If you plan to spend a little money on insulating your home, then most people decide what is better for this: foam plastic or penoplex. Both materials are considered reliable and high quality. They can be used for a long time without the risk of deformation. They do not absorb water very well, which is an important advantage.

Which is better: foam plastic or penoplex?

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

Let's jump ahead a little; be sure to calculate the minimum thickness of house insulation with different insulation materials in your region using a special calculator.

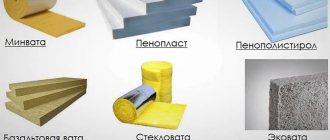

Comparison of penoplex and polystyrene foam

These are two fairly cheap and popular materials. They are easy to install. However, you need to understand what the difference is in order to choose the most appropriate option.

Production

Polystyrene foam is produced by treating polystyrene granules with steam. Thus, their volume increases almost 10 times. They are glued together, so the material is of sufficient quality, which is easy and pleasant to work with. There are small voids between the granules. It is necessary to choose high-density foam for insulation.

Foam sheets can be of different thicknesses

Penoplex is produced by extrusion of polystyrene foam. This material is evenly pressed at high temperature to obtain insulation with good density. It is higher than that of foam plastic. But it also weighs more.

Important . Both insulation materials are sold in sheet form. However, it is easier for the manufacturer to fulfill an individual order for polystyrene foam if it is necessary to create a slab of a specific non-standard size. In the case of penoplex, you must have a special press of the required size.

Thermal conductivity

This is the most important parameter. It determines how much heat the room will lose when using a particular material. It is required that it be minimal. However, the insulation materials under consideration have average thermal conductivity, therefore, when using them, it is strongly recommended to create a layer on the outside and inside. This will reduce the cost of heating your home.

The foam has a lot of free space between the granules. This means that heat will pass through them. Therefore, the main indicator of this insulation is lower.

Practice shows that to obtain the same effect it is necessary to use approximately 25% more polystyrene foam than penoplex

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

How to insulate walls with foam plastic yourself? More details in a special article.

Moisture permeability and vapor permeability

These are two more important parameters on which the quality of room insulation depends. If we consider the properties of both materials, it turns out that penoplex is better. It has a water absorption rate of 0.35%, while polystyrene foam has about 2%.

As for vapor permeability, both insulation materials have approximately the same performance. Penoplex - 0.013 mg/mchPa, polystyrene foam 0.05 mg/mchPa. This means that it is necessary to additionally use a high-quality ventilation system when using these materials.

Properties of expanded polystyrene

This thermal insulation material has been known in Europe for more than 50 years. Its popularity is explained by the presence of closed pores, where the use of freon is not expected, as well as low cost of production. You can purchase extruded polystyrene foam at any building materials store. Despite its low cost, it has high thermal insulation efficiency.

Polystyrene foam consists of air bubbles, frozen foam. This is where the name Expanded Polystyrene comes from.

The differences lie in a completely new production method and a more modern material base.

The original foam is not permeable to steam, but it can absorb moisture up to 4%. Expanded polystyrene practically does not absorb water due to its density. But the improved waterproofing properties do not prevent this material from breathing. This happens due to the molding method; extruded polystyrene foam Penoplex is molded by cutting. The strength of this insulation is much higher due to the production method using extruders. The molecular bonds in this material are several times higher than in simple foam.

The fire safety of Penoplex is due to the addition of fire retardants to it. These are special substances that prevent the material from catching fire. Like any polymer, foam will burn if it can be set on fire. This is prevented by high resistance to sunburn. Its biological stability is also high. Molds cannot live on polymers.

It is necessary to take into account a number of properties that polystyrene foam cannot provide:

- Low noise absorption ability. The rigid cells of insulated air act as resonators rather than sound dampers.

- Expanded polystyrene is not resistant to aggressive environments. He is afraid of acetone, varnishes, drying oil and turpentine. But it does not react with bitumen, soap and mineral fertilizers.

