In our cold climate it is physically impossible to live without full-fledged heating radiators. There are different radiators - steel, cast iron, aluminum and bimetallic. But if we take into account the low cost and durability of operation, then the leaders in this list are cast iron and aluminum radiators, which can be freely purchased at almost any plumbing store.

Design, principle of operation of aluminum radiators

Aluminum radiators are a complex-shaped structure based on aluminum tubes through which coolant flows from the heating system. Heat transfer plates are attached to the tubes. The shape allows the thermal energy received from the system to be radiated and heat to be transferred by air convection between the radiator plates.

Calling home heating batteries aluminum is not entirely correct; they are made not of pure metal, but of an alloy with a number of substances. The most common component is silicon.

Batteries for apartment and house heating systems made of aluminum alloy are made in two ways:

- Casting is a complex, labor-intensive method. Batteries are more expensive, but of better quality. The service life of the system is at least 15 years.

- Extrusion. The method is reminiscent of squeezing cream from a culinary cone into a mold. It is technologically simpler and therefore is used by manufacturers from Far Eastern countries. Heating batteries are quite cheap and look little different from injection molded ones. The downside is the poor quality of the walls and seams. The service life of batteries as part of the heating system does not exceed 10 years. They often fail after 2-3 heating seasons.

Some manufacturers apply electrochemical anodizing to the inner walls of radiators. Radiators are less susceptible to corrosion, the amount of hydrogen released from water is reduced (the anti-air vent cannot be excluded from the battery piping).

The number of sections made of aluminum alloys is usually even. They are connected by nipple adapters and integrated into the heating system using threaded connections. The flow of water is somewhat difficult. There are completely cast non-dismountable battery models. The number of sections cannot be changed. They are distinguished by a smooth inner surface, which simplifies the flow of coolant from the apartment or home heating system (often anodized).

Home heating battery made of aluminum alloys FONDITAL CALIDOR 500-100 B4

Heating system as a criterion for choosing the type of batteries

To find out which is better: aluminum or cast iron radiators, you must first decide on the heating system. Aluminum radiators are fundamentally not suitable for installation in central heating systems. There are several reasons for this:

- poor resistance to water hammer;

- high sensitivity to the chemical composition of the coolant;

- poor resistance to abrasive wear, which occurs due to the presence of impurities in the coolant;

- The passage channels of the aluminum battery have a small cross-sectional diameter and quickly become clogged when using contaminated coolant.

Taking these factors into account, aluminum batteries can only be used in autonomous heating systems, where clean water is used as a coolant and there is no excess pressure or water hammer.

A significant advantage of cast iron radiators over aluminum ones is that they can be used in difficult conditions. High-quality cast iron batteries operate as part of centralized heating systems for 50 years or more. There are no fundamental restrictions on their use as part of autonomous systems. However, how effectively will they work in this case?

Design and principle of operation of cast iron radiators

Radiators have a simple design that has been proven over many decades. Cast from gray cast iron. The internal clearances are large. The flow of water inside is not impeded, even with significant contamination.

Separate sections of cast iron heating radiators are connected by fasteners. To prevent leaks, they are sealed with heat-resistant rubber gaskets. A common design is the MC type. Collapsible, available in different sizes. Rare - solid cast. More often these are designer expensive models.

The internal volume of cast iron heating devices exceeds the volume of aluminum structures. This slows down complete heating and prolongs the period of heat release in the event of a central heating system shutdown. Cast iron is less thermally conductive. Advantageous features are chemical inertness, resistance to corrosion, and temperature changes in the system.

When properly connected to the system, cast iron house central heating batteries will last a long time, without repair or replacement of parts.

Unlike aluminum, cast iron can withstand freezing of the coolant. With careful, competent defrosting of the system there will be no consequences.

Cast iron, aluminum models

How to make the right choice

Knowing the strengths and weaknesses of central heating in an apartment or house, as well as the advantages and disadvantages of steel and aluminum batteries, you can make the best choice.

The following parameters are also taken into account:

- For all radiators, the pressure declared by the manufacturer must exceed the working pressure inside the system by at least one and a half times. If you do not make a reserve, the risk of ruptures during operation will increase, and this is very dangerous.

- The ability to withstand water hammer is very important. It is impossible to protect yourself 100% from pressure changes in an apartment, but it is easy to prevent trouble from occurring. If there are regular clicks and hums inside the heating radiators, you will need to contact the utility services in charge of the house - something is wrong in the system, and it is difficult to predict in advance when everything will fail.

- The quality of water in urban heating systems is low, and the materials used to manufacture radiators must withstand contact with aggressive substances without breaking down. It is optional to use radiators with a special coating on the inside or chemically neutral walls. The thickness should be such that small stones and sand particles do not rub the material like sandpaper.

