The method of heating a summer house is one of the pressing problems that require a quick and economical solution. As a rule, there is no possibility of connecting to centralized heating networks. In addition, it is impractical to constantly heat (and pay for the process) the dacha, since people are there only periodically. Therefore, the best option is to have your own source of thermal energy.

This issue is solved in different ways, from the construction of stoves to the use of other effective devices. One of them is a gas ceramic heater, which has an optimal set of operating qualities and allows you to heat the room much faster than conventional devices.

Let's take a closer look at it.

Advantages and disadvantages

Industrial air heaters are the ideal solution for large rooms.

They heat them throughout their entire volume and do not interfere with anyone, since in most cases they hang from the ceiling or are located on tripods (on stands). IR radiation travels over fairly long distances, so it easily reaches surrounding objects, floors, and is even partially reflected to ceilings. Let's see why infrared industrial heaters are so good. First of all, we note the fact that they are absolutely harmless to human health - provided they are installed correctly. Some experts note that they are even useful. In any case, they do not harm at all and give a pleasant feeling of warmth - standing under them, you begin to feel how life-giving warmth penetrates literally every cell of the skin and its inner layers. Absolutely silent operation is a very important advantage. It’s one thing when it’s noticeably loud in production premises (machines, pumps, various technological equipment are working)

And it’s another matter when the production is quiet - in this case, industrial heaters with fans will add a few extra decibels. Therefore, the noiselessness of infrared devices is a significant plus.

Other advantages:

When using IR heaters, it is not at all necessary to cover the entire area of the heated room with them. It will be enough to concentrate them directly above people’s workplaces.

- High efficiency - heating industrial premises with infrared heaters allows you to deliver heat directly to consumers. They are located above equipment and workstations, creating a comfortable environment. Their high speed of operation is also noted - if the room has not previously been subjected to total freezing, then it will warm up quite quickly;

- The ability to work in rooms with high ceilings - industrial infrared heaters warm from top to bottom. Being suspended from the ceiling or on cables, they send IR radiation down to consumers;

- No Maintenance Required – Industrial electric heaters do not require any attention. We hang them at the required height and use them;

- Economy - the use of industrial infrared heaters allows you to reduce heating and energy costs by 10-15%;

- Uniform heat distribution - only infrared devices can boast of this.

There are also some disadvantages:

- If industrial infrared heaters are placed incorrectly, people may experience headaches - be sure to maintain the correct installation height of the equipment;

- Electric models are quite power-hungry – but there’s no getting around it. An alternative to them is gas infrared heaters for industrial premises;

- Burns are possible – the radiating plates of infrared industrial heaters are heated to a high temperature, so accidental contact (for example, when placed on a wall) can cause a burn.

Some of the shortcomings are quite serious.

Gas infrared industrial heaters still require periodic maintenance - they need to be cleaned and checked for leaks. In addition, gas equipment is more dangerous than electric equipment.

Questions and answers

Let's look at the most common questions that inexperienced users have. The answers will provide significant time savings and eliminate the possibility of errors.

Is it possible to sleep with the heater on?

Manufacturers claim that the devices are completely safe and do not require constant attention. However, experienced users recommend turning off or at least setting the heating mode to minimum, as well as opening the windows or setting the shutters for micro-ventilation.

How long does it take from the moment the heating is turned on until the temperature rises?

As a rule, the effect of heaters begins to be felt from the very moment they are turned on. However, if the room is large, you will have to wait from a few minutes to half an hour.

Can I connect a regular propane tank to the heater?

This depends on the type of connector installed on the connecting hose. Different models may have their own design features, however, all the necessary adapters are commercially available.

If the room is large, is it possible to install two heaters?

There are no fundamental objections to the use of several devices in one room. You just need to take into account the specifics of the device’s operation and direct the heaters to different points. If they radiate to one point, there is a danger of overheating the floor covering or furniture. This can cause swelling and deterioration of finishes.

How dangerous are such heaters in terms of gas leakage?

Any gas equipment creates a certain danger and requires compliance with certain rules. Before starting use, you must carefully study the manufacturer's instructions and strictly follow its points. Then the danger from using the devices can be reduced to a minimum.

Which model is better to choose

To decide which device is right for you, you should carefully study its characteristics, capabilities and control system. It all depends on the area of the heated room, operating conditions and the goals you are going to achieve. For example, where exactly will the device be placed, will it have to be dragged to another room or installed permanently?

There are wall, ceiling and baseboard infrared heaters.

