A vertical heating system is a heating network in which radiators are connected to vertical risers. Depending on the design features, it can be used in private houses with a height of 2-3 floors, and in multi-apartment buildings. Due to the location of the main pipes, the vertical system has minimal heat loss.

TM Ogint sells equipment for laying heating networks, which is certified in accordance with the requirements of ISO 9002 and is designed for operation in the Russian Federation. The range of products offered includes bimetallic, cast iron and aluminum radiators, as well as a variety of valves and other pipeline fittings.

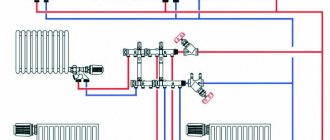

Single pipe vertical system

A single-pipe vertical system is characterized by coolant circulation in a closed loop. When installing such a heating network, radiators are connected in series, so there is a significant difference between the degree of heating of the first and last batteries. However, this disadvantage can be compensated for by the short length of the highways.

For additional adjustment, heating devices of single-pipe systems are equipped with various types of pipeline fittings. In the range of TM Ogint it is represented by the following devices:

- angle and straight thermostatic valves;

- thermostatic kits;

- shut-off valves allowing autonomous repairs without shutting down the entire network.

To ensure the efficient functioning of a single-pipe circuit with natural circulation, it is advisable to install a Mayevsky valve with a cap for a screwdriver or another type of air vent on the heating radiators.

The advantages of a vertical single-pipe network include:

- minimal consumption of materials;

- the optimal amount of coolant, the volume of which can be adjusted by selecting the diameter of the pipes;

- possibility of installing the system without using a circulation pump.

However, it is effective for small rooms, and to heat rooms with an area of 40 m2 or more, you will have to install several risers, otherwise it will be difficult to achieve a comfortable temperature. Therefore, installation of a single-pipe vertical system is advisable in apartment buildings with a height of at least 5 floors. In addition, it is necessary to have good insulation and small rooms.

Two-pipe vertical system

A vertical two-pipe heating system involves the installation of two lines for transporting the coolant. One of them supplies the heated working medium, and the second serves as a drain after cooling. Since the radiators are connected in parallel, it is necessary to ensure that the pipelines are laid next to each other.

An additional line increases the cost of materials and the volume of coolant, for the movement of which natural circulation is not enough, since hydrodynamic resistance increases. For efficient operation, autonomous engineering heating systems in private cottages are equipped with powerful circulation pumps.

According to the method of supplying coolant, two-pipe networks are usually with top wiring. This option for organizing heating is more efficient and requires less effort during installation. A system with bottom wiring is labor-intensive to install and difficult to operate the equipment.

The use of a vertical two-pipe scheme in multi-apartment buildings provides the following advantages:

- the ability to supply coolant with the same degree of heating to all heating devices, regardless of the floor;

- ease of flushing and carrying out preventive maintenance when preparing the pipeline for operation.

A heating network of this design is almost not prone to the formation of air jams. To completely eliminate the likelihood of their occurrence, you can install one of the air vent options offered by TM Ogint. For radiators, a Mayevsky tap is sufficient, but for the entire system an automatic device will be required.

In the context of rising tariffs for heating housing in multi-apartment buildings, it is important to not only regulate the temperature, but also control the heat consumption. A two-pipe vertical heating system allows the installation of in-house heat metering devices. The use of individual heat consumption meters in each apartment is complicated by the peculiarities of legislation and the need to install the device on each riser.

The range of heating equipment TM Ogint allows you to select components for laying vertical systems of different types. A large selection of thermostatic and shut-off valves, as well as other types of pipeline fittings, makes it possible to create an effective heating network at minimal cost. High quality products ensure the functioning of heating systems for a long time.

Simple but useful tips

Some useful tips for those who do their own heating installation for an apartment:

- To easily pull the polyethylene pipe through the corrugated casing, carefully remove the chamfer at the end; it will insert freely, even when the corrugation has bends.

- To prevent the corrugation from slipping off the sleeve during installation and sealing the groove with mortar, wrap it with tape.

- Consider the layout of the apartment, the heating will heat the floor in the places where it is installed. Install along aisles.

- Attach the radiator from above and below for rigidity and full circulation.

- Be sure to make a self-compensation loop on each extended collector.

- Install converters, they are more expensive, but much more efficient.

Important! To install the PE-X line polymer, you will need a special hydraulic tool. The set can be rented or purchased from 16,500 rubles.