- In the heat, the foam oxidizes. While it is impossible to carry out complete polymerization of the components in production, harmful substances will be released when exposed to high temperatures.

Advantages and disadvantages of materials

Table. Pros and cons of materials

| Material | Advantages | Flaws |

| Styrofoam |

|

|

| Penoplex |

|

|

polystyrene foam 15

comparison table

Many people find it difficult to decide which material to use for insulation: polystyrene foam or penoplex.

A comparative table of insulation materials will help you decide which is better.

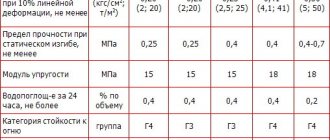

| Properties | Styrofoam | Penoplex |

| Density (kg/m³) | 11-40 | 25-47 |

| Compressive Strength(MPa) | 0,05-0,16 | 0,2 |

| Flexural strength (MPa) | 0,7 | 0,5 |

| Water absorption (%) | 1-2 | 0,5 |

| Thermal conductivity (W/m•°C) | 0,029-0,032 | 0,039 |

| Fire resistance | G3-G4 | G1-G4 |

Indicators vary depending on the type of insulation chosen. Accurate information about the characteristics of the purchased thermal insulation material is indicated in the technical documentation.

Scope and installation technology

According to the recommendations of builders who have been working in this field for a long time, these materials should be used for exterior or interior work. They are considered universal. It is best to use these insulation in the following situations:

- External wall insulation. But in this case, it is necessary to ensure that the material is sufficiently protected from moisture. Otherwise, its quality characteristics may change.

- For internal insulation. There is no need to additionally use a layer for sound insulation, since polystyrene foam and penoplex cope well with this task, among other things.

- When creating a vapor barrier layer.

- Roof insulation.

External wall insulation with penoplex.

Installation can be carried out in several ways:

- Using glue. In this case, it is necessary to glue the insulation to the surface. Builders recommend additionally using umbrella dowels for greater reliability. After the glue is applied to the surface, you need to attach the insulation to the wall. There are different adhesives available, so you need to read their instructions to ensure the best adhesion.

- By creating a ventilated façade. That is, you need to make the slats so that cells form inside. Insulation is placed in these cells. It should be packed fairly tightly. After this, the top layer is applied. It is strongly recommended to use this technology only for internal insulation.

Installation of foam plastic with glue

A special article described in detail how to insulate walls with penoplex, what materials and tools will be needed.

This is the most important information regarding these insulation materials. But it is also worth considering popular manufacturers so that you can buy high-quality material that meets safety requirements.

Important . All building materials must have a fire safety certificate. It is available upon request. If it is missing, then it is better to refrain from purchasing from a specific manufacturer or supplier.

What to look for when choosing

Extruded polystyrene foam Penoplex is produced in the form of slabs of various markings - Penoplex 35, 31, 31С, 45С, 45, 75. Moreover, recently the marking of slabs 35, 31, 31С has been replaced by new types:

- 35 (without fire retardants) - Penoplex-Foundation;

- 35 — Penoplex-Roof;

- 31 - Penoplex-Wall;

- 31C - Penoplex-Comfort.

The average consumer is unlikely to be interested in super-dense slabs marked 45C, 45, 75 to solve pressing insulation problems.

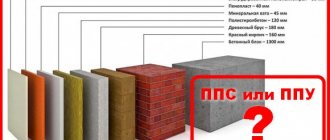

Plates with increased strength are used for thermal insulation of load-bearing structures of buildings and structures, road surfaces, for loaded structures and airfield runways. The thickness of the slabs is 40, 50, 60, 80 and 100 mm, and the size is 600 by 2400 mm.

Therefore, the question of choosing between the materials expanded polystyrene and penoplex 45 or 75 is raised only on an industrial scale.