The most convenient solution, especially for owners of small apartments, will be the ceiling option for placing the heater. It does not require much space and is mounted directly into a suspended ceiling or attached to a regular ceiling using brackets.

The heater can also be installed on the floor. Floor-standing electrical appliances are less efficient than ceiling-mounted ones, because the radiation flow will not be directed directly, and heating will be more difficult.

The carbon heating element is a tube made of quartz. Inside it is a vacuum space with a carbon spiral. When a heater with a carbon tube operates, a characteristic reddish glow appears, which is not very pleasant to the eyes. The ceramic element is of lower quality, but does not glow during operation. And halogen can even have a negative effect on the human body due to the emitted waves being too short.

Types of industrial gas IR emitters

Light emitters

These heating systems are considered high-temperature and highly efficient, since the most suitable ceiling height in the installation premises should not be lower than 4 m. When calculating the power of the device, the following ratio is used: 1 kW of equipment power = 20 m3 of room.

The annular air intake draws in ambient air due to the hot air and combustion products escaping from the burner nozzle.

This heated mixture is directed to the pressure balance chamber, and then transported to the combustion chamber through through holes. To eliminate combustion products, supply and exhaust ventilation or artificial exhaust are most often used.

Similar devices are used in forges, foundries and high-tech machine shops. It is also allowed to install devices in dusty rooms and rooms with high air humidity. Often such heaters are installed in camp pavilions, tennis courts, etc.

Expert opinion Mikhail Yurievich Afanasyev Leading engineer of a company engaged in the production of energy-saving heating equipment.

IMPORTANT: An additional frame for the gas infrared light radiation heater system is not required, since they do not exert significant loads on the supporting structures.

Dark emitters

These devices received this name due to the method of low-temperature combustion of a gas mixture. If in light systems temperatures up to 1000 °C were reached, then in dark ones they did not exceed 450 °C. Moreover, combustion occurs in a closed system with heating of the screen tube.

That, in turn, emits waves of the infrared spectrum in a range invisible to humans. Therefore, the heating element never turns red, yellow or white, as is observed in light types of heaters.

The device design includes the following components:

- gas outlet;

- emitting screen tube;

- reflector;

- gas stove.

Today you can find models with U-shaped or linear tubes. In the first case, due to the decomposition of the warm and cold luminescence spectra opposite each other, uniform heating of the space is achieved.

In linear systems, the temperature will be higher than the end that is adjacent to the burner nozzle, so the radiation will slightly change temperature and intensity in certain areas. Such installations are used in rooms with a ceiling height of at least 3 m.

Expert opinion Mikhail Yurievich Afanasyev Leading engineer of a company engaged in the production of energy-saving heating equipment.

SAFETY MEASURES: The distance from the dark gas IR heater to explosive and flammable materials should not be less than 1.5 m.

This type of heater cannot be used in workshops and industrial warehouses with the processing and storage of flammable materials, offices and residential premises. Due to their larger size, installation complexity and significant fuel consumption, such systems are installed:

- in workshops where it was not possible to install light burners for some reason;

- in rooms where high temperature maintenance is not required;

- in narrow passages and corridors;

- in poorly ventilated large buildings located isolated from the heating system.

Model Alpine Air NGS-20F

This is a representative of panel heaters, the design of which is designed for wall installation in the house. According to the manufacturer, the working life of the cast iron heat exchanger allows it to last about 50 years, so the device can be regarded as an investment in a long-term heating system. According to the owners of Alpine Air gas burners, such heaters feel confident even under extreme operating loads, maintaining high temperature conditions.

The user himself can adjust the equipment parameters through non-volatile automation. But you won’t be able to completely abandon the electrical supply – the built-in fan of the gas heater depends on the network. Reviews, however, praise this functionality, since it quickly and evenly distributes heat throughout the workspace, even in large rooms. If we talk about the disadvantages, the model requires creating a hole in the wall for a coaxial tube that removes combustion products. The price tag of the heater, which is 20 thousand rubles, is also considered a disadvantage.

Electrical: long wave, short wave

In addition to the numerous advantages of electric infrared heaters, they also have their disadvantages. The main disadvantage is the high cost. Cost reduction is carried out through the additional installation of auxiliary devices - thermostats, also of an industrial level.

Based on the type of radiation, IR can be divided into two groups:

- Long wave. They can be used where people work; these devices are not harmful to their health.

- Shortwave. Most often they are used for drying wood, but are not used in rooms where people are constantly present.

