Penoplex and mineral wool

“The wise power of a builder is hidden in every person, and one must give free rein to its development.” (Maksim Gorky).

A huge hello to all blog readers! I hope you have already “come to your senses” from the holidays and are ready for the next portion of construction information. If yes, then read on, if your health still leaves much to be desired, close the site, turn off the computer and go to visit friends for “treatment.” Well, we will continue...

Today I decided to choose the topic of choosing two main “ideological competitors”, well, like a car with front or rear wheel drive. Or something similar, which has approximately an equal percentage of supporters on both sides. I’ll try to make a neutral comparison, and the choice is clearly yours. So, penoplex or mineral wool, which is better?

The right question is - what are we going to insulate? Well, let's take a little look at the main structures: walls, foundation, floor.

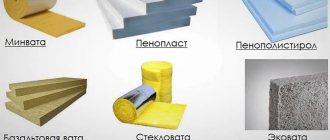

Variety of mineral wool

Subtle point. If penoplex* is, in fact, the name of the final product, then mineral wool is a broad concept, including glass wool, slag and stone wool. Therefore, as the Germans say, “apples must be compared with apples,” which means we’ll focus on one thing. I choose stone mineral wool, which is more often called basalt. It has better thermal insulation properties in comparison with its “slightly backward brothers”.

*There is another subtype of penoplex - technoplex. This is a bird of a feather. True, there is not a big difference in the name and minor parameters, but we will not go into these details. That's it, let's begin. In the red corner of the ring there is penoplex, in the blue corner there is mineral wool. Gong!

Comparing two materials

Penoplex and mineral wool differ in structure, appearance and parameters, since they contain different components.

Penoplex and mineral wool differ in structure, appearance and parameters, since they contain different components. In addition, both materials are produced using different technologies. Before determining whether it is penoplex or mineral wool, it is worth studying the situation in detail, the properties of insulation and choosing the one suitable for thermal insulation in terms of effect and cost.

Description of materials and appearance

Penoplex is an advanced polystyrene foam that has been processed under the influence of temperature and pressure. This technology made it possible to create a dense, durable material with low weight and high thermal insulation qualities. In appearance, it resembles frozen polyurethane foam.

Mineral wool has a fibrous structure, which is due to the use of silicate rock solution as the main raw material.

The raw materials are fused, which gives the material the qualities necessary for insulation.

Types of materials

Mineral wool is presented on the market in several types: glass wool, slag wool and stone wool. Insulation is carried out with the latter type, since it surpasses the previous ones in technical characteristics. Penoplex is produced in different types, suitable for thermal insulation of roofs, foundations, walls and more. The parameters of extruded polystyrene foam or mineral wool depend on the type chosen.

Pricing policy, weight, packaging

The cost of high-quality basalt insulation is comparable to penoplex. Therefore, insulation with both materials will cost almost the same. The cost of insulation from different manufacturers varies. Basalt wool weighs more than extruded polystyrene foam, which makes its installation a little more complicated. Stone and polystyrene insulation is packaged in shrink film, which provides reliable protection during transportation and storage.

Thermal insulation properties

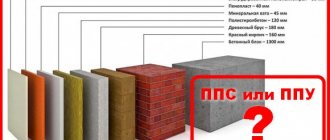

Insulation is best done with materials with low thermal conductivity. In this aspect, penoplex wins. But the difference is insignificant, since it will be possible to replace 50 mm extruded polystyrene foam with 60 mm thick mineral wool. In this case, the thermal conductivity indicator may deteriorate if there is inadequate protection or violation of installation rules. What is warmer depends on the specific situation, so other properties should be taken into account.

Vapor permeability of materials

The vapor permeability indicator is an ambiguous criterion. Warmer penoplex has a vapor permeability coefficient almost equal to zero, which makes it airtight. Mineral wool is breathable, which is important to prevent condensation. It allows air to pass through, unlike penoplex. At the same time, the installation of mineral wool requires the installation of waterproofing, which reduces the coefficient of vapor permeability.

