Organizing a heating system for a large commercial or industrial premises is not an easy task. If the area of the room is really large, a classic heating system simply will not be able to heat it efficiently. The use of additional heating devices is accompanied by additional financial costs, which is not always acceptable or justified.

Is there equipment that can efficiently heat large rooms while consuming a minimum of energy resources? Yes, it exists. One of the options that is definitely worth paying attention to is a heating system using water fan heaters.

Water fan heaters are modern heating equipment that is ideally suited for servicing large premises. Water fan heaters allow you to use the best capabilities of two heating systems - water and air.

Principle of operation

Inside the housing of the water fan heater there is a heat exchanger and the fan itself. Its blades form an air flow that is heated by a heat exchanger, inside which hot water circulates. Thus, the air temperature gradually increases.

Power calculation

To calculate the optimal power of a device for heating a specific room, use the formula:

S × h/30 = X kW, where S is the area, h is the height, X is the desired power value of the water fan heater.

Example:

It is necessary to heat a commercial warehouse with an area of 300 square meters. m., its height is 6 m.

We count: 300 × 6/30 = 60 (kW). This means that we will need one water fan heater of the resulting power, or several with a lower value.

Of course, this is a general formula that is not universal. The actual performance of the purchased equipment depends on the required temperature, the number of doors and windows, and the presence of reinforced insulation. What matters is the initial air temperature at the entrance to the device, the height of the suspension and the temperature of the coolant.

Thermaltake NiC C5 CLP0608

As we already mentioned in the introduction of today’s article, Thermaltake has released four coolers of the new NiC line. Model C5 (CLP0608) is the oldest and most expensive of them. The NiC (Non-interference Cooler) series of coolers is designed specifically for systems with memory modules equipped with high radiators, which have recently become very popular.

The box, made of thick cardboard, is no less informative than that of Phanteks. Here are technical specifications, a description of key features with photographs, and a list of supported platforms.

Inside the cardboard box there are soft polyurethane inserts in the shape of the cooler, in which it is fixed. Accessories are sealed in a separate box. These include steel guides and a set of fasteners, a plastic reinforcing plate, as well as instructions and thermal paste.

The Thermaltake NiC C5 costs $5 more than the Phanteks, which is $55. The cooling system comes with a three-year warranty. Country of origin: China.

Thermaltake NiC C5 is a bright and catchy mid-sized cooler. The red fan frames contrast with the black impellers and black plastic “shells” that cover the radiator.

You simply can’t help but pay attention to such a cooler. Its height is 160 mm, width is 148 mm, and thickness is only 93 mm, which is really not much for a cooler with two fans.

The fans are set to blow-in and blow-out and are secured in plastic shells that leave the sides of the radiator open...

...as well as its top and bottom in the heat pipe areas.

The radiator itself is made of 52 aluminum plates 0.4 mm thick, pressed onto heat pipes with an interfin distance of 1.7 mm.

The area of this radiator is slightly larger than that of the Phanteks PH-TC12DX - it is 5780 cm2.

Five six-millimeter nickel-plated heat pipes are soldered to the base in grooves in which they are laid without gaps.

The nickel-plated copper plate measures 40x40 mm and has a minimum thickness of 1.5 mm (under the tubes) and is perfectly polished.

However, unlike the Phanteks base, its evenness leaves much to be desired. The bulge in the center of the base did not fail to affect the usefulness of the contact between the cooler radiator and the processor heat spreader.

Two fans of standard size 120x120x25 mm rotate synchronously and are equipped with a speed controller.

It is installed on a short cable extending from the three-pin connector for connecting fans to the motherboard.

In our opinion, this method of adjustment is inconvenient, since to change the fan speed you will have to open the system unit case each time. As for the fans themselves, they are interesting in the shape of the blades, consisting of two sail-shaped halves.

The description of Thermaltake NiC C5 does not explain this solution in any way, which is strange, because marketers are so fond of such “features”. In our opinion, these blades are made to increase the pressure of the air flow pumped between the fins of the radiator, because the NiC C5 has a relatively dense air flow.

The fan speed can be adjusted from 1000 to 2000 rpm. Maximum airflow is stated at 99.1 CFM, static pressure is 2.99 mm H2O, and noise levels should range from 20 to 39.9 dBA.

The 40mm stator sticker shows the name of the fan model and its electrical characteristics.

With 3.8 W stated in the specifications for each “turntable,” one fan consumed a little more than 4 W, which is twice as much as Phanteks. But the starting voltage turned out to be slightly lower - 3.8 V. Cable length - 300 mm. The bearing is ordinary - sliding, with a standard service life of 40,000 hours, or more than 4.6 years of continuous operation.