- The main function of any battery is to heat. That is, it is better to choose those heating radiators that have maximum heat output.

- Design matters too. The scary cast iron monsters of the old generation do not fit very harmoniously into modern interior designs.

The last thing is the service life of the product. It is desirable that it be maximum and that the battery be maintenance-free.

Since heating radiators are installed for many years, every moment must be taken into account

Advantages and disadvantages of aluminum models

Advantages of aluminum radiators:

- Light weight.

- Easy to install.

- Large thermal power.

- Low temperature inertia in the system.

- Design.

- Large selection of models.

Negative characteristics:

- High cost compared to cast iron.

- Low chemical resistance.

- Short service life.

- Instability to mechanical stress.

- Fast cooling.

- Demanding pressure conditions in a home heating system.

- Inability to resist corrosion and mechanical wear.

- Installation of additional devices to ensure battery operation.

Aluminum radiators have more negative characteristics than positive ones.

Durability of heating devices (comparative table)

Main differences between batteries

There are two types of pressure in heating plants:

- Working.

- Crimping.

The latter always has higher rates. For aluminum radiators, the operating pressure is considered to be up to 16 atmospheres, which corresponds to the performance indicators in heating networks. Sometimes the pressure can reach up to 28 atmospheres, which is a critical value for aluminum radiators. Experts do not recommend using them in apartment buildings. Not only because of the pressure, but also because of the characteristics of the coolant. In private households, the pressure in the boiler usually does not exceed 1.5 atmospheres, so aluminum radiators are more preferable.

Crimping pressure is more relevant, it is necessary to know about its existence. Before the start of the heating season, it is recommended to test the tightness of the entire system. In professional language this process is called: crimping. That is, at a higher pressure (1.5-2 times) water will be driven through the radiators.

In private homes, the pressure in the heating system is objectively lower. In multi-story buildings, for water to rise to a height of ten meters (a three-story building), a pressure of one atmosphere is required.

Utility services do not always adhere to GOST standards; sometimes the pressure “jumps” in large ranges, so it is better to buy batteries with a reserve

Manufacturers often indicate different units of measurement in performance characteristics. One bar corresponds to one atmosphere; if the calculation is in megapascals, then in order to convert them into familiar atmospheres, you need to multiply by a factor of 10. Example: 1.3 megapascals corresponds to 13 atmospheres.

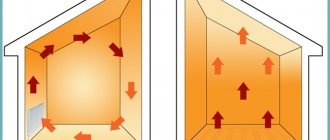

Half of the heat that aluminum radiators give off is so-called heat rays. The rest of the heat is convection currents, they are generated when air masses move from bottom to top. This design effectively increases heat transfer.

Heat dissipation is measured in watts; for an aluminum battery with an axis up to half a meter, the heat dissipation can be up to 155 watts. Aluminum batteries have high heat transfer; in this indicator they are ahead of cast iron ones.

Cast iron radiators largely depend on the battery model. During the Soviet Union, cast iron batteries occupied up to 90% of the market, and the P140 design was especially popular.

- The power of such a product ranged from 0.122 to 0.165.

- Average weight is within 7.5 kg.

- Surface area 0.25 sq. meters

- Functional pressure 9.2 atm.

In order for the room to have an acceptable temperature in winter, it should be taken into account that 140 watts of power are required per square meter (if there is one window and one external wall). The battery temperature must be at least 65 degrees. If the room is too large, then about 1.5 kW of power will be required per ten square meters. All numbers are given as a guide. You can get more accurate ones using heat calculations.

Old cast iron batteries work fine, but they don't look modern. Heating devices are often covered with special grilles or screens. Modern modifications are also produced that have a modern appearance. Particularly interesting are the products of the World Championship plant in the city of Cheboksary.

Example:

- ChM-1: depth up to 72 cm, power 0.076 to 0.12 kW, weight of one section 4.2 kg. Withstands pressure up to 9 atm.

- World Cup - 2 can also withstand pressure of nine atmospheres. Depth up to 1.1 meters, power 0.1082-0.143 kW. One section weighs up to approximately 6 kg.

Interesting models (MS-110) are produced by the Setehlit plant; the radiators are compact and easily fit into various openings.

Cast iron radiators are produced in Turkey, the Czech Republic and China. There are very attractive models that look ultra-modern. Example: the Conner company makes the “Modern” model: it has a depth of only 82 cm, withstands pressure up to 12.2 atm., and a power from 0.122 to 1.52 kW. The weight of one section does not exceed 5.5 kg.

Advantages and disadvantages of cast iron models

The positive qualities of cast iron radiators include:

- Low price

- Durability. The material is quite hard and durable. Sufficiently strong mechanical impacts do not cause harm.

