Published on March 09, 2014 Category: Heat engineering | 22 comments

“Are your radiators warm?” or “Are your radiators hot?” — these are the questions we ask our neighbors if it’s cool in our apartment, office, or industrial premises. All various heating devices are popularly called radiators or radiators.

These terms include panel and sectional radiators, finned pipes, registers made of smooth pipes, various convectors and even sometimes relatively exotic ceiling radiators.

The article you are reading will present a small program in MS Excel that allows you to perform thermal calculations of heating radiators and convectors.

A heating radiator is a device that heats the air and objects in a room through radiation and convective heat exchange, while transferring thermal energy from a hot coolant (most often water) through its walls.

The convector transfers thermal energy into the space surrounding it exclusively (95%) through convective heat exchange - heating by hot walls of air jets.

The share of heat transferred by convection (the remaining part, respectively, by infrared radiation) for some types of heating devices is given below:

Cast iron radiators (batteries) – 25…35%

Aluminum sectional radiators – 50…60%

Panel steel radiators – 65…75%

Convectors – 90…98%

It is impossible to say unambiguously which type of heating appliances is better. Everyone has flaws. However, the increased quality of design and manufacture of convectors has allowed this type of device to constantly increase its market share in recent years.

Over the past five years, I have had the opportunity to participate in the selection and design of heating systems for a large shopping complex (4 floors, more than 30 thousand square meters) and for a production workshop (500 square meters). In both cases, convectors were used as heating devices according to the “price / quality / efficiency” criterion, which significantly “outperformed” competitive options (including the air heating option). The practice of subsequent operation confirmed the correctness of the chosen solution - convectors heat objects perfectly!

Like most calculations in heating engineering, the proposed calculation of heating radiators will be approximate. “Approximateness” lies in the fact that the actual heat transfer of devices is influenced by a dozen factors, some of which in “accurate” calculations are taken into account by coefficients determined in practical experiments, and some factors are completely ignored due to their low significance.

The calculation of heating radiators proposed below takes into account 90...95% of factors when a number of conditions are met:

1. The atmospheric pressure at the place where the devices are used should be about 760 millimeters of mercury. For high mountain areas, it is necessary to introduce an additional correction for “accurate” calculations.

2. The water supply to the device should not be “bottom-up”! The feed can be anything, preferably “from top to bottom”. Otherwise, you will not receive about 15...20% of heat.

3. The installation of the radiator must ensure free movement of air along its surfaces in the vertical direction. The distance from the floor to the bottom of the device and from the top of the device to the window sill or the top of the installation niche of the wall should preferably be at least 100 millimeters.

The following calculation in Excel can also be performed in the OOo Calc program from the Open Office package.

You should read about the colors of Excel sheet cells that are used in the articles on this blog on the “ About the Blog ” page.

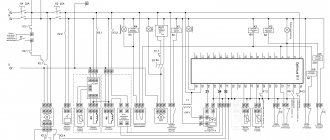

Calculation of heating radiators and convectors in Excel.

Initial data:

1.

Write down the type of heating device selected

into combined cells C3D3E3: Radiator MS-140-108

2.

Number of devices (sections) connected in series

N

in pcs. enter

to cell D4: 10

We take the following 5 parameters from

the technical characteristics of the device manufacturer.

3.

the nominal heat flux of the device (section)

Qn

in W

to cell D5: 185

4.

the nominal temperature difference of the device (section)

dtн

in °C

to cell D6: 70

5.

the nominal water flow through the device (section)

Gn

in kg/hour

to cell D7: 360

6.

We write down the indicator of nonlinearity of heat transfer from temperature

n

to cell D8: 0,30

7.

We write down the nonlinearity index of heat transfer from flow rate

p

to cell D9: 0,02

We set the next 3 parameters based on the expected reality of subsequent operation . They depend on the source of heat supply and the type of room.

8.

the

“supply” water temperature

tp in °C

to cell D10: 85

9.

the return water temperature

tо in

°C

to cell D11: 60

10.

Enter the air temperature in the room

t in

to cell D12: 18

Calculation results:

11.