In addition to these types, there is also a gradation according to the type of installation - wall or ceiling heaters. Some modifications are provided for any type of fastening. In addition, there are stationary devices, and there are mobile (portable) ones. No flammable objects, furniture or animals should be placed near such installations.

Types of industrial IR heaters

Currently, gas and electric industrial infrared heaters are distinguished, which, in turn, are divided into several types, based on the type of fastener:

- wall;

- floor;

- ceiling

Wall-mounted models are designed for small-sized rooms; they are mounted on a wall at a height of 2.5-3 meters.

Ceiling heaters are used to heat large rooms. The power of such devices is high; they are mounted at great heights, on suspensions or torsos.

The IR heater is a floor-mounted one, which is rare; such a unit is a single stand with emitters attached to it. Scope of application: spot heating.

Gas

Such devices are highly economical. Provided they operate continuously, such devices fully pay for themselves in 1-2 heating seasons.

Industrial-type infrared ceiling heaters operating on gas can be divided into two categories:

Light radiators are used to supply heat to industrial premises where the ceiling height starts from 4 meters and above. The models are considered one of the most effective. The operating principle is based on the combustion of a mixture of gas and air in a special burner at a temperature of 800-1000°C. Combustion products are removed through a drainage channel. Dark emitters - the gas combustion process is carried out at a temperature of 350-400°C. As a result, the metal tube, which acts as an emitter, does not glow red-hot, which contributed to the name of the device

When attaching dark-type heaters, you need to take into account that the emitters have a larger mass than light-colored heaters.

For industrial premises, heaters of either light or dark type are selected. The choice is influenced by the technical characteristics of the building itself (ceiling height, good air circulation), as well as the type of production activity.

Advantages of gas heaters:

- possibility of local heating of premises;

- reduction of heat loss;

- payback occurs very quickly;

- There is no need for any costs for maintaining boiler room personnel.

Electrical

Wall-mounted and floor-mounted units are used for local and general heating of premises inside and outside buildings. Depending on the principle of operation and design features, the following types of devices are distinguished:

- According to the type of mounting, electric infrared heaters can be ceiling, floor, wall or universal, which can work anywhere with equal efficiency. There are stationary and mobile installations, which are very popular among construction teams.

- According to the principle of operation, emitters are distinguished that emit short and long infrared waves. Short-wave heaters are actively used for drying wood and equipment for painting booths.

Short infrared waves have a negative impact on human health. Therefore, the installation of industrial electric short-wave infrared heaters in a room where people are constantly present is strictly prohibited.

Emitters that use long waves have a beneficial effect on people's health, so they can be installed in production shops without any problems. Long-wave heaters act as the main source of heat in winter.

Wavelength affects everything

Infrared heaters emit in the range with a wavelength of 0.75-2000 microns and a frequency of 0.15-400 THz. They are divided into three types:

- Short-wave (wavelength 0.75-2.5 microns, frequency 120-400 THz);

- Medium wave (wavelength 2.5-50 microns, frequency 6-120 THz);

- Long-wave (wavelength 50-2000 microns, frequency 0.15-6 THz).

The shorter the wavelength, the more thermal energy the heater produces with the same radiation area. But the temperature of the radiating element is higher.

Short-wave and medium-wave heaters are usually equipped with an open-type heating element. It emits orange light in the visible range. This leads to a loss of effective power (up to 10%).

Long-wave heating elements do not emit visible light. They are usually used in closed-type panel heaters. They have a lower operating temperature and the percentage of thermal energy released due to convection is lower than that of short- and medium-wavelength ones.

The effect of IR radiation depending on the wavelength is described in the section “ Infrared radiation and human health ”.

Operating principle of a gas ceramic heater

Gas ceramic heaters are small-sized heating equipment powered by mains or liquefied gas. They are focused on heating rooms and open areas using infrared radiation - it does not heat the air, but warms the surrounding objects, which begin to emit heat. The main advantage of such devices is that they cope well with heating large rooms.

The operating principle of a ceramic infrared heater is that it heats the objects around it, not the air.

Ceramic heaters running on mains or bottled gas are actively used in dachas - there is no central heating here, so summer residents have to rely only on autonomous heating. Heating with electricity is fraught with high costs, since electrical equipment is characterized by gluttony. As for gas heaters, they use cheaper fuel.

Ceramic gas heaters for summer cottages are distinguished by their versatility. They can heat:

- country houses;

- outbuildings (sheds, garages, poultry houses, etc.);

- open areas (country yards, playgrounds);

- semi-closed areas (gazebos, verandas).

