For any heating system, including an open type circuit, an expansion tank (hydraulic tank) is needed. As the temperature of the coolant increases, the volume of water circulating in the pipes increases, which leads to an increase in pressure in the lines. If measures are not taken, the excess liquid will rupture the pipes, cause battery leaks, and breakdowns of shut-off and control valves.

The hydraulic tank serves as a damper - shock absorber. It absorbs excess water and balances the operating parameters of the heating system. In this design, it communicates with the surrounding air, which is why the design is called open.

Advantages and disadvantages of an open heating system

This scheme is still used to heat private houses and cottages. Hot water from the boiler, according to the laws of thermodynamics, without a pump, rises up the riser, and then spreads along the supply lines located with a slope of 0.5 cm/m. At the same time, it fills the radiators. The liquid then flows by gravity back into the boiler or boiler to be reheated.

Main elements of an open heating system:

- Boiler

- in an open circuit, gas and solid fuel boilers of single- and double-circuit types are used. - Radiators

- the pressure in an open heating system is low, so any battery model is connected to it. Aluminum heaters work efficiently, heat up quickly and release heat intensively. You can install bimetallic radiators with an aluminum body and a steel water-conducting part. Traditional cast iron options also serve reliably. - Pipes

- in modern houses, models with a diameter of 25–50 mm made of heat-resistant polymer are used. Pipes of the maximum size are installed at the outlet of the boiler, and minimum size at the outlet. This allows you to maintain the required pressure and proper fluid circulation. - An open-type expansion tank -

you can buy it in a specialized store, order it online, or make it yourself. - Shut-off valves

- installed on the riser and collectors for emergency shut-off of water. - Control taps and automatic thermal heads

are additionally mounted on batteries to adjust the temperature. - For Mayevsky's wounds

there are air vents necessary for releasing air and preventing air locks. Installed on radiator housings.

Advantages of an open system:

- Energy independence

- this circuit works without a pump, so it is not afraid of power outages. If there is a power outage, the water and pipes will not cool down. - Budget-friendly

- no pumping equipment is required for operation; you can weld the tank yourself, buy it inexpensively, or adapt an ordinary canister. - Easy to use

- owners only need to monitor the condition of its elements and add water.

Flaws:

- The complexity of calculations and installation - when installing collectors, it is important to maintain the required angle - even small errors will lead to stagnation of water and poor heating of the batteries.

- Impossibility of use in buildings with irregular occupancy - non-freezing liquid cannot be poured into such a heating system. When it comes into contact with air in the tank, it evaporates and loses its properties.

- Difficult to operate in houses with a large area and number of floors - for such buildings, a closed heating system is preferable, which is able to warm up a building of any size.

However, despite the disadvantages, an open heating circuit is appropriate in small houses with permanent residence. Therefore, she does not lose her popularity.

How does a hydraulic tank work in an open heating system?

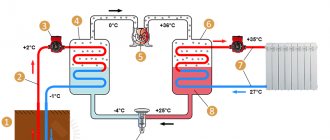

This hydraulic tank works as follows:

Water expands when heated in a boiler. If measures are not taken to remove the increased volume, the excess coolant under pressure will rupture pipes, batteries, and damage taps. To solve the problem, a hydraulic tank is installed in the system, where the resulting excess liquid goes. The heating system continues to function normally. Expansion tank for closed heating ,

having a different design, works on the same principle

The hydraulic tank dampens pressure surges caused by sudden closure of shut-off valves, air locks and other reasons. It plays the role of a hydraulic accumulator: after the pressure in the system decreases, the water from it returns back to the pipes.

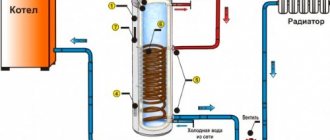

This device is a stainless steel container or an adapted canister. It can be completely open, but it is better to use a lid so that dirt and foreign particles do not get inside, and the water evaporates less.

For ease of use, the tank can be equipped with additional accessories:

- An overflow hose or pipe through which, if overflowed, excess water will be poured into the sewer or outside the building.

- Supply pipe for topping up, connected to the water supply system.

- Float device. When the liquid level decreases, the float will lower and the water supply from the water supply will turn on. When the liquid fills the tank to the required level, the float will return to its place and water will stop flowing into the hydraulic tank.

Homemade sheet metal construction

A rare heating system will hold more than 200-300 liters of coolant, therefore, the volume of our tank will be 10-15 liters. To make such a tank we need a sheet of metal with dimensions of 50x75 centimeters. The thickness of the sheet can be arbitrary, but the 2-mm option is considered optimal.

A sheet metal tank can only be assembled by an experienced welder.

Well, the assembly process itself looks like this:

- Using a grinder, we cut the sheet into two pieces 25×75 centimeters.

- Using a grinder, we cut these strips into six pieces of 25x25 centimeters.

- We burn a hole in one workpiece with a cutter or electrode and weld a fitting with a 1.0 or ½ inch threaded tap in this place.

- We weld two workpieces at right angles to each other. We proceed in the same way with two more blanks. Next, we assemble a cube without a bottom and a lid, connecting these corners by welding.