- Chemical resistance. Almost no corrosion. Hardness, acidic, alkaline characteristics of the coolant do not play a role.

- Easy to use. It is enough to install it correctly and carry out a preventive inspection once a year.

- Undemanding to pressure and temperature conditions in the home heating system

Negative qualities of cast iron radiators:

- Heavy weight.

- Difficult to install (due to weight).

- Unpretentious appearance of models. Requires additional painting and decorative screen.

Heat transfer coefficient for different types of heating devices

Cast iron batteries: pros and cons

For many consumers, parting with old cast iron radiators causes anxiety. Although they are tired and often noisy, they have warmed apartments for decades without requiring special care. Today, the parameters of cast iron heating radiators are such that they are qualitatively different from their Soviet “brothers”, still not claiming the attention of the owners.

- If the old “accordions” weighed more than 7 kg per section, then modern cast iron batteries weigh 4 kg, which significantly lightens the load on the wall and fasteners.

- The volume of Soviet analogues was 1.5 liters, while the new models are 0.8 liters, which is almost half as much.

- Their price is still the lowest on the market. Although aluminum is also considered an inexpensive metal, a comparison of cast iron and aluminum radiators will show that the former are more cost effective.

- Modern cast iron batteries consist of sections that have become much easier to install, add or remove.

- Their thermal power is still capable of effectively heating apartments, therefore, when it comes to replacing old Soviet designs, many consumers are wondering which radiators are better: cast iron or bimetallic, aluminum or steel? Or replace them with a new version made of cast iron?

It is unlikely that such questions and doubts would arise if people knew the features of a centralized apartment heating system and the technical parameters of modern radiators.

Installation of aluminum radiators

Due to their low weight, aluminum radiators can be installed by one person. You will need: shaped wrenches, rack adjustable pliers, a drill - screwdriver, a set of fasteners, auxiliary equipment included in the radiator kit supplied by the manufacturer.

Demir Dokum Retro 600 (cast iron)

If the radiator is connected to a heating network made of plastic pipes, the process will take one and a half to two hours.

Be careful not to allow strong impacts on the radiator housing or falls. Deformation and rapid failure of the device are possible. Aluminum is a soft metal.

When installing an aluminum heating radiator, you must strictly follow the manufacturer’s recommendations and do not forget to install the required harness.

When placing the radiator on the wall, you need to maintain the necessary indentations:

- 3 cm from the wall,

- 5 cm from the windowsill,

- 10 cm from the floor.

A heat-reflecting screen must be placed between the outer wall and the battery. Will save 5-7% energy.

Before installing the battery under the window, you need to make sure that there are no gaps at the junction of the window sill and the wall. Otherwise, a significant part of the heat will go outside.

Alpine Air History 600 in retro style (cast iron)

Bimetallic radiators

Despite their novelty, bimetallic radiators have taken one of the leading positions. Thanks to research, it was found that it is much more efficient to use steel pipes to transport the heat conductor. At the same time, it is much more efficient to use aluminum panels for heat transfer.

Thanks to the combination of the best qualities of each material, it was possible to make more efficient bimetallic radiators.

In addition, aluminum panels look more modern. The weight of the final radiator is lower than that of cast iron, which is one of the additional advantages of this design.

The image shows the principle of the structure of bimetallic radiators.

Of course, everything is quite individual. Both aluminum and cast iron batteries are good and bad at the same time. For some, the main thing is cheapness and efficiency, for others aesthetics are much more important. But any battery, even the most ugly one, can be transformed/hidden with the help of decorative panels. Read about how to make a decorative panel that, among other things, will direct heat where it is needed. For private homes, steel radiators can be a reasonable compromise. But still, it's up to you to decide.

- User's blog 5energy

- Login or register to post comments

Installation of cast iron radiators

For cast iron radiators, installation is more labor-intensive. The reason is the significant weight of the batteries. It will take the efforts of two or three people. Cast iron is quite fragile. Do not drop or hit with anything (for example, a hammer).

Model in retro style Guratec (cast iron)

The choice of location for mounting a cast iron radiator is dictated by weight. More often, batteries do not have legs; they are mounted on brackets or pins made of steel rod (about 10-15 mm in diameter). It must be securely hammered into a solid wall (brick, concrete). It is better to drill holes in the wall with an impact drill or hammer drill that are 3-5 mm larger than the diameter of the brackets. For strong fixation, it is better to use plastic caps (often used in combination with screws).

Cast iron CONNER HIT-Modern

Before installation, you need to carefully paint the cast iron radiator and visually check the surface.

Comparison of heat transfer of devices made of different materials

A cast iron radiator can be covered with a decorative screen. This will reduce heat transfer (by 3-5%), but will make it less alien in the interior. You can simply paint the battery the same color as the wall.

