Due to the constant increase in prices for utilities and space heating, the problem of finding a rational type of autonomous heating is becoming increasingly important. A variety of systems have been developed and are successfully used, each having their own distinctive features, advantages and disadvantages. One of the most promising systems is gas convectors. Let's try to figure out in what cases their installation is recommended, what types of such devices are and how they work.

When and why is it effective to use gas convectors?

Gas convectors have low resource consumption, but are not able to develop the required power to heat large rooms. Therefore, the scope of their application has become small private houses with one or two living rooms, cottages, garages and temporary buildings. In such conditions, the heating gas convector provides the following advantages:

- compactness, relative cheapness and ease of installation of equipment;

- no need to develop and approve project documentation;

- autonomy when the convector is powered from gas cylinders;

- high efficiency (up to 90% in industrial devices and up to 80% in home-made convectors);

- resistance to low temperatures , no “freezing effect”;

- use of atmospheric oxygen rather than indoor oxygen;

- fuel versatility, that is, the ability to switch from methane to propane by replacing injectors .

Among the disadvantages of the system, the most significant are serious losses in efficiency when heating large rooms and an increase in their warm-up time.

The second problem is partly eliminated by installing convectors with forced circulation, that is, equipped with a blower fan, however, in houses with three or more rooms, the rationality of such a solution is very doubtful.

Another problem that may arise when trying to convert an apartment for convector heating is a ban from the municipal gas service , caused by the potential danger of the device for neighbors. Therefore, residents of apartment buildings need to coordinate such work in advance.

Hyundai H-HV15-10-UI617

Photo: https://beru.ru

Hyundai H-HV15-10-UI617 is an inexpensive heater from a well-known manufacturer of household appliances. The device copes well with heating a room of 10 - 15 square meters. The product is safe to use and allows you to adjust the heating over a very wide range. Ideal for a dacha or private home where living is not carried out all year round. Considering the low cost of such products, with a large heating area, you can install 2 convectors. At the same time, the load on the electrical network will not be significant, because the power of each device is only 1 kW. Despite the presence of some shortcomings, the device is one of the highest quality in its price class.

Convector Hyundai H-HV15-10-UI617

Advantages:

- light weight

- nice price

- simple controls

Flaws:

- low power

- mechanical control

Classification of gas heating systems

Gas heating systems are classified according to several criteria. The most common and obvious is the classification according to the configuration of devices, that is, the method of their installation. It includes two groups:

- Wall convectors - are rigidly mounted on the wall of the room and communicate with atmospheric air through a technological opening, taking in oxygen and throwing combustion products out.

- Floor-standing - do not have a rigid fixation; they communicate with the external environment, as a rule, through flexible tubes.

There is no functional difference between these types, and when choosing between them, you should only focus on personal preferences and the pricing policy of suppliers. More important from the point of view of the efficiency of the system and the ease of its operation is the classification according to the type of fuel used.

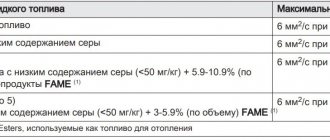

The following groups of devices are regulated:

- Main gas convectors running on natural gas . Natural methane is taken from a public gas pipeline, connection to which can only be carried out by authorized bodies. The advantage of fuel is availability, uninterrupted supply, and relatively high quality.

- Reviews characterize a gas convector using bottled gas The fuel for it is still relatively cheap, is under high pressure, but is quickly consumed due to the small capacity of the cylinder.

- Gas convector using liquefied gas . Liquefied methane or propane is obtained by sharply lowering the temperature of the substance and is somewhat more expensive than compressed one. A gas cylinder of this type holds 2-3 times more fuel.

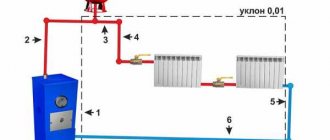

A detailed overview of possible connection diagrams for heating radiators in a private house.

Choosing a high-quality electric oil heating radiator - expert advice.

Eternal classic - Leningrad heating system: connection diagram, pros and cons.

