By giving preference to autonomous heating methods, homeowners want to solve the problem of heating an apartment or house once and for all. Independent heating not only provides optimal temperature conditions in residential premises, but also provides significant cost savings in the family budget. It’s up to you to decide which type of autonomous heating you prefer. First, let's get acquainted with the main existing home heating options, based on the energy they consume:

- Electrical devices.

- Solid fuel devices.

- Liquid fuel units.

- Gas appliances.

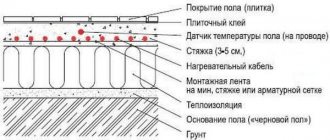

Each of the listed groups is divided into subgroups according to the installation method, the coolant used, the area of application, etc. But to this list of devices used as the main means of heating a home, it is necessary to add systems involved in the heating process as additional devices that increase comfort temperature conditions in the room. Such systems include so-called heated floors, electric and water.

Be sure to read: independent heating in the apartment.

Of particular interest in this regard is a water heated floor, operating from a gas boiler - an autonomous hot water generator. The system is relatively new, but has been sufficiently studied and is superior in efficiency to devices such as, for example, heated fans.

*

Connecting a heated floor

This work is carried out in a certain sequence:

- Choose a suitable place. As a rule, before connecting a heated floor to a gas boiler, a separate room is prepared for installing the unit - all the pipes from the collector and other engineering systems important for living in the house are assembled in it.

- The supply and return pipelines are inserted into the manifold. The return pipe will receive cold water and subsequently send it back to the boiler for heating, and the supply pipe, as its name implies, will direct the heated liquid to the floor heating system.

- Then the pipe of the unit is connected to the valve using the appropriate fitting, and then the collector inlet is connected to this valve.

- As in the case of connecting pipes to a collector, shut-off valves and thermostats should be installed at the inlet/outlet in order to ensure control and, if necessary, shut them off.

- In conclusion, all that remains is to test the equipped heat supply structure.

Before connecting the heated floor to the boiler, you need to make sure that the resulting screed has reached the required degree of drying.

It is necessary to carry out finishing measures only when the operability of the heat supply structure has been checked. If it functions reliably, you can begin installing the flooring and cleaning the room. If you do not follow these recommendations, there is a high probability of flooding of the room.

By the way, all diagrams for connecting heating units to heating systems are indicated in the technical documentation of heating equipment manufacturers. The attached documents and the recommendations contained therein should be carefully studied.

Results

So, what should you choose? The best option is a gas boiler for heated floors with condensing heat extraction technology. In all three respects, it occupies good positions. The situation is a little worse if you install a gas installation with a “warm floor” function. But, unfortunately, not everyone has the opportunity to connect to main gas. And then the easiest way to implement a water heated floor with an electric boiler. A small electric boiler can be installed to heat heated floors in utility rooms, for example, in a garage or in a country house: it is very easy to install. The next “quality” unit is a pellet unit, followed by liquid fuel. The most difficult task and high costs await when using solid fuel boilers for water floor heating.

Electric boiler installation

Installation of this equipment in a house does not require a chimney and approval from regulatory authorities. The only requirement is that the electrical wiring is in good working order. The connection diagram is quite simple. In addition to the boiler, it includes temperature sensors on the pipelines, a heating radiator, drain and shut-off valves, an expansion tank and a filter with a circulation pump. You will also need a voltage stabilizer, since electric boilers are sensitive to voltage drops, and they are inevitable in the electrical network.

When installing, you must try to isolate it from the water supply system so that if a pipe breaks, water does not enter the unit, causing a short circuit. The installation room must be thermally insulated to prevent the formation of condensation - it can also lead to serious damage. The boiler must be installed on a flat surface.

Connection

To connect equipment, couplings and adapters are used. First, you need to turn off the water supply in the water supply using ball valves. The connection is made in accordance with the installation diagram attached to the accompanying documentation. The circuit assumes the presence of grounding, installation of a circuit breaker, as well as an RCD for short circuit protection.

Cables must be installed in cable ducts, and the electrical part of the equipment is protected by a casing. The unit itself must be securely fastened. And only after that you can let water into the heating system and check the functionality of the equipment.