Flammability and fire resistance

Mineral wool has the best fire resistance characteristics: it does not ignite, since the mass fraction of the adhesive mass capable of burning in the composition is small, and for melting it will be necessary to reach more than 1000 ° C. Extruded polystyrene foam belongs to highly and moderately flammable materials (class G3-G4). In certain lines of penoplex, the manufacturer managed to reduce flammability by introducing additives into the composition.

What is the difference (main characteristics)

Penoplex is extruded polystyrene foam, the “grandson” of foam plastic, which has surpassed its “grandfather” in almost all consumer qualities, except price.

Mineral wool (basalt) is a fibrous material obtained from silicate molten rocks. In comparison with the usual glass wool known since Soviet times, basalt is already a product of evolution.

The raw materials and production technology of both materials are completely different.

Which is warmer? To be fair, we will choose one option, for example, insulation for the facade. If we use 50 mm thick penoplex, then the equivalent would be a 60 mm thick basalt slab. In general, there is little difference.

Vapor permeability. Everything is immediately clear here. Penoplex - 0.013, basalt wool - 0.3. The difference is tens of times.

Conclusion: mineral wool is a “breathable” material, penoplex is virtually airtight. I can't say for sure whether this is good or not. It all depends on the application situation.

Water absorption. Everything is clear here too. Mineral wool absorbs liquid much more actively, after which it loses its thermal insulation qualities.

Penoplex (according to test results), lying in a bath of water for a whole month, increased its mass by only 0.2%.

Noise insulation. With equal dimensions, a basalt slab will provide much more silence than penoplex.

Weight. It would be possible not to consider this indicator. Everything is clear to everyone, penoplex is several times lighter than a similar-sized piece of basalt insulation.

Flammability. The clear leader is mineral wool. It practically does not burn (unless you place it in a melting furnace with a temperature of more than 1000 ° C). Although the binder adhesive base it contains is subject to combustion, this is a very small volume of the product.

Penoplex not only melts, but also burns when exposed to an open flame (and the antipyrines added to its composition are not designed for long-term fire protection). In addition, when it burns, toxic substances are released.

Conclusion: penoplex is not suitable for insulating rooms with a high fire hazard.

Environmental friendliness. It's hard to say here. The fact is that manufacturers of both materials have sanitary and hygienic documents allowing their use for housing. Previously, when there was no polystyrene foam, but foam plastic (in the production of which freon was used), there was a danger, but now (according to official data) new materials based on expanded polystyrene foam use safe technologies and materials. The same applies to basalt wool. Although for both materials it is assumed complete isolation from respiratory and tactile contact with them inside the house.

Ease of installation. According to reviews from builders (and I’ll say the same thing myself), if a flat surface is insulated, the penoplex is installed faster. It is lightweight, easy to cut and grind, and if there is a side L-shaped edge, then the problem with cold bridges is solved. And it does not require a layer of vapor barrier. But if there is no tongue-and-groove edge, the seams must be sealed or laid in two overlapping layers. And this is already additional labor costs.

In the photo - L-shaped edge of penoplex

Basalt wool is heavier, but it fits complex geometric structures and disproportionate areas more effectively. True, working with it requires special clothing, and ideally, also goggles with a respirator to protect the eyes and respiratory organs from fibrous particles. Although in most cases, installers neglect this. But in vain.

Life time. Indecently large. Both of them (according to the manufacturers) last at least 50 years. But this is provided that the materials are protected from external atmospheric, mechanical and chemical influences. Has anyone checked? They have been produced for a little over 20-30 years.

By the way, they are not afraid of biological destruction in the form of fungal mold, rot, bugs and rodents (again, according to the manufacturer). Although I remember before, mice didn’t particularly disdain polystyrene foam and mineral wool, in any case, they gnawed out their own passages. And a year ago, in a friend’s temporary hut, insulated with penoplex, mice were gnawing through rather voluminous tunnels. So, here you can argue with the manufacturer about rodents...