The third classification criterion takes into account the characteristics of the distribution of generated heat, of which there are only two:

- A gas convector with a fan is a forced circulation system that provides faster and more uniform heat exchange, but is noisy and more resource-intensive.

- Without a fan - a natural heat exchange system, the action of which is based on the natural property of warm air to rise upward, displacing cold masses.

In addition to these factors, when choosing or designing a convector, it is important to take into account the material used to make parts and mechanisms, the power of the device and those parameters that will ensure an optimal balance of efficiency and cost-effectiveness of the equipment.

pros

Economic indicator. Electric convectors are cheaper. But a special advantage of gas convectors is their reduced operating cost. For example, popular models with cast iron heat exchangers and a power of up to 3 kW cost twice as much as electric ones with similar parameters.

However, this difference is very quickly covered during operation. The fact is that, according to calculations, the cost of heating the same area of a room when using natural gas is sometimes 10 times lower than when using electricity. The price of a cubic meter of gas and a kilowatt of electricity are approximately similar. But savings are achieved due to the fact that only 0.1 m3 of gas is needed to produce 1 kW of thermal power. All these statements are valid only when a gas convector is connected to a main pipeline and natural gas is used.

Work on liquefied gas. A gas convector can be easily converted to bottled gas. This makes it possible to use such heating devices in areas where there is no electricity or where it is supplied intermittently. But from an economic point of view, convectors using liquefied (cylinder) gas are also economically imperfect, like electric ones.

Lack of coolant. This is a noticeable plus in the absence of running water in the rooms where heating devices are planned to be connected. This is also an excellent factor if during the frosty season you need to leave the building for a long time - the water in the convector will not freeze, since there is none there. This is a good option, for example, for cottages, garages, utility rooms.

Environmental friendliness. The gas convector does not burn oxygen and is safe if all operating standards are observed.

Temperature adjustment. Such convectors have the full possibility of easily setting the required temperature and adjusting it.

Principle of operation

Despite the apparent diversity of technological types of heating systems, their design and operating principle are almost identical. So, the design of any convector device contains the following components:

- gas burner with igniter , ensuring ignition and stable combustion of fuel;

- heat exchanger , which warms up the moving air and, as a rule, finned - to increase the working surface area;

- system for capturing and eliminating (emission into the external environment) combustion products;

- thermostat , which acts as a temperature valve - its main function is to maintain the set temperature;

- control automation , deactivating the system in the event of breakdowns and failures;

- housing , which serves as the basis for housing the main components, as well as a protective mechanism that prevents their interaction with the internal environment of the room.

The work of all the considered elements is possible only in close interaction with each other. In order to verify this, let us consider the dynamics of the processes occurring in the system during its operation.

Gas wall convectors have the following operating cycle:

- Gas coming from the main line or an attached cylinder to the burner is ignited by the ignition device and burns, heating the heat exchanger.

- A stream of cold air , which is usually taken from below, passes through a heat exchanger, where it is heated. Next, the air flows either directly to the exhaust window or into the fan chamber, which forces it into the room.

- Exhaust manifold , usually equipped with a forced exhaust electric motor, captures fuel combustion products and removes them outside through a coaxial (double-wall) pipe. Atmospheric air enters the same way, the oxygen of which is necessary to maintain combustion.

These are the general principles on which the operation of any gas convector is based. The nuances of the functioning of specific elements and their internal structure will be discussed in more detail in the next section.

Types of devices

A gas air heater, like other heating equipment, is an excellent option for creating a comfortable temperature regime. Depending on the place of use, they are made in two types:

- Stationary are gas heaters using natural gas for the home; they are connected to the appropriate mains (they can also be powered by a liquefied gas cylinder); a prerequisite for installing such equipment is the presence of a chimney that ensures the removal of combustion products and the flow of air. For ease of use, models are available equipped with replaceable nozzles that provide various ways to connect the device.

- Portable devices are not able to provide full heating of a residential building or an entire apartment, so they are used in dachas, in the garage, to maintain heat in the room. Due to their mobility (small size and weight), the devices can be placed in any room and, if desired, moved to other rooms. Such heaters operate on liquefied gas (connected to a household cylinder).

