Hello to you, my reader! I dedicate this post to an interesting question that different people periodically ask me.

This question sounds like this: “I heard that you can connect a storage water heater to a double-circuit boiler and not buy an indirect heating boiler.

Is it true?" I will say right away that such a scheme exists. Let's figure out together why all this is needed.

Correct selection of a water heater with indirect heating

The indirect heating boiler (IBC) is a highly efficient device with modern automation systems for thermal processes, used to produce hot water T up to 65 C.

Externally, the BKN is similar to a traditional electric water heater, although its modern modifications have a more ergonomic rectangular shape.

The source of thermal energy is a heating boiler that runs on any energy source from waste to electrical energy.

The basic element is a steel or brass coil-type heat exchanger with a large heating area in a relatively small volume of a storage tank coated with a protective enamel layer.

To impart heat-storing functions to the battery tank, the outer surface of the structure is covered with a heat-insulating layer and an additional protective casing.

Before installing the BKN, it is necessary to correctly select it for the actual operating conditions: the source of heat supply and the volume of water use for DHW services.

Basic parameters for choosing a connection diagram for an indirect heating boiler:

- Working volume in liters. At the same time, the terms “total volume” and “working volume” are different, since the coil heat exchanger takes a certain part of the tank, so you need to choose according to the working indicator.

- External heating source, fuel type and coolant outlet temperature.

- Thermal power of an external source. The boiler must provide not only the heating load, but also DHW. So, to heat a volume of water of 200 liters, a reserve power of at least 40 kW will be required.

- Material of the working container: coated with enamel, glass ceramics and glass porcelain, stainless metal or heat-resistant plastic.

- Thermal insulation - to protect the BKN from heat losses, it is best if polyurethane is used as thermal insulation.

- Protection and regulation system.

Important Features

In addition to choosing the geometric and thermal characteristics of the BKN, it is necessary to take into account many parameters so that the thermal circuit for connecting an indirect heating boiler to a gas boiler is as efficient as possible.

To do this, the user must fulfill certain conditions:

- Choose the optimal location; experts say that the location of the BKN should be as close as possible to the boiler.

- To provide protection against thermal elongation of the structure, to do this, integrate a membrane hydraulic accumulator with a volume of 10% of the working volume of the boiler into the BKN circuit at the DHW outlet from the device.

- Before connecting the boiler, each supply/discharge line for the heating and heated medium is equipped with ball valves.

- To protect against backflow, a check valve is installed on tap water.

- Water purification is carried out with the installation of a filter before supplying tap water to the BKN.

- The installation of the BKN wall structure is carried out on permanent walls with preliminary treatment with fireproof materials.

- The installation of the BKN is carried out above the level of the boiler unit or at the same level as it.

Selecting tank volume

In the trading network today there are many offers for BKN devices, both domestic and foreign manufacturers, with containers of round and rectangular cross-section, floor and wall mounting. And if for electric heaters the most popular are models with a volume of 80 to 100 liters.

For BKN, more powerful options are used, ranging from 200 to 1500 hp. This is due to the fact that many owners use this design to create a storage tank in order to create a uniform load on the heat supply source at night. In this scheme, water for domestic hot water is heated at night and consumed during the day.

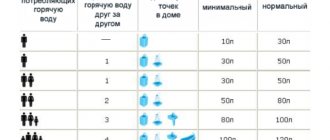

The size of the working tank is chosen taking into account the need to provide all family members with hot water. There is a formula for calculated water consumption.

In practice, the following data is often used:

- 2 users - 80 l;

- 3 users - 100 l;

- 4 users - 120 l;

- 5 users - 150 l.

The dimensions of the BKN are also important to consider during installation. For wall-mounted installations, installations with a tank working volume of up to 150 liters can be used, while larger sizes can only be installed with floor-mounted installations.

The installation site must have free access so that the piping can be properly completed and auxiliary equipment in the form of shut-off and control equipment, safety valves, air vents, pumps and a hydraulic accumulator can be placed.

Important Buyer Tips

The experience of specialists involved in the development of heating systems powered by natural gas and conducting tests, including in our climatic conditions, will allow you to make the right choice. Just follow the tips below:

- When purchasing a small-sized boiler, be sure to look at the lower power value. If it slightly exceeds the calculated value, then it is worth purchasing a thermostat in addition. It will save money on equipment operation in the long term, and will also significantly increase the service life by reducing the number of equipment starts.

- The heat exchanger is known to suffer from one serious ailment, the deposition of salts and lime. To avoid this, in conditions of “hard” water, you should take equipment with bithermic heat exchangers. If the water undergoes pre-treatment, the so-called “softening”, then it is better that the heat exchanger is separate; in the first case you will reduce the formation of lime, and in the second you will save money.