An ordinary buyer, as a rule, needs to choose one of two options - expanded polystyrene or penoplex 35? Or, in light of the latest innovations from the penoplex manufacturer - Penoplex-Foundation, Penoplex-Roof, Penoplex-Wall and Penoplex-Comfort.

The new labeling of thermal insulation boards speaks for itself here. Extruded polystyrene foam or Penoplex 35 is divided by the manufacturer into two types - without the use of special treatment to reduce flammability for Penoplex-Foundation and with impregnation with fire retardants for Penoplex-Roofing.

Expanded polystyrene Penoplex-Comfort is the most versatile brand of material. The slabs are used for thermal insulation of balconies and loggias, roofs, walls, plinths, foundations and floors, as well as insulation of garages and outbuildings.

The almost complete waterproofness of the slabs makes it possible to use them for thermal insulation of bathhouses, saunas and swimming pools with high levels of humidity. The thickness of the slabs is 20, 30, 40, 50, 60, 80 and 100 mm, and the size is 600 by 1200 mm.

Prices

The production of both expanded polystyrene and penoplex is quite cheap. What is their retail price?

The price of extruded polystyrene foam and penoplex with the most minimal parameters (density, thickness, quantity per package) starts from 1000 rubles, respectively. and 1200 rub. per package. Conclusion - the brand name of various manufacturers also matters when choosing and purchasing insulation.

Penoplex turned out to be the most expensive insulation among all brands of extruded polystyrene foam. And with an increase in the characteristics of heat-insulating boards of different brands, the price correspondingly increases further - up to 3,000 rubles. and 4200 rub.

The cost of expanded polystyrene (foam) also depends on the physical characteristics and manufacturer and is in the range of 1000 - 3000 rubles. per package. The price of penoplex and expanded polystyrene on the building materials market is slightly different in favor of the latter.

The small price difference between expanded polystyrene and penoplex is most likely due to the more complex manufacturing technology of penoplex. or maybe the seller’s trade markup is too high.

What is the difference between penoplex and technoplex – World of Glazing

Technoplex TechnoNIKOL insulation boards are produced by mixing polystyrene granules with a foaming agent at high pressure and temperature. One of the most famous and widespread insulation materials is Technoplex - a product of the TechnoNIKOL company, which is known for the production of construction and thermal insulation materials.

These insulating boards are moisture resistant and are not afraid of mechanical stress and loads. They can be used for both interior and exterior decoration. What is Technoplex? This is extruded polystyrene foam, which is used to insulate balconies, loggias, interior walls, facades of private houses, and can also be used to install heated floors.

The insulation is used for thermal protection of private houses, insulation of balconies, outbuildings, including as a substrate for a “warm water floor”

This extrusion insulation is made from special graphite nanoparticles, which are “responsible” for thermal conductivity and strength. The color scheme of this material is a usual dark gray shade.

Advantages of technoplex:

- Moisture resistance;

- Ease of use;

- Resistance to rodents and insects;

- Long service life;

- Safety and environmental friendliness - the material does not contain toxic substances;

- Minimal risk of shrinkage, deformation and rotting.

The high level of strength of the insulation allows it to be used even where heavy loads are expected. True, fairly low vapor permeability requires high-quality ventilation in the room.

Also, when working with technoplex, it is worth considering that it is quite flammable and susceptible to gasoline, organic solvents and bitumen glue.

Extruded polystyrene foam and technoplex: application features

High-quality thermal insulation is necessary for any living space. Therefore, during the construction or renovation of a house, it is advisable to use durable, well-proven insulation materials.

Technoplex is a warm material that can be used at all stages of housing construction, be it facades or internal partitions, heated floors, balconies or garages.

Features of external use of technoplex:

- On the outside, slabs of material 100 mm thick are used;

- Before installing them, the surface is leveled and primed;

- Technoplex is fixed using a certain adhesive composition;

- The slabs are laid starting from the bottom, tightly touching each other;

- Each row should shift by half a sheet compared to the previous one;

- After the glue has dried, the material must be secured with plastic dowels, and the outside must be reinforced with fiberglass mesh and the surface must be plastered.