In this video we will look at a gas heater and its capabilities:

For ease of placement, wall, floor and ceiling models are available. The combustion chambers also differ. The closed type of chamber is more practical to use, since the air required for combustion comes from the street and the products of work are discharged there.

Despite the variety of models produced, gas heaters have the same components. The main components of the devices are:

- Frame.

- Burner.

- Heater.

- Heat exchanger.

The most common models of gas heaters are:

- Infrared heaters are equipped with metal or ceramic emitters that, when heated, emit heat (infrared waves), which heats the objects in the room, rather than the air.

- Catalytic models are considered safe. During operation, there is no combustion process itself; the release of thermal energy occurs as a result of a chemical reaction. The fuel supplied to the catalytic panel is oxidized, resulting in the release of heat. The room is heated using both convection and infrared or mixed types.

- Convection heaters are the simplest units. As a result of gas combustion, finned radiators heat up, from which heated air rises, and cold air falls in its place and heats up.

When used correctly, these devices will be reliable assistants capable of quickly creating a comfortable thermal regime in any room, even in the absence of electrical energy.

Internal layout and materials

As mentioned above, the main task of the heating system - heating the air - is solved by a heat exchanger. Therefore, the choice of its configuration, size and material of manufacture must be carried out especially carefully. In the first two points (configuration and size) there is a unity of opinion.

Thus, the most effective is the S-shaped position of the tubes in a ribbed radiator , which ensures uniform heating of the metal and rapid release of the body to the passing flow. The dimensions are set in proportion to the power of the device. Manufacturing materials are more difficult.

The buyer or system assembler will have to choose from several options, each of which has its own advantages and disadvantages.

The most popular are:

- Steel is cheap, heats up quickly, but also cools down quickly. It is susceptible to corrosion, and therefore is relatively short-lived, and gradually loses efficiency during operation.

- Cast iron is another budget solution, but more promising than steel. Cast iron is fragile, so products made from it should be installed carefully, and the large specific gravity of the material imposes additional requirements on the reliability of mounting the system on the wall. Among the advantages of cast iron is its high heat capacity, that is, the ability to release accumulated heat for a long time even after the burner is turned off.

- Aluminum alloys – due to their low weight, high strength and chemical stability, are capable of functioning reliably for a long time. In terms of heat capacity, they are practically not inferior to cast iron, but they are an order of magnitude more expensive.

- Copper – provides maximum heat capacity , is practically not subject to corrosion, can withstand temperature and pressure changes well, and is easy to mold and install. However, you will have to pay well for such versatility - copper heat exchangers are the most expensive offered on the modern market.

Having analyzed the advantages and disadvantages of each of the materials, we can come to the conclusion that in industrial gas convectors, heat exchangers made of cast iron and aluminum alloys are preferred , since they provide the optimal price-quality ratio.

In home-made devices, it is better to give preference to aluminum alloys or copper as they are more reliable and not so demanding on the skills of the assembler.

Another dilemma to be solved is whether the system is equipped with an open or closed combustion chamber.

- The open chamber takes cold air directly from the room, warming it up and removing combustion products into the external environment. However, if there is an installation error, an insufficiently efficient exhaust hood, or in a poorly ventilated room, there may be a lack of oxygen and an increase in the concentration of carbon monoxide. It is recommended to install a convector with an open combustion chamber exclusively in non-residential premises.

- The closed chamber forces atmospheric air inside through a coaxial pipeline. Combustion products move along it in the opposite direction, which preheat the clean air through the pipeline wall. This system is more reliable and safer, it is compact and easy to install. However, a closed chamber is not without certain disadvantages - its operation requires electricity, which is not always convenient in suburban conditions, in addition, the price of a convector with a closed burner is always higher.

And the last feature, which was already mentioned above, is the presence of a fan heater. Everything is simple here - the more powerful the fan, the faster the heated air will reach remote rooms and walls , ensuring a more uniform distribution of heat. And as the fan power increases, the noise level and electricity consumption increase. In powerful devices, the fan also prevents the heat exchanger from overheating, thereby extending its service life.

