A private garage is a specific room and is usually very cold in winter. Such a microclimate is completely useless for either a person or a car. At the same time, the use of standard electric heaters often turns out to be too expensive and ineffective.

All that remains is to make a stove for the garage with your own hands, choosing one of the suitable options. We offer for consideration four methods of arranging stove heating, each of which has its own characteristics in creation and operation.

Visual diagrams and video instructions will help you decide on the design of the furnace, assemble and connect the unit yourself.

General information about homemade stoves

To save money, heating devices are often made independently from scrap materials and scrap metal. Such structures are characterized by ease of maintenance and operation. As stated in the regulations, the car must be stored at a temperature not lower than +5 degrees. A drop in temperature makes it difficult to start the car. Severe frosts can also cause antifreeze to freeze, which usually leads to damage to the cylinder block or its head.

In such a situation, the car owner has to turn on the engine in advance to warm up. However, the life of the motor is not eternal, and sooner or later this leads to premature wear of parts and components. The transmission also needs to be warmed up, for which a blowtorch or fire is used. A more practical solution to the issue is to maintain a comfortable temperature inside the garage, for which you can use a factory-made or homemade wood-burning stove.

An effective garage heater should be:

- Compact.

- Versatile in terms of fuel consumption.

- Able to warm up quickly.

- Have good heat capacity, which is reflected in maintaining the temperature for a long time after the end of combustion.

- Possess a simple and compact design.

- Cheap.

- Have a reliable chimney and exhaust hood.

- Fireproof. The device is usually installed as far as possible from flammable materials.

Since the area of the garage or utility room has limited parameters, it is very important to take care of safe smoke removal.

Features of garage heating

A major garage with insulation is not available to every car owner. Most often, the vehicle owner has a metal structure at his disposal, devoid of any insulation. Any thermal energy leaves such a structure almost instantly.

When solving the problem of heating a garage space, you should not estimate its heat requirement based on similar experience with a residential building. And it’s not just the lack of thermal insulation.

There is the so-called square-cube law, which states that when the dimensions of a geometric body decrease, the ratio of the surface area of this body to its volume increases.

For normal storage of a car in a garage, the temperature inside the box should not fall below +5º and rise above +18º during the presence of the owners and repair work. The requirements are regulated by SP 113.13330.2012

This affects the size of the heat loss of the object, so to heat one cubic meter of a small room, for example, a garage, more heat is needed than to heat a large house.

If for a two-story building a heating device with a power of 10 kW may be sufficient, then for a much smaller garage you will need a unit with a productivity of about 2-2.5 kW of thermal energy.

To maintain a very modest operating temperature of 16°C, a 1.8 kW stove is sufficient. If you only need to maintain the optimal temperature for storing a car in a parking lot - 8°C - a 1.2 kW unit is suitable.

It turns out that fuel consumption for heating a unit volume of garage space can be twice as high as that for a residential building.

To thoroughly warm up the entire garage, its walls and floor, you will need even more thermal energy, i.e. an even more powerful heater. But even with insulation, heat will leave the room too quickly. Therefore, it is recommended to heat not the entire garage, but only the so-called workspace.

Effective heating of a garage can be achieved using the so-called “warm cap”, formed during the process of naturally limited convection of warm air in the room

The idea is to concentrate heated air in and around the center of the room so that there is a layer of cold air between the walls and ceiling. As a result, equipment and people will constantly be in a cloud of air at a comfortable temperature, and thermal energy consumption will be noticeably reduced.

Experts call this phenomenon a warm cap; it occurs due to naturally limited convection. An intense flow of heated air rises, but does not reach the ceiling a little, since its kinetic energy is dampened by denser cold layers.

Next, the hot flow is distributed to the sides, lightly touching the walls or at a short distance from them. Almost the entire garage becomes warm; even the inspection pit warms up under the influence of convection processes.

To achieve a similar effect, garage stoves of relatively low power are suitable, creating an intense, but not particularly dense flow of warm air.