As for interior decoration, sheets of material up to 40 mm thick are used for such purposes. The insulation itself is glued, leaving a small space between the insulation and the finish for ventilation.

During installation of heated floors, Technoplex is laid directly on the screed and covered with polyethylene. A backing with foil is placed on top, and then the cable mats are fixed. After this, everything is filled with concrete.

When insulating the floor along the joists, polystyrene foam is placed on the waterproofing located between the bars. And all the connecting points are foamed.

Due to the fact that Technoplex does not change its characteristics even in difficult conditions, it is sometimes used for thermal insulation of underground areas of blind areas and foundations of houses.

Technoplex insulation: material characteristics

In appearance, technoplex looks like a smooth slab, slightly reminiscent of foam plastic. And if you cut the material, you can see that its composition and basis are a large number of small pores and particles.

Installation of Technoplex is carried out using polystyrene foam glue or by fastening with dowels with a wide head.

By the way, the strength of technoplex depends on its thickness, but freezing and subsequent thawing do not cause any change in properties.

The dimensions of such plates are as follows:

- Length can be 1180 or 1200 mm;

- Width – 580 or 600 mm;

- Thickness varies from 20 to 100 mm.

The technical characteristics of the material are as follows:

- Thermal conductivity – up to 0.031 W/m*K;

- Vapor permeability – 0.011;

- Sheet density – up to 35 kg/m3;

- Low moisture absorption – 0.2%;

- Flammability class G4.

The insulation can be used at temperatures from -70 to +75 degrees.

What can replace technoplex: photos of the material and its analogues

Despite all its advantages, Technoplex is not the only insulation on the domestic market. Thanks to the wide range of products, you can find something to replace it with if you compare it with other materials.

How to untangle small knots

- This method is suitable in cases where the hair is not severely damaged and there are no complex (large) knots on the hair.

- To begin manipulation, choose a comfortable place with good lighting. The treatment is performed on dry hair, so there is no need to wet the curls.

- Take the tangle in your hand so that it is clearly visible. Start taking out one hair at a time, gradually stretching each of them to its full length. Your movements should be carried out from the tips to the roots, that is, from bottom to top.

- If you don’t have the time or patience for such activities, use a wide-tooth comb. Do not process the knot itself, carry out normal combing from the tips to the root area.

- In this case, with a comb you risk tearing the hairs. To prevent this, use special sprays or gels that make combing easier. They are marked accordingly; the products do not require rinsing.

Date: September 25, 2022

Exceptions to the rules

As usual, there are exceptions in construction practice when it is impossible to apply rules that work perfectly in all other cases.

So it is in the question when we decide what is better polystyrene foam or polystyrene foam. For external wall insulation, exceptions may be made in the following cases:

- When insulation is carried out on a high base and the insulation along the wall is brought to the bottom line of the windows. In this case, it is quite reasonable to use vapor-tight insulation at the bottom of the wall.

- When we install insulation in a frame wall on a wooden or steel frame, we may not have to choose which is better, polystyrene foam or polystyrene foam. To insulate the walls on the outside, vapor-permeable insulation will be used, and on the inner layer, vapor-tight insulation will be used.

Thus, you can save at the stage of installing a vapor barrier by using a heat insulator with a minimum steam throughput as the inner layer.

Gnomes

Let's make some more helpers for grandpa. We have to design holiday gnomes. Prepare:

- small bumps;

- wooden balls (look for materials with a diameter greater than two centimeters);

- felt;

- glue;

- threads;

- felt-tip pens.

Cute creations are made quickly. These DIY pine cone crafts are among the most interesting crafts. Be sure to involve him in this magical creativity.

Making holiday gnomes:

Gnomes (Step 1)

- Let's start the creative process by making a hat. For gnomes it has a triangular shape. You can choose any height for your product; in our case, the cap measures about six centimeters. Roll the material until a cone is formed. We sew the fabric and cut off the excess. Turn the cap inside out.