In the case of using retro models, Euro-standard, camouflage is not required.

Connection diagram for aluminum model

Difference between cast iron and bimetallic batteries

Radiators, consisting of two types of metals at once, came to the domestic market from Italy and quickly won the hearts of consumers, despite their high cost. This can be explained in one word: “reliability”. If you choose which is better, cast iron or bimetallic batteries, then you should compare their technical indicators:

- Structure:

- Cast iron structures now look stylish, but they are also assembled from sections equipped with a fairly wide channel for the coolant. Their weight has become significantly less (3.5 kg versus 8 kg previously), their appearance is more presentable, and their reliability is the same. The market offers classic sectionals and artistic, retro style ones. The latter are very expensive, and mostly imported.

- Bimetallic structures consist of a steel or copper core with aluminum fins and housing. The coolant comes into contact exclusively with stainless steel, which protects the device from corrosion, and the casing ensures high heat transfer. Such a heater weighs little, is easy to install, and additional thermostats allow you to monitor the heating of the coolant.

- Heat dissipation level:

- If you decide whether cast iron or bimetallic radiators heat better, then their performance will be approximately equal . So the heat transfer of a cast iron section ranges from 100 W to 160 W. Many consumers feel that they take too long to warm up, and they are right. At the same time, everyone forgets that these batteries also take a very long time to cool down.

- The heat transfer of one section of a bimetallic radiator is 150-200 W, which, with instant heating, brings this type of heaters to a leading position.

- Operating pressure:

- Although many years of experience in using cast iron batteries suggests that they are strong and reliable, this is not entirely true when it comes to high-rise buildings. Even in five-story buildings, quite strong water hammers can occur in the heating system, let alone buildings of 16 floors and above. The operating pressure of cast iron batteries is 9-12 atmospheres, which may not be enough if the pressure rises sharply, for example, up to 15 atmospheres. In this case, the cast iron sections will simply burst.

- Bimetallic radiators are more reliable, since their operating pressure is 25-40 atmospheres, and in some models even 100 atmospheres. At this point, designs made of two types of metal also lead.

- Coolant resistance:

- Cast iron is absolutely “indifferent” to the quality of water and its acidity. Completely draining it in the summer does not affect it, but the pebbles that sweep through the system gradually weaken the cast iron, drain it and render it inoperable. This process is lengthy, and if the radiator walls are thick enough, it is completely endless.

- A bimetallic radiator is weaker in this regard. It is not afraid of the acidity level of the water as long as it is in the system, but as soon as it is drained, corrosion begins to appear after 2-3 weeks of contact with air. In this indicator, bimetal loses to cast iron.

- In terms of temperature, both types of radiators tolerate temperature changes well. For cast iron, the maximum water heating is +110, and for bimetal - +130 degrees.

- Today you can find cast iron batteries whose age has exceeded 100 years, but on average they have a service life of 50 years. Manufacturers set a limit of 25-30 years for bimetallic radiators, which is less than that of cast iron.

Bimetallic heaters are the best option for replacing old batteries. In key respects, they are superior to cast iron devices, which guarantees their effective operation in the unfriendly environment of centralized heating. In addition, they are much easier to install, they are lightweight and do not require additional maintenance.

If the question is whether to replace cast-iron radiators with bimetallic ones or not, then residents of five-story buildings do not have to do this, especially since the latest devices are twice as expensive . Residents of high-rise buildings will have to abandon cast iron batteries, since they will not withstand the load of the system and will leak. In this option, there is definitely nothing better than bimetallic structures.

What to choose for an apartment or country house?

Considering the positive and negative aspects of cast iron and aluminum radiators, we can recommend the following:

- Cast iron batteries are suitable for a city apartment. They will operate trouble-free for a long time and will withstand the negative factors associated with centralized heating (pressure and temperature surges, contaminated, low-quality coolant, water hammer). The appearance of the available models can be corrected with decorative screens.

Installation of the aluminum model

- Batteries made of aluminum alloys are suitable for a country house. They will heat the house and last without accidents. Home heating boilers do not create pressure in the heating pipes above 3-5 atmospheres; the quality of the coolant and temperature are completely under the control of the householder. The regulation of parameters in new boilers is automated. You can use cast iron models, which are less efficient in heat transfer and more expensive. More difficult to install.

Installed aluminum model produced by Teplopribor

Conclusion

We tried to give as much information as possible about which of the presented options is most suitable for a living space. But do not be confused that the advantages of a certain type become disadvantages in a variety of situations; it is important to take into account many nuances, right down to the size of the heated area.

In the video presented in this article you will find additional information on this topic.

Did you like the article? Subscribe to our Yandex.Zen channel