The nominal heat flow

N

devices (sections)

ΣQ n

in kW is calculated

in cell D14: =D4*D5/1000 =1,850

ΣQ n = N * Q n /1000

12.

The temperature difference

dt

in °C is determined

in cell D15: =(D10+D11)/2-D12 =54,5

dt=( t p + t o )/2-

t in

13.

The estimated optimal water consumption

G

in kg/hour is calculated

in cell D16: =((0.86*D14*1000*((D15/D6)^(D8+1))*(1/D7)^D9)/(D10-D11))^(1/(1 -D9)) =44

G =((0.86* ΣQ n *1000*(( dt / dt n )( n +1) )*(1/ G n ) p )/( t p -

t o )(1/(1- p ))

14.

the estimated heat transfer

N heating devices (sections) Q

in kW

in cell D17: =D14*((D15/D6)^(D8+1))*(D16/D7)^D9 =1,281

Q = ΣQ n *(( dt / dt n )( n +1) )*( G / G n ) p

and do a check

in cell D18: =D16/0.86*(D10-D11)/1000 =1,281

Q = G /0.86* ( t p -

t o )/1000

15.

The share of real heat transfer

of N

devices from the nominal heat flow

∆

in % is determined

in cell D19: =D17/D14*100 =69

∆= Q / ΣQ n *100

At this point, the Excel calculation of the heating radiator MS 140-108, consisting of 10 sections, is completed.

Let's perform a similar calculation in Excel for the KSK 20-2,083PS convector.

Calculation of thermal power of heating radiators

Radiator power

– this is the thermal energy of the radiator, usually measured in Watts (W)

There is a direct connection between the heat loss of the room and the power of the radiator. That is, if your room has a heat loss of 1500 W, then the radiator accordingly needs to be selected with the same power of 1500 W. But not everything is so simple, because the temperature of the radiator can be in the range from 45-95 ° C and, accordingly, the power of the radiator will be different at different temperatures.

But many, unfortunately, will not understand how to find out the heat loss of a room... There are simple calculations for determining the heat loss of a room. They will be written about later.

At what temperature will the radiator heat up?

If you have a private house with plastic pipes, then the temperature of the radiators will range from 45-80 degrees. Average temperature 60 degrees. Maximum temperature 80 degrees.

If you have an apartment with central heating, then from 45-95 degrees. Maximum temperature 95 degrees. The central heating temperature is now weather dependent. This means that the temperature of the central heating fluid depends on the outside temperature. If it’s cold outside, then the coolant temperature is higher and vice versa. The power of radiators according to SNiP is calculated at ∆70 degrees. But this does not mean that you need to select it that way. Designers set the power to heat your apartment less and save money on thermal energy, and remove money from rent as usual. Today it is not prohibited to change the radiator to a more powerful one. But if your radiator takes away a lot of heat and there are complaints about the system, then measures will be taken against you.

Let's assume that you have decided on the coolant temperature and radiator power

Given:

Average radiator temperature 60 degrees

Radiator power 1500 W

Room temperature 20 degrees.

Solution

When you search and ask for a radiator with a power of 1500 W, they will offer you a radiator with a power of 1500 W with a temperature difference of ∆70 °C. Or ∆50, ∆30…

What is the temperature difference of a radiator?

Temperature difference

– this is the temperature difference between the temperature of the radiator (coolant) and the temperature of the room (air)

The radiator temperature is the conditionally average temperature of the coolant. That is

Let's assume that there is a series of radiators of certain capacities with a temperature difference of ∆70 °C.

Model 1, 1500 W

Model 2, 2000 W

Model 3, 2500 W

Model 4, 3000 W

Model 5, 3500 W

It is necessary to select a radiator model with an average coolant temperature of 60 degrees.

In this case, the temperature difference will be 60-20=40 degrees.

There is a formula for recalculating the power of radiators:

Uph – actual temperature difference

Un – standard temperature difference

More details about the formula: Calculation of radiator power. Standards EN 442 and DIN 4704

Solution

Answer:

Model 5, 3500 W

| Like |

| Share |

| Comments (+) [ Read / Add ] |

A series of video tutorials on a private house

Part 1. Where to drill a well?