Features of choice

When choosing a gas convector model, you must take into account its operating conditions. Among others, the area of the room and the required temperature for heating should be highlighted. The described heating devices have additional features, including:

- circulation method;

- thermal power;

- drawing method;

- installation option;

- heat exchanger material.

As for the first factor, circulation may be absent or provided by a fan heater

Convectors can be wall-mounted or floor-mounted, sometimes this is important if the room area is limited. The heat exchanger can be based on cast iron or steel

As for the installation location, wall convectors are more practical. They take up little space and are usually installed near the window, creating a thermal curtain between the cold and warm zones. However, such devices should be quite light so as not to create additional load on the wall. Such devices are limited in thermal performance, which does not exceed 10 kW.

If it is necessary to heat a larger area, floor-standing equipment is selected, which usually has large dimensions and significant weight. The cost of wall-mounted and floor-standing units is approximately the same with similar capacities.

Calculation of power and gas consumption

The average power of a gas convector can be determined by multiplying the area of the room by a coefficient that takes into account the type of system and its operating conditions. The general formula is:

P = k * S , where:

- P – convector power, kW;

- k – correction factor;

- S – room area, sq. m.

Correction factor

- taken equal to 0.1 for balloon-fed systems or rooms with good thermal insulation.

- The value k = 0.12 is set in the case when convector heating is the only source of heat in the living room and is operated stably throughout the day.

- If the heating device is installed in a walk-through or poorly insulated room , as well as in country houses or dachas, where residents visit only periodically, take k = 0.15 .

But calculating gas consumption is a much more labor-intensive task. It would seem that it is enough to find out the throughput of the burner and multiply it by the operating time, but the fact is that this will not allow taking into account factors such as:

- fuel pressure in the cylinder or line;

- initial temperature of the external and internal environment;

- intensity of gas supply to the burner;

- thermostat response threshold;

- the time during which the thermostat will keep the burner off (room cooling time).

Which is better to choose a wall-mounted gas heating boiler: types and best manufacturers.

A very useful table for calculating the heat transfer of heating radiators when designing.

Since these factors cannot be predicted, the minimum gas consumption is selected from summary tables.

Here are some values demonstrated by the Uzhgorod gas convector:

- power 2 kW - 0.13 cubic meters. meters per hour;

- power 2.5 kW - 0.15 cubic meters. meters per hour;

- power 3 kW - 0.2 cubic meters. meters per hour;

- power 4 kW - 0.23 cubic meters. meters per hour;

- power 5 kW - 0.29 cubic meters. meters per hour.

Products from other manufacturers of similar power have approximately the same consumption. In the process of warming up a cold room, it increases by one and a half to two times, but if the convector is used exclusively to maintain the temperature, the minimum flow rate is reduced by another 35-50%.

Flaws

All of the above belongs to the category of advantages of gas convectors. Next we will look at the shortcomings. All pros and cons are such only in the context of this article. For example, if we take the speed of acceleration of a car, then high engine power can be considered a plus, and driver safety and fuel efficiency can be considered a minus.

This is the case with gas convectors. The biggest disadvantage of this device is that you need to drill into the wall to install it. And not just make a hole, but a hole for a coaxial gas outlet. The gas outlet is a special tube in a pipe through which exhaust gases exit, and the fresh air necessary for combustion enters the convector through an external pipe. It is logical to assume that there should be a hole in the wall in the place where the convector is located, and if they are located under every window in every room, imagine how many holes there will be in your house! And these holes cannot be hidden or brought to one place. And remember another hole in the wall for gas supply. A vivid picture of a house appears before your eyes, shrouded in gas pipes and full of holes in the walls. Agree, not a very inspiring sight!

Let's imagine a living room with an area of 30 square meters with two windows. Using a standard heating system, a convector would need to be placed under each window. In the case of gas convectors, this option does not work. We will need to install one convector with increased power in a certain place on the external wall of the room, where there would be optimal conditions for supplying gas there and making a duct for exhaust gases. With this installation there will be no temperature balance in the room. It will be hot in one corner and cold in the opposite. For comfort, you need to place another low-power convector under each window, which immediately doubles the cost of the entire system and the aesthetics of the room. We conclude that this option is inferior to a conventional water heating system.