Application

In various situations, penoplex or mineral wool is used for thermal insulation.

What is better is determined taking into account the nuances of each specific case, climatic conditions, the material from which the structure is constructed, and financial capabilities.

What material to insulate what with?

The best way to carry out thermal insulation is determined by each owner himself, but there are a number of recommendations from professionals that will help make the right choice:

- You can insulate walls from the inside with both materials. But it is better to insulate wooden buildings with mineral wool. Because it has higher vapor permeability.

- It is better to insulate the foundation of a house, blind area, basement, and basement with penoplex foam, since it has higher strength and can withstand significant loads.

- The roof is insulated with both mineral wool and extruded polystyrene foam. Here the choice should be given, taking into account the material of construction. Most often, house floors, attics and attics are insulated with stone wool.

- For rooms with high humidity: car washes, baths, saunas, the use of polystyrene foam insulation is strictly not recommended.

It is impossible to say unequivocally which insulation is better. There are many factors to consider to make the right choice.

What is better to insulate with penoplex?

There will be no categorical answer, but based on the opinion of experts, penoplex is very good for private houses. But there is an important point. “Non-breathable” penoplex clogs the walls, and moisture in the form of steam will accumulate in the enclosing structures without leaving the premises. Excess moisture inside the house can be removed using mechanical ventilation or regular ventilation. Unless, of course, you have dilapidated wooden frames. Then there is always ventilation.

We insulate the foundation with penoplex

But with regard to the insulation of foundations, blind areas, basements and floors (which is not always), everything is in order. Penoplex is often used for multi-layer foundations, installed as a middle layer. A very rational decision. By the way, you can read about how to insulate a foundation with this polymer in this article.

Floors and interfloor ceilings are also perfectly insulated (under cement screed, of course).

Let me remind you that for buildings with a certain fire category, as well as with high internal humidity (for a bathhouse, gym, car wash, etc.), this material is undesirable.

Ease of installation

Thermal insulation with both insulation materials has nuances. For installation to be effective and safe, you should strictly adhere to the technology:

- Penoplex weighs little, which makes installation simple. But when insulating with extruded polystyrene foam, reliable adhesion must be ensured. For this purpose, some manufacturers produce slabs with a special tongue-and-groove fastening. If it is absent, then it is rational to carry out insulation in two layers with overlapping seams. These are additional costs. At the same time, working with penoplex is comfortable, since it is easily cut and eliminates the formation of cold bridges.

- Mineral wool is heavier, but it is also convenient to work with, since it perfectly covers any unevenness. But thermal insulation should be carried out using personal protective equipment.

Penoplex and mineral wool effectively retain heat and are easy to install. Even an inexperienced person can carry out insulation with these materials.

Hygroscopicity

Hygroscopicity is the ability of something to absorb water. It is measured as a percentage of absorbed moisture per day relative to its own weight.

This factor determines the scope of application of the insulation. If the indicator is high, it means that the material needs additional insulation from moisture.

| Material | Hygroscopicity |

| Styrofoam | 1% |

| EPS (extruded polystyrene foam) | 0,04% |

| Mineral wool | 1,5% |

If you compare the performance of foam plastic and mineral wool, you can see that they are almost identical. Does this mean that mineral wool is not afraid of moisture?

The answer can be seen in the structure of these materials. Mineral wool is a “blanket” of fiberglass. By the way, this is why it is more suitable for soundproofing rooms. What happens to an ordinary blanket if you put it in water. It will become saturated with liquid, gain weight and lose its blanket properties. The same thing happens with mineral wool. Although it is not like a kitchen sponge, it is still very difficult to drain or remove water that gets inside the cotton wool.

Considering the fact that mineral wool is mainly used for insulation indoors, in particular walls, when saturated with moisture it simply slides to the floor, leaving the insulated surface bare.