Drawing up a heating project for an apartment and using apartment-by-apartment systems is mandatory when constructing new multi-story, multi-functional buildings. Residents of such apartments can independently regulate the temperature, close or completely close the supply taps to heating devices to create comfortable conditions. Payment for the use of thermal energy is carried out strictly according to the meter. In addition, watch a useful video on heating in an apartment.

| PE-Xb | 16.0 | 2 | 59 |

| PE-X/EVOH | 16.0 | 2 | 28 |

| Elsen PE-Xa | 25 | 3,5 | 208.6 |

| PexPenta PE-Xc | 16 | 2 | 50 |

| Stainless steel corrugated pipe S9 304 | 15 | 95 | |

| Casing, HDPE corrugated for polyethylene 16 mm | 25 | 12 |

Vertical layout

This type of wiring is still used in apartment buildings, since this type is most suitable for heating a large number of floors. Also, vertical wiring saves materials and is easier to install. This type of circuit can be one-pipe or two-pipe, and the two-pipe type is more preferable. The two-pipe vertical heating distribution also allows you to change heating devices without stopping the entire heating system. Heaters can be equipped with automatic or manual temperature control valves.

A single-pipe vertical type circuit does not allow radiators to be turned off individually, but the installation of such a system requires much less pipes than a two-pipe circuit. The vertical type of wiring allows you to evenly distribute heat throughout the room, but the heated area of the rooms is somewhat limited. It is advisable to use vertical wiring if the building has three floors or higher.

Vertical wiring also allows you to organize a heating system that will not be equipped with a circulation pump. This technical solution is applicable to private housing construction. The main disadvantage of a vertical heating scheme is that it cannot be scaled. It may also cause inconvenience that it will not be possible to regulate the temperature in each individual room.

Vertical heating wiring can have an upper or lower location. These two types have some special features. If a single-pipe vertical distribution of the upper type is used, then the supply is carried out from the attic, where a special tank (bed) is installed. Next, the coolant from the reservoir is distributed into risers, which supply heat to the heating devices.

The vertical type distribution with bottom supply is equipped with a reservoir in the basement, from which water flows into the risers. The coolant moves upward along the risers, simultaneously passing through the heating devices in each apartment. If the vertical distribution is installed according to a two-pipe scheme, then adjustable heating devices can be used in its circuit. Heat metering devices can also be connected to such a system.

Additional items

How does a closed heating system work?

In addition to the boiler, pipes and batteries, it contains:

- A circulation pump that drives the coolant.

- Jumper with cold water supply for filling the system with water.

- Drains at the lowest points of the circuit, allowing it to be completely drained.

- Expansion tank. It compensates for the increase in coolant volume as the temperature rises.

- A safety valve that is triggered when the tank is overfilled and the pressure increases above the design pressure.

- Pressure gauge or thermomanometer to monitor system parameters.

- Automatic air vent.

However: the pump, air vent, safety valve and (sometimes) expansion tank are often mounted in the boiler body, effectively turning it into a mini boiler room. Before you go shopping, study the documentation.

Construction of a modern gas boiler.

In addition, optionally the following can be installed:

- Cutting off individual heating devices and sections of the valve circuit.

- Mud trap in front of the pump.

- Throttles or thermostats that regulate the temperature of radiators.

- At the upper points of the circuit there are additional air vents.

How to install heating yourself in a one-story house? According to the author, the best solution would be Leningradka - a single-pipe distribution along the perimeter of the floor with radiators connected parallel to the main bottling. It is absolutely fail-safe and eliminates the possibility of stopping circulation in some part of the circuit due to air congestion.

How to properly install heating on two floors?

There are two possible options here.

- Two rings (one per floor) with a throttle that limits the passage of the shorter circuit.

Leningradka version for two floors.

- Two-pipe scheme with bottlings on the ground floor and in the attic and risers connecting them with heating devices.

How to connect radiators correctly?

For short (no more than 7 sections) heating devices, the traditional side connection is optimal. It is better to connect longer batteries diagonally or from bottom to bottom.

Relevance for autonomous heating

An example of a vertical heating scheme for a private two-story house.

The first problems may arise at the stage of connecting the batteries. This is due to the location of the pipes and the design of the heating device itself. Almost all models are designed for installation in a horizontal system. Therefore, experts recommend installing special vertical wall-mounted heating radiators.

