- February 10, 2020

- Construction

- Irina Fendak

Insulation coated with a thin layer of aluminum foil has found widespread use in construction. Applying the film by thermal welding ensures a reliable connection of the layers and strengthens the material.

Foil insulation is used in the construction of houses, garages, baths, in mechanical engineering and the aviation industry. It is used for the manufacture of certain types of specialized containers, insulation of pipelines, and ventilation ducts.

Performance characteristics of insulation with foil

Traditional thermal insulation materials after applying a layer of foil acquire additional quality indicators. Existing ones are also improved. Such materials:

- more resistant to temperature changes;

- moisture resistant on the foil side;

- have increased sound insulation;

- save heating costs due to reflective properties;

- fireproof;

- do not emit toxic substances;

- easy to install;

- have little weight.

Among the disadvantages, one can note the impossibility of using them directly under finishing mixtures due to the softness of the material. Some types require the use of additional adhesive or special fasteners during installation. Thin insulation cannot provide good thermal insulation in areas with very cold climates; in some cases it is necessary to lay a second layer of uncoated material.

How to decorate a bedroom?

When choosing wallpaper for this room, we advise you to pay attention to calm, soft shades of lilac. Lavender walls promote relaxation and improve mood

Pleasant color for relaxation and rest

If there is a pattern on the wallpaper, it should not be flashy. It is appropriate to choose a lilac base with abstraction, flowers or circles for this room. It is worth adding wallpaper with small circles to the room if it is decorated in the style of shabby chic, Provence or boho.

In fusion, hi-tech and minimalism styles, monochromatic and strict geometry will look organic. You can create a bright accent in the bedroom if you decorate one wall using photo wallpaper, and the others in the shade “lilac”.

Lightweight pattern fits any style

Additional shades will help to brighten up the lavender room nicely. In our opinion, the following color duets would look most appropriate in the bedroom:

- "Lilac" and white. This combination of colors is suitable for a classic bedroom. If the walls are decorated using lilac wallpaper, then they can be diluted with a white ceiling, curtains, pillows and blankets. Avant-garde lovers can add a little black to these two colors.

- Yellow, gold, orange, green and lilac. Such bright shades will ideally complement the dominant lilac and make the room positive and rich.

An appropriate duet of lilac and white

Kinds

Insulation with foil is divided according to the form of release and the number of layers of coating. Depending on the area of application, the heat insulator is produced in the form of:

- rolls;

- sheets and plates;

- hemispheres with fastenings or cylinders.

Aluminum is applied on one or both sides. Also, one-sided material on the opposite side can be covered with a layer of adhesive and film. Before installation, the film is removed, the insulation is easily glued to the surface without the use of additional fasteners.

Construction insulation with foil is also divided according to the type of base layer.

Preparing tools before work

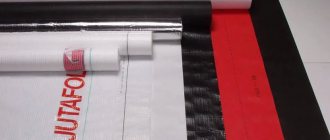

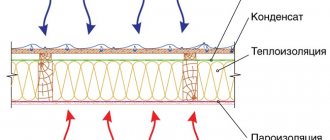

a layer of vapor barrier must be laid between the insulation itself and the wall .

If one-sided foil insulation was chosen, that is, the foil is on only one side, the main layer will come into contact with the wooden wall, and this is unacceptable, especially if the insulation is based on basalt wool. If the choice was made in favor of double-sided foil insulation, then a vapor barrier is not needed.

It is necessary to ensure air flow between the wall and the insulator so that the walls can be ventilated and moisture does not accumulate. To do this, you need to attach 20 mm thick slats to the wall. It would be enough.

Tools for work:

- construction stapler;

- foil adhesive tape;

- dowels and screws;

- screwdriver;

- insulation;

- vapor barrier.

If a product with a self-adhesive side is chosen as insulation, then a stapler will not be needed. The adhesive side adheres well to slats and other surfaces. In this case, you will need a degreaser, such as a solvent.

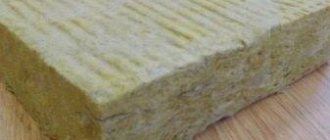

Foil-coated stone wool

Foil-coated stone wool is produced in rolls and sheets. Its thickness can reach 10 cm.

The advantage of this material is its natural composition. The technological production process is based on the action of a volcano: crushed stone and blast furnace slag are melted under the influence of very high temperatures, then, entering a centrifuge, under the influence of air flows they turn into thin threads. Binders are added to them, molding, firing, and foiling are carried out.