Natural convection of the air mass in the garage ensures the formation of a temperature favorable for work even in the inspection pit

An alternative option for heating a garage is to use various infrared heaters. For a garage with metal walls, such equipment is not particularly suitable. Infrared radiation is poorly reflected from metal surfaces, it penetrates through them, as a result, all the heat will simply go outside.

For a brick garage with half-brick walls, experts also do not recommend an infrared heater. This material does not transmit infrared waves, but does not reflect them either. Brick absorbs this type of thermal energy and releases it over time. Unfortunately, the process of storing energy and returning it takes too much time.

Practical recommendations for choosing a garage heater are given in this article.

Varieties

Garage stoves are classified according to the type of fuel used.

Based on this feature, the devices are divided into four groups:

- Gas . They are distinguished by their affordable cost and high heating speed. Due to the risk of explosion, such devices must be operated with great care. Since main gas is rarely supplied to garages, it is replaced with liquefied fuel in cylinders.

- Solid fuel (potbelly stoves) . A very popular method of heating various technical rooms, for which any solid fuel is suitable.

- Electrical . They are famous for their compact dimensions, high safety and environmental friendliness (in this case, a chimney is not required). The disadvantage of electric heaters is the high cost of energy consumed.

- Liquid fuel . The energy carrier for such stoves is used motor oil. This heating option is considered the most inexpensive. Homemade camping stoves are also popular. A DIY camp stove that you make will serve no worse than a factory stove.

Principle of operation

The operation of the furnace is based on the combustion of motor oil vapor in a closed container.

The product is not just the cheapest, but a waste product. Most often, used oil and its disposal are a headache for service stations and garage owners. After all, it is strictly forbidden to pour waste into the ground or domestic sewage system. And here “harmful” oil is poured into the stove and serves to benefit humans. The design of the most common modification, made of metal, consists of cylindrical tanks, lower and upper, a short transition compartment and a chimney. It’s hard to imagine anything simpler. First, the fuel is heated in the first tank: the oil boils, begins to evaporate, and the gaseous product passes into the next compartment (short pipe). Here, oil vapors mix with oxygen, ignite intensely and completely burn in the last, upper reservoir. And from there the exhaust gases are released into the atmosphere through the chimney.

Tools and materials

Having decided on the fuel and the design of the furnace, they move on to procuring the necessary tools and materials.

To make your own garage heater you will need:

- Sheet metal, scrap metal (used gas cylinders work well).

- Metal barrel, pipes, angle, channel.

- Fireproof brick.

- Welding machine.

- Pliers, hammer, etc.

Each of the above designs can be made on your own using the following instructions.

Types of stove heaters

There are a lot of stoves for summer cottages into which you can load firewood. But based on the material from which the stove is made, they are divided into two types.

Table 1. Efficiency of different types of furnaces.

| Type of oven | Efficiency |

| Dutch oven | 45 — 55 % |

| "Swede" | 50 — 60 % |

| Iron potbelly stove | 60 — 70 % |

| Long burning stove | 80 — 90 % |

Brick ovens

Such structures are built from refractory brick - red, which is not afraid of temperature and does not crack from heating. Hollow bricks are used to lighten the load on the foundation. The furnace can have a different shape and configuration, not only its dimensions depend on this, but also the efficiency and degree of fuel combustion. The well-known Russian stove is also made of brick, and then coated and whitewashed. But it is not suitable for a modern dacha: it is too large and heavy, difficult to build, and in addition, it must be constantly heated. After complete cooling, it will heat the room only after a few hours.

More compact options with quick heating are much better suited for a country house: “Dutch” and “Swedish” . Both of these stoves do not require rough construction; heat is emitted by walls with a chimney duct running inside them. The heat transfer of the furnace, the degree of fuel combustion and other factors depend on the number of elbows and bends in the channel. can build such stoves with his own hands if you follow the instructions.