The installation procedure for NiC C5 is described in detail in the instructions, but in our case - for a platform with an LGA2011 connector - it is no different from installing the Phanteks PH-TC12DX.

Once installed on the board, the distance to the bottom edge of Thermaltake NiC C5 is only 36 mm.

However, as we mentioned above, it is narrower than most other dual-fan coolers, so it is unlikely to interfere with the installation of RAM modules with tall heatsinks.

Thermaltake is only 3 mm taller than Phanteks, so it will most likely fit into narrow system unit cases without any problems.

Well, in our opinion, it looks more attractive. However, it depends on the taste and color, as they say...

Connecting a water heater

Most modern devices are connected to a 220 V or 380 V power supply:

You can install the heating unit in 10 steps:

- Select the connection location: it can be a ceiling, a wall or a corner. Make sure it can bear the load.

- Check the pipe diameter for compliance with specifications, coolant temperature and flow rate.

- Purchase electrical wires of the required length to connect the device to the power supply. Connect power supply and control circuits. Purchase mounts for the fan heater, preferably from the manufacturer.

- Mark the mounting holes and drill them.

- Screw the screws into them, leaving a small gap.

- Make it convenient to mount the console.

- Route the heating pipes to the device.

- Secure the mounting bracket, taking into account the selected angle of the fan heater.

- Hang the device on the console and secure it with two bolts. To remove air from the heating system, you can first install Mayevsky’s apparatus. To change the flow of heated air when turning the device on the console, install metal hoses.

- Connect flexible hoses to the heating pipes in accordance with the instructions for your fan heater model. Fill the device with coolant and release the air. Ready!

- Administrator to Gas heating02/04/2022

The most optimal option is gas heating. And it doesn’t matter whether there is main gas or not. You can always put... - Administrator to Autonomous water supply at home01/08/2022

Autonomous water supply at home - independent water supply from a central water supply system, for example: from a well or borehole - Technical department for House heating 12/31/2021

Heating from an electric boiler As in the above examples, the main priority in design is the minimum price for materials and installation.… - Administrator to Heating a country house options and prices 11/03/2021

Heating a country house options and prices: in this article - Administrator to Autonomous heating point November 3, 2021

A professionally performed calculation of a heating point will provide warmth and easy control of the heating system of a room, hangar, warehouse..

Blowing batteries with a fan

I’m making repairs, I’m going to sew up the radiators (by adding ventilation grilles), naturally, the heat transfer will worsen. To improve heat transfer, I plan to blow the batteries (if necessary) with built-in fans. Are there any prohibitions on this? After all, with effective airflow, I can take more than calculated according to the project. I pay for heat according to the norms, there is no separate meter, apartment 15.

You won’t get much more - the room is rated at 20*C - you won’t heat it up to 40.

20 doesn't always happen. I plan to tie the fans to a sensor and set the system to 22 degrees. There is also a sensor for the battery, so that it doesn’t thrash in vain when the heating is turned off. Although. What prevents it from being used as a fan in the summer, if necessary. Plus, of course, dust filters.

They will make noise. They will disturb sleep.

Plumbing work Moscow and region

3-4, depending on the length of computer batteries. I have tons of them. Plus reduced power supply, 9 volts, to reduce speed. In this case, a jet stream is not needed. We get a stream of warm air, something like a fan heater. Maybe it will add comfort? Then, the heat distribution throughout the room is more uniform. Electricity consumption for the battery is 20 watts, not much. It will not work all the time, but when the temperature in the room drops. The fans themselves have a large gap between the blades, which will ensure natural air convection when turned off. fans.

Place your bet with confidence. The PTE states that the return line can be lowered as much as desired. Thermal engineers will only thank you, especially if the heating is steam. When you write the story, please take pictures. I really want to take a look and maybe take it into service.

yes, but here you just shouldn’t forget that if the supply of coolant to the radiators at some point becomes lower than planned and the fans are running, then I think this will not add heat since the accumulative effect will be blown out ahead of time

you need to think about which radiators for this scheme it is more correct to use cast iron or aluminum, for example, the rate of heat transfer and cooling is different for them

I have not encountered any prohibitions regarding fans. They also produce convectors with fans.

2sansei I’ll put a sensor on the air temperature and on the temperature in the battery (a cheap option is some diodes in reverse connection), I’ll make a circuit so that the fans spin when the air temperature is below 22 degrees, plus the temperature in the battery is higher than the air temperature, for me it’s not difficult. My batteries are cast iron. About the air flow. I think it's better sideways, i.e. It's warm up there anyway.