Stone wool is environmentally friendly, durable, and fireproof. Light weight and flexibility allow it to be used for surfaces of any shape.

Mistakes when laying fiberglass mesh

The reinforcing layer of wall insulation provides protection from mechanical damage. It is made from fiberglass mesh and reduces thermal deformation, increases strength and prevents the formation of cracks.

The mesh must be completely immersed in the adhesive layer

It is important that the mesh is glued without folds. We also do not recommend using cheap Chinese meshes. They are not alkali-resistant, which will lead, over time, to corrosion by the solution, which means the plaster layer will not be sufficiently protected from temperature and mechanical deformation

They are not alkali-resistant, which will lead, over time, to corrosion by the solution, which means the plaster layer will not be sufficiently protected from temperature and mechanical deformation.

In places vulnerable to loads, an additional layer of reinforcement is performed - in all corners of window and door openings, mesh strips measuring at least 35x25 are glued at an angle of 45°. This prevents cracks from forming in the corners of openings.

To strengthen the corners of the house, corner profiles with mesh are used.

Fiberglass wool

The industry produces fiberglass insulation materials, for example, Izover insulation with foil. Its production is similar to the process of producing stone wool. Basalt rocks and remains of the glass industry are used here. When purchasing, you should pay attention to the direction of the fibers. The best option is a material with a chaotic arrangement.

Good performance characteristics allow this type of wool to be used for various purposes: internal and external thermal insulation of walls, insulation of floors, roofs. Due to its heat resistance, it is widely used in the construction of baths.

The disadvantage is the moisture permeability of the material, so insulation from steam and water is necessary.

Wallpaper for children's boy

Parents can decorate a boy's children's room with wallpaper in several variations.

- Pastel range of shades. Plain or faintly patterned wallpaper of any muted color is suitable.

- Photo wallpaper with a three-dimensional pattern that will suit the interests of the child.

- Wallpaper with small bright patterns. The room will always feel an atmosphere of celebration and childish spontaneity.

At the age of 7-11 years, children tend to be distracted by extraneous things, so it is best if the room is decorated in neutral colors.

Foamed polyethylene

This material is obtained by introducing a gas mixture into its structure. The result is a durable, elastic heat insulator with a cellular structure. Foil coating is done on both one and two sides.

Polyethylene is often used as an insulating underlay for floors, as it adheres tightly to surfaces and can easily restore its original shape. The material has good sound insulation; when using it, you can do without vapor barrier, because it is moisture-proof. This heat insulator does not rot and is not attractive to rodents. Not everyone knows which side to lay insulation with foil on. But if done correctly, it will reflect heat waves towards the room.

For external insulation, foamed polyethylene is used in combination with other materials.

Technical characteristics and types of base layer

Foil insulation is considered a relatively new material, but has already won the respect of consumers. It is designed for installation on building facades, interior walls, ceilings and roofs. The material is a combination of polyethylene foam and polished foil. Thanks to the presence of the latter component, the insulation reflects heat and retains it in the room. Research was conducted on its effectiveness, which showed that the reflectivity is at a level of more than 95%.

In addition to thermal insulation, protection from noise and moisture, the material is quite elastic, which makes it convenient for transportation and further installation. The insulation is thin and will not hide the usable area of the room. Resistance to moisture means that the material does not become damp over time. It will be able to protect the building from wind and severe frost. An important point is the environmental friendliness of foil insulation.

The scope of application of the material is extensive. Depending on the purpose of the object, it is necessary to select the appropriate type. It is used to insulate wooden houses, the interiors of apartments, bathhouses, outbuildings, various partitions and even pipelines.

What does foil wall insulation look like?

By insulating the facade of a building, you can be sure that your home will become much more comfortable and will not be afraid of even the most severe frosts, winds, high humidity and temperature changes. Foil thermal insulation is resistant to ultraviolet and radon radiation. The insulation also interacts well with any facing materials.

Expanded polystyrene

This insulation is an improved type of foam. Improved performance is achieved through extrusion. Foiled polystyrene foam is available in the form of sectional rolls or slabs.

This heat insulator is used mainly for insulating floors. It can be used in combination with a “warm floor” system. For convenience, most types of this insulation have markings for installation of coolants.

Foiled polystyrene foam can also be used to insulate the roof.