Therefore, it is fundamentally important to protect mineral wool from moisture absorption. For this purpose, PVC film, diffusion films and a vapor barrier are used.

Their correct combination, or creating a pie wall, will give maximum protection from water.

What to use for external insulation – polystyrene foam or basalt wool? If you use stone wool (basalt), it does not have the disadvantages of glass wool, and is much cheaper than EPS. You can verify this by reading a comparative article on mineral and basalt wool.

Polystyrene foam is a hydrophobic material. Although it does not absorb water like cotton wool, it can penetrate into its structure, destroying the bond between the foam beads. At the same time, the slab itself begins to crumble, crumble and eventually settles on the floor.

This doesn't usually happen, but it's important to understand that foam also needs protection from moisture. Especially the bottom sheets when insulating the facade

For these purposes, a base profile is usually used, under which waterproofing is laid.

Due to its high density, extruded polystyrene foam practically does not absorb moisture. Therefore, it can be used without any moisture protection.

Pros and cons of insulation

The main advantage of extruded polystyrene foam is its thermal conductivity and strength. The insulation is not attractive to rodents; it will retain its integrity and performance characteristics longer. Among the disadvantages, users highlight a high degree of flammability, as well as low vapor permeability, which leads to the appearance of condensation.

Mineral wool also has excellent thermal insulation properties. The main feature is the ability to combine with all types of bases, including breathable ones. Disadvantages include a high degree of moisture absorption and low strength, which can lead to deterioration in thermal insulation qualities and deformation of the insulation. Rodents can also spoil mineral wool. If the material accumulates moisture, mold appears.

Soundproofing

- Mineral wool, due to its weight and specific structure, has excellent sound dampening ability. By using it to insulate walls, the acoustic comfort in the room also improves. Therefore, mineral wool is often used in the construction of internal partitions, for example, made of plasterboard. Mineral wool slabs, which have the lowest density, are fluffier, well insulate sound traveling in the air, while hard and semi-solid slabs suppress noise caused by the operation of appliances well.

- Expanded polystyrene has mediocre acoustic characteristics, especially when it comes to sounds traveling through the air and vibrations emanating from devices. It should be noted that there are special types of polystyrene that dampen impact sounds.

Service life

Manufacturers of expanded polystyrene and mineral wool indicate a service life of at least 50 years. To achieve this and extend the period of use, the insulation should be reliably protected from the influence of external factors:

- Penoplex - from ultraviolet radiation, which impairs performance characteristics.

- Mineral wool - from mechanical stress and moisture. Which can lead to deformation and shrinkage.

Users note the average service life of mineral wool is 25-35 years.

As for penoplex, there is no specific data, since insulation has appeared recently.

Mineral wool

This material is obtained by melting glass (glass wool), rocks (basalt, stone wool), blast furnace slag (slag wool). All materials are fibrous and porous. They are characterized by high thermal conductivity, which is why they are widely used in construction work, especially for insulating houses. Mineral wool has a number of advantages; they have made the material a leader in the list of insulation materials.

- High fire resistance. The insulation can withstand very high temperatures; some types of materials are resistant to combustion at +1000°C. In moments of fire, mineral wool does not support combustion, even when in contact with fire.

- Good vapor permeability. Mineral wool perfectly allows air to pass through, this property helps not to retain condensation, but to remove it effectively.

- Moisture resistance helps mineral wool not to let water through; when it gets wet, the material dries, does not lose its shape, does not deform and retains its positive properties. Mineral wool at the production stage is treated with special oily agents or water-repellent substances.

- Thermal insulation properties made it possible to use all types of mineral wool, both for external and internal construction work. The insulation is able to regulate the microclimate in the room.

- Mineral wool is capable of absorbing many sounds, therefore it has high sound insulation.

- Environmental friendliness is also an important advantage; mineral wool does not emit substances harmful to the body. Even when exposed to high temperatures, the material is harmless.