2a-xel-1 I’ll definitely take photos, but the results may not arrive in time, it’s not known when it will become warm and the radiators will be turned off, but I have the ceilings first, then the casing of the radiators.

Yesterday I installed 4 fans on 2 brackets, on top of the batteries, connected them (however, I couldn’t find a powerful power supply, due to repairs somewhere in the boxes, which is weak, it dropped to 8V). I liked the effect, warm air comes out, something like a heater. True, all this is still purely for testing; after sewing, a full-fledged airflow will form. There is no sound at 8V. The power consumption of one fan is 1.5 W, four - 6 W. You can leave it on without any problems, without worrying about electricity bills, you don’t even have to worry about electronics, just a switch. If anyone wants to repeat this, work more carefully with 220V, after all, the battery is grounded, it is better to put the trans in a separate box, further from the battery, only 12V is connected to the battery. My 12V wiring will be done from the ceiling. I plan to mount the fans on top, directly on a narrow grille, through pads made of foamed polyethylene, so that together with the grille I can get a filter between the fans and the grille, for which I will use non-woven material (I don’t know what it’s called, it’s in stock), There is also a narrow grille with a filter on the bottom of the box. I will cover the wall behind the radiator with a heat insulator and foil, so why heat the street. It is better to use acrylic putty for the seams of the structure; it will not create dust on the back side of the plasterboard structure; treat the sections with a primer.

Photos in the studio. So, does the air flow go down?

Manufacturers rating

The leading manufacturers of water fan heaters are:

Teplomash. For more than 25 years, the manufacturer has been producing high-quality and durable heating equipment for Russia, the CIS and foreign countries, including the USA and Canada. The company's customers are commercial enterprises, large industrial facilities and individuals. The plant's arsenal includes a wide range of models, among which any client will find what he needs.

Ballu. The company produces compact water heaters for cottages, homes and offices. The devices are easy to use and have an original design. Heaters keep oxygen at the right level. Some models have a built-in thermostat that maintains the set mode automatically. The brand highlights an innovative approach to the development of manufactured equipment.

Tropic. The company has been specializing in universal heating technology since 1998 and is distinguished by an innovative approach. Compact devices from Tropic-line are suitable for heating production, warehouses, car washes and service stations. Some models are equipped with a thermostat that turns off when the set temperature is reached. It is very convenient for home use.

In the middle of the content

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

Introduction

For quite some time now, in the field of air cooling systems for central processors, we have not seen any innovations or truly interesting solutions to increase efficiency while reducing noise levels. So manufacturers have to update their cooler lines and attract potential buyers in other ways, in particular by equipping devices with two fans at once. This trend has indeed been observed recently, since this is the simplest and, as you probably understand, inexpensive way to increase efficiency without significantly affecting the final price of the product. In particular, Thermaltake, having previously shown at CES 2013, in March of this year announced four new coolers of the NiC (Non-interference Cooler) series, three of which are equipped with two fans. Phanteks, a less prolific company in this regard, has also released a new product, which also has a pair of fans in its arsenal. There are other companies that have recently added coolers with two “turntables” to their product range. That is, it is quite possible to talk about a peculiar fashion for two fans in processor coolers. We will find out how all this turned out using the example of the Phanteks PH-TC12DX and Thermaltake NiC C5 coolers.

Principle of operation

Inside the housing of the water fan heater there is a heat exchanger and the fan itself. Its blades form an air flow that is heated by a heat exchanger, inside which hot water circulates. Thus, the air temperature gradually increases.

Power calculation

To calculate the optimal power of a device for heating a specific room, use the formula:

S × h/30 = X kW, where S is the area, h is the height, X is the desired power value of the water fan heater.

Example:

It is necessary to heat a commercial warehouse with an area of 300 square meters. m., its height is 6 m.

We count: 300 × 6/30 = 60 (kW). This means that we will need one water fan heater of the resulting power, or several with a lower value.

Of course, this is a general formula that is not universal. The actual performance of the purchased equipment depends on the required temperature, the number of doors and windows, and the presence of reinforced insulation. What matters is the initial air temperature at the entrance to the device, the height of the suspension and the temperature of the coolant.

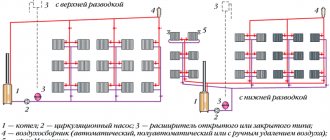

Connecting a water heater

Most modern devices are connected to a 220 V or 380 V power supply:

You can install the heating unit in 10 steps:

- Select the connection location: it can be a ceiling, a wall or a corner. Make sure it can bear the load.

- Check the pipe diameter for compliance with specifications, coolant temperature and flow rate.