That is, unlike many other heating devices, they are truly universal equipment with which you can heat anything. Neither heat guns, nor convectors, nor any other heating devices can boast of such versatility.

Gas ceramic heaters are mostly self-contained equipment. They are very rarely fed from gas mains - most often the source of fuel for them is gas cylinders of various designs. These can be small liter or one and a half liter compact cylinders, or capacious refillable cylinders with a capacity of up to 27-30 liters.

If necessary, gas cylinders used to operate kitchen stoves can be connected to gas ceramic heaters. They are connected through reducers that reduce gas pressure.

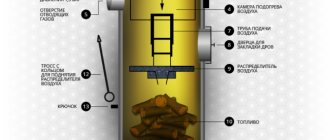

The device of a gas ceramic infrared heater.

The operating principle of gas infrared heaters is clear from their design. Burners are installed inside them, which heat ceramic heating elements (emitters). The ceramics begins to generate infrared (thermal) radiation that is sent into space. Reaching surrounding objects, it begins to heat them, and they, in turn, begin to emit heat.

Advantages of gas heaters:

- high heating efficiency - they work well even in large rooms (including those with high ceilings);

- low gas consumption - allows you to make heating less expensive;

- versatility in use - you can heat any rooms and open areas with them;

- ease of transportation - they are easily transported from place to place.

There are also a couple of disadvantages:

- such devices (like any heating equipment) are characterized by low safety - their improper operation can lead to a fire or explosion;

- the need for good ventilation - such devices burn oxygen and emit combustion products that require removal.

Thus, such gas-powered equipment requires extremely careful handling and compliance with safety regulations.

What is

A gas heater is an autonomous type of equipment that does not require electrical energy. To operate it, you need liquefied gas, which you can stock up on for future use using special cylinders. It is this autonomy and mobility that makes them indispensable in places where power outages are possible, or where it is absent due to distance from civilization:

- somewhere at remote locations where geologists, researchers, and builders work;

- at small dachas;

- in spacious country houses;

- on winter hikes;

- on picnics, etc.

The power of these gas appliances reaches 4.2 kW and is designed to heat an area of 30-60 m2.

How it works

The device circuit is simple and consists of:

- a metal case containing a gas cylinder inside;

- ceramic plates having a complex system of crater-type holes;

- gas burner.

All models of this type of heating equipment are necessarily equipped with:

- A gas control system that operates automatically, turning off the device if the flame goes out.

- A carbon dioxide content monitoring system, which also turns off the device when the CO concentration level is exceeded

- Power regulator.

- Piezoelectric ignition of the burner.

- Wheels for easy movement of the unit.

Gas heater design (diagram)

Safety precautions

Gas devices are devices that require unquestioning compliance with safety regulations:

- Do not remove the safety grille while the appliance is in use.

- Do not cover the device with rags or other things to dry clothes.

- It is prohibited to direct IR rays at flammable objects: light curtains, curtains, tablecloths.

- When the heater is turned on, it must be in a vertical position, unless another specific model requires a different position, as indicated in the instructions.

- The room in which the device is installed must be well ventilated.

Armed with knowledge about infrared ceramic heaters, you can successfully use them, adding comfort and life-saving warmth to your life, which will keep you and your loved ones healthy!

Types of infrared industrial heaters

Let's see what infrared industrial heaters for industrial premises are. To begin with, they are divided according to the type of fastener - there are wall, ceiling and floor. Wall-mounted models are designed for small spaces. They are mounted on walls at a height of 2.5-3 meters and are most suitable for buildings of limited volume and small area.

For uniform heating, IR heaters should be placed at an equal distance from each other.

Ceiling-mounted industrial air heaters are designed for large areas. They are characterized by high power, so they are mounted at high heights, on suspensions or cables. Such devices are quite popular and the most convenient - they have great power, do not interfere with anyone, and eliminate the risk of burns.

The floor-mounted industrial IR heater is the rarest type of heating equipment. A device of this type is a tripod or a single stand with emitters attached to them. Purpose: spot heating.

The next division of industrial infrared heaters is based on the type of power supply. Industrial gas heaters operate using liquefied or natural gas. They are equipped with miniature burners with automatic ignition. They heat metal or ceramic emitters, as a result of which they begin to generate infrared radiation that is sent into the room.