However, the peculiarities of their functioning should be taken into account. The lower the battery is located, the more efficient it will work. Cold air has more mass than warm air, so it concentrates near the floor. The battery's job is to heat it up. Therefore, it should be located as low as possible. Narrow vertical heating radiators are structurally unable to fully perform this task.

But this is not the only drawback characteristic of vertical wiring of the heating system. This can be solved by slightly increasing the length of the radiator inlet pipes. If you adhere to the canons of the scheme, another problem will arise. It consists of tying vertical tubular heating radiators to the location of the thermal risers. For rooms with a small square footage this is not significant. However, if the room has an area of 40 m2 or more and there are 2 external walls, it will be necessary to install several thermal risers.

To summarize, we can highlight the following conditions when installing a vertical single-pipe heating system makes sense:

- Relatively large number of floors. Usually from 5 or more;

- Relatively small area of rooms;

- Good thermal insulation and uniform heat distribution throughout the room.

Alas, these characteristics are unusual for most private cottage houses. That is why they prefer to install a horizontal heating system as one of the best ways to maintain a comfortable temperature.

In old apartment buildings with a two-pipe vertical heating system with bottom wiring, to account for heat, you need to install a meter on each riser. There can be from 2 to 5.

Where is it used?

It is logical to assume that the horizontal distribution scheme of thermal circuits is more suitable for private houses with individual heating. But in practice, such wiring is successfully used for door-to-door service in apartment buildings. Each apartment receives its own branch of the distribution heat circuit with its own metering, however, no regulation methods are proposed without a special jumper.

But there is another argument in favor of using such systems exclusively in private engineering – the premium quality of the materials. Indeed, if vertical systems are usually based on metal pipes, then horizontal ones are mounted from polymer materials with a heat-resistant coating. Obviously, cross-linked polyethylene PEX significantly increases the cost of the technical implementation of such a scheme. But it is the durability and reliability of this material that allows the use of horizontal heating systems in low-class apartment buildings. Costs for both installation and maintenance of the system are reduced. For example, if for welding work with metal pipes in vertical risers it is necessary to connect a highly qualified welder, then the technology for assembling contours from plastic pipes is within the power of a home craftsman. Using permanent connections, it is easy to assemble the structure and only in extreme cases is cross-linked propylene welded with special soldering stations at the joints.

When can a bottom or top spill scheme be installed?

A pipe system with bottom filling consists of a pair of risers connected by jumpers. Such a system can be installed either on the top floor of the property or in the attic.

Top filling pipe systems are installed on the technical floor.

An air vent and special valves must be connected here, which would allow each individual riser to be closed.

This option is considered more advanced and in demand when installing central heating, but has a number of nuances:

- As hot water moves downwards, its temperature decreases, which means that the lower floors of a heated building will be colder than the upper ones. Therefore, when installing such a system, you should think about increasing the number of radiators or the area of convectors.

- When discharging hot water from a certain riser, you must first locate and shut off this riser on the technical floor, and then also find and turn off the valve for this riser in the basement, which is considered a rather complicated procedure.

However, the top-spout system allows you to start heating quickly. You just need to open the valves and vent on the expansion tank. After this, heat will begin to flow to the object.

System installation

Installation of heating system components and even laying of pipelines is possible after completion of construction, but it is recommended to carry out technical operations with commissioning activities as the house is being built. This allows, if necessary, to make adjustments to design solutions at the stages of finishing work. The most labor-intensive process is organizing a horizontal heating system for underfloor water heating. In this case, you will need to install a concrete screed on top of the pipes or heating mats. In contrast, wall-mounted convectors and radiators require virtually no “dirty” work and are mounted to surfaces using brackets.

Regulatory means

In systems organized in multi-apartment buildings, simple mechanical thermostats are more often used, through which the heating mode is adjusted. It is recommended to turn off such regulators when people are unoccupied for energy saving purposes only in single-family houses. Since the thermal insulation properties of the materials of floors and internal walls are lower than those of external surfaces, after the horizontal heating system is turned off, heating of the home will occur at the expense of neighboring apartments. For this reason, thermostats are used in residential apartment buildings that limit the ability to adjust the temperature regime to both maximum and minimum values.

Selecting a radiator for vertical wiring

Methods of connecting radiators

For the systems discussed above, it is difficult to find vertical water heating batteries. This is due to the limited ways to connect them to the circuit. The greatest heat transfer from the radiator will be with a one-sided upper and lower location of the pipes.