The gas convector has low inertia. In other words, it heats up very quickly and cools down at the same speed, which can be considered both a plus and a minus, it all depends on how the device is used. In a residential area, of course, this negatively affects the comfort of the temperature regime, but for a garage, workshop or shed, quick heating is a definite plus.

There is one more nuance in a gas convector, which can, in a certain case, be considered a plus or a minus. It has a combustion chamber in which the gas, burning, heats a certain body and a chamber, which then heats the air. For a long service life of the convector, it must use steel that is resistant to fading. It’s good if it uses just such a special steel. But in this case it will not be cheap at all. If it uses cheap steel, then the convector will very quickly fail due to corrosion, burnout, etc. Now, if in a convector the combustion chamber is made of 10 mm cast iron, then such a device will practically last forever.

How to make a gas convector with your own hands

Independent production of such a device is possible only in the understanding of its assembly from ready-made structural elements.

Making a convector from scratch is not only extremely difficult, but also unsafe . The assembly allows you to optimize the characteristics of the system, as it combines elements that are most suitable for specific operating conditions.

Making a gas convector with your own hands includes the following steps:

- Selection of installation location , preliminary assessment of the project.

- Carrying out technological calculations, developing drawings , justifying the effectiveness of the system, determining its parameters.

- Selection and purchase of burner , heat exchanger, thermostat and electronics in accordance with the requirements that the system must satisfy.

- Manufacturing of inlet and outlet pipes , pipelines; production or purchase of mounting parts.

- Mechanical work on forming a sheet metal body , drilling technological holes and installing fastening surfaces, applying heat-resistant paint.

- Installation of structural elements in the convector body.

- System installation.

- Test run.

The last two points should be discussed in more detail, since they are characteristic not only of home-made devices, but also of any other heating system.

Installation should be carried out close to the windows or under them, the gas inlet should be made at the same level, but the air exchange pipeline should go outside a little higher.

- Fastening the convector to the wall is usually ensured by four self-tapping screws screwed into reliable dowels. All residual gaps and cracks are sealed with polyurethane foam, fitting connections are coated with silicone to prevent gas breakthrough and facilitate installation.

- Before the test run, all gas pipe joints are covered with a solution of soap or shampoo . If it begins to bubble in certain places, the depressurization of the system is fixed and eliminated.

- When all leaks have been eliminated, gas is released into the convector , but they do not immediately ignite it, but wait at least a minute. Of course, this should be done with the windows open, and the point of the operation is to eliminate air pockets in the gas pipes.

- When the operation is completed, you can turn on the burner .

The first few hours of operation of the device will be accompanied by a burning smell, which is completely normal. But if it persists even after two or three days, you should contact a specialist in the repair and maintenance of gas systems.

Hosseven HP-3

Photo: https://beru.ru

Do you need super-powerful heaters? Are you more interested in “low-voracious” ones? Then the Hosseven HP-3 is perfect. Very modest gas consumption (both main gas and bottled gas can be used), low power consumption, low weight - what more could you want? The effective heating area of such a unit is 50-60 square meters. meters, and it reaches the specified power a few minutes after the start of work. The walls of the heat exchanger are thin and elegant, but not at the expense of reliability. The design is excellent. You don’t have to worry about installation – everything is extremely simple.

Gas convector Hosseven HP-3 2.6 kW

Advantages:

- economical

- beautiful appearance

- the most reliable gas fittings

- low price

Flaws:

- relatively small heating area

Review of popular models and their prices

The range of wall converters available on the modern market is not that wide. Several large companies that supply high-quality products stand out from the crowd.

The following models are the most popular today:

- Gas convector Alpine Air NGS 20F – has a wall-mounted configuration, is equipped with a closed combustion chamber and an improved gas exhaust system. With a power of 2.2 kW, it is capable of heating rooms with an area of up to 40 cubic meters. m. It has established itself as a reliable and durable heating device, capable of operating even in the harshest climatic conditions. The price for the NGS 20F model varies between 20-23 thousand rubles.

