The basis of any heater is the process of heat release when burning fuel or heating a conductor, in which all the conditions are created for the occurrence of electric current in it. On these foundations, many models of various stoves are built, the individualization of which is ensured by various features. But the most important thing that personalizes each model is the useful energy output, defined as efficiency. That is, all design improvements are aimed at increasing, at fixed costs, the share of energy converted into heat and used to heat the room.

You can work on the task in several directions.

- Increased combustion intensity. This will increase the energy released per unit time, but the efficiency often decreases as fuel consumption increases.

- Long burning technology. It is based on reducing intensity by limiting air access. As a result, the share of the released heat can be increased.

- Increased heat transfer efficiency. Many developments are based on the idea that the quality of room heating can be improved due to more efficient heat transfer. Convector ovens operate in this direction.

Modern metal heating device

Design and principle of operation

The convection heating stove first appeared in Canada, the very first models looked like small portable convectors that could supply heat to a 100 m³ room in just 20 minutes. They were originally intended for lumberjacks who had to work outside in very cold temperatures.

This design of the stove allows you to heat the room in a very short period of time, while consuming very little fuel.

A convection oven for home looks like a metal structure in the shape of a cylinder. There are pipes welded into its body that are directed up and down.

The principle of operation of such a device is that the air, which is heated from the body, moves upward through the pipes, and the cold air is sucked from the floor by the lower pipes. Thus, air masses constantly and continuously circulate in the room.

The main structural elements of a convection oven are:

- a furnace in which fuel burns;

- ash pan: in this area the combustion product (ash) is collected;

- grate: a metal grate designed to hold coals;

- chimney: combustion products are discharged through it.

A hot air stream flows from the pipes, the temperature of which reaches +150°C.

Construction of a convector oven Termofor Valerian

The air temperature can be adjusted using a special power regulator. This is very convenient when using convection ovens to heat a house that is already well insulated and you just need to maintain the desired temperature.

The convection oven can operate in “instant heating” mode to maintain optimal temperature conditions.

Modes are changed using special dampers.

With one stack of wood, the stove can heat a house for 12 hours.

Thus, a convection oven for a summer house, home, garage and other premises is distinguished by its ability to heat air in a short time and maintain a set temperature for a long time, while consuming little fuel. Can work on wood, coal, peat, paper.

You can read about convector models of Termofor stoves here.

Conclusions and useful video on the topic

An example of using a wood stove in a country house:

Design features of cast iron products:

Comparative review of Berezka and Vesuvius stoves:

Modern wood stoves have excellent functionality and serve as an effective source of heat not only for dachas, but also for cottages.

However, with all their advantages, we should not forget that wood is a renewable resource, and logging harms the environment. In addition, wood heating has an efficiency of no higher than 80% and quickly pollutes the chimney with soot and soot.

Are you choosing a wood stove for home use and want to consult with other users who have experience in operating similar heating devices? Ask your questions in the block below the article - our experts and other site visitors will try to help you.

If you use one of the stove models mentioned in our rating, please write your opinion about it, indicate the disadvantages you noticed during operation, as well as the main advantages, in your opinion.

Advantages and disadvantages of a convection oven

Wood-burning convection oven Teplodar TOP-140

Convection ovens are in great demand among users. And this is not surprising, because the many advantages that distinguish such designs justify this choice:

- Heat is distributed evenly throughout the room.

- Such units are highly economical.

- They can even work on wood and paper waste.

- Convection ovens are characterized by high productivity: efficiency reaches 80-90%.

- It is possible to adjust combustion modes.

- A large selection of products of various shapes and capacities, so you can choose a heating device for different-sized rooms.

- Long service life.

Despite the large number of advantages of such a system, there are also a number of disadvantages:

- During operation, hazardous combustion products are formed and released.

- During the installation process, you may encounter difficulties, because a prerequisite is permission from the fire department.

- When a convection oven operates, ash is released through the chimney, which undoubtedly pollutes the environment.

The disadvantages that convection ovens have must be taken into account when choosing a heating unit.

What is the difference between convection and oven

Considering the question of what a convection oven is, it’s worth talking about the differences with a classic oven.

According to reviews from many users, such equipment expands the options for baking and roasting food. Every homeowner has their own preferred cooking style, although convection ovens do have advantages worth considering.

Here are just a few reasons why such equipment is changing the way users cook:

- A healthy alternative to frying in fatty oils.

- Evenly heated oven cavity.

- Less product drying when using air instead of direct heat.

- Food retains more moisture during cooking.

- Lower cooking temperatures result in a cooler kitchen.