In most cases, vertical tubular heating radiators are characterized by the installation of mounting units on one side. From the point of view of distributing hot water throughout the entire volume of the structure, a detailed scheme is considered the most effective.

Accuro-Korle

Radiator Accuro-Korle Caftan

Currently, this is one of the most famous manufacturers of vertical wall-mounted radiators. A feature of its models is the predominance of Hi-Tech style. A striking example of such a design solution is the Caftan line of radiators. They can perform not only the functions of a heating device, but also a heated towel rail. Currently, the average cost of a Caftan ranges from 30 to 43 thousand rubles.

The Escape model is a typical tubular hydronic vertical heating coil. The strict classic shape will make it possible to fit the radiator into almost any interior of a bathroom or hallway. Its cost is slightly lower than that of Caftan - from 23 to 34 thousand rubles. with the same technical characteristics.

Radiator Accuro-Korle Escape

In addition to this well-known manufacturer, there are several reliable suppliers of such radiators - Caftan (Turkey), Kermi (Germany), Jaga (Belgium). Alas, the economy segment of the vertical battery market does not exist as such. The only way out is to make a similar design yourself. But its technical characteristics will be significantly lower than those of factory models. This is another factor in the unpopularity of vertical wiring of the heating system.

Should I give preference to a vertical heating system? Wiring, radiators, and batteries for it will not be cheap, and installation has a number of significant drawbacks. The main thing is to find out for yourself the feasibility of installing it. It can be used for a small apartment building with autonomous heating. But first you need to make all the required calculations.

The video shows an example of a vertical two-pipe heating system in an administrative building:

Heat supply of a multi-storey building

Heating distribution unit for an apartment building

Heating distribution in a multi-storey building is important for the operational parameters of the system. However, in addition to this, the characteristics of the heat supply should be taken into account

An important one is the method of supplying hot water - centralized or autonomous.

In most cases, a connection is made to the central heating system. This allows you to reduce the current costs in the estimate for heating a multi-storey building. But in practice the level of quality of such services remains extremely low. Therefore, if there is a choice, preference is given to autonomous heating of a multi-storey building.

Autonomous heating of a multi-storey building

autonomous heating of a multi-storey building

In modern multi-storey residential buildings, it is possible to organize an independent heat supply system. It can be of two types - apartment-based or communal. In the first case, the autonomous heating system of a multi-storey building is carried out in each apartment separately. To do this, make independent piping and install a boiler (most often a gas one). A common house installation involves the installation of a boiler room, which has special requirements.

The principle of its organization is no different from a similar scheme for a private country house. However, there are a number of important points to consider:

- Installation of several heating boilers. One or more of them must perform a duplicate function. If one boiler fails, another must replace it;

- Installation of a two-pipe heating system of a multi-storey building, as the most efficient;

- Drawing up a schedule for scheduled repairs and maintenance work. This is especially true for heating heating equipment and safety groups.

Taking into account the peculiarities of the heating scheme of a particular multi-storey building, it is necessary to organize an apartment-by-apartment heat metering system. To do this, energy meters must be installed on each incoming pipe from the central riser. That is why the Leningrad heating system of a multi-storey building is not suitable for reducing operating costs.

Features of the vertical heating system

Vertical wiring of the heating system is used in both autonomous and centralized heating networks. Depending on the method of transporting the working medium through the pipeline, it can be with natural or forced circulation. In the first case, the coolant moves due to the difference in density. In low-rise buildings with an autonomous heating network with forced circulation, the movement of the working medium occurs due to the pump, and in the presence of centralized communications - due to pressure drops.

According to the coolant supply option, the following vertical heating systems are distinguished:

- with top wiring. The pipeline for such networks is laid in the attic or under the ceiling;

- with bottom wiring. Installation of lines for transporting the working fluid is carried out through the basement or in the floor screed.

Compared to a horizontal heating system, a vertical heating network is not prone to the formation of air pockets and allows you to control the temperature of the batteries. TM Ogint offers a large selection of thermostatic valves and thermostatic elements, with the help of which you can establish and maintain a comfortable microclimate in the room.

Depending on the design nuances, the vertical heating network can be single-pipe or double-pipe. When choosing a specific type of system, the number of floors of the building and the need to install individual heat meters are taken into account.

What does the project consist of?