- In the case of spruce, the house area is large, and the consumption of hot water is also high due to the large number of points of its consumption, it would be more advisable to purchase such a wonderful thing as a boiler. In some double-circuit boilers it is already present, but if not, then it must be added. The boiler will allow you to increase the consumption of hot water several times, so you will not experience a shortage of it.

Information!

It is important to remember that gas boilers are mostly designed to work with a central gas pipeline, but if there is no such thing, and it is necessary for the equipment to operate on liquefied gas, then be sure to notify the seller during setup and installation, use only the services of a qualified specialist, not expose yourself and your loved ones to unnecessary risk

Also, if there is a need to connect such things as heated floors, ventilation and other third-party circuits to the boiler, it is important to entrust the calculations and selection of components to a specialist. When purchasing a boiler, you should take care of purchasing and installing an automated control system in your home. Automatic controls will not only more than pay for themselves in the long run, but will also significantly reduce the cost of heating premises

They work on the principle of adjusting and regulating the boiler power during daily operation. By purchasing an automated control system once, you can save about 20% on fuel, which will definitely affect your wallet.

The issue of heating a living space and providing hot water requires maximum responsibility and care. It is necessary to buy a wall-mounted gas double-circuit boiler with a boiler in specialized stores and centers with mandatory preliminary consultation. Otherwise, inattention and frivolity can lead to accidents and disastrous consequences. Only qualified specialists and consultants can guarantee the correct operation of such delicate equipment throughout its entire service life.

How does a boiler work in tandem with a boiler?

There are several schemes for connecting the BKN to a gas boiler. They depend on the type of boiler and its power, type of fuel and heating circuits. Before installing a water heater in the DHW circuit, you will need to choose the principle of its inclusion according to the supply coolant: with or without priority.

In the first option, a high-speed mode for water preparation in the storage heater is provided, when all the coolant from the boiler unit passes through the BKN coil. After reaching the set temperature of the hot water in the tank - 65 C, according to a signal from the thermostat, the coolant enters the intra-house heating system.

The second option is implemented by a separate heating circuit of the boiler unit, with a calculated flow rate of the heating medium through the BKN. It is not regulated in any way, works in the “open-closed” modes and does not affect the heating.

The difference between a double-circuit and single-circuit boiler

To implement heating systems in the house, single-circuit boilers are installed based on heat exchangers of various types.

But there is a method of combining the heating and water supply system in the house through another heating boiler - a much more functional one, called a double-circuit boiler.

The main difference between double-circuit boilers and single-circuit boilers is their ability to heat not only the coolant - water (while burning gas or other energy resources for which they are intended) for the heating system, but also supply it to the consumer for his own domestic needs, ensuring the process of water supply in the house . And usually for these purposes, double-circuit boilers are made automatic. The operation of such a boiler is monitored by automation (water heating and gas consumption sensors with microprocessors). As soon as the boiler receives a command to request water into the water supply system, it immediately switches its mode to this task from the heating system, since it is its priority - at a higher level.

The maximum temperature that can be set on a hot water boiler is + 60 degrees Celsius, otherwise the automation will work and burns are possible.

Wall-mounted gas boilers are the most widely used, since gas is the cheapest heating material and walls are best suited for their placement and use, although other varieties are not uncommon.

Boiler to boiler connection diagrams

Before connecting an indirect heating boiler, an executive connection diagram and installation parameters for the BKN are developed. They depend on the modification of the device, the boiler unit layout and the heating system in the household.

It is extremely important to choose not only the type of installation, but also the location of the BKN in relation to the boiler unit and installed pumps in order to ensure the efficiency of the heating system as a whole.

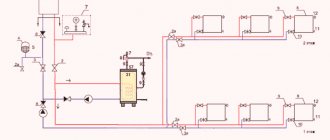

The most commonly used boiler connection kit is BKN for dual-circuit units and with three-way valves.

Piping with boiler water circulation pumps

A circuit with 2 electric circulation pumps is used for temporary heating of hot water supply, for example, during seasonal operation of the BKN and when used on weekends. In addition, this option is applicable when the DHW temperature is set lower than the coolant temperature at the boiler outlet.

It is performed with two pumping units, the first is placed on the supply pipe in front of the BKN, the second on the heating circuit. The circulation line is controlled by an electric pump through a temperature sensor.

Based on its electrical signal, the DHW pump will be turned on only when the temperature drops below the set size. There is no three-way valve in this version; the piping is performed using conventional mounting tees.

Connection with a non-volatile boiler unit

This scheme is used for a non-volatile boiler unit operating with natural coolant circulation, therefore, in order to ensure the required hydraulic mode, the coolant could circulate through the boiler unit and radiators in the rooms. This diagram is for wall modifications that allow installation at a level of 1 m from the “O” mark in the combustion chamber.