- Faster cooking means saving time, energy and money.

Varieties

The main criteria on the basis of which convector stoves for heating a dacha, home, etc. are differentiated. - this is the material of manufacture.

In this regard, the following are distinguished: metal, cast iron, brick stoves.

The first are constructed of high-strength steel that can withstand high temperatures. Such an installation heats the room in the shortest possible time. However, due to the fact that the metal layers are very thin, the heat also disappears quickly. For greater effect, stainless steel is used. Another disadvantage of a metal stove is that if the seams are made poorly, they may come apart under strong heating.

Cast iron ones have proven themselves well. They are compact in size and can take up any space in the house. A chimney is mounted on such a structure, which goes out onto the street, and it is through it that combustion products are discharged.

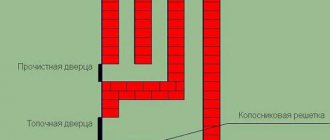

Brick kilns have gained the greatest popularity and have been able to gain the trust of users. Of all the varieties, they are the most durable and reliable. The chimney is made in the form of a coil. Thanks to this, combustion products, which are a source of heat, are efficiently preserved. A similar convection oven for heating a house heats up quite slowly, but the brick itself has the ability to retain heat for a long time. Such structures are multifunctional; they can be used to cook food and also be used as a fireplace.

Convection oven for heating in the interior

The role of convection in heating a room

Heat in the house appears due to heated air. Even infrared emitters heat objects in the room, which, in turn, release energy to the surrounding air. But its thermal conductivity is too low, so heat transfer can only be accomplished through convection, that is, the movement of the air masses themselves.

The heated air rises upward under the influence of buoyant force. Cold air from neighboring areas enters the freed space. The air cools at the top and gradually falls down. This is how natural convection occurs, thanks to which uniform heating of the room space is possible.

Air movement in the room

In the process of transferring heat from the working fluid (let's call the heated elements of the furnace) to the coolant, whose role is played by air, convection will play a key role, ensuring effective heat exchange and increasing the overall share of useful energy. It’s worth mentioning right away that this is not the only way to transfer heat from the stove to the room. Do not forget about radiation and the penetration into the room of some combustion products that have a high temperature.

Good to know: How to build a baby brick oven, from foundation to masonry

If there were no convection, then heat from the furnace would be transferred by conduction. The nearby layers of air would have a high temperature, but further the heating process would stop due to low thermal conductivity. Convection ensures the entry of a new batch of cold coolant and its removal after heating. This principle is used as the basis for the operation of convection ovens.

Features of choosing a convection oven

As already noted, stoves operating on the convection principle are multifunctional and suitable for any purpose related to space heating. However, for example, a residential building and a country house are two completely different environments, each of which requires a personal approach to choosing a stove.

It is important to take into account temperature changes; therefore, heating the stove more or less depends on each specific situation. Therefore, when choosing wood-burning convector stoves for your cottage or home, you need to consider the following:

- it is important that the stove can distribute heat evenly over 24 hours;

- the stove itself should also warm up evenly;

- outside temperature should vary between 90-95°C;

- with low fuel consumption, the temperature in the house should be stable;

- It is important to consider the size of the firebox, since the speed of the combustion process will depend on this indicator. The larger the firebox, the longer the heat will remain in the room;

- the stove must be free of cracks and visible damage;

- she must work for twenty years or more;

- appearance is also important; here, follow your personal preferences.

To summarize, convection ovens are a good alternative heat source that are easy to use and highly efficient. Such designs are in great demand among users and have many positive reviews.

Wood stove prices

The secret to the popularity of wood-burning stoves lies in their wide capabilities and variety of offerings. On the market you can find both budget compact options and luxurious units that can decorate the most sophisticated interior. No matter how charming a stove may be, constantly throwing firewood into the firebox is a boring task, which is why more and more owners of country cottages prefer long-burning stoves.

A modern version of a traditional way of heating a homeSource savoie-mont-blanc.com

If you look at average prices (in the Moscow region), they will look like this:

- Metal stoves. Heating: 5-16 thousand rubles. (depending on design). Heating and cooking: 9-35 thousand rubles. (domestic and imported). Stove-fireplace: 20-40 thousand rubles. (may have a stove and heat exchanger).

- Cast iron: From 20 to 120 thousand rubles, depending on the size and design.

- Stoves lined with tiles (tiles): 50-80 thousand rubles.

- Stone (from granite to Brazilian sandstone): 60-200 thousand rubles.

- With a water circuit: 20-55 thousand rubles.

- Long-burning stoves: 15-45 thousand rubles.