- We cut out miniature mittens from the same material. Glue them to the bump. The product can be improved. And do as shown in the example. Glue chenille wire to the cone and then mittens to it. You can do it easier and simply replace such handles with plasticine ones.

- Cut out fabric hearts. We'll need them for our legs. We glue the material at the base of the cone. If you notice that the craft is unstable, replace the fabric with plasticine.

- Place a bead on the top of the cone. This is the head. We put a hat on her. To prevent it from falling off, the material can be placed on glue.

We draw eyes and a mouth. DIY children's craft gnome made from a pine cone!

We have already described earlier how to make autumn crafts for school, we propose to supplement the list of crafts with several more products that can be created.

For floor

For floor insulation, only penoplex is used, since it can easily withstand the weight of furniture and other active loads. Expanded polystyrene slabs insulate, and also level and strengthen the floor.

Photo: floor insulation with penoplex

This material is often used in the installation of “warm floor” systems; it has proven itself in rooms with stable humid conditions – baths, bathrooms.

Production

These two materials are completely synthetic, but they are produced using different technologies. To produce polystyrene foam, a polystyrene or formaldehyde base is used. Substances are added to it that form foam.

These substances use air to create foam. As a result, a huge number of bubbles are formed, filled with a synthetic base. The entire process takes place under normal conditions without elevated temperatures or pressure.

After the reaction is complete, small polystyrene or formaldehyde balls remain. To make polystyrene foam, elements with a diameter of 3–5 mm are selected and pressed. The result is slabs of different thicknesses from 1–2 cm to 10 or more.

As for penoplex, it is made from ready-made polystyrene balls. The finished mass is loaded into a high-pressure oven called an extruder. Everything melts there, decreases in size and floats onto the prepared base. The result is a slab that is slightly thinner than foam would otherwise be.

Types of foam plastics according to their use in housing construction

Home builders are showing the greatest interest in using Penoplex 35 expanded polystyrene. Low-rise construction using modern technologies is interested in inexpensive and efficient building materials.

In this regard, there is a classification of foam plastics according to their scope:

- "Penoplex Wall" - a material of relatively low density, which is used to insulate walls during construction.

- "Penoplex Foundation" - material of increased strength and high waterproofing. It is used for insulating foundations, basements, septic tanks and wells.

- "Penoplex Roofing" - lightweight heat-saving material with high waterproofing properties.

- "Penoplex Comfort" - a material developed specifically for insulating the walls of apartments, loggias and balconies. Characterized by increased control over environmental friendliness.

Any brands of Penoplex comply with GOST standards and are environmentally safe.

For external walls

For external insulation of the walls of a new building, it is better to use penoplex because:

- stronger, not afraid of moisture;

- immune to physical and biological stress;

- Suitable for brick, concrete, wood surfaces.

Photo: house sheathing with penoplex

It is better to choose models with fire-resistant impregnation, which significantly reduce the risk of ignition of the material.

Finishing from foam beads is considered a budget option, however, to obtain good thermal insulation of the walls, it is advisable to purchase thick blocks. To insulate areas located at height, foam plastic is mainly used, since it is lighter, which has a positive effect on the work process.

Photo: sheathing the building with foam plastic

Regardless of the choice, both types of material require protection from ultraviolet radiation by applying putty or installing protective panels. To insulate the base or foundation, penoplex is more often used, which more effectively protects the walls from soil pressure and ground water. When finishing the foundation, the blocks are sunk 1 m below the soil freezing line.

Both types of insulation are suitable for use in any climatic conditions:

- tolerate heat and severe frosts down to -50 degrees;

- limit for foam plastic – +60 degrees;

- The maximum temperature for penoplex is +75 degrees.

When working with any type of material, it is necessary to exclude contact of the panels with acetone, since the substance destroys their structure.