Foam plastic, its types, production

Each of you, when you hear the word polystyrene foam, imagine in your head a picture of small white round balls combined into a single weightless block. Let's look at what polystyrene foam is.

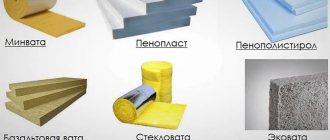

Polystyrene foam is not just one type of raw material. Polystyrene foam is plastic saturated with air particles. Depending on the type of foam used, its scope of application changes.

The foam manufacturing technology consists of three main stages:

- Connection of components.

- Saturation of the composition with oxygen

- Form formation.

An important point in the production of polystyrene foam is the saturation of the composition with oxygen, or, as it is also called foaming. How intensely the composition is saturated with oxygen affects the scope of application and type of foam.

Another important factor in the thermal conductivity of polystyrene foam is its ability to absorb moisture. The less the foam absorbs water, the higher its ability to retain heat.

According to production technology, there are two types of polystyrene foam:

- Foamed polystyrene foam;

- Extruded polystyrene foam.

Disadvantages of insulation

When purchasing insulation, you must remember that all manufacturers, when advertising their products, emphasize only the positive aspects of their product.

The myths about orange insulation discussed below are those facts that you will not find in advertising brochures, but which have a direct impact on human safety and health.

Fireproof or not so much?

Insufficiently high fire resistance is one of the main disadvantages of orange insulation. In general, the issue of flammability of foam plastics is not as simple as it might seem if you do not delve into the essence of the matter.

For the reason that their various modifications have different degrees of fire safety and, in terms of flammability, belong to materials of different categories - from G1 (low-flammable) to G4 (highly flammable).

Pure polystyrene foam is a flammable material, which is its main disadvantage. It ignites easily from any open flame - a lit match, a burning blowtorch, even welding sparks. Therefore, unmodified foam plastic is rarely used in construction.

To increase its fire safety, combustion inhibitors are added to it - flame retardants (substances that prevent fire). Foams with fire retardant additives are called self-extinguishing.

Burning or smoldering of polystyrene foam produces thick black smoke, which can be very toxic due to the additives it contains.

In addition to carbon monoxide, it may contain hydrogen cyanide, phosgene, hydrogen bromide, etc. Inhalation of such substances has a detrimental effect on the respiratory system and nervous system of a person and can lead to rapid death.

It would seem that the issue with the fire resistance of polystyrene foam is easily resolved: add more fire retardant - and the problem is solved. But, firstly, this makes the material more expensive, and secondly, some types of fire retardants contain toxic substances.

Such, for example, as hexobromocyclododecane, which is a bioaccumulative toxin and has been banned for use in the European Union since 2015.

Insulation service life

One of the requirements for insulation materials is that their service life must be commensurate with the durability of the object that is insulated with it. Domestic standards provide for insulation materials to operate for at least 25 years.

If you believe the manufacturers, their polystyrene foams more than provide this period.

Some sources indicate the durability of foam plastics to be 50 years or more. But objective research does not confirm this. The experiments carried out revealed that after 10 years of operation, signs of destruction begin to appear in polystyrene foam.

Speaking about the durability of polystyrene foam, you need to pay attention to one more aspect - the safety of the material that is insulated with it. Although polystyrene foam is a vapor-permeable material, its vapor permeability is low

Moisture that penetrates into wooden structures from the inside or outside is unable to completely leave them through the insulation layer to the outside. This lack of insulation contributes to the formation of fungi and mold on the wood, leading to its rotting.

Although polystyrene foam is not a breeding ground for fungi, they feel quite comfortable on its surface, especially if this surface interfaces with wood.

Safety and environmental friendliness

As for pure polystyrene, it is truly safe, but the same cannot be said about the components and additives used in the production of expanded polystyrene.

As mentioned above, fire retardants added to polystyrene foam can pose a direct threat to human health and the environment. But the matter is not limited to them alone.