You can lay out a brick oven according to your design

Metal furnaces

The material for these products is cast iron or steel . Cast iron structures are good because they have thicker walls with a porous structure. Once heated, they cool down more slowly , continuing to give off heat. Steel ones have their own advantage - they weigh less , since the steel is stronger, and the walls of the furnace are made thinner. Such a stove, having gone out, quickly cools down, but also heats up in a matter of minutes - just right for a small house.

Market Review

Steel stoves include a potbelly stove - the simplest cylindrical stove with one door and a chimney made of a simple pipe. If you have the materials, you can do it yourself using a home inverter welding machine. At dachas they also install more complex structures - “Buleryan” , Butakova . Their configuration allows the stove to operate as a convector, pumping air through flame-heated pipelines. Such systems are characterized by a very high warm-up rate .

The main advantage of metal stoves is that they are ready- made; you just need to pick them up and buy them. On the other hand, the price may be higher than when laying a brick oven yourself.

The iron stove is ready for use

Video - Review of heating stoves for summer cottages

Find out how to install a fireplace stove for a long-burning cottage, and also check out the rating in a special article on our portal.

Prices for the range of solid fuel boilers

Solid fuel boilers

Brick

This wood-burning garage stove is solid and reliable. Brick is a suitable material due to its ability to retain and transfer heat well. However, it must be taken into account that a brick stove is a static structure, and the process of its construction does not occur very quickly. Standard parameters are 2x2.5 refractory or fireclay bricks. The solution consists of sand, fireclay and fireclay powder.

To construct the combustion chamber, you must use exclusively fireclay material. Most often it is positioned at the level of the second, third, fourth rows of masonry. The total height is usually 9 bricks. To remove combustion products, a brick chimney with a stainless insert is installed. Most often, the chimney of garage stoves is vented through the roof. Less often, an outlet in the wall located at a certain height is used for this.

Criteria for a good stove for a summer residence

A country stove must satisfy several conditions, which makes it a more or less desirable heating device in a country house:

- It should warm up quickly and give off heat well . This will allow you, when you arrive at the dacha, not to walk around the room for several hours in winter boots and a jacket.

- It should have compact dimensions , if only because the larger the stove, the longer it will heat itself until it begins to warm the air in the rooms. Proper placement of the stove at the junction of rooms will allow you to heat even several rooms. In a one- or two-room house, building a bulky stove makes no sense at all.

Compact stove does not take up space in a small room

- No one wants to buy a carload of firewood and find out there isn't enough for the heating season. Economic considerations are paramount, which means the furnace must have the highest possible efficiency .

- Since the summer cottage can be located far from the gas main, the stove turns from a heating device into a means of cooking. Having an oven and hob is a plus.

- Implementing a long-burning mode will allow you not to waste time and not be distracted by constantly adding logs to the firebox.

Potbelly stove

Making an iron stove in the garage usually does not pose any particular difficulties. To do this, thick metal sheets are used, connected via an inverter. In addition, to construct the structure you will need a metal corner, a pipe and a barrel. Metal sheets work well for making a square or rectangular oven. It is easier to make a cylindrical potbelly stove from a pipe or an old gas cylinder.

Only thick sheets should be used - at least 5 mm. The pipe must have a diameter of 300 mm. The best place to remove the chimney pipe is the roof. To exit through the rear wall, you will need to maintain a slope of at least 30 degrees. The chimney is made of a metal pipe with a diameter of 120 mm. At the bottom, such a pipe should have a thickness of 2–3 mm: walls that are too thin will quickly burn out.

An ash pan is placed under the firebox to dump ash, welded from a thick sheet of metal with slots. Its dimensions are influenced by the size of the stove and the type of fuel used. If coal and fine solid fuel will act in this capacity, the slots are made 10–12 mm. When using firewood, the gaps are increased to 40 mm.

As an ash pan, you can use a small steel box installed under the partition. Ash will accumulate there, which needs to be thrown out from time to time. It is recommended to make the ash pan from a steel sheet 3 mm thick. To increase the efficiency of the potbelly stove, thick steel plates (from 5 mm) are welded onto its side walls. In this case, the area of interaction between air and the heated surface expands.