As a rule, any construction and installation work is preceded by calculations and design, and heating is no exception. This applies to both private houses and high-rise buildings.

The apartment heating project includes all the work that must be carried out, what materials have been purchased, calculations for the length of the pipeline and the number of radiators in each room, what coolant is used, its supply power, what the pipe layout will be and much more.

In addition to the project, you will need a detailed sketch, which will indicate all the heating batteries, the boiler room and its equipment, components with the exact dimensions of each part of the system and the method of their installation.

Documents must comply with SNiP standards.

Beam horizontal systems with two pipes

An even more technologically complex heating system, in which the advantages of a two-pipe scheme increase. If horizontal wiring as such is the concept of constructing an individual branch with heating for a separate apartment, then the radial diagram assumes partial isolation of the circuits already inside this branch. Supply and return pipes are provided for each heating device. What does this mean in practice when operating a horizontal heating system? Firstly, more accurate, convenient and efficient control with zonal microclimate adjustment. Secondly, it becomes possible to organize circuits with their own shut-off valves, automatic control system, etc. On the other hand, for the full functioning of the beam model, the installation of circulation pumps and a distribution manifold with the ability to cover all consuming circuits on the branch is required.

Manifold cabinets and blocks

In an apartment with horizontal radiant heating distribution (on the floors of private houses), distribution manifolds (supply and return) are installed, collecting all supply and return pipelines at their outlets. They are placed in specially designed metal cabinets, often built into the partitions of bathrooms and opening inside them. It is also possible to install distribution manifolds in specially designed wall niches. Often the collector unit is combined with a heat metering unit in one collector cabinet.

Manifold cabinet with thermal energy metering unit.

Collectors can be complete, consisting of sections of thick pipes with outlet pipes, or assembled on tees. The materials for these devices can be:

- plastic;

- nickel plated brass;

- copper;

- stainless steel.

Many well-known manufacturers of heating equipment (VALTEC, etc.) produce ready-made manifold blocks that combine supply and return manifolds, manual adjustment valves (on the supply manifold), thermostatic valves (on the return manifold), automatic air vents, drain valves and mounting brackets.

Complete collector block.

The task of individually adjusting the thermal regime of each single-radiator branch of a collector-radiant heating system is solved by tuning valves with built-in flow meters. The branches are of different lengths, and the coolant tends to flow the shortest way with minimal hydraulic resistance. It flows more intensely around short branches, warming up the radiators installed there more strongly.

Adjustment valves on the supply manifold change the flow of water (antifreeze), narrowing their nominal passages in short circuits, and widening them in long ones. Setting up is a painstaking process, and the setting valve is not intended to quickly shut off or open the coolant flow along the circuits. This function is performed by thermostatic valves.

Thermal valves on the manifold – “return” – are valves that smoothly shut off the flow manually or automatically. The radiant heating system is easily hydraulically balanced.

Types of radiator connections

The main methods of connecting heating system devices are several types:

- Lateral (standard) connection;

- Diagonal connection;

- Bottom (saddle) connection.

Side connection

Lateral radiator connection.

Connection from the end of the device - supply and return are located on one side of the radiator. This is the most common and effective connection method; it allows you to remove the maximum amount of heat and use the entire heat transfer of the radiator. As a rule, the supply is at the top and the return is at the bottom. When using a special headset, it is possible to connect from bottom to bottom, this allows you to hide the pipelines as much as possible, but reduces the heat transfer of the radiator by 20 - 30%.

Diagonal connection

Diagonal radiator connection.

Connection diagonally to the radiator - the supply is on one side of the device from the top, the return is on the other side from the bottom. This type of connection is used in cases where the length of a sectional radiator exceeds 12 sections, and a panel radiator is 1200 mm. When installing long radiators with side connections, there is uneven heating of the radiator surface in the part furthest from the pipelines. To ensure that the radiator heats up evenly, a diagonal connection is used.

Bottom connection

Bottom connection from the ends of the radiator

Connection from the bottom of the device - supply and return are located at the bottom of the radiator. This connection is used for the most hidden installation of pipelines. When installing a sectional heating device and connecting it using the bottom method, the supply pipe approaches on one side of the radiator, and the return pipe on the other side of the bottom pipe. However, the heat transfer efficiency of radiators with this scheme is reduced by 15-20%.

Bottom radiator connection.