In addition to the advantages, the material also has disadvantages that need to be discussed.

- Mineral wool in a roll is difficult to process; when working with it, you must have protective equipment - a mask and gloves.

- The rolled material may lose its shape, the tightness at the joints may become poor, so experts recommend. To avoid heat leakage, buy mineral wool in slabs. In this form, the insulation must be well secured and laid more tightly.

- If the production technology is violated, toxic substances can be released from basalt wool, this happens when low-quality raw materials are used in the production of the material. Experts advise buying basalt wool only from well-known brands and following all sanitary and technical installation rules.

comparison table

The characteristics of penoplex and mineral wool are described in detail in the table.

| Properties | Mineral wool | Penoplex |

| Density (kg/m³) | 115 | 25-47 |

| Compressive Strength(MPa) | 0,1 | 0,2 |

| Flexural strength (MPa) | 0,5 | 0,5 |

| Water absorption (%) | 1 | 0,5 |

| Thermal conductivity (W/m•°C) | 0,043 | 0,03 |

| Fire resistance | NG | G1-G4 |

The indicators are averaged, since the indicators differ from one manufacturer to another.

Mineral wool and extruded polystyrene foam provide reliable insulation, subject to the purchase of high-quality material and compliance with operating conditions. Which insulation is better is a user decision, since it depends on the specifics of the situation.

Basalt wool

This material is one of the varieties of mineral wool, since it comes in different fractions:

Basalt wool slabs differ from their mineral counterparts. Both materials contain fiberglass mixed with special components. In the production of basalt wool, volcanic rock (stone) is used, hence its name. Available in the form of rolls or slabs.

If we compare mineral wool with basalt wool, then stone wool is much denser, it is brittle and inelastic. Stone wool does not absorb moisture, and even when wet by 30%, it continues to be a material with good thermal insulation properties. It does not shrink, so it is excellent for insulating many surfaces.

In the event of a fire, basalt wool does not ignite, does not support combustion and has low hygroscopicity.

Drawing a conclusion, we can say that basalt wool has more advantageous characteristics

When purchasing material, you need to pay attention to the manufacturer and product certification

Differences between penoplex and mineral wool according to different evaluation criteria

To make the right choice regarding insulation materials, you need to familiarize yourself with the characteristics and features of each type of interest.

Benefits or harm to health and the environment

Both materials are made from synthetic materials. Although, according to manufacturers, the polystyrene used to make penoplex is safe and does not harm the environment. This fact is relative. The thing is that the starting material is styrene, which is very toxic and harmful to the human body and the environment.

And even though it undergoes strong chemical treatment, a certain part of the toxic substances remains in the original material - penoplex.

Mineral wool refers to glass, slag and stone wool compositions. Most often they are sold in soft rolls, and less often - felt or granulated. The initial material for making mineral wool is an inorganic substance, which is processed using artificial glue.

As a result, the material contains harmful synthetic dust, which, when deposited in human lungs, cannot be removed from there by any means.

Operating data

Many people wonder which is better: penoplex or mineral wool. Both of them are perfect for insulating interior rooms.

Types of mineral wool

But not every material retains heat well when located outside the building, for example on a balcony. There are several main performance characteristics by which insulation materials are evaluated:

- Heat retention level. This point is perhaps the most important. The thermal conductivity of penoplex is from 0.03 to 0.032. At the same time, mineral wool has the following indicator: from 0.032 to 0.046. The high quality of the thermal insulation material is indicated by the low indicator of this item. This means that penoplex can provide more heat.

- Waterproof. Penoplex insulation guarantees complete protection of the building from excess moisture, since this material does not absorb water at all. At the same time, mineral wool is very susceptible to moisture and steam. Therefore, if there is a need to carry out external insulation with it, you must first treat it with special means. But even then it will not be waterproof.