Recommendations for safe installation of a potbelly stove

The use of homemade potbelly stoves, as well as any other heating units, requires compliance with a number of safety regulations.

First of all, choose a suitable place to place the stove. It is best to install a potbelly stove in a corner, near the walls opposite the garage door.

How to install a potbelly stove

You cannot install a potbelly stove closer than 1.5-2 m to the location of the car. Any flammable products and materials must be removed from the stove at a similar distance.

It is recommended to lay brick walls on the sides and front of the stove. They will not only protect against accidental touches to a hot unit, but will also accumulate the generated heat, which will significantly increase the efficiency of the potbelly stove.

Potbelly stove in the garage

If the garage walls are made of wood, there must be at least 100 cm of free space between them and the potbelly stove. Cover the walls themselves with asbestos sheets, cover them with bricks or protect them with other fireproof materials.

Potbelly stove in the garage

Place a steel sheet 1-2 cm thick under the potbelly stove or pour a concrete screed - this will prevent the spread of fire if sparks, coals, etc. fall out of the furnace firebox.

The potbelly stove can only be used in a room with good ventilation. Fresh air must enter the garage in normal volumes, otherwise the fire in the stove simply will not burn. Usually, to ensure the necessary air flow, it is enough to leave a small gap between the ground and the garage door. If there is no such gap, you will either have to make one or install a supply ventilation duct.

Do not leave any flammable materials near the stove. Wood, gasoline cans, all kinds of oils and lubricants and other similar materials can all catch fire, leading to catastrophic consequences.

Potbelly stove for garage

Additionally, you can use your potbelly stove for cooking and heating water by equipping it with a cast iron stove with burners and a water tank.

Thus, there is absolutely nothing complicated in making a potbelly stove for your garage yourself. With proper skill, all work is completed in less than a day. Follow the instructions, and very soon your garage will be warm and comfortable.

Good luck!

Stove in progress

These small garage stoves are the most convenient from an economical point of view. As you know, firewood and coal are not always available in the garage, which cannot be said about used engine oil and fuel oil: motorists have plenty of such goods. Devices of this type consist of two sections: the first is designed to burn oil, and the second burns a mixture of gas and air.

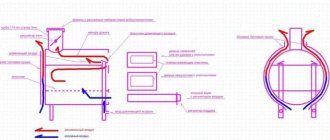

A do-it-yourself garage stove drawing includes the following components:

- Fuel tank.

- Afterburner chamber.

- Temperature section.

- Chimney.

The burning fuel produces vapors that enter the next section to be mixed with air. This allows for another combustion reaction at high temperature. You can make your own liquid fuel stove from sheet metal. The lower part is often a ready-made box with welded legs. It must be equipped with a hole with a flap for fuel supply.

The damper allows you to regulate the air flow. The upper part of the chamber has a cylindrical shape. For connection to the tank, a pipe with a cross-section of 10 mm is used: secondary air is pumped through it. The chimney can only be located on top. Various oils, kerosene, diesel fuel and fuel oil are used as fuel for the furnace during mining.

Why a wood stove?

If we exclude gas and electricity, the first - due to the complexity of installing a separate pipeline, the second - as an expensive energy source for heating, there are not many types of fuel left for a country stove. Coal has a high heat capacity and produces long-lasting and persistent heat . But its cost in regions that are far from coal mining areas negates its advantages. Wood pellets and briquetted fuel have now become popular. The calorific value of these materials is higher than that of firewood, but they are also more difficult to obtain and the price is higher.

At the same time, firewood is a renewable material that grows in abundance throughout most of Russia. In forested regions it is the cheapest type of fuel . A wood-burning stove is also convenient because, if necessary, it can burn not only quality firewood, but also wood waste - old boards and wood products that are not covered with varnish and paint. Although this is not the main source of fuel, such recycling can still be beneficial.