Advantages and disadvantages

pros:

- efficiency;

- efficiency;

- reliability;

- high quality work, possibility of self-installation.

Minuses:

- the need for coordination with Gosgortekhnadzor;

- possibility of gas leakage;

- the need to comply with the boiler installation conditions (separate equipped room);

- The gas supply is shut off automatically if there is poor ventilation or a leak.

The last disadvantage is also an advantage - the possibility of an accident is eliminated.

Types of coatings for water floors discussed on our website: under linoleum, under tiles, under laminate.

Technology for connecting a heated floor to a boiler

The boiler has five outputs (if the boiler is double-circuit, that is, for the heating and hot water supply system):

Outputs from left to right: 1 – hot water outlet from the boiler to the heating system (supply); 2 – exit from the boiler to the hot water supply system; 3 – gas supply; 4 – cold water inlet; 5 – return from the heating system.

When connecting a heated floor to the boiler, you should pay attention to the following (see photo)

All pipeline connections to the boiler are detachable: using union nuts and combination couplings. A ball valve is installed on each pipe.

A corrugated stainless pipe is used for gas supply.

Each boiler has a make-up tap (the blue lever of this tap is visible below) to feed/fill the heating system from the water supply system:

Replenishment is made by opening this tap, and then using the pressure gauge on the boiler panel we monitor the pressure in the system (1-1.5 atm.):

The following photo shows a safety unit consisting of an automatic air vent, valve and pressure gauge:

This block is installed for a floor-standing boiler (since we remember that wall-mounted boilers already have all this built-in).

Next in the photo is the connection of pipelines to a floor-standing boiler (this has already been discussed in the relevant articles on radiator heating, so here I do not go into detail about what is what in the image, yes, I think that everyone who tinkered with plumbing, pipes, etc. . personal belongings, he will understand everything without my chewing; however, I am giving a link to the section where you can read about connecting and piping boilers in more detail, in as many as three articles):

Return circulation pump:

- and between the pump and the boiler there is a ball valve and the expansion tank is visible (red):

And this is the “Signal” floor-standing boiler connected to the system:

From the boiler there is a chimney made of tin.

On wall-mounted boilers, a corrugated pipe is usually used:

The reason for the difference is that in floor-standing domestic boilers the temperature of the exhaust gases is high, and the corrugated air ducts cannot withstand it.

In general, the diagram for connecting the heated floor to the boiler (pipeline connection diagram) must be included in the boiler’s passport. And in order to connect everything correctly, you just need to carefully read the passport.

connecting a heated floor to the boiler

Types of heating equipment

On the modern market you can find many floor-standing units equipped with 2 types of burners: atmospheric (characterized by quiet operation, simple design and affordable cost) and forced or turbo (have higher efficiency, but are noticeably more expensive).

Gas floor-standing boilers are also single-circuit and double-circuit, and can often operate without electricity.

Non-volatile units

Non-volatile boilers can be chosen for use in areas where power outages occur regularly. In order for such a floor-standing gas boiler to function normally, there is no need for access to electricity, but there must be a nearby gas main.

The coolant circulation here is based on a natural cycle, which excludes the use of a pump, which obliges the user to use pipes with a minimum slope.

The most modern models of floor-type gas heating units are equipped with a “smart” system for monitoring the functioning of the system, which includes a safety valve, pressure gauge and air vent.

Important! If there is a need not only for heating the room, but also for heating and circulating hot water, then it would be advisable to connect a boiler and pump to a non-volatile boiler. .

Do-it-yourself installation and connection of a gas boiler and pump for heated floors

A standard boiler, powered by gas and used to supply hot water and heat rooms, has 5 terminals located sequentially from left to right:

- Output of hot water into the heating system.

- Output of hot water into the water supply system.

- Gas supply.

- Cold water inlet for heating and supply.

- Cold water inlet from heating (return).

The connections of all pipes with the heating element are detachable and installed using couplings and nuts.

The heating system is controlled separately from the water supply, which allows for independent connection.

Two pipes must fit into the boiler from the warm water floor manifold. One will supply cooled water, the other will supply hot water to the heating system.

The pump is included in most modern boilers. If it is missing, it must be installed in series with the collector and heater.