- Alpine Air NGS-40F is another interesting solution from the same company, this time at 4 kW. Technologically it follows the design of its “younger brother” and is equipped with an excellent cast-iron heat exchanger. The heated volume has increased to 70 cubic meters, but the price does not lag behind - 26-30 thousand.

- Hosseven HDU-3 is a budget solution from a well-known Turkish company. The HDU-3 is a 2.7 kW wall convector with a steel heat exchanger and provides an efficiency of up to 89% - one of the best results in its category. A closed combustion chamber, a coaxial exhaust tube and an affordable price (from 13,000 to 14,500 rubles) are the main advantages of the model.

- Hosseven HDU-5DKV is a high-performance convector that can be purchased for 21-23 thousand rubles. It has a cast iron heat exchanger with an electrically independent fan and an improved closed burner, thanks to which it produces 4.5 kW of power. The efficiency of the device reached 91%.

Of course, the list of convectors worthy of attention is not limited to these models. It includes products from such brands as Karma, ATON, Emax, AKOG, KORDI, etc.

Purpose

The convector is designed to run on natural gas for heating premises for various purposes. In this case, combustion occurs in a closed chamber, air is supplied from the street and combustion products are discharged there. The heat released during fuel combustion is transferred to the combustion chamber body and heat exchanger, and then to the indoor air. Due to rapid heating, the air rises, making room for colder air, maintaining an active convection process throughout the room.

A gas convector heats the air faster and more actively than its electric counterparts or, especially, converter-type radiators for a water heating system. This is due to the higher surface temperature of the heat exchanger and the increased rate of heat transfer from the combustion chamber.

A gas convector is an excellent solution in the following situations:

- The main heating of a small room or house with one or two adjacent rooms.

- As a replacement for a solid fuel stove, which was previously used to heat the house.

- For quick warming up and maintaining a comfortable temperature in the garage, utility room, or small country house.

- As an addition to the central heating system in rooms where installing a water radiator is difficult (basement and semi-basement, attic, veranda, etc.).

- For heating greenhouses.

As a replacement for main heating, a gas convector is only suitable for small houses or individual rooms. The efficiently heated area is easily calculated based on the available power models of gas convectors. Devices with a power of 2.5-6 kW are more often found on sale, less often up to 12 kW. In the first case, the convector is enough to heat a room up to 50 m2. The most powerful models are in demand only for industrial and public premises with an area of up to 100 m2.

Ballu BIGH-3

Photo: https://beru.ru

This model is ideal for tourists or fishermen. The relatively light weight of 1.5 kg makes the device mobile and easy to transport. A power of 3 kW at maximum mode will allow you to heat an area of 30 m2. At the same time, fuel consumption is only 200 g per hour. Heating is produced by infrared radiation, which arises from gas heating of the ceramic panel. An important feature of this device is the rotating burner with a grid on legs. Thanks to this function, it can be placed in a horizontal position and the heater can be used as a stove for cooking, which makes the model an indispensable “comrade” when hiking and fishing. A nice bonus is that the kit already includes a 1.5 meter long hose and a reducer.

Gas stove Ballu BIGH-3

Advantages:

- light weight and compact size

- mobility

- budget price

- efficiency

Flaws:

- relatively short hose

When choosing a gas convector, as you already understand, you should pay attention to such important factors as:

- price

- safety

- heating area

- noise level

- installation specifics

- additional features

By following all the selection standards, you can easily choose the device you need. Enjoy the shopping!

#Top 10

Read us first - add the site to your favorite sources.