Stabilization of pressure in the heating system

Expansion of water as a result of heating is a natural process. In this indicator, the pressure may exceed a critical value, which is unacceptable from the point of view of heating operation. In order to stabilize and reduce pressure on the internal surfaces of pipes and radiators, it is necessary to install several heating elements. Adjusting the heating system in a private home will be much easier and more efficient with their help.

Adjusting the expansion tank

Expansion membrane tank

It is a steel container divided into two chambers. One of them is filled with water from the system, and air is pumped into the second. The air pressure value is equal to normal in heating pipes. If this parameter is exceeded, the elastic membrane increases the volume of the water chamber, thereby compensating for the thermal expansion of water.

Before adjusting the pressure drop in the heating system, you need to check the condition and settings of the expansion tank. You can adjust the pressure in the heating system by purchasing a tank model with the ability to change it in the air chamber. As an additional measure, install a pressure gauge to visually monitor this value.

However, if there is a significant surge in pressure, this measure will not be enough. This way you can adjust the pressure drop in the heating system if it does not exceed a critical value. Therefore, it is recommended to install additional devices.

How to adjust a security group

Heating safety group

This group of devices includes the following elements:

- Pressure gauge . Designed for visual monitoring of the heating system operation;

- Air vent . If the water temperature exceeds 100 degrees, excess steam acts on the valve seat of the device, releasing air from the pipes;

- Safety valve . It works in the same way as a water drain, but is needed to drain excess coolant from the pipes.

How to adjust a heating radiator using this unit? Alas, it is designed to prevent emergency situations throughout the entire system. Batteries require another device to be installed.

Mayevsky crane

Structurally, it is similar to a safety valve. A special feature is its small size and the ability to be mounted on a radiator pipe with a small diameter.

In order to correctly adjust heating radiators, you need to know in what cases the Mayevsky tap is used:

- Eliminating air pockets in radiators. By opening the valve, air is released until the coolant flows;

- Setting the critical pressure value parameters. If an emergency expansion of water occurs, the valve opens and the pressure in the radiator stabilizes.

Design of the Mayevsky crane

The last function is additional and is most often not used. This task is best handled by the security team. Proper adjustment of heating in the house should include all of the above elements.

When independently regulating a two-pipe heating system while the boiler is running, you need to constantly monitor the readings of thermometers and pressure gauges.

Features of work on replacing pipes, risers and heating radiators

Dismantling heating risers

Replacing risers

Since heating modernization may affect the systems of other apartments, it is necessary to inform the housing office about the upcoming work. Their employee must shut off the riser in case there is water in the system. When pipe replacement is not an emergency, it must be carried out during the non-heating season.

Before changing heating pipes,

you need to come to an agreement with the neighbors below and above, because if sections of old pipes remain in the ceilings, there will still be a possibility of leakage.

Stages of dismantling work:

- The housing office employee must shut off the risers and drain the water from them.

- The riser is cut off from the upper and lower floors using a grinder.

- Since the new riser pipes are plastic, a thread is made on the riser pipe, it is lubricated, and sealed with fum tape. Then a coupling is screwed on, connecting the plastic and steel pipes.

Installation of heating radiators

The best for central heating are bimetallic or modern cast iron radiators - they have a large enough flow for water, so they rarely become clogged.

Types of radiators

Battery installation features:

- First, the radiator installation locations are marked.

- Brackets must be used to install radiators.

- Installation of the battery must be carried out exclusively according to the level, since if it is skewed, air may collect in it and it will not work well.

- As a rule, radiators are installed under a window to prevent cold air from entering the room.

- The distance between the radiator and the wall should be about 5 cm, the gap to the floor - a maximum of 12 cm, to the window sill - 10 cm.

When replacing pipes and heating radiators, they must be equipped with shut-off valves. This is necessary so that in the event of a radiator leak, this section can be closed, and this will not affect the functioning of the entire heating system.

Connecting pipes to radiators

Heating system diagrams

- A single-pipe system where only hot water flows through the risers. For risers with this system, pipes with a diameter of 32 or 25 mm are used. For pipes supplying coolant to radiators, a diameter of 20 mm can be used.

- A two-pipe system, where hot water is supplied through one pipe (“direct”) and discharged through the second (“reverse”). With this system, the diameter of the pipes is selected depending on the number of radiators: when there are 8 or more batteries, pipes with a diameter of 32 mm are used, when there are fewer batteries, 20 mm. For the riser system, a pipe diameter of 32 mm is also used.