It is recommended to place the pump between the manifold return system and the pipe inlet to the boiler. It is possible to install separate pumps for each circuit.

Why is it needed?

The operation of a heated floor is based on the use of coolant energy. If there is no connection to the central heating network, the heating floor must be powered from its own boiler. Heating of the coolant during autonomous operation of the heated floor system can only be carried out in this way. Since gas is the most economical fuel, the cost of 1 kW of energy obtained from burning gas is several times cheaper than heating with electricity, then powering a water heated floor from your own gas boiler becomes the most preferred method.

Classification of solid fuel boilers

According to the principle of operation, solid fuel heating boilers are divided into three groups:

- Classic. They have a traditional design with a combustion chamber and a coolant tank. Very often they can operate on any type of solid fuel.

- Pyrolysis heat generators. Their distinctive feature is the presence of two combustion furnaces.

- Long burning boilers. In this case, the fuel burns gradually, so it is added 1 or 2 times a day.

Let's look at each category separately, consider the advantages and disadvantages of these boilers and hear advice from experts.

Wood boilers

But the advantages of this type of heating boilers do not end there. Such units can operate not only on wood and coal, but also on wood processing waste. And these are sawdust, stumps and so on. In addition, there is no need to connect the unit to an alternating current network, since it is a non-volatile unit.

ATMOS DC22S

And a little about the shortcomings. Boilers of this type can only be used in open heating systems with natural coolant circulation. There are no other options. In order to always have a comfortable temperature inside the premises, you will have to add fuel at intervals of at least 5–6 hours, which is not very convenient.

Let's add a couple more indicators. This type of heating units does not combine very well with automatic temperature control. Much depends on the fuel used. And if you change it for a short time, it will be difficult to adjust the temperature of the coolant even manually. After all, each type has its own indicator of the amount of heat generated. Therefore, my advice is to stock up on one type of fuel for the winter. This will make it easier to control the internal temperature of the premises.

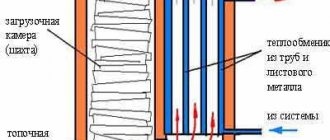

Pyrolysis heat generators

Let's say right away that this is a very efficient boiler. It got its name from the process of pyrolysis - when, for example, firewood does not burn with an open flame, but smolders, releasing gases saturated with thermal energy. Subsequently, these gases should simply burn. That is why such a unit has two fireboxes - the lower one, where the wood smolders, and the upper one, where the released gases burn. By the way, the lower firebox is closed with a minimum oxygen content, and the upper one is open, that is, with access to outside air.

Pyrolysis boilers

How does such a boiler work? Firewood is placed in the lower combustion chamber, where it smolders, releasing generator gas. The installation works especially well on wet wood - of course, the percentage of humidity must be within certain limits. After combustion, only charred firebrands remain in the firebox. But the gas, under the influence of high temperature, rises into the upper chamber, for which a special nozzle is provided. There it burns, heating the heat exchanger located in the second firebox. Heat is transferred from the fuel to the coolant only through an intermediary, which is the generator gases. And the last stage is the removal of waste combustion products through the chimney.

Long burning boilers

Long burning devices of the KW “Leader” series

Many experts believe that this type of heating equipment has every chance of becoming the most popular. The point here is that the fuel burns gradually due to the special design of the chimney and combustion chamber.

Air saturated with oxygen comes from outside through the interpipe channel, which is created in the chimney by two pipes inserted into each other. Combustion products are removed through the inner pipe, and a gap remains between the outer and inner pipes through which air enters the firebox. Oxygen comes into contact with the fuel and supports combustion of only its upper part.

For example, firewood stacked in a chamber does not burn completely, but only in the top layer. And until the entire bookmark burns, a lot of time will pass. This is where this type of heating unit gets its name.

Degree of autonomy

Requirements for the comfort of heating equipment are not the whims of spoiled consumers: not everyone has the opportunity to constantly monitor the operation of the heating system and add fuel. That’s why we consider this parameter first.