Part 2. Construction of a water well Part 3. Laying a pipeline from the well to the house Part 4. Automatic water supply Water supply Water

supply for a private house.

Principle of operation. Connection diagram Self-priming surface pumps. Principle of operation. Connection diagram Calculation of a self-priming pump Calculation of diameters from a central water supply Water supply pumping station How to choose a pump for a well? Setting up a pressure switch Pressure switch electrical diagram Operating principle of a hydraulic accumulator Sewage slope of 1 meter SNIP Connecting a heated towel rail DHW recirculation diagram - the best solution! Heating schemes

Hydraulic calculation of a two-pipe heating system Hydraulic calculation of a two-pipe associated heating system Tichelman loop Hydraulic calculation of a single-pipe heating system Hydraulic calculation of radial distribution of a heating system Scheme with a heat pump and a solid fuel boiler - operating logic Three-way valve from Valtec + thermal head with remote sensor Why the heating radiator does not heat well in an apartment building How to connect a boiler to a boiler?

Options and connection diagrams DHW recirculation. Principle of operation and calculation You are not correctly calculating the hydraulic needle and collectors. Manual hydraulic calculation of heating. Calculation of a warm water floor and mixing units. Three-way valve with a servo drive for DHW. Calculation of DHW, BKN. We find the volume, power of the snake, warm-up time, etc. Heating temperature conditions 90-70, 80-63, 70-55, 60-50 Water supply and heating designer

Bernoulli's equation Calculation of water supply for apartment buildings

Automation

How servo drives and three-way valves work Three-way valve for redirecting the flow of coolant

Heating

Calculation of the thermal power of heating radiators Radiator section Overgrowth and deposits in pipes worsen the performance of the water supply and heating system New pumps work differently... Calculation of infiltration Calculation of temperature in an unheated room Calculation of the floor on the ground Calculation of a heat accumulator Calculation of a heat accumulator for a solid fuel boiler Calculation of a heat accumulator for storing thermal energy Where to connect the expansion tank in the heating system?

Boiler resistance Tichelman loop pipe diameter How to choose the diameter of a pipe for heating Heat transfer of a pipe Gravity heating from a polypropylene pipe Why don’t they like single-pipe heating? How to love her? Smart selection of diameters in a heating system Balancing heating radiators - a step-by-step guide Top 5 problems in designing heating systems Heat regulators

Room thermostat - operating principle

Mixing unit

What is a mixing unit?

Types of mixing units for heating Characteristics and parameters of systems

Local hydraulic resistance.

What is KMS? Bandwidth Kvs. What it is? Boiling water under pressure - what will happen? What is hysteresis in temperatures and pressures? What is infiltration? What are DN, Du and PN? Plumbers and engineers must know these parameters! Hydraulic meanings, concepts and calculation of heating system circuits. Flow coefficient in a single-pipe heating system. Hydraulic paradox in a heating system. Riddle No. 4 Video

Heating Automatic temperature control Simple replenishment of the heating system Heat engineering.

Walling. Warm water floor Combimix pump mixing unit Why choose underfloor heating? Water heated floor VALTEC. Video seminar Pipe for heated floors - what to choose? Warm water floor - theory, advantages and disadvantages Laying warm water floor - theory and rules Warm floors in a wooden house. Dry heated floor. Warm water floor cake - theory and calculation News for plumbers and engineers Plumbers Are you still doing hack work? The first results of the development of a new program with realistic three-dimensional graphics Thermal calculation program. The second result of the development of Teplo-Raschet 3D Program for thermal calculation of a house through enclosing structures Results of the development of a new program for hydraulic calculation Primary secondary rings of the heating system One pump for radiators and underfloor heating Calculation of heat loss at home - wall orientation? Regulatory documents

Regulatory requirements for the design of boiler houses Abbreviations

Terms and definitions

Basement, basement, floor Boiler houses

Documentary water supply

Sources of water supply Physical properties of natural water Chemical composition of natural water Bacterial contamination of water Requirements for water quality

Collection of questions

Is it possible to place a gas boiler room in the basement of a residential building ?