In the production of expanded polystyrene, at the foaming stage, sometimes not only safe CO2 and isopentane are used, but also chlorine- and bromine-containing freons. When heated, the latter are capable of releasing toxic substances, in particular, the well-known phosgene, which is the main component of some types of chemical weapons.

In addition, freons have a detrimental effect on the ozone layer, which protects the Earth from solar radiation. In addition, their greenhouse activity is more than 1000 times higher than that of carbon dioxide. It is not for nothing that the use of freons has been prohibited in the European Union since 2010.

Conclusion from all of the above

When choosing a thermal insulation material for your home, pay attention to the entire range of its characteristics, and not just the heat-insulating properties. Not only the comfort and efficiency of your home, but also the health of all family members depends on the right choice.

Expanded polystyrene foam

The most common type of foam used in everyday life. It is used for transporting furniture or various household items for safety. It is used as insulation.

The composition is saturated with gases by foaming.

- Expanded polystyrene is made according to the following principle.

- Initially, foam particles are mixed, and carbohydrate particles are added to them to foam the composition.

- Special additives are also added to improve the quality of the finished product.

- It is possible to add various dyes and form granules. The finished mixture is steamed and the final shape is formed.

Production

Dense foam is created using the pressing method. In this case, the granules are connected very firmly. Therefore, the insulation almost does not crumble and is difficult to break. This material will help:

- reduce costs for the construction of heating equipment;

- save heating costs;

- reduce the thickness of the walls;

- visually increase the area of the room.

Extruded polystyrene foam

The manufacturing technology differs from foaming in that the finished mixture is not doused with steam. Individual granules are not formed from the finished composition. Carbon dioxide is used as a foaming element.

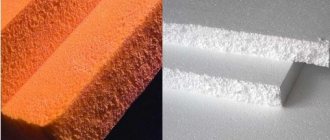

The appearance of the sheet has a continuous structure with closed porous cells.

If we look at the structure of the foam in more detail, we can understand that 2% is solids and 98% is air, enclosed in small chambers.

Preparation

Before you begin installing foam plastic on the outer surface of the facade, you need to prepare the walls of the building.

For easy ascent to the third or second floor, build or order scaffolding on the Internet - a temporary auxiliary structure made of wood (boards are knocked together) or metal structures.

This also has its own subtleties: scaffolding cannot be placed close to the wall - be sure to leave a distance to the wall of at least 60 cm (this includes the width of the foam).

The next step is to check the walls for unevenness or defects.

Clean the cinder block or aerated concrete blocks from dirt (depending on what the house is built from), and cover any damage, holes or cracks with cement mortar. Drill the necessary holes for wires or pipes.

Facade system

If the house is made of aerated concrete, sand-lime brick or foam block, then additional treatment of the walls with a soil solution is required - 2 times instead of 1.

Dilute the deep penetration primer with water (add a third or half of the volume) and treat the walls only in those places that require it. You should not waste the solution over the entire area if the walls are perfectly flat and smooth, however, this is rare.

Application of polystyrene foam

Main types of expanded polystyrene

Let's look at different types of polystyrene foam.

- Pressless. The foam granules are dried at a temperature of 80 degrees and foamed. This action is repeated several times. Then fill the form. More fragile look.

- Extruded.

- Extrusion. It is used in the food industry.

- Pressed. Quite durable looking.

- Autoclave.

Advantages of expanded polystyrene

- Retains heat well

- Long service life. At temperature readings from -40 to +40 it can last for 50 years.

- Resistant to moisture.

- Microorganisms, various bacteria, mold and mildew do not develop.

- Non-toxic. It can also be used in the food industry.

- Very light.

- Foam plastic with a thickness of 3 cm can be used as a good sound insulator.

- Some types have a fire-resistant coating.

Foam plastic for insulation

In order to keep the house warm during the cold season, the house is additionally insulated with polystyrene foam. The best polystyrene foam for insulation is considered to be PSB-S-25.

This brand is chosen because of the following qualities:

- Dense material that can be installed on any surface.

- Retains heat quite well.

- Small mass.

- Tolerates transportation well.