Internal wall insulation

Thermal insulation of walls from the inside with foil material is similar to the installation of conventional insulation. There are some features that need to be taken into account. The main question that arises when using a two-layer material is: which side should the insulation with foil be laid on the walls? Experienced builders answer unequivocally: the metallized side should face the inside of the room. If you do the opposite, the properties of the insulation will be reduced to a minimum.

Another important point: an air gap of approximately 1.5 cm must be left between the finishing and the heat insulator.

Insulation of room walls is carried out in five stages:

- The surface is thoroughly cleaned of old finishes and accumulated dirt, then impregnated with an antiseptic.

- Further actions depend on the shape of the insulation. If rolls with an adhesive layer are used, they are simply glued to the wall. Rolls without glue are attached using a stapler and special fasteners. You can apply an adhesive composition to the material and glue it. For the slabs, you need to make a sheathing and attach the insulator to its cells, not forgetting which side the insulation with foil is laid on.

- If necessary, the material is additionally secured using a stapler or dowels.

- Seams and cracks are sealed with aluminum construction tape.

- Wooden slats are stuffed to form an air gap.

Builders note that roll modifications, when used for walls, are much more convenient to install.

When insulating a room from the inside, you need to take into account some rules:

- the insulating material is laid close to each other, avoiding gaps between the rows;

- to prevent the appearance of cold bridges, the seams are taped with aluminum tape;

- the rolled material is not overlapped;

- for insulation with double-sided coating, it is necessary to provide an air gap on both sides;

- It is recommended to additionally fix the self-adhesive material around the perimeter.

Internal insulation is a difficult process, which has its drawbacks. Firstly, the area of the room is reduced. Secondly, while the work is being carried out, residents must be evicted and things must be removed. Thirdly, this method is more expensive. However, with the right choice of material and careful attention to the work process, this task is quite feasible.

Types of material

Let's look at what types of insulation are called:

- With foamed polyethylene, it looks like a roll of self-adhesive material, similar to film with foil. Scope of application in various equipment, lining of pipes, shafts, roofs, since it has a high temperature range from -160 to +160 degrees, it is fire resistant.

- Mineral wool with foil coating can have the form of a plate or cylinder. It also has a high degree of fire resistance.

- Expanded polystyrene, coated with foil on both sides. It also has a wide temperature range, the diameter can be 5mm, 10mm, 15mm.

- Basalt, just like the materials described above, is made on the basis of foil material, however, thanks to its unique technology, it can withstand temperature fluctuations from -200 +600 degrees, and is resistant to aggressive chemical environments.

How to put insulation on pipes

As a rule, such material has the form of a pipe “cocoon” made of mineral wool (withstands high temperatures) or polystyrene foam (moisture resistant). And how to insulate them, the question disappears in itself, since they have the appearance of a “cocoon”, which is put on top and fixed. There are main ones for chimneys of various diameters and temperature conditions.

Related article: What is the best way to break down a wall in an apartment

However, if you decide to purchase sheet insulation, you may be faced with the question of how to glue it to metal? Aluminum tape will come to your aid, which is wound onto the insulation over the pipe. And, as in the options described above, you need to wear it with the shiny side facing you.

Is it possible to insulate the walls from the outside?

To insulate the walls from the outside, perforated foil insulation is used. This is a material that, among other things, has soundproofing qualities, can protect your home from moisture and wind, and also does not prevent moisture from leaving the room. This option is ideal for those who do not have the opportunity to perform such work indoors. However, such activities can only be carried out in the warm season and in dry weather.

To do this you will have to do the following:

- If you had any covering on the wall, you need to get rid of it. Then treat the surface with an antiseptic solution. It is better to do this in hot weather so that everything dries well; treat the lower part of the building especially carefully. Within two days the surface will dry completely.

- Next, build a frame from timber, secure it with self-tapping screws. Lay Penafol, then leave an air tunnel, glue the joints, then install the outer frame.

In conclusion, we suggest watching a video about the installation of Penofol thermal insulation:

Insulation of walls outside

Experts disagree on which method of thermal insulation is more effective. Many people believe that external insulation is better. The dew point moves outward, which prevents premature destruction of the walls. This is especially true for wooden structures. With the external method, no additional ventilation is required; the walls “breathe”, creating a favorable microclimate. External insulation does not affect the area of the rooms in any way.