Gas industrial infrared heaters are divided into dark and light. In the dark, the combustion process is hidden; it occurs in a sealed pipe through which air is supplied. IR radiation is emitted using fin emitters. The combustion temperature in the system does not exceed +400 degrees.

Light infrared industrial heaters operate at higher temperatures - they are equipped with high-temperature burners that produce flames with temperatures up to +1000 degrees. Compared to dark devices, they are lighter, so they can be used in pre-fabricated buildings where various restrictions apply.

Gas infrared heaters using bottled gas: prices for popular models

Due to its fairly wide popularity, buying a gas infrared heater from a cylinder is not difficult.

Prices for some popular heater models:

| Name | Power, W | Heating area, m² | Size, mm | Weight, kg | Average price, rub. |

| Floor-standing gas infrared heater Ballu Bigh 4 | 4500 | 60 or more | 270 (length) | 2,8 | 2800 |

| Gas infrared heater Ballu Bigh 3 | 3000-4500 | 45 | 338x278x372 | 2,3 | 2400 |

| Gas infrared heater Pathfinder Hearth with cooking capabilities | 1500 | 15 | 275x275x180 | 1,8 | 3000 |

| basic infrared heater NeoClima UK-02 | 2500 | 25 | 192x150x86 | 1 | 1300 |

| Outdoor gas infrared heater Master 34 CR | 3400 | 160x350x460 | 2,6 | 2200 |

Using reviews as a guide, the Ballu Bigh 55 Gas Infrared Heater is also a very good option. It has a high power of 4200 W, and also provides the ability to install a cylinder directly inside the device itself. Of course, this is reflected in its size.

Helpful advice! If you want to purchase a gas infrared heater for a greenhouse, then you need to choose among outdoor models. Room heaters will not cope with this task.

Dark emitters

The combustion process of a gas-air mixture in a low-intensity IR device occurs in a closed system in which a metal pipe serves as the radiating element. It works on the same principle as the light emitter, but at reduced temperatures of about 350-450 degrees. During operation, flue gases heat up the screen tube, which begins to emit infrared rays.

The gas IR heater received its name “dark” due to the fact that its radiant tube never becomes red hot.

The design of the device includes:

- gas burner;

- reflector;

- screen emitting tube;

- gas outlet

Manufacturer Pakole ZENIT

Screen tubes are available in linear and U-shaped. In the latter case, infrared radiation is distributed more evenly in space due to the location of the hot and cold segments in the structure opposite each other. When choosing a model with a linear screen tube, keep in mind that at its end the temperature will always be lower than at the burner side.

Dark gas infrared heaters are installed in rooms whose height is three meters or more. When installing heating devices in warehouses with high racks, it should be taken into account that flammable materials and explosive objects are not allowed to be placed at a distance of one and a half meters from the radiator.

It is prohibited to use dark emitters:

- in residential premises and offices;

- in workshops where the work process involves flammable substances.

Dark gas heaters are heavier and larger than light ones, so the costs associated with their installation will be more expensive. They do not take up useful space, as they are suspended from the ceiling. And they are used for both general and zone heating.

It is most beneficial to use dark emitters:

- in isolated large buildings with minimal air exchange;

- in narrow passages;

- in rooms with reduced heat requirements;

- in workshops with relatively low ceilings (3 meters), where the use of light-colored models of gas emitters is not allowed.

It should be noted that with high humidity conditions in the room, it is necessary to choose a device made of stainless steel.

How to make a garage heater with your own hands

In some cases, the price for a gas heater from a cylinder can reach several tens of thousands of rubles. Therefore, folk craftsmen learned to make such devices with their own hands.

Basic rules that need to be taken into account before you start working:

- The emphasis should be placed not on beauty, but on the safety of the installation.

- In order not to expose yourself to danger, the elements responsible for supplying and shutting off gas need to be purchased factory-produced.

- The simpler the mechanism, the better - the likelihood of breakdown will be reduced.

- Economical consumption is also important, because otherwise a homemade unit will be more expensive than a store-bought one.

To manufacture the device you do not need a lot of expensive materials.

Details:

- sheet of metal (preferably steel);

- scissors;

- rivets and riveters;

- fine metal mesh;

- sieve;

- gas cylinder.

If possible, it is better to purchase a special burner equipped with a valve.

Manufacturing stages:

- First you need to attach the heater to the burner. To do this, surround the sieve attached to the metal sheet with a marker.

- Parallel and perpendicular to each other, you need to draw rectangular ears (one of them should be 2 times longer than the others). Then, using metal scissors, cut out the resulting design.