Firewood continues to be the most affordable fuel

Long burning

A long-burning wood stove for a garage is convenient because the wood here does not burn, but smolders. This allows you to increase the frequency of fuel loading to 20 hours. To maintain this mode, you will need a dense loading of the fuel compartment and the presence of a control valve. As a result, the stove's draft will be moderate and stable: this will ensure slow burning of the wood with a constant release of heat.

A homemade wood-burning garage stove is made from a 200-liter metal barrel. Its upper part is cut off, creating a channel for a chimney with a diameter of 100 mm. A second hole with a diameter of 100 mm is cut for the air pipe. After this, a special weight is made for free movement inside the barrel. A metal circle reinforced with channel cuttings is suitable for this. Next, the stove body is equipped with a series of slots, after which a piece of 100 mm pipe is welded to it.

The load is placed inside the body, closing the lid on top. The air pipe is welded inside the cut hole. You will also need a couple of hatches for loading firewood and cleaning out ash. It is advisable to install the finished structure on a brick, concrete or cement platform.

Solid fuel stoves

Portable stoves are popular at all times. Car owners are equipping their garages with this heating method more and more often, since the device not only provides great heat, but also looks quite aesthetically pleasing.

Advantages of solid fuel stoves:

take up little space, which allows you to equip even a small garage with the help of such equipment; easy to install and dismantle if necessary

For example, in the summer it can be removed from the garage altogether to free up more space; safe to use; They have a high level of heat transfer, which allows you to heat a large garage.

Important! The only significant disadvantage of such heating may be that during your absence there will be no one to supply firewood, which means the stove will cease to perform its function. However, this problem is easily solved, since there are several acceptable fuel options.

Advantages and disadvantages

Like any heating device, a wood stove has its advantages and disadvantages.

Let's look at some of the benefits:

- Relatively low price of fuel.

- The versatility of the device during operation. You can use the heater to heat the room, cook and heat food.

- Installation and installation of a garage stove is very simple and does not require large expenses.

- For the manufacture of the unit, scrap materials can be used.

- During operation, the use of additional installations and devices is not required.

- The small overall dimensions of the unit make it universal for use in garages.

- The operation of such a device does not require the use of an additional type of energy (electricity).

The disadvantages of this design include:

- Such furnaces have a high heat output, as a result of which they heat up quickly and cool down quickly.

- To maintain a high temperature in the oven, it is necessary to periodically add firewood.

- Constant monitoring of the heating process is necessary to ensure safety.

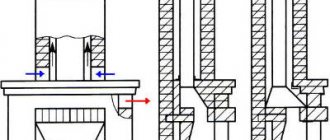

Chimney outlet through the roof

Diagram of the outlet of a stove chimney for a garage through the ceiling/roof:

As in the case of installing a chimney through a wall, when installing through a ceiling, preliminary assembly is first done in order to accurately mark the future passage through the roof. Once the installation hole is made, the steel penetration through the roof is installed.

Next, in the same sequence, the pipe is assembled and the passage through the roof is laid with non-combustible material. The passage of the chimney through the roof requires reliable waterproofing so as not to encounter leaks in the future. As in the first option, you should protect the pipe from moisture getting into it and insulate the outer part of the pipe to reduce the formation of condensation.

Manufacturing a horizontal heater

If you lay a standard propane cylinder horizontally and install a door at the end, you will get a fairly spacious firebox that can accommodate meter-long logs. For better heat transfer and afterburning of the resulting pyrolysis gases, you need to make a secondary chamber with partitions, as shown in the drawing.

The afterburning of combustible gases in this potbelly stove is combined with the extraction of heat from combustion products that flow around hemispherical partitions (cut out from the cylinder body). Well, an indispensable attribute of intense heat exchange - external ribs made of steel strips - are required. Practice shows that such a stove heats a garage of up to 50 m² in medium combustion mode, as described in the next video:

The heating unit is simple to manufacture: doors are installed in the front part, and a hole is cut in the back part, into which a secondary chamber from a pipe or a second cylinder is welded. In order not to take away the useful volume of the firebox, the ash pan is made hinged. If necessary, a hob is installed on top of the horizontal part.