To calculate the parameters required when designing a home heating system, there are special programs and calculators, including on-line ones. I prefer the Valtec heating system calculation program. It has all the necessary tools to determine the heat losses of the house and the hydraulic resistance of the system.

Before we start calculating the heating system, let's get acquainted with the capabilities of the Valtec program.

Unpack the downloaded archive with the program. You will have a folder that you need to go into and run the program by double-clicking on the icon:

1. Program icon for calculating the heating system.

The program's working window will open immediately, since the program does not require installation:

2. Program window for calculating the heating system.

So what can you do with Valtec?

Calculations and software for plumbing engineering VALTEC

Calculation of hydraulic and thermal parameters of engineering systems is a very responsible job. Any of the mistakes made during its implementation may result in the inability of the equipment to provide comfortable use and the need for a major rework of the system. At the same time, the times of mass application of standard projects are in the past, and the designer each time has to deal with solving a unique problem. VALTEC specialists are developing tools to avoid labor-intensive manual calculations of engineering systems or to make them as easy as possible.

VALTEC.PRG.3.1.3. Program for thermal and hydraulic calculations

The VALTEC.PRG program is publicly available and makes it possible to calculate water radiator, floor and wall heating, determine the heat demand of premises, the required flow of cold and hot water, the volume of sewage, and obtain hydraulic calculations of the internal heating and water supply networks of the facility. In addition, the user has a conveniently arranged selection of reference materials at his disposal. Thanks to its clear interface, you can master the program even without having the qualifications of a design engineer. The program meets the requirements of Russian regulatory documents governing the design and installation of engineering systems (certificate of conformity).

Training videos:

TOP 6 professional programs

Such software is suitable for builders, engineers, pipe laying and other communications specialists.

HERZ CO

This is the main graphic editor for creating designs for hydraulic equipment and two-pipe heating and cooling systems.

you can from the official website.

Advantages and disadvantages

selection of pipeline diameters;

water flow analysis;

water flow analysis;

selection of settings for the regulator of intermediate pressure indicators;

calculation of the required authorities of thermostatic valves;

preliminary assessment of configured valves that reduce excess pressure;

displaying data in graphical form;

entering information on objects into tables created in the Hertz assistant;

reflection of entered values in the help system;

automatic identification of areas with a connected pipeline, heating devices, fittings, indicating the area of the room.

Herz is only suitable for creating heating schemes without taking into account other room parameters.

RAUCAD/Rauwin 7.0

Provides modular design through a single database.

and you can get acquainted with the training material on the official website.

Availability of the Rauwin tabular module, created for thermotechnical calculation of external fences, flooring and thermal power of the heating system, selection of a heating device of the Rehau brand.

Advantages and disadvantages

arbitrary calculation of the internal heating system with water supply and drainage;

works on AutoCAD® with the basic graphical symbol GOST;

wide functionality: project management, drawing up orders for commercial proposals;

a clear interface for creating models of pipeline heating networks in 2D and 3D;

generating diagrams, making drawings using tables and providing graphical data;

calculation of water supply projects;

distribution of eliminations in a stagnant zone, dangerous from the point of view of a possible increase in the number of bacteria.

it will be difficult for beginners to understand the requirements and settings;

the software is not suitable for older models of PCs and laptops;

The program is adapted only for Rehau products.

Video: how to calculate a warm water floor in the RAUCAD/Rauwin 7.0 program.

Valtec “Sputnik” software package

The Valtec “Sputnik” software package is intended for use in the housing and communal services sector (management companies, homeowners' associations) and industry. The intuitive interface makes it easy for users to quickly learn. A number of special reports for management companies (homeowners associations, resource supply organizations) and integration with accounting programs (1C) make it easy to generate payment receipts. The control center includes reports that allow you to track emergency situations, unauthorized access to resources, and requests from subscribers from your personal account.

Integration into the Housing and Public Utilities GIS has been introduced to simplify reporting in organizations.

To familiarize yourself with the program's capabilities: Login: demo Password: demo

In the case of a comprehensive supply of metering devices and dispatch systems, a license file that allows you to fully work with the program is issued free of charge. The server is formed on the customer's side.

As an additional paid service, it is possible to use a Valtec remote cloud server.

For commissioning, commissioning of a facility or testing of dispatch system equipment, a free test license file valid for 1 month is provided.

For details on obtaining a test license, please contact the managers working in your region.

Source

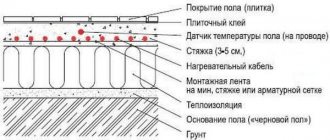

Installation technology for water heated floors

The most common way to implement underfloor heating systems is monolithic concrete floors, made by the so-called “wet” method. The floor structure is a “layer cake” made of various materials (Fig. 1).