Floor-standing models in such a design will have low circulation and heating rates. A situation may arise that the required heating level cannot be achieved.

This scheme is used only for emergency modes when there is no electricity. In conventional energy-dependent modes, circulation electric pumps are installed in the circuit to ensure the required speed of coolant movement.

Trim with 3-way valve

This is the most common piping option, since it allows parallel operation of both heating and hot water. The circuit has a fairly simple design.

The BKN is installed next to the boiler unit; a circulation electric pump and a three-way valve are mounted on the supply line. Instead of one source, a group of boilers of the same type can be used.

The three-way valve functions as a mode switch and is controlled by a thermal relay. When the temperature in the tank decreases, the temperature sensor is triggered, sending an electrical signal to the three-way valve, after which it switches the direction of movement of the heating water from heating to DHW.

In essence, this is a BKN operating scheme with priority, ensuring rapid heating of the hot water supply when the radiators are completely turned off during this period. Once the temperature is reached, the three-way valve switches and the boiler water enters the heating system.

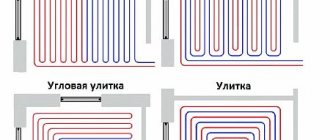

Scheme with recirculation line

Coolant recirculation is used when there is a circuit in which hot water must circulate all the time, for example, in a heated towel rail. This scheme has great advantages, since it does not allow water to stagnate in the pipes. The user of hot water services will not need to drain significant volumes of water down the drain in order for hot water to appear in the mixer. Consequently, recycling saves costs on water supply and hot water services.

Modern large BKN installations are supplied to the market with a built-in recirculation system, in other words, they are equipped with ready-made pipes for connecting a heated towel rail. Many people purchase an additional small tank for these purposes, connected to the main BKN through tees.

Is it possible to connect a boiler to a double-circuit boiler?

This option is carried out using a connection diagram for an indirect heating boiler with a hydraulic arrow for structures with a working volume exceeding 220 liters and multi-circuit heating schemes, for example, in a multi-storey building with a “warm floor” system.

Gidrostrelka is an innovative component of a modern intra-house heating system that simplifies the operation and repair of a water heater, since it is not necessary to install recirculation electric pumps on each heating line.

It increases the safety system, since it prevents the occurrence of water hammer, since it maintains equal pressure of the medium in the circuits of the double-circuit boiler unit.

What happens when the boiler is running?

The way it works is incredibly simple. Cold liquid enters the tank through the inlet, the coolant circulates along the coil or between the walls of the tanks, depending on the design of the unit, and brings the liquid to the desired temperature, and then maintains it in this state. The coolant is heated by heating equipment.

Boiler operation diagram

In addition, the design provides input and output pipes that provide supply to a gas or other boiler and directly to points of consumption. The thermostat controls the temperature of the coolant. As soon as it drops below normal, this device gives appropriate signals.

It is worth noting that if the flow rate does not exceed 1.3 l/min, then the installation of such a water heater and a single-circuit boiler is irrational. In this case, preference should be given to dual-circuit heating equipment. There is also no point in giving preference to this system if you use electric heating equipment that runs on energy from a diesel generator.

Connecting a boiler to a water supply system made of different materials

The boiler is connected to a heat supply system using both traditional steel pipes and more modern polypropylene and metal-plastic pipes. A cheaper option is polypropylene.

The choice will depend on the price of the project and the operating temperature of the heating fluid at the outlet of the boiler. For example, in a solid fuel boiler, the coolant temperature is difficult to regulate; there may be cases where it will spontaneously rise to 100 C, so in this case it is better to install steel pipes.

Although they are less durable, they are designed for the high temperature operating conditions of solid fuel devices.

Polypropylene pipelines

Polypropylene pipes are easily installed using a specialized soldering iron and scissors for cutting pipelines. After selecting the connection point, a section in the pipeline is cut out in width equal to the tee, with a deduction of 20 mm: 10 mm for each.

Using a soldering iron, heat the pipe and fitting to the required technical condition and connect them. At the same time, it is forbidden to scroll them, since this can disrupt the tightness of the connection.

Next, connecting parts of pipes of various lengths and angles, a connection is made to the BKN nozzles. A threaded coupling is soldered to the end of the pipe section and then the entire line is firmly connected.

Insertion into a metal pipeline

Today, it is possible to connect the BKN to water supply utilities without the use of welding; for this, there is a modern “vampire” adapter device, which has a technological hole and a clamp in the body. Installation of this design is very simple. Select a cutting point and clean the area.

A clamp with a heat-resistant gasket is installed on top of the prepared area and tightened with bolts to secure it. Next, turn off the water supply and drain it from the desired section of the pipeline by opening the hot water tap on the mixer.

Next, the pipe section is drilled through the hole in the clamp with an electric drill and then the valve is screwed on and the BKN piping is continued according to the diagram.