- Purchase electrical wires of the required length to connect the device to the power supply. Connect power supply and control circuits. Purchase mounts for the fan heater, preferably from the manufacturer.

- Mark the mounting holes and drill them.

- Screw the screws into them, leaving a small gap.

- Make it convenient to mount the console.

- Route the heating pipes to the device.

- Secure the mounting bracket, taking into account the selected angle of the fan heater.

- Hang the device on the console and secure it with two bolts. To remove air from the heating system, you can first install Mayevsky’s apparatus. To change the flow of heated air when turning the device on the console, install metal hoses.

- Connect flexible hoses to the heating pipes in accordance with the instructions for your fan heater model. Fill the device with coolant and release the air. Ready!

Manufacturers rating

The leading manufacturers of water fan heaters are:

Teplomash. For more than 25 years, the manufacturer has been producing high-quality and durable heating equipment for Russia, the CIS and foreign countries, including the USA and Canada. The company's customers are commercial enterprises, large industrial facilities and individuals. The plant's arsenal includes a wide range of models, among which any client will find what he needs.

Ballu. The company produces compact water heaters for cottages, homes and offices. The devices are easy to use and have an original design. Heaters keep oxygen at the right level. Some models have a built-in thermostat that maintains the set mode automatically. The brand highlights an innovative approach to the development of manufactured equipment.

Tropic. The company has been specializing in universal heating technology since 1998 and is distinguished by an innovative approach. Compact devices from Tropic-line are suitable for heating production, warehouses, car washes and service stations. Some models are equipped with a thermostat that turns off when the set temperature is reached. It is very convenient for home use.

Brief overview of the main lines

| Model | Characteristics |

| Teplomash MW KEV-32M3.5W2 | Wall/ceiling water heater. Suitable for heating warehouses, industrial premises and retail facilities. Provides fast and uniform heating of air up to 28 degrees over a distance of 8 m. Electric motor power is 16.1 kW. Productivity – up to 1,700 m³/h. Connects to a single-phase power supply with a voltage of 220 V. The angle of rotation and tilt is adjustable thanks to the mounting bracket. The HL10 remote control allows for convenient control. |

| Teplomash MW KEV-100M5W2 | Wall/ceiling water heater. Suitable for heating large industrial premises and warehouses. It differs from the previous model in power - 50.8 kW - and heat distribution range, 28 m. Productivity - up to 6,500 m³/h. Has three operating modes. |

| Teplomash TW KEV-180T5.6W3 | One of the most powerful models in the line. Thermal power is 120 kW. Productivity – up to 7,600 m³/h. Connects to a three-phase network with a voltage of 380 V. Reinforced with a durable steel case with overheating protection. The temperature is adjustable. There are pipes for connecting to the water supply system. |

| Ballu BHP-W2-100-S | Universal heater with three operating modes. The thermal power of the device is 95 kW. Connects to a single-phase 220 V network. The advantages of the model are low noise level, a three-row copper-aluminum heat exchanger and increased energy efficiency. There is a Fan Coil cooling function. |

| Ballu BHP-W3-15-LN | Suitable for uniform heating of any room with a height of more than 3 m. The device body absorbs engine noise. Equipment power is 18.3 kW, productivity is 2,800 m³/h. Can be installed on walls or ceilings at any angle. |

| Tropic-line AERO 35D40 | Compact water fan heater with a power of 41.4 kW. Equipped with a double-row aluminum heat exchanger. Has a durable galvanized steel body. Capacity – 4,300 m3/h. |

| Tropic-line AERO 25D35 | The power of the device is 29.6 kW. Productivity – 2,400 m³/h. Heated by a double-row aluminum-copper heat exchanger. The body is made of galvanized steel. It is compact and economical in energy consumption. Warranty period – 3 years. |

Heating by water fan heater

conclusions

- A water fan heater is a powerful, safe and efficient device for heating rooms of various sizes with economical energy consumption.

- The principle of operation of the device is to heat the air throughout the entire area of the room. This happens through the formation of a hot air flow by the fan blades. The air flow, in turn, is heated by a heat exchanger with circulating hot water inside.

- When choosing a water fan heater, you can be guided by the general formula - S × h/30 = X kW. This way you will determine the required power of the device.

- Depending on the operating characteristics, fan heaters are connected to electrical networks with voltages of 220 V (two-phase) and 380 V (three-phase).

- Teplomash, Ballu and Tropic-line are leading manufacturers of water fan heaters in Russia.

We make a convector from an ordinary battery

Water heating radiators, or simply batteries, used in centralized heating systems, distribute heat throughout the rooms using the principle of passive convection. This approach is very irrational in terms of heat loss, especially if the radiator is located in the corner of the room.