- Potbelly stove: 9-16 thousand rubles.

Conclusion

Convection ovens are an excellent alternative heat source that are very easy to operate and very efficient. Such ovens are very popular on the market, so manufacturers have significantly expanded their variety and capabilities.

The basis of any heater is the process of heat release when burning fuel or heating a conductor, in which all the conditions are created for the occurrence of electric current in it. On these foundations, many models of various stoves are built, the individualization of which is ensured by various features. But the most important thing that personalizes each model is the useful energy output, defined as efficiency. That is, all design improvements are aimed at increasing, at fixed costs, the share of energy converted into heat and used to heat the room.

You can work on the task in several directions.

- Increased combustion intensity. This will increase the energy released per unit time, but the efficiency often decreases as fuel consumption increases.

- Long burning technology. It is based on reducing intensity by limiting air access. As a result, the share of the released heat can be increased.

- Increased heat transfer efficiency. Many developments are based on the idea that the quality of room heating can be improved due to more efficient heat transfer. Convector ovens operate in this direction.

Main advantages

The use of technologies that make it possible to increase the efficiency of a heater without increasing the amount of fuel burned has opened up new opportunities for manufacturers of heating devices. A convection oven for home or industrial premises has some key advantages that allow it to attract the attention of consumers.

- Independence from electricity (with the exception of electric convectors) is in demand among residents of suburban areas that experience long-term power outages. Indeed, in the most difficult conditions, a metal stove can be heated with almost any type of fuel. The only recommendation is not to use plastic products or any paraffin-containing materials, as this can lead to premature cleaning of the chimney.

- Uniform heating not only affects the degree of comfort, but also reduces the time it takes to warm up the room. Today there is no more effective phenomenon than convection. Therefore, this type of heat transfer is used twice: when transferring energy to cold air and when distributing heated air throughout the room.

- Convection ovens are one of the few types of devices that allow you to effectively control and regulate the intensity of combustion.

- The possibility of using long-burning technology increases the interval between adding fuel portions to ten hours.

The list of positive qualities is not exhaustive, since the task was to identify precisely the distinctive features of the design.

A convection oven is a type of oven that has high efficiency, can quickly heat a room and is economical in terms of fuel use. The shape of this furnace resembles a cylinder with pipes welded into the body.

Species and types

The operating principle of such furnaces is the same, but there are several types of this design, which differ from each other in a number of characteristics.

Firebox type

- Wood-burning (solid fuel). If this is a brick version, then it is a fairly large structure that is laid out in houses on a separate foundation. Their design initially includes convection channels next to the firebox. Essentially, an empty space and a hole at the bottom are left around the firebox, through which cold air will be drawn in. If these are metal structures, then they will not have much weight and require the installation of a foundation. They are already completely ready, so the buyer only has to choose the appropriate option based on the thickness of the metal layer, as well as the dimensions of the structure.

- Gas. There are also two options available here. This can be a stationary convection oven for cooking and heating the room. It is installed in a selected location in the room in such a way as to heat the house. There is also an alternative option in the form of a special fireplace that can be installed in any room. This design runs on bottled gas, but it is also possible to connect a main gas pipeline to this structure.

- Electric convection oven. One of the most common stove options. They are also called electric convectors, which can heat a room very quickly and efficiently. The advantage of this type of design is the possibility of its transportation due to its compact dimensions and the presence of mains power.

How to choose?

To choose a quality device, you need to decide on your needs and pay attention to the option that best suits them.

For a summer residence, it is recommended to choose solutions that have a surface for heating food. For home use in small spaces, electric options are the best. They will be a mini oven with convection.

When purchasing, you should pay attention to such indicators as:

- power;

- dimensions;

- material of manufacture;

- presence of a hob;

- installation safety;

- fuel used.

Models for home

- Flames KP-2. This stove has small dimensions, its weight is only 44 kg and there is a 40 liter combustion chamber. It is suitable for use in cabins, because it helps to uniformly heat the room.

- Flames KP-4. This oven is slightly larger in size. It has a power of 4 kW, so it can be used for medium-sized rooms. It has a simple design and attractive appearance.

- Furnaces of Professor Butakov. This option is suitable for heating your own home. It can be installed in the basement. The design works with solid fuel and consumes very little of it.

- Teplodar Matrix 100. This design has the advantage of being compact. At the same time, it can quickly heat about 100 cubic meters of area. It has a glass heat-resistant door and a two-channel afterburning system.

- Heater 100. There are also smaller models, so you should choose the appropriate option based on your needs. This stove can heat up to 100 cubic meters. The body is made of hardened steel. Best suited for household use.