Metal-plastic

This is the most reliable and simplest option for connecting a BKN boiler to a double-circuit boiler. The metal-plastic material is simply bent to the desired outlet angle, and the connections of the nodes are made with various crimp fittings.

Before tying the BKN, the pipe is cut to the required length and size. Next, select the insertion point, taking into account the size of the tee and the part of the pipe that will be occupied by the connection.

To prepare a hole in a small area, special scissors are used. The nuts are removed from the tee and, together with the fixation rings, they are put on different ends of the pipe. Flare the ends of the metal-plastic using a special calibrator or screwdriver.

The tee is inserted all the way, then the rings are moved and the nuts are tightened with a wrench. You can also use fittings for metal-plastic pipes, which will require crimping and additional specialized tools and devices.

Types of boilers

In principle, indirect heating water heaters are divided into two categories: with and without a control unit. The first category applies when connecting to boilers without automatic control.

They are equipped with a water temperature sensor and an automatic system that blocks the flow of code from the boiler to the coil if necessary.

When connecting such installations, you only need to connect the supply and return pipelines, supply cooled water, and a distribution manifold to the upper connection. Then you need to fill the tank with water and start heating it. Water heaters without control are connected to boilers with automation.

When installing the boiler, you need to mount the temperature sensor into a special hole in the housing and connect it to the unit. Then the boiler is tied up. Such boilers can also be connected to boilers without automation, but for this you need to use special circuits.

Photo: astana.pulscen.kz

The water in the boiler reaches a lower temperature than the water in the coil, so if the boiler is running on low heat, the water in the tank will not be hot.

To get rid of this problem, they came up with combined boilers, which, in addition to the coil, have an electric heating element. The heating element brings the water temperature to the required temperature.

This type of boiler is convenient to use in conjunction with a solid fuel boiler, since the water will be warm even after complete combustion of the fuel. It is also possible to install several coils in the tank - this helps reduce heating time. For this purpose, thermally insulated models can be used.

Connecting the boiler to the electrical network

An indirect heating boiler does not use electricity for the main heating process. It is used in high-tech modern BKN devices for the operation of electronic control and protection systems.

Since the control unit requires low power to operate, the BKN device is connected through a regular socket equipped with a grounding contact.

In order to correctly connect the boiler to the electrical network, you will need an electrical diagram drawn up by specialists. It should provide that the cable is laid in a hidden way and connected to the nearest electrical box or directly to the electrical panel.

In a convenient place, install a two-pole 20 A circuit breaker in a protective plastic box, connect a cable to it with clamps, which goes to the furnace and can also be sent to a double-circuit gas boiler to power the automation system and circulation pump.

Materials and tools

Materials:

- Pipes, shut-off valves, check valves - there are no special requirements for them: use the same materials as for working with hot water supply or heating systems.

- Expansion tank - a separate one is required for the domestic water supply system; it serves to prevent sudden pressure changes when opening/closing taps.

Attention! The tank must be designed for use with hot water; usually such devices are marked with special markings. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater

Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate water in the DHW circuit.

This will eliminate the need to wait for hot water to arrive through long pipes from the installation site of the water heater: the water will immediately be hot.

- Wires and small electrical wiring - if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall installation, also for securing pipes and pumps.

- Standard plumbing set of sealants, seals, gaskets.

Tool:

- gas key;

- wrenches of various diameters;

- Adjustable wrench;

- building level;

- hammer drill, screwdrivers, screwdriver;

- Minimum electrician's kit: knife, wire cutters, electrical tape, phase tester.

Installation process: how to connect

Ideally, the boiler should be located as close as possible to the heating boiler to minimize heat loss.

Cold water is always supplied to the bottom pipe of the boiler, and hot water is drawn from the top.

- Choose a location for the water heater so that it is not in the way and is easy to maintain. Mount brackets, stands, and secure it to them.

- Connect to the cold water network: make a tap, install a shut-off valve and a coarse filter.

- Through a tee, take the cold water line to consumers, connect the second output to the boiler through a safety valve.

- Connect the domestic hot water line to the boiler, not forgetting about the expansion tank on it. In addition, install bypass taps so that you can disconnect it from the circuit during maintenance.

- Now connect the boiler to the gas boiler according to one of the given diagrams. Don't forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

Startup and testing

After installation, the first thing you need to do is connect and fill the boiler with cold water. Make sure that all air pockets are removed from the system and that the boiler is completely filled to avoid overheating.

When the boiler is full, set the desired temperature using automation. Start the boiler, open the coolant supply from the heating system to the boiler.

When the system reaches operating mode, make sure that the safety valve (usually set to 8 bar) is not leaking, i.e. there is no excess pressure in the system. You should also check all connections, seals and taps for leaks.