For this reason, there are convection radiators equipped with a fan that improve heat distribution throughout the room by accelerating air circulation between the battery sections.

In this master class I will show you how to upgrade a regular battery to a convector battery with your own hands.

Step 1: Fan Assembly

I took 4 fans Brushless DC Cooling Fan 7 Blade 24V 120mmx120mx25mm

.

This type of fan is very quiet and was a good size for my battery. A combination of 4 of these fans is enough to cover the entire length of my pipe.

Fan characteristics: - 7 plastic blades - speed 1600 rotations per minute - air flow 58 cubic meters. ft/min.—noise 38 dB.—power: DC 24V, 0.20A

These fans cost me 1,200 rubles including delivery. Structural strength is provided by cable ties that pass through holes in the corner of each fan and connect them together.

Step 2: Connecting the Wires

The fans use standard 2-pin connectors, just like motherboards. They hold copper cables well. You can also combine 2 connectors with a small piece of cable by inserting one into the back of the other.

This will help reduce the number of cables connecting the fans to the power supply. The power supply is connected by a 2-wire AC cable on one side and DC cables from the fans on the other.

The photo does not show the switch and the standard plug at the end of the AC cable. I took the power supply like this - 24V Universal Regulated Switching 25W Power Supply

.

Step 3: Check the fans are working

I connected the fans and checked their operation before installing them under the battery.

Step 4: Legs and other finishing touches

I equipped my fans with 4 legs from angle iron cut into 15cm lengths. Then I simply placed the section under the battery. As a result, I got excellent heat distribution throughout the room, with the help of almost silent fans consuming a total of 24 W:

— fans: 4*0.2A*24V=19.2 W—power consumption: 80% of the total supply—total power: 19.2/80%=24W

This is how I pumped my standard hot water radiator up to the convection radiator.

Heating by water fan heater

With the onset of autumn cold weather, the question of choosing a method for heating a room becomes especially relevant.

Power, economical energy consumption and safety are three criteria that play an important role when purchasing climate control equipment. Water fan heaters have all these characteristics – we will talk about them in this article. Among the many heating systems for homes, production workshops and sales areas […] Read more

26.11.2021

Operating principle and system equipment

Air heating equipment is divided into two types:

- The first type is with a heat exchanger in the form of a combustion chamber in which gas is directly burned. The air passing through the heat exchanger is heated and supplied to the room.

- The second type is with a water heat exchanger. For such a system, the heat source can be a wood stove, solid fuel, gas or universal boiler. It is also possible to install an electric heater in the system, but it should be understood that electricity costs will be very significant, in addition, this option is not suitable for houses for which a small allocated electrical power is provided.

The most modern option is to install an air-to-air heat pump. An advantageous feature of this solution is that if an air conditioner is included in the system, then such a system will not require large additional costs for equipment, but can significantly save on resources during operation.

The use of heat pumps of this type for heating homes is a global trend, since heat is obtained without burning fuel and the accompanying air pollution.

Main components of air heating:

- Fan . The heart of the system, it must be productive and durable.

- Heat exchanger . It serves to warm up the air flow.

- Air ducts . These elements are used for directed air supply into the room.

- Filters, humidifying devices . They are necessary for cleaning and maintaining an optimal microclimate inside the building.

- Air conditioner . Allows you to cool all rooms in the house.

- Control system . It automatically maintains and controls temperature conditions, turns the climate system on and off.

Effective and aesthetically pleasing for houses with panoramic glazing and second light Source indivi-dom.ru

Note! There are no radiators in the air heating system. After heating, the air enters the rooms through the grilles, the cold masses are forced upward and sent through the air ducts to the heat exchanger. Circulation ensures proper heating of rooms and promotes effective ventilation.

Circulation can be natural or forced. In the first case, the flow moves due to the temperature difference; in the second, a fan is used. As a rule, systems equipped with such equipment are quite powerful and productive. They are installed in houses with an area of up to 400 square meters; if the area of the house is larger, several systems are installed.

Operating principle of air heating Source ongun.ru

You can get professional advice on air heating of a private home directly from specialists and ATM Climate. Or check at the “Low-Rise Country” house exhibition.

Which is better: a fan heater or a heater?

In the autumn-winter period, many workshops, warehouses, greenhouses, livestock buildings, and especially our homes need heating and maintaining the temperature at an appropriate level. And the question arises, which is better: a fan heater or a heater. Some of the most commonly used devices for this are: gas street heaters; infrared heaters; air heaters; electric convectors; water heaters. Air temperature is one of the most important factors determining [...]

Read more

25.11.2021