The highest degree of autonomy in . There is electricity - they work without human intervention. Moreover, after a power failure, they start working independently; many of them have “memory” and save settings. But there are three types of electric colas:

- on heating elements;

- electrode;

- induction

An electric boiler for underfloor heating with heating elements is a traditional solution. They just have one “disease” - heaters burn, and quite often. But their cost is average, and the technologies have been tested and proven; even a person who is not very good at communicating with technology can replace a burnt-out heating element. In general, a good (but not the best) option.

The most “independent” are solid fuel installations. You need to add fuel to them often, regularly remove ash and slag, and regulate the intensity of combustion. Of course I have, . The best models can work on one bed of coal for several days (up to 7 days for some models from the company). But there are also difficulties here: they are demanding on fuel (you need dry firewood or coal of a certain standard), and the price can also be a deterrent.

A solid fuel boiler for water heated floors requires constant human presence. Pyrolysis units and long-term combustion units require “refueling” two to three times less often

You can use a regular solid fuel boiler for a water heated floor, but you will have to spend a lot of time near the stove. Although there are already solid fuel units with automated supply. They are equipped with pellet-type bunkers and a screw feed. Only the requirements for the size and quality of fuel in them are no less stringent than those that run on pellets. But you can leave your home for a few days and not be afraid that the system will expand.

Fifth place for liquid fuel - it's not cheap. Operating costs also include the need to heat the fuel tank, or install the tank in a heated room. In addition, installations using diesel fuel require a boiler room. Moreover, it is better to build a boiler room at a decent distance from the house: the noise during operation of the burner is decent, and the smell is strong, and it penetrates everywhere.

It is generally accepted that the most expensive heating is electricity. But when using automated modern devices you have to pay only a little more than when using coal or firewood. So don’t discount electric boilers for heated floors. It’s just that for more economical heating, it is advisable for you to take a heating unit with the ability to adjust the power. In some traditional electric boilers, heating elements are assembled in groups, and automation, turning the groups on/off, regulates the operating power and saves energy. For heated floors, it is advisable to take a three-stage, or, in extreme cases, a two-stage unit. Induction and electrode boilers themselves are economical (if controlled electronically) and have low inertia, that is, they do not waste energy.

The second way to connect a heated floor to a solid fuel boiler

Another way to connect a heated floor to a solid fuel boiler is through a heat accumulator:

Essentially, a heat accumulator is the same hydraulic arrow, only very large. The heat accumulator in the diagram above is a large red tank with many outlets, giving it the appearance of an underwater mine. Such a heat accumulator can be made independently (if you know how to use a gas welder) from a large-volume tank, to which pipes with threads are welded to connect the supply and return from the boiler and from the heated floor, and from the boiler, etc.

In general, everything in the diagram is quite clear. If the electricity is turned off or the pumps stop for any other reason, the boiler will work to heat the coolant in this tank. The volume of such a tank is selected at the rate of 40 liters per 1 kW of boiler power. Of course, this can be problematic to implement due to the large volumes of the tank, but what can you do: the more coolant in the tank, the longer the boiler will heat it, the more peaceful you can sleep (especially if the boiler is solid fuel with automation).

Well, again, the pipes between the boiler and the battery are only steel and all slopes are observed - so that the coolant from the boiler flows into the battery without any pumps.

Instead of a homemade tank, you can install a factory-made indirect heating boiler of the appropriate volume.

The only drawback to installing an accumulator tank is the need to purchase such equipment. However, it is purchased once.

Using these schemes, you can make a heated floor from a solid fuel boiler, so, as we see, the lack of gas is not a death sentence for your heated floors.

connecting a heated floor to a solid fuel boiler

general information

A gas boiler is a device for heating water (coolant) using the combustion energy of natural gas or propane.

There are no specialized devices for heated floors, but there are models of boilers with the “warm floor” function , when turned on, the usual power limitation occurs, which is irrational.

A connection to a gas main or imported gas in cylinders is used, which significantly increases costs. Externally, a gas boiler looks like a small cabinet or wall cabinet; it usually has an attractive modern design (at least the new models). Thus, powering the heated floor in the house from the boiler is very convenient and efficient.

Features of connecting a heated floor to a boiler

The simultaneous operation of the boiler and underfloor heating can provide the home with the necessary amount of heat. Such a system will eliminate the use of other types of boilers, for example, electric.

a collector device, which is designed to uniformly distribute the heated working medium to consumers connected to the boiler and, due to the circulation of the working fluid, it returns through it for heating.

