summarize. URSA PureOne mineral wool is excellent for thermal insulation and sound insulation of residential premises. In terms of environmental friendliness, sound absorption and thermal conductivity, this material is today a world leader. It is very easy to work with, the material does not prick and does not cause irritation on the skin, which can be confirmed by the video below.

Technoplex

Technoplex insulation is an extruded synthetic material that has proven itself well in construction. It is made from polystyrene granules: under high temperature and pressure they are mixed with graphite (it gives the sheets a gray-silver color) and a foaming composition. The mixture is poured into molds and pressed. After hardening, the sheets are cut to standard sizes.

The material is available in 2 versions:

- 118*58 cm;

- 120*60 cm.

The thickness varies - from 2 to 10 cm. The edges of the sheets have a special edge, thanks to which the parts fit together better and do not form gaps.

The result is a homogeneous structure with closed gas cells. Since almost all 100% of the pores are closed, the material has good technical characteristics: being light in weight, it is resistant to deformation and bending, retains heat well and almost does not absorb moisture.

"Technoplex" is used in a variety of areas:

- During the construction of private houses, for example, if the external cladding is made of sandwich panels, as well as when insulating the foundation;

- When arranging outbuildings;

Technoplex Source krov-m.ru

- For insulation of balconies and loggias, floors, including when installing “warm floors”;

- When insulating roofs, attics, interior, internal and external walls.

In addition, insulation is often used in the construction of railways and roads, and in the construction of refrigeration chambers.

Advantages and disadvantages

"Technoplex" is used in various fields of construction and repair due to its high technical characteristics. But, like any material, it has its pros and cons. It is important to know about them when analyzing how penoplex differs from technoplex.

The advantages of insulation include:

- Has high thermal insulation rates. Technoplex is 1.5 times more effective than polystyrene foam and 2 times more effective than glass wool.

- It tolerates temperature changes well and does not deform due to heat or frost. The sheets can withstand from -70 to +75 degrees.

- It practically does not absorb moisture, and therefore does not swell or rot. It can be used in conditions of high humidity.

- Does not shrink and can be used for a long time. Bacteria and mold also do not develop inside the material.

- The insulation is not susceptible to rodent attacks.

Technoplex is easy to cut Source cstor.nn2.ru

- The material is easy to use and process: it does not fray or crumble, the proposed shape and size are most convenient to use. Its installation does not require special skills or the use of special equipment.

- It has low weight and thin thickness. When used, it does not increase the weight of the building and does not reduce the usable area inside.

- The average service life is 50 years. At the same time, the characteristics of the material do not change over time.

Also, Technoplex is an environmentally friendly material. It does not contain substances hazardous to health and, subject to operating conditions, the insulation is completely safe.

Its disadvantages include:

- Flammability. "Technoplex" has a flammability class of G4, it is highly flammable and emits acrid smoke when burned.

- The material is easily destroyed by ultraviolet radiation. Open packaging should not be stored under the sun; keeping the insulation outdoors for a long time is not recommended at all. Installation is best done on a cloudy day.

- When working, do not use organic solvents, as the sheets begin to collapse.

Foundation insulation Source remontnik.ru

It is also noted that the price of Technoplex is higher than that of other popular insulation materials. If the volume of work is large, the cost of the material may be too high.

See also: Catalog of companies that specialize in home insulation