Installation of a heated floor system begins with preparing the surface for installation of a heated floor. The surface must be level, unevenness in area should not exceed ±5 mm. Irregularities and protrusions of no more than 10 mm are allowed. If necessary, the surface is leveled with an additional screed. Failure to comply with this requirement may lead to air-filling of the pipes. If there is high humidity in the room below, it is advisable to install waterproofing (polyethylene film).

After leveling the surface, it is necessary to lay a damper tape at least 5 mm wide along the side walls to compensate for the thermal expansion of the heated floor monolith. It must be laid along all walls framing the room, racks, door frames, bends, etc. The tape should protrude above the planned height of the floor structure by at least 20 mm.

Pipe layout

It is carried out with a certain step and in the required configuration. It is recommended that the supply pipeline should be laid closer to the outer walls.

When laying a “single coil” (Fig. 2), the temperature distribution of the floor surface is not uniform.

When laying spirally (Fig. 3), pipes with opposite flow directions alternate, with the hottest section of the pipe adjacent to the coldest. This leads to an even temperature distribution over the floor surface.

After laying out the loops, immediately before pouring the screed, the system is pressure tested at a pressure of 1.5 of the working pressure, but not less than 0.3 MPa.

The system is started only after the concrete has completely dried (approximately 4 days per 1 cm of screed thickness). The water temperature when starting the system should be room temperature. After starting the system, increase the supply water temperature daily by 5°C to operating temperature.

Set of water heated floors for 15 m 2

Heated floor kit for heating rooms with an area of 15-20 m2 with a mixing unit with manual adjustment of the coolant temperature based on the mixing and separating valve MIX 03. The operating temperature of the coolant is adjusted manually by turning the valve handle.

When laying a heated floor loop in a spiral (screed thickness 3 cm with a ceramic tile floor covering) in increments of 15-20 cm and an estimated coolant temperature of 30°C, the floor surface temperature is 24-26°C, coolant flow is about 0.2 m 3 / h, flow speed 0.2-0.5 m/s, pressure loss in the loop approximately 5 kPa (0.5 m).

Avito Fryazino rent 2 room apartment

Accurate calculations of thermal and hydraulic parameters can be carried out using the free underfloor heating calculation program Valtec Prog.

General information on the calculation results

- Total heat flow - The amount of heat released into the room. If the heat flow is less than the heat loss of the room, additional heat sources are needed, for example, wall radiators.

- Heat flow in the upward direction - The amount of heat released into the room from 1 square meter of area in the upward direction.

- Heat flow in the downward direction - The amount of heat that is “lost” and not involved in heating the room. To reduce this parameter, it is necessary to select the most effective thermal insulation under the TP* (*warm floor) pipes.

- C total specific heat flow - The total amount of heat generated by the heating system system from 1 square meter.

- Total heat flow per linear meter - The total amount of heat generated by the TP system from 1 linear meter of pipe.

- C average coolant temperature - The average value between the calculated coolant temperature of the supply pipeline and the calculated coolant temperature of the return pipeline.

- Maximum floor temperature – The maximum temperature of the floor surface along the axis of the heating element.

- M minimum floor temperature – Minimum temperature of the floor surface along the axis between the TP pipes.

- Average floor temperature – Too high a value of this parameter can be uncomfortable for a person (standardized by SP 60.13330.2012). To reduce this parameter, it is necessary to increase the pipe pitch, reduce the temperature of the coolant, or increase the thickness of the layers above the pipes.

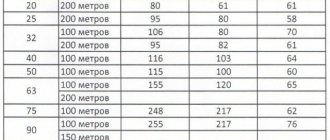

- Pipe length – The total length of the TP pipe, taking into account the length of the supply line. With a high value of this parameter, the calculator will calculate the optimal number of loops and their length.

- Thermal load on the pipe - The total amount of thermal energy received from thermal energy sources, equal to the sum of the heat consumption of thermal energy receivers and losses in heating networks per unit time.

- Coolant consumption - Mass quantity of coolant intended to supply the required amount of heat to the room per unit of time.

- With the speed of movement of the coolant - The higher the speed of movement of the coolant, the higher the hydraulic resistance of the pipeline, as well as the level of noise created by the coolant. Recommended value is from 0.15 to 1m/s. This parameter can be reduced by increasing the internal diameter of the pipe.

- Linear pressure loss - A reduction in pressure along the length of a pipeline caused by the viscosity of the liquid and the roughness of the internal walls of the pipe. Without taking into account local pressure losses. The value should not exceed 20000Pa. Can be reduced by increasing the internal diameter of the pipe.

- About the total volume of coolant - The total amount of liquid to fill the internal volume of the pipes of the TP system.