When it is necessary to replace heating pipes, it is important that the diameter of the pipes going to the radiators is not smaller than those that were previously installed. Installation of pipes to radiators:

Installation of pipes to radiators:

- With a single-pipe system, a Mayevsky valve is located in the upper part of the radiator, which is necessary for venting air. The bottom hole is closed with a plug. The surface must be cleared of paint before installing the plugs. Then they install the heating taps using a special wrench - preferably with union nuts. When changing heating pipes ,

the pipeline leading to the radiator is installed after its installation. - With a two-pipe system, grooves are made for the pipes in the floor, the pipes are sheathed with insulation and laid in the grooves. The pipes that go to the radiators are similarly hidden in the walls.

Heating pipes built into the walls

Final stage:

- connecting pipes to risers;

- when replacing heating risers, it is necessary to install a jumper (if the taps on the battery are closed, in the absence of a jumper, the entire heating riser will not work);

- the assembled system must be checked for leaks by testing it under pressure 1.5 times higher than normal.

If the heating system in an apartment is correctly replaced, the problem of heat and leaks will be solved for at least 20 years.

Heating temperature control

An important parameter of any heating system is the optimal temperature regime for its operation. A ratio of hot and cooled coolant of 75/50 or 80/60 is considered suitable. However, this value is not always acceptable for certain parts of the network. How to properly adjust the heating in the house in this case? Installation of special equipment is required. Some of them are designed for adjusting heating radiators.

Mixing units

Three-way valve

Their main element is a two or three-way valve. One of the pipes is connected to the heating pipe with hot water, the second to the return pipe. The third is mounted on a section of the main line where it is necessary to ensure a lower level of coolant temperature.

As additional options, the mixing units are equipped with a temperature sensor and a thermostatic control unit. A signal is received from the sensor about the heating level of the coolant and it opens or closes the mixing valve, thereby regulating the two-pipe heating system. Most often, such mechanisms are installed in water-heated floor collectors.

If you need to adjust the heating of a water heated floor in an apartment building, you need to take into account the temperature conditions of the pipes. Most often it does not exceed 45 degrees.

Servo drives

Servo drive for radiators

How to adjust the heating in an apartment building if it is not possible to independently change the temperature of the water in the pipes? This requires the installation of special shut-off valves. You can limit yourself to installing simple taps - with their help, the flow of coolant into the radiators is regulated. However, in this case, the adjustment will have to be done independently each time. The best option would be to install servos.

The design of this device includes a thermostat and a servo drive. To work, you must perform the following steps.

- Set the desired temperature value on the thermostat.

- The servo drive will automatically open or close the flow of coolant into the radiator.

In addition to similar models, you can purchase an economy version that includes only a thermostat. In this case, the level of adjustment will not be as accurate. But how to adjust the heating system in an apartment building if old radiators are installed? There are models of thermostats that are designed for installation in cast iron radiators. This measure will make the temperature settings for the apartment more accurate.

Thermostats cannot be used to regulate the pressure drop in the heating system. They will only limit the flow of coolant into the radiator without affecting the temperature regime of the entire system.

You can’t do without a circulation pump

Diagram of a collector heating system.

The layout of this heating system involves forced circulation of liquid. This function is assigned to the pump. It is this part of the beam system that distills liquid at a designated pressure and guarantees the best temperature values that are comfortable for people.

The parameters of the pipes and the dimensions of the heat exchangers affect the type of circulation pump that will be in the heating system being organized. It is preferable to purchase a pump that moves liquid through pipelines at high speed. It is more difficult to select a pump for a radiant floor heating system. Here you will need devices that are large in power and capable of pumping water.

The power of such a pump and the power of the radiant heating system should have equivalent parameters. Anyone who ignores this warning will receive noise as a result of a stupid mistake.

The circulation pump should begin to function if the resulting heating system is completely filled with water. Otherwise, damage may occur.

The pump should only be started when it is clean; it must first be thoroughly rinsed.

The collector heating system being created requires placing a pump to circulate the liquid closer to the expansion tank. According to the plan, it is fixed to the return pipeline. The temperature there is not too high, and in this place it fulfills the conditions specified in the instructions.

When preparing a plan for radiant heating, you need to think it over and double-check it several times. High-quality materials, tools and the beam system assembly itself will require time, money and attention. But this will result in comfort in terms of uniform heat generation in any of the rooms of the home being equipped.