Most often, for thermal insulation of walls from the outside, building insulation with foil in the form of layers of mineral wool is used. The following work is being carried out:

- Cleaning the walls and applying antiseptic impregnation.

- Laying vapor barrier.

- Installation of wooden or metal sheathing. Preference is given to a metal structure because it eliminates deformation of the final finish due to changes in temperature and humidity.

- Fastening the insulation using adhesive, additional fixation with dowels.

- Fastening the windproof film.

The finishing is installed taking into account the required gap.

Work on external insulation of building walls is carried out at positive air temperatures and in the absence of rain.

Minvata

This material has a foil layer on only one surface. The product is produced in the form of slabs or rolls. The layer thickness here is slightly greater, and the minimum value is 5 cm. Basalt wool or fiberglass can be used for production.

If you want to know what shiny wall insulation is called, then you should know that in this case we are talking about foiled mineral wool. It has limitations in its use, since cotton wool can negatively affect health. This insulation is used in non-residential premises or for exterior decoration. The products have certain properties that are suitable for thermal insulation of baths, ceilings and walls.

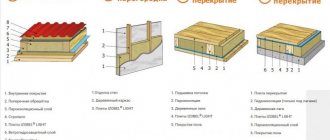

Floor insulation

Floor insulation is carried out in buildings with both wooden and concrete floors. Technology for laying material for wooden floors:

- Surface cleaning.

- Coating with impregnation and primer.

- End-to-end laying of thermal insulation.

- Sealing seams with tape.

- Installation of sheathing for air gap.

- Flooring with plywood or boards.

In areas with a harsh climate, the insulating “pie” is made multi-layered: double-sided insulation, sheathing with ordinary material, one-sided insulation, gap bars, flooring. At the same time, we must not forget which side to lay the insulation with foil - the metallized layer inside the room.

Application area

Foil-coated thermal insulation products are often used for heating equipment (heaters, oil radiators, boilers).

In addition, wall surfaces and floor bases are covered with such insulation with foil towards the room. The reflective layer retains maximum heat in the room and does not let it out.

Since the product is small in thickness, it is often used to insulate small areas. It is used for thermal insulation of saunas, garage cooperatives, outbuildings, pipeline communications, wells and boreholes.

Penofol for floor insulation.

Ceiling

Work on thermal insulation of the ceiling does not take much time, but the effect is noticeable. Everyone knows that warm air moves upward. In the absence of an insulator, it heats the ceiling and gradually goes into the attic. Foil material turned out to be especially effective for the ceiling. You now know which side to lay the insulation with foil, so you will do everything correctly. In this case, the ceiling will reflect heat waves towards the room, preventing them from passing outside.

For houses with a wooden floor, which is the ceiling for the first floor and the floor for the attic, everything is done simply. It is enough to lay a roll of thermal insulation under the subfloor of the attic. Which side should I lay insulation with foil on? Answer: metal film down.

When insulating concrete ceilings you need:

- Clean the surface.

- Apply antifungal agent and primer.

- Glue the insulation with foil to the ceiling and seal the seams.

- Additionally secure with special dowels.

- Make a wooden sheathing.

- Screw the drywall.

- Seal the cracks with sickle tape.

If necessary, you can use foil insulation in combination with regular insulation. The material without foil is attached to the ceiling, and roll insulation with foil is laid on it.

Insulating a house or apartment with two-layer insulation makes staying there more comfortable and significantly saves heating costs. You just need to carefully consider the selection of material according to technical characteristics and purpose and avoid mistakes during the installation process.

Price

in the production of foil insulation on the Russian market :

- Jermaflex;

- Izolon;

- Penofol;

- Tepofol;

- Folgoizol;

- Ecofol.

| Firm | Characteristics | Price |

| Jermaflex | 1.2 m x 8 mm | 80 RUR/m² |

| Izolon | Type A, thickness from 2 to 10 mm, length 1 m | 140-260 RUR/m² |

| Penofol | Type A, thickness from 3 to 20 mm, length 36-12 m (the thicker, the shorter the meter) | 53-278 RUR/roll |

| Tepofol | Type A, thickness from 2 to 10 mm, length 2.5 m | 40-1200 RUR/roll |

| Folgoizol | Type A, thickness 10 mm, length 15 m | 1650 RUR/roll |

| Ecofol | Type A, thickness from 2 to 15 mm, length 25-10 m | 780-1030 RUR/roll |