Warm floor (water heated floor)

Water underfloor heating is becoming increasingly popular because it has a number of advantages and is more energy efficient than traditional radiator systems. Since heat in this case is transferred by radiation from the heated surface, there are practically no convective flows. The vertical distribution of heat from floor to ceiling does not allow the upper areas of the room to overheat, which significantly reduces heat loss through the roof and upper parts of the walls and creates optimally comfortable temperature conditions for people in the room. Savings from using water heated floors can reach 10–30%. This is possible due to a decrease in the average air temperature in the room by 2 °C and the heating temperature of the coolant to 30–45 °C. In addition, low-temperature heating systems (warm floors) have a pronounced self-regulating effect, that is, heat transfer from the floor surface stops when the temperature in the room, as a result of external influences (the sun comes out), reaches the temperature of the floor surface. At the same time, heat transfer increases when the room temperature decreases. Radiators work on the same principle, but the temperature difference between the air in the room and the surface of the radiators is so great that the self-regulation effect practically disappears.

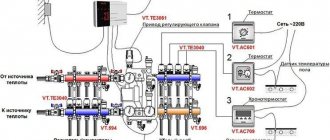

VALTEC supplies the Russian market with a wide range of high-quality products, allowing the implementation of underfloor heating systems of any complexity. This is a metal-polymer pipe, reliable crimp and press fittings, manifold blocks, pumping and mixing units, as well as automation that ensures a given level of comfort in the premises. For specialists, an Album of standard water heating schemes for residential buildings has been developed, which contains various options for organizing single- and multi-circuit systems, as well as a software package for calculating elements of VALTEC engineering systems. The VALTEC.PRG program makes it possible to determine the heat demand of premises and correctly determine the thermal and hydraulic parameters of underfloor heating.

VALTEC's comprehensive approach to underfloor heating systems guarantees their efficiency, optimal cost and long-term trouble-free operation.

Tools in the Valtec Main Menu

Valtec, like any other program, has a main menu at the top.

We click on the “File” button and in the submenu that opens we see standard tools known to any computer user from other programs:

Next: “Tools” - “Calculator”:

— the “Calculator” program built into Windows is launched to perform calculations:

Using the "Converter" we will convert one unit of measurement to another:

There are three columns here:

On the far left we select the physical quantity we are working with, for example, pressure. In the middle column is the unit from which you need to convert (for example, Pascals - Pa), and in the right column - into which you need to convert (for example, to technical atmospheres). In the upper left corner of the calculator there are two lines, in the upper one we will enter the value obtained during the calculations, and in the lower one we will immediately display the conversion to the required units of measurement... But we’ll talk about all this in due time, when it comes to practice.

In the meantime, we continue to get acquainted with the “Tools” menu. "Form generator":

This is necessary for designers carrying out custom projects. If we do heating only in our house, then we don’t need the “Form Generator”.

The next button in the main menu of the Valtec program is “Styles”:

It controls the appearance of the program window - it adapts it to the software that is installed on your computer. For me, this is an unnecessary gadget, because I am one of those for whom the main thing is not “checkers”, but getting there. And you decide for yourself.

Next in the main menu is the “Help” button:

Let's take a closer look at the tools located under this button.

In “Climatology” we select the construction area:

Heat loss in a house depends not only on the materials of the walls and other structures, but also on the climate of the area where the building is located. Consequently, the requirements for the heating system depend on the climate.

In the left column we find the area in which we live (republic, region, region, city). If our settlement is not here, then choose the nearest one.

"Materials". Here are the parameters of different building materials used in house designs. That is why, when collecting initial data (see previous materials on design), we listed the materials of walls, floors, and ceilings:

Openings tool. Here is information on door and window openings:

"Pipes". Here you can find information about the parameters of pipes used in heating systems: internal and external dimensions, resistance coefficients, roughness of internal surfaces:

We will need this for hydraulic calculations - to determine the power of the circulation pump.

"Coolants". Actually, there is nothing here except the characteristics of those coolants that can be poured into the heating system of a house:

These characteristics are heat capacity, density, viscosity.

Water is not always used as a coolant; it happens that antifreeze, popularly called “anti-freeze,” is poured into the system. We’ll talk about choosing a coolant in a separate article.

“Consumers” are not needed to calculate the heating system, since this tool is for calculating water supply systems:

"KMR" (local resistance coefficients):

Any heating device (radiator, valve, thermostat, etc.) creates resistance to the movement of the coolant, and these resistances must be taken into account in order to correctly select the power of the circulation pump.

"DIN devices". This, like “Consumers”, applies more to water supply systems:

Valtec water-heated floor: there are answers to all questions

Everyone who started building a new home was faced with the problem of choice. First, it is the choice of project, design, construction organization, then - materials, technologies, etc. Wanting to help readers choose a heating system, we talked with the head of the “Water Heated Floor” department at VALTEC, Sergei Piskarev.