After choosing a collector, it needs to be connected to the boiler. To perform this operation, you must strictly follow the instructions in the operating instructions for both units.

Specifications

Familiarization with the technical characteristics of a gas boiler allows you to quickly and fairly fully learn all its properties and capabilities.

Main indicators reflected in the technical characteristics of the device:

- boiler power;

- type of combustion chamber (open or closed);

- number of circuits (one or two);

- heating area (maximum, usually the upper limit of distribution is indicated);

- volume of fuel (gas) used;

- water consumption, ability to heat it. (2.5-17 l/min on average, there are also more productive models);

- Device efficiency (usually within 80-90%).

Pumping and mixing unit for the boiler: combining radiators and heated floors

And we will have the most ordinary heating radiators - with hot water inside. To reduce the costs associated with the operation of combined systems, you can install the same radiators only where there is a real need for them: in storerooms and in some other technical premises they are not needed.

with your own hands

It is noteworthy that pipes for distribution are chosen with a small cross-section - 20 mm is best. It is reliable and economical. You can also select a mixing valve from the assortment of three-way models that does not automatically maintain the set temperature. Each consumer makes the final choice of a heating boiler, radiators, pipes for connecting them and for heated floors, as well as the wiring diagram, taking into account many factors.

This reduces the comfort and efficiency of the system. Radiators and heated floors - joint work, as ensured, regulated Radiators and heated floors - joint work, as ensured, regulated In houses, it is recommended to create a combined heating system - radiators with heated floors. The disadvantage is low comfort. During the coldest weeks, the heating output at normal temperatures will not be sufficient. When forming an autonomous heating system, it is possible to independently regulate the set temperature.

And if parasitic circulation through the radiator circuit can be dealt with by installing a check valve at point A towards the radiators, then parasitic circulation through the boiler cannot be dealt with.

Additionally, the heating is equipped with pumps for forced circulation of the coolant. Water or electric floor - which is better? Unresistant to corrosion and susceptible to water hammer. The main issue is the cost of the systems. There is such a high probability. 14-Heating, underfloor heating and radiators Date: September 25, 2022

Water system

A water heated floor is a dense (10-30 cm between adjacent pipes) mesh or, more precisely, a spiral-shaped system of thin (15-20 mm) pipes located in the thickness of the concrete screed or without it under the floor covering. The coolant circulating through them transfers heat to the floor surface, which, in turn, radiates it into the interior of the room.

The density and large area of placement of the pipes (or circuits) of the heated floor allows you to do without reaching high coolant temperatures - 45-50 degrees is enough. The uniformity of pipe laying makes the heating dense, there are no colder areas. The warm floor is comfortable for contact and pleasant to walk on barefoot.

This convenience results in the need for precise temperature control, since the radiation power is such that an increase or decrease of several degrees is perceived as a significant change in the operating mode of the system.

The temperature of the coolant in the supply line is much higher than required. If you put such a hot coolant directly into the circuits, the room will become hot like a sauna. To prevent this from happening, the hot coolant is diluted with coolant that has cooled down, passed through the circuits and given up its energy - the return.

This dilution is done in a mixing unit, which limits the flow of hot water from the direct pipeline and simultaneously mixes it with the return one. By adjusting the amount of hot and cooled water, the desired temperature of the heated floor is achieved.

If the system is powered from its own boiler, then the dependence on networks (and their tariffs) is removed. The ability to independently prepare the coolant is a very valuable circumstance that ensures the operation of the system independent of external factors. For a frame house, such independence can result in considerable savings, since the ability to connect is not always available, and it is very expensive.

Read about the installation of water heated floors in this article.

conclusions

Using a gas boiler to power a water-heated floor in a frame house provides an effective and economical way to prepare the coolant. The costs in this case are the lowest compared to any other type of boiler, in addition, the operation of the heated floor is seasonal, which provides additional opportunities for saving money.

The ability to start the system at any time at will, relative heating autonomy, preparation of coolant with simultaneous heating of hot water are important advantages of gas boilers that provide the comfort and coziness of a frame house.