- Duration of the service life. Penoplex is not prone to rotting, drying out, deformation and crumbling. If you install and store it correctly (do not expose it to high temperatures and direct sunlight), it will provide warmth and comfort in your home for many years. At the same time, mineral wool is durable and tolerates hot climates and direct sunlight. But it can settle and crumble over time.

- Noise isolation. Using penoplex it is almost impossible to protect a building from external sounds. However, mineral wool copes with this mission perfectly.

- Fire safety. Some types of penoplex are classified as low-flammable materials, while others are normally flammable. At the same time, mineral wool does not react at all to temperature. Even seven hundred and fifty degrees Celsius is not a problem for mineral wool. And it can lose color at temperatures of about a thousand degrees.

Also, when deciding which is better, penoplex or mineral wool, for insulating a balcony, you should think about this.

Installation of penoplex on the balcony

Which material is easier to install, since a robot at height is in itself complex and dangerous. Using penoplex is convenient not on a surface that has been leveled in advance. It is easy to measure, cut, sand and glue.

Also, this material does not require additional moisture insulation. But on surfaces where there are a lot of bends and turns, it is more convenient to use cotton wool, since it is flexible. But it is necessary to work with it only in special protective clothing. Which of course implies inconvenience.

Penoplex or mineral wool. What you can learn best from the video:

Noticed a mistake? Select it and press Ctrl+Enter to let us know.

Description of foams

Polyurethane foam and polystyrene foam are foam plastics; they have simple installation, which affects the price of the finished insulation. Expanded polystyrene can be regular or extruded. The regular one consists of soft small white balls; the extruded one is denser, warmer, more durable and more expensive than the regular one.

The advantages of expanded polystyrene include:

- low cost 277 rub. for 1 sq.m. 5 cm thick;

- ease of installation;

- low thermal conductivity 0.028 - 0.035;

- different sheet thicknesses.

The disadvantages include the following:

- water absorption of polystyrene foam leads to an increase in the thermal conductivity of the insulation;

- it is easily destroyed by exposure to the sun;

- mice love to chew through it and make nests in it;

- very short service life - 10-15 years, but we are building seriously and for a long time;

- fire hazard - it is very flammable; when burned, it emits soot and toxic gases;

- at 60 degrees it begins to fall apart, so it is not at all suitable for roofs;

- at 20 degrees polystyrene begins to release toxic gas;

- presence of seams between sheets of insulation, cracking of seams;

- deformation during operation;

- it is necessary to fill the seams with polyurethane foam and fasten the sheets to the surface; this somewhat delays the commissioning of the construction project.

conclusions

When choosing durable and reliable insulation, many developers pay attention to mineral wool and polystyrene foam. Many inexperienced owners prefer mineral wool to polystyrene foam because it is environmentally friendly and has high vapor permeability.

However, this solution is not always optimal. This insulation is capable of allowing air and water to pass through. Moisture can settle on the inner surface of the facade. This can lead to freezing and destruction of the facade. The decorative layer deforms over time, and the insulation becomes like a sponge that has absorbed moisture.

Foam boards are capable of allowing air to pass through, but not too much. Since the material has no pores, and it itself is quite dense, moisture cannot pass through it. Due to the fact that air passes through the joints, a certain ventilation is created.

Advantages of expanded polystyrene assortment

Almost all the requirements of modern technologies are met by the high-density insulation Penoplex Foundation. The price of this material can rightfully be called moderate.

- The material combines effective heat conservation and a minimum level of loads on the insulated base, as well as moisture and frost resistance and preservation of working properties over a 45-50 year designated service life.

- Simple mastic-adhesive installation allows home craftsmen to partially or completely master the entire scope of work on their own. Assembly of panel cladding and sealing of joints is simplified by tongue-and-groove or step joints.

- Low thermal conductivity makes it possible to use 30 mm Penoplex panels for insulating building structures. Depending on design requirements, this figure can be increased to 50-60 mm.