First of all, VALTEC is known as a manufacturer of pipes and fittings for internal engineering systems. Why have underfloor heating systems become one of the priority areas of its development since 2010? – Any business needs development. The slightest downtime is a step back. But it is also necessary to move in a promising and sought-after direction. After analyzing the market situation and assessing our capabilities, we came to the decision that water heated floors are exactly what we need. VALTEC specialists have been working on such systems for a long time. We already had most of the equipment necessary for their installation. And market research has shown that in the future this technology may be in great demand. Although many users still do not know about the benefits of underfloor heating and use only radiators the old fashioned way.

What are these advantages? - There are quite a lot of them. First of all, comfort. Unlike traditional convective-type heating devices (radiators), underfloor heating transfers heat mainly by radiation, and it is distributed evenly throughout the room; there are no areas of local overheating or insufficiently heated areas. At the same time, the air temperature gradually decreases from floor to ceiling, and for the human body such conditions are closest to optimal. It is also necessary to note such advantages of “warm floors” as energy efficiency, aesthetics, and hygiene.

You said that water underfloor heating is an energy efficient system. How is this ensured? – Energy savings when using a water-heated floor system can be very significant. The fact is that the temperature of the coolant entering the heated floor pipes is only 35–50 °C, which reduces energy costs for heating. In this case, you can use a low-temperature condensing boiler with increased efficiency. The vertical distribution of heat from floor to ceiling does not allow the upper areas of the room to overheat, therefore heat loss through the roof and upper parts of the walls is reduced. Because heat is distributed evenly throughout the room, the average room temperature can be lowered by 2°C without changing how warm a person feels, resulting in energy savings of 10–20%. And this is with a standard ceiling height of 3 m. If we use heated floors in a room with high ceilings, where there is no need to heat the upper layers of air, the savings are 30% or more. At the same time, the effect of self-regulation of water heated floors plays an important role in savings, that is, the system itself reacts to temperature changes in the room, changing the power of the heat flow. For example, imagine that the sun came out and the air in the room warmed up by 2–4°C. In this case, the heat transfer of the heated floor spontaneously decreases by 36–70%.

roof rack honda stream rn1

What are the aesthetics and hygiene of a “warm floor”? – All elements of the system are securely hidden under the floor covering, which, you see, is better suited for modern interiors than pipes protruding from the floor and walls. This becomes especially important when using panoramic windows in construction - from floor to ceiling. And radiators don’t fit very well into a retro interior. Since heat is transferred not by convection, but by radiation, there is practically no circulation of dust and microorganisms in the air of the room. This feature of underfloor heating is perfect for allergy sufferers. In addition, unlike electric heated floors, water floor heating does not create electromagnetic fields. Plus, underfloor heating eliminates the possibility of child injury, and in some cases, such as when building a gym, it is the safest solution.

Tell me, what pitfalls can a cottage owner expect if he decides to use a water underfloor heating system? – The main thing is to make the right choice in favor of one manufacturer or another and not to make a mistake with the installation organization, or rather, with the qualifications of its specialists. Illiterate installation can negate the benefits of even the most advanced equipment. That's why we pay a lot of attention to installer training. Every month our specialists visit partners in various regions of Russia and other CIS countries, conduct seminars, and answer questions from practitioners. Anyone can sign up for the seminars, which are held every Friday at the VALTEC office. In addition, VALTEC has published a large amount of technical literature and developed a computer program for accurate calculation of the system. Like other VALTEC products, underfloor heating components come with a 7-year manufacturer's warranty.

Source

Simple layout

We save material - we save time - we get an accurate layout

. I used the program myself and, thanks to it, I performed all the calculations myself, purchased everything and was not disappointed - even in the demo version, I printed the results via a screenshot, wound everything up and everything works - I’m very pleased. Thank you.

From a conversation on an online forum

They ask us questions

Good afternoon Will the program continue to live? People on the forumhouse are worried. It was possible to draw all the loops, albeit approximated, but without studying any compasses, autocads, etc. I drew a 300 square meter 3-level house for myself, made the purchase, installed everything, I’m just delighted with the program

From a user letter

Builders are looking for

You need a simple program in which you can calculate the length of TP loops. I don't need heat loss calculations. You just need to decide how many loops to make and how much pipe to take. What is recommended on the Internet either does not download or does not run for me. A huge request, send me an email or give me a link to the working program!

In many apartments today, water-heated floors are installed for reasons of economy. The heating supply temperature in these systems is much lower than when using radiators. Before you design and plan a heating system, it is necessary to determine the heat energy requirements, power and load to heat each room in the building. To calculate a water heated floor according to the program, you need to decide on the parameters of the future coating.