Add a comment

{"commentics_url":"\/\/express-novosti.ru\/comments\/","page_id":1396432,"enabled_country":false,"enabled_state":false,"state_id":0,"enabled_upload": false,"maximum_upload_amount":3,"maximum_upload_size":5,"maximum_upload_total":5,"securimage":true,"securimage_url":"\/\/express-novosti.ru\/comments\/3rdparty\/securimage\ /securimage_show.php?namespace=cmtx_1396432″,”lang_error_file_num”:”\u041c\u0430\u043a\u0441\u0438\u043c\u0443\u043c %d \u0444\u0430\u0439\u043b\u043e\ u0432\u043c\u043e\ u0436\u0435\u0442 \u0431\u044b\u0442\u044c \u0437\u0430\u0433\u0440\u0443\u0436\u0435\u043d\u043e.","lang_error_file_size":"\u041f\u043e \u0436\u0430\u043b\ u0443\u0439\u0441\u0442\u0430, \u0437\u0430\u0433\u0440\u0443\u0437\u0438\u0442\u0435 \u0444\u0430\u0439\u043b \u0440\u0430\ u0437\u043c\u0435\u0440\u043e \u043c \u043d\u0435 \u0431\u043e\u043b\u0435\u0435 %d MB.","lang_error_file_total":"\u041e\u0431\u0449\u0438\u0439 \u0440\u0430\u0437\u043 c\u0435\u0440\ u0432\u0441\u0435\u0445 \u0444\u0430\u0439\u043b\u043e\u0432 \u0434\u043e\u043b\u0436\u0435\u043d \u0431\u044b\u0442\u044c \ u043d\u0435\u0431\u043e\u043b\ u0435\u0435 %d MB.","lang_error_file_type":"\u041c\u043e\u0436\u043d\u043e \u0437\u0430\u0433\u0440\u0443\u0436\u0430\u0442\u044c \u0442\u0 43e\u043b\u044c ""lang_text_loading":" u0437\u043a\u0430 ..","lang_placeholder_state":"\u0420\u0435\u0433\u0438\u043e\u043d","lang_text_country_first":"\u0421\u043d\u0430\u0447\u0430\u043b\u0430 \u0432\u044b\u04 31\u0435 \u0440\u0438\u0442\u0435 \u0441\u0442\u0440\u0430\u043d\u0443″,”lang_button_submit”:”\u0414\u043e\u0431\u0430\u0432\u0438\u0442\u04 4c","lang_button_preview":" \u041f\u0440\u0435\u0434\u0432\u0430\u0440\u0438\u0442\u0435\u043b\u044c\u043d\u044b\u0439 \u043f\u0440\u043e\u0441\u043c\u 043e\u0442\u0440″,”lang_button_remove ":"\u0423\u0434\u0430\u043b\u0438\u0442\u044c","lang_button_processing":"\u041f\u043e\u0434\u043e\u0436\u0434\u0438\u0442\u0435..."}

Ballu BOGH-15

Photo: https://beru.ru

If we talk about models designed only for outdoor work, then the Ballu BOGH-15 is truly the best option. It is not only multifunctional, but also quite effective, and also meets all the necessary requirements in the field of safety and environmental friendliness. The device is turned on with the electric ignition button, which is located directly on the body. The height of the flame in a glass flask (of course, resistant to high temperatures) can reach about one and a half meters. The maximum heating radius of this heater is 3 meters, and the area is about 28 m2.

Gas outdoor heater Ballu BOGH-15

Advantages:

- stylish design

- simple controls

- safety

Flaws:

- high gas consumption

- high price

Which chamber to choose a convector with?

In standard convectors, gas burns in an open chamber, and combustion products are discharged through a chimney, which causes significant inconvenience. Installing a chimney passing through the floors and roof is not an easy task and incurs additional costs. The advantage is lower cost.

Modern gas heaters are often equipped with closed chambers. In them, combustion products are released and air is taken in through a special chimney, consisting of two pipes of different diameters inserted into each other. This gas outlet is much easier to install and more practical.

Gas convector - front view

Fan heater

Before choosing a gas convector, be sure to consider the presence of a fan heater in it. This design element allows you to more evenly and quickly distribute heated air throughout the room. In addition, this function of the device allows you to blow on the heat exchanger, thereby reducing the temperature of the case. This leads to an increase in the service life of the gas convector. This is especially true for high-power units with a capacity of more than 100 kW.

This is interesting: Heat-reflecting screen behind the radiator: how to install it yourself and the advantages of using it