- Fasten all the elements together: the burner is attached with bolts to a metal circle that has been cut out. The ears are wrapped in opposite directions, and a strainer is attached to them, which will serve as a diffuser. This is a ready-made element of a homemade heater.

- Next, you can proceed to attaching the metal mesh. For this purpose, you need to once again draw a circle with ears on a metal sheet and then cut it out. Then you need to secure the mesh, which is attached to the ears of each of the circles, forming a mesh cylinder.

- It is most convenient to fasten using rivets and a riveter. In this case, you need to start by attaching the lower part, and only then move to the top.

- The finished elements should be connected to each other and a test run should be carried out.

It is recommended to make such a gas heater from a cylinder only if you are confident in your own abilities and the safety of your creation.

Gas: dark, light emitters

Among gas equipment that emits heat in the infrared spectrum, heaters are divided into the following two types according to the intensity method:

- Light emitters. The main feature is the bright reddish-orange color of the heating devices when they are incandescent. Variations of this class are capable of heating their metal tubes (heating elements) to a bright, intense color-light, without overheating.

- Dark emitters. The main difference is the muted color of the hot heating devices - metal tubes. They do not become red hot, which is why they are conventionally called “dark” heaters.

Light infrared heating devices are used to heat space in a room with a height of at least 4 meters from floor to ceiling. Their performance is always higher than those with lower heating intensity. Installing such devices follows a simple calculation: for every 20 cubic meters. m. it is required to install one heater with a power of 1 kW. If we take into account large areas of premises, then for every 100 sq. m. of space you will need one device with a power of 5 kW.

Dark ones are designed to heat a space in a room with an installation height of 3-3.5 m. Gas is burned in this case at temperatures from 350 to 400 degrees Celsius. These units are significantly heavier in weight than light type equipment. Therefore, this factor should always be taken into account during installation. To select this or that equipment, you need to look at the height of the ceilings in the room, the type of activity of the enterprise and the current ventilation.

Types of convectors for home

Gas appliances come in closed and open chamber types. The difference between the first version of convectors is the presence of a coaxial tube. Their power reaches 4 kW, which is quite enough to heat 40 “squares” of area. This type of convectors is practical to use.

Gas and combustion products do not penetrate into the room. Models with closed chambers are low cost and comply with environmental and safety requirements.

As for the open version, such convectors do not have a coaxial pipe. They have a built-in air analyzer and safety valve. When a critical moment occurs, they automatically react to the lack of oxygen in the air and turn off the heater. This device must not be used in a confined space.

Gas heating appliances for a summer house or other country property have a number of advantages:

- Compact sizes.

- Heat transfer is in the range of 2 – 15 kW.

- Economical fuel consumption.

- Energy independence from power supply.

- Easy to use.

- There is no burning of oxygen.

- Affordable price.

There are also disadvantages:

- Installation of a coaxial pipe, which serves to remove combustion products, requires making a hole in the wall.

- We should not forget about creating a through opening for laying a pipe supplying gaseous fuel.

- Inertia - the device heats up quickly and cools down similarly. But at the same time, the heater is safer for garages or utility room heating.

Varieties

There are several types of mobile gas heaters for summer cottages.

Infrared

It works on the principle of converting the heat released during fuel combustion into infrared radiation.

The metal housing houses the burner, valve, combustion regulator and heated panel. She is that same emitter. The panel can be made of metal pipe, mesh, perforated sheet, ceramics, etc. When heated to 700-900 degrees, the panel emits infrared waves. They give off thermal energy not to the air, but to surrounding objects. They gradually warm the air. An infrared gas heater works on this principle.

This option of direct heating, when combustion products are vented inside and not outside, is optimal for short-term use in well-ventilated areas.

If it is possible to install an indirect heating heater, it is better to buy it.

Infrared gas heater for a summer residence with a cylinder.

Ceramic

According to the method of heat transfer, a gas ceramic heater is of the infrared type. The main element of the heater is a ceramic insert or panel. It serves to convert combustion energy into thermal radiation.

If it is possible to connect to a portable cylinder, the device will work autonomously. This is convenient, especially for owners of country houses located where there is no infrastructure yet, or where it is turned off during the winter months.

To turn on the heater without automatic ignition, you need to bring the flame from a match or lighter to the top of the ceramic panel. It is strictly forbidden to light a flame near the nozzle.

Ceramic gas heater for a summer house with a cylinder.