- Acceptable price.

- Long service life.

Is vapor barrier and waterproofing necessary?

Polystyrene foam is a material that has fairly good resistance to the passage of vapors. When insulating walls made of block materials or brick, there is no need to install vapor barrier membranes.

When insulating the facade of a wooden building, a vapor barrier membrane is needed. It is attached between the wall and the foam plastic so that a ventilation gap is formed.

Waterproofing is not installed under foam plastic.

IMPORTANT!

If walls are insulated with foam plastic under siding, then a diffusion membrane is used, not a vapor barrier.

These two materials differ in their ability to pass vapors.

Application of façade foam plastic

Facade foam is used in two cases. It is used as a base for plaster or as an independent coating that performs both insulating and decorative functions.

As a base for plaster, polystyrene foam is installed on the wall using cement glue. It is designed specifically for these purposes. It must be diluted in small portions with water. Within 30 minutes the glue sets. You need to work quickly.

- Glue is applied to the surface of the foam sheet and secured to the surface by pressing the sheet firmly. There is no need to apply glue to the side edges.

- After which the sheet is additionally secured using snipe umbrellas. IN

- Make a hole in the canvas and then install an umbrella. There must be at least five umbrellas per 1m2.

- After which the foam sheet is covered with a layer of cement glue. For better adhesion and improved strength of the structure, it is additionally reinforced with reinforced mesh.

- A mesh is installed on the not dried layer of glue, and with light movements it is embedded in the composition.

After the first layer of cement glue has dried, it is coated again, completely hiding the mesh. This coating must be coated with a primer and any plaster.

In its pure form, foam does not tolerate UV rays. For a longer service life, it must be coated with a protective layer. You can purchase already coated decorative sheets for the facade.

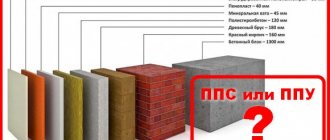

Wall pie device

When insulated with foam plastic, the classic version of the wall pie looks like this:

- bearing wall;

- adhesive base;

- base profile;

- insulation;

- reinforcing mesh;

- adhesive base;

- primer;

- finishing layer.

The finishing layer can be facade plaster, paint or other facing material chosen when determining the design of the wall.

Wet facade

Foam glue

Basically, foam plates are attached to the surface using glue. You need to choose glue for suitable conditions. If you attach it to the facade of a building, the glue must withstand temperature changes.

Adhesive for foam plastic should not contain gasoline or acetone, as they destroy the structure of the foam plastic. The glue is also selected for the surface on which the foam sheet will be attached.

Foam glue can be either dry or wet.

- To avoid making a mistake with your choice, you should not take the cheapest glue.

- It is better to spend a little more money, but get a product with detailed instructions and composition in accordance with GOST.

- When purchasing a dry mixture, pay attention to whether the packaging is damaged.

- Is the mixture really dry? Slight moisture may change the properties of the adhesive.

Chemical properties

The operational parameters of the material that determine durability under the influence of external factors include:

- chemical resistance - polystyrene foam is impervious to many substances, except solvents and oxidizing acids. Mixtures based on acetone, ethers and light hydrocarbons quickly dissolve foam, without leaving even visible traces of it. Foam plastic is moderately resistant to alkalis, however, it is still not worth specially exposing them to them;

- temperature resistance – foam plastic has a low temperature limit of destruction. Already at 60-70 °C, gases begin to be released from it, which are products of the destruction of the original polymer. At temperatures above 100 °C, the decomposition of polystyrene occurs especially intensively and is accompanied by an even greater amount of toxic emissions. Serious consequences on the body can occur even several days after inhalation.

The fire safety of polystyrene foam is interpreted in two ways by supporters and opponents of the material. The first claim about its high resistance to flame, arguing that the ignited foam practically does not support the fire without an external heat source. The latter complain about the release of large amounts of gases during a fire that are harmful to humans. When viewed objectively, polystyrene foam is a fairly flammable substance that requires proper handling when finishing buildings.