Is it possible to attach a boiler room to a residential building? Is it possible to place a gas boiler room on the roof of a residential building? How are boiler rooms classified according to their location? Personal experiences in hydraulics and heating engineering

Introduction and introduction.

Part 1 Hydraulic resistance of a thermostatic valve Hydraulic resistance of a filter flask Video course Calculation programs

Technotronic8 - Program for hydraulic and thermal calculations Auto-Snab 3D - Hydraulic calculation in three-dimensional space

Useful materials Useful literature

Hydrostatics and hydrodynamics

Problems in hydraulic calculations

Pressure loss along a straight section of a pipe How does head loss affect flow?

Miscellaneous

Do-it-yourself water supply for a private house Autonomous water supply Scheme of autonomous water supply Scheme of automatic water supply Scheme of water supply for a private house

Privacy Policy Answers to questions Client 1 Client 1. Boiler efficiency

How the choice of components for a heating system affects hydraulic calculations

The material from which the heating system pipes and fittings are made, as well as the technique for connecting them, has a significant impact on the hydraulic calculation.

Sergei Bulkin

Pipes with a smooth inner surface reduce friction losses during coolant movement. This gives us advantages - we use pipelines of smaller diameter and save on material. The energy costs required to operate the circulation pump are also reduced. You can use a pump of lower power, because... Due to less resistance in pipelines, less pressure is required.

At the “fitting-pipe” connections, depending on the method of their installation, there may be large losses, or, conversely, losses due to flow resistance when the coolant moves are minimized.

For example, if the “slide sleeve” joining technique is used, i.e. the end of the pipeline is flared and a fitting is inserted inside, then due to this there is no narrowing of the live cross-section. Accordingly: local resistance decreases and energy costs for water circulation decrease.

Characteristics of various equipment

Heating equipment is selected taking into account a set of various criteria. Among them, efficiency is important. For example, many believe that aluminum batteries, with the same power as cast iron ones, have higher efficiency. This is justified by the better thermal conductivity of non-ferrous metal. However, the material in production is used with impurities, which significantly reduce the performance. Let us consider in more detail the characteristics of individual samples.

Bimetallic

In practice, the heat transfer of bimetallic heating radiators is the highest.

Bimetallic sectional radiator Source klimatvspb.ru

Indicators typical for one section range from 140 to 180 W. In terms of design, such equipment is represented by steel contours with aluminum fins. The design pressure here is limited to 35 Atmospheres, the operational life is calculated at least 20 years.

Aluminum

The heat output of aluminum radiators can be in the range of 130-220.9 W, which is relevant for one section. The working material here is represented by silumin (an alloy of aluminum and silicon), which provides the batteries with good energy efficiency. But due to the relatively low mechanical strength of the metal, batteries can function properly at pressures within 10 Atmospheres. There are also restrictions regarding the acidity of the coolant and alkali content - the pH level should not exceed 7.5 units.

Ways to increase heat transfer

There are several ways to increase the heat transfer of heating devices:

- Regular wet cleaning to clean the surface of the batteries. The cleaner they are, the higher their level of heat transfer.

- Equally important is the correct painting of the radiator, especially for cast iron appliances. The fact is that multi-layer applied paint prevents effective heat transfer. Before you start painting the heating radiator, you should remove the old layer. No less effective is the use of special enamels intended for pipelines and heating devices, since they have low resistance to heat transfer.

- To ensure maximum power, these devices must be installed correctly.

- Among the main mistakes made during installation, experts note: – tilting the battery; – installing the device too close to the floor or wall; – blocking access to radiators with furnishings and installing inappropriate reflective screens.

- To increase the efficiency of heating batteries, it would not hurt to inspect their internal cavity. Often, in the process of connecting heating radiators to the system, burrs are formed, due to which, during operation, blockages are formed that prevent the free movement of the coolant.

- You can place a heat-reflecting screen made of foil material on the wall behind the heating device.