Catalytic

One of the safest heating devices is a catalytic gas heater. The main difference from other types of similar devices is the flameless combustion of fuel and the release of heat during the oxidation reaction. Since a gas heat source operates without fire, combustion products are not released into the room air.

The main element is a catalytic or catalytic plate made of fiberglass, with the addition of platinum. When fuel hits its surface, an oxidation reaction begins, during which thermal energy is released.

The consumer heats the house, but does not receive the negative side effects that occur during normal combustion, such as burning of air oxygen and saturation with carbon dioxide. In this regard, a catalytic gas heater is much safer and more environmentally friendly. These are the main advantages of such a device, judging by user reviews. It also has disadvantages, the main one of which can be considered cost. The catalytic plate reaches its end after 2500 hours of operation. Replacing it costs almost the same as buying a new heating source.

It is more advisable to replace an exhausted unit with a new one rather than buy a plate for it.

Catalytic gas heater for a summer residence with a cylinder.

Portable

Portable gas heaters for heating are useful in camping conditions, in buildings not equipped with any type of heating. At the back of the device there is a small gas cylinder with a volume of 200 ml to 3 liters. The fuel consumption of such a heater is 100-200 g/hour, the power is no more than 1.5 kW/h. The portable heat source operates as infrared. With the help of piezo ignition, a flame appears in the burner, which heats the ceramic plate. The radiation from it provides the necessary heat.

Relatively inexpensive, cheap, lightweight, convenient, designed for heating small, up to 15 m2, rooms, garages, tents.

Portable gas heater for a summer residence with a cylinder.

Application area

Gas ceramic heaters can use not only autonomous gas sources for operation, they can also be connected to the main network. Devices connected to the main network successfully cope with heating:

- spacious living quarters;

- sheds, outbuildings;

- production premises.

Autonomous heaters are used to heat:

- garages;

- tents;

- open areas of restaurants;

- country houses and dachas.

Outdoor gas heaters are used as a thermal umbrella for heating gazebos, barbecue areas, trees during severe frosts, and any open areas.

Gas heater for small utility rooms, garages

Since utility rooms and garages can often be storage for things or various fuels and lubricants, a heater with an open fire source cannot be used in it. A gas ceramic heater is perfect for this purpose as a safe device equipped with automatic control systems.

To heat the garage, small compact models with low power are produced. Both a floor-mounted and portable option will be convenient. The portable heater is equipped with a convenient handle, so this model can also be used to thaw frozen locks.

Gas ceramic tent heater

During hikes, people traditionally warmed themselves by fires. But it is not always possible to light fires if there is no dry wood. A gas heater is not afraid of any weather, and it can warm people not only in the evening, but throughout the night if installed in a tent.

Ultra-compact models have been developed especially for tents that easily fit in a backpack.

Variants of devices have been developed whose designs allow them to also be used as a gas stove.

Gas infrared heater for cottages and country houses

To choose the right heater for a country house, you need to consider how you are going to use it: for a long time or occasionally?

From an economic point of view, it is not advisable to use a gas appliance as the main source of heat. Of course, if there are no other sources of energy, then there is no choice.

For short-term heating of a country house during a winter holiday, using a gas appliance will be the optimal solution.

When choosing the optimal heater power, you do not need to take into account the total area of the entire room, because it is capable of heating only a certain area. You can also use it to heat an open space:

- summer terrace,

- picnic areas,

- children's playground.

Characteristics of a gas heater

This unit has the following functional features:

- Power

. Experts advise choosing a gas heater with a capacity of 1 kW per 10 m². If the thermal insulation of the room leaves much to be desired, then you can look at a more powerful unit. It’s good if this parameter can be adjusted and the wavelength can be selected. - Protection from moisture

. Its level is indicated in the markings on the surface of the case, as well as in the accompanying documents. - Heating type

. There are devices with direct heating or with the need to remove combustion products. The latter requires a chimney, which must be taken into account when purchasing. - Mobility

. There are stationary units, and there are portable ones. - Heating element type

. A gas outdoor patio heater can be infrared, catalytic or convection. - Installation method

: on the floor or wall. - Additional functionality

. We are talking about piezo ignition, control system and others.

Review of the KOVEA Fire Ball heater. Video

An overview of the advantages and disadvantages of the KOVEA Fire Ball KH-0710 gas heater is presented in the video below.

Today there are a huge number of options for heating a home or cottage. One of the main types of fuel is gas. An important advantage of this type of fuel is that if there is no main gas pipeline in the area, its presence can be compensated by liquefied gas in cylinders. Gas heaters have a high degree of efficiency and relatively low operating costs. An online forum where consumers leave their reviews about a particular type of product will help determine which heater will be the most effective for a particular case.

How the device works

The gas ceramic infrared heater works on the following principle:

- In the mixing chamber, gas is mixed with air.

- The gas-air mixture, passing through the holes in the ceramic plates, burns, acting as a heater for them.

- Ceramic plates heated to 900°C emit infrared heat.

A notable feature of infrared radiation is the heating of objects that find themselves in the heated zone. And the heated objects then warm the environment with their heat (for more details, see the article on the operating principle of a heater with infrared radiation). This amazing property of infrared rays allows you to significantly save energy. Sometimes savings reach 80%.

Types of industrial IR heaters

Currently, gas and electric industrial infrared heaters are distinguished, which, in turn, are divided into several types, based on the type of fastener:

- wall;

- floor;

- ceiling

Wall-mounted models are designed for small-sized rooms; they are mounted on a wall at a height of 2.5-3 meters.

Ceiling heaters are used to heat large rooms. The power of such devices is high; they are mounted at great heights, on suspensions or torsos.

The IR heater is a floor-mounted one, which is rare; such a unit is a single stand with emitters attached to it. Scope of application: spot heating.

Gas

Such devices are highly economical. Provided they operate continuously, such devices fully pay for themselves in 1-2 heating seasons.

Industrial-type infrared ceiling heaters operating on gas can be divided into two categories:

Light radiators are used to supply heat to industrial premises where the ceiling height starts from 4 meters and above. The models are considered one of the most effective. The operating principle is based on the combustion of a mixture of gas and air in a special burner at a temperature of 800-1000°C. Combustion products are removed through a drainage channel. Dark emitters - the gas combustion process is carried out at a temperature of 350-400°C. As a result, the metal tube, which acts as an emitter, does not glow red-hot, which contributed to the name of the device

When attaching dark-type heaters, you need to take into account that the emitters have a larger mass than light-colored heaters.

For industrial premises, heaters of either light or dark type are selected. The choice is influenced by the technical characteristics of the building itself (ceiling height, good air circulation), as well as the type of production activity.

Advantages of gas heaters:

- possibility of local heating of premises;

- reduction of heat loss;

- payback occurs very quickly;

- There is no need for any costs for maintaining boiler room personnel.

Electrical

Wall-mounted and floor-mounted units are used for local and general heating of premises inside and outside buildings. Depending on the principle of operation and design features, the following types of devices are distinguished:

- According to the type of mounting, electric infrared heaters can be ceiling, floor, wall or universal, which can work anywhere with equal efficiency. There are stationary and mobile installations, which are very popular among construction teams.

- According to the principle of operation, emitters are distinguished that emit short and long infrared waves. Short-wave heaters are actively used for drying wood and equipment for painting booths.

Short infrared waves have a negative impact on human health. Therefore, the installation of industrial electric short-wave infrared heaters in a room where people are constantly present is strictly prohibited.

Emitters that use long waves have a beneficial effect on people's health, so they can be installed in production shops without any problems.

Long-wave heaters act as the main source of heat in winter. Date: September 25, 2022

Infrared heating as the main one. Is it worth it?

IR heating integrates perfectly with traditional heating systems. Thanks to interaction, you can create a cozy corner of increased comfort in any room.

In everyday life, IR heating is very convenient as a backup (auxiliary or emergency). Heat losses during its operation are minimal and do not exceed 10%.

Infrared heating devices differ from their traditional counterparts in their greater controllability. This is due to the lack of inertia characteristic of radiators, which need time to heat up and cool down. IR equipment starts up instantly after connecting to the power supply, and the heat flow also subsides quickly after disconnecting from the power supply.

Using a system as a main one with built-in heat regulators (temperature sensors) can significantly reduce energy consumption. But here it is very important to carry out a competent calculation of the equipment and correctly install it. The general characteristics of the building, its level of insulation in conjunction with the technological properties of the installed IR devices are of great importance.

If the building is large enough, with high ceilings, and with areas of significant heat loss (ventilated zones), infrared heating of a private house will be the only suitable option. But such characteristics are more characteristic of buildings of industrial rather than residential significance. If local heating in individual areas of the property is inexpensive, then using infrared heating as the only source of heat can easily ruin the owners during operation.

From the point of view of rationality, it makes more sense to take an integrated approach to heating a home: basic heating in the traditional way and, in addition, implementing infrared heating locally.