- We weld the seams until they are sealed. We test joints with chalk and kerosene.

To check the tightness of the seam, apply chalk from the outside, kerosene from the inside. If after some time no greasy spots appear on the chalk strip, the seam is welded hermetically.

- We weld the bottom to the cube - a blank with a welded pipe. Check the seams for leaks.

- Using a cutter or arc from the electrode, we burn a 5x5 centimeter hole in the last workpiece.

- We weld the workpiece with a hole on the side of the cube lid. In this case, it is not necessary to check the tightness of the seams.

As a result, we get a capacity of 15.6 liters (25 × 25 × 25 = 15625 cm3 = 15.625 l). Moreover, during the assembly process we consume metal without a trace, and the total capacity of such a tank is enough for a 300-liter system.

The only drawback of this option is the significant complexity of the process. Only an experienced welder can assemble such a tank. And if you do not know how to weld hermetic seams, then it is better for you to turn to another type of metal structures, for example, a tank based on a ready-made container - a cylinder.

How to calculate the parameters of the expansion tank

For correct operation of the heating system, it is necessary to calculate the volume of the installed hydraulic tank. Then there will always be enough space for the coolant inside the container. The pressure in the heating expansion tank does not play a role here, so it does not need to be calculated.

First you need to calculate the total volume of coolant. To do this, you need to sum up the volume of all elements of the heating system or use a simplified calculation based on the power of the boiler. It is believed that for every kilowatt of power, 15 liters of coolant are required. The parameters of the boiler unit are indicated in its passport.

Let's calculate the volume of coolant using the formula:

Vwater = P boiler x15l

For example, a 10 kW boiler is installed in the system. Then the total volume of coolant is 150 liters.

Now we calculate the parameters of the tank:

η = ε x C

η is the expansion volume of the liquid, which is what the hydraulic tank should accept.

ε – expansion coefficient – the difference in water volume when the heating is turned off and on.

C is the volume of water in the system. In our calculation it is equal to 150 liters.

We take the expansion coefficient from the table.

| Temperature, degrees | Expansion coefficient | Temperature, degrees | Expansion coefficient |

| 0°C | 0.0001 | 60°C | 0.0171 |

| 10°C | 0.0003 | 70°C | 0.0227 |

| 20°C | 0.00018 | 80°C | 0.0258 |

| 30°C | 0.00044 | 90°C | 0.0359 |

| 40°C | 0.00078 | 95°C | 0.0397 |

| 50°C | 0.0121 | 100°C | 0.0435 |

For example, the difference in liquid temperature in the switched off and switched on heating system is 90°. Then the total volume of coolant must be increased by a factor of 0.0359. From the calculation it is clear that 150 liters of water when heated will add 5.385 liters in volume.

0.0359 x 150 = 5.385 l

You need to round the results up - it would be better if the hydraulic tank is a little larger, so let’s take the result equal to 6. To the resulting volume you need to add another 2% for evaporation and topping up. In our case it is 0.12 l or 120 ml. The total volume of the expansion tank must be at least 6.12 liters. You can buy a seven-liter model - the extra volume won't hurt.

How to choose or make an expansion tank

A factory hydraulic tank can be purchased at a specialty store or ordered online. It is a container with a lid and outlets, ready for installation. When purchasing, evaluate the full and useful volume, the thread parameters of the pipes and the overall dimensions of the model.

If you want to save money, weld your own stainless steel container or find a suitable plastic canister. Polymers and stainless steel are not subject to corrosion, so they last a long time. This homemade damper works no worse than the factory one.

You can do it simpler - take a canister, connect it to the heating system, cut a hole in the upper part and insert a funnel there. Water will need to be added manually, and at the end of the heating season, the tank will need to be removed and washed.

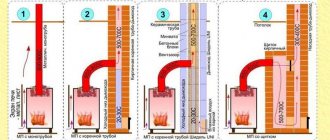

Location

Basically, such tanks are installed between the boiler pipe and the very first battery from it or behind the pressure fitting. This placement of the expansion tank becomes an alternative to the water safety valve. If the boiler overheats, excess steam will not remain in the system, but will go outside into the air.

When installing heating systems in multi-storey buildings, such expansion tanks are located in the attic part of the building, and in boiler rooms - under their ceilings.

In this case, such a tank should become the highest point of the thermal system. For this purpose, a tee is installed. It is located in the node where the vertical part of the pressure pipeline mates with its horizontal branch. A piece of fittings is attached to the upper threaded outlet of this tee to connect the system to the expansion tank itself.

How to install an expansion tank with your own hands

To install the tank, choose the highest point in the system. Otherwise, according to the law of communicating vessels, liquid will flow out of the hydraulic tank. Connect the container not to the supply circuit, but to the return circuit - it is not so hot there, so the water will evaporate more slowly. In addition, the low temperature will allow you to attach a transparent flexible hose to the device, through which you can easily control the water level in the heating system.

You can use pipes made of opaque material. In this case, it is advisable to retrofit the tank with a float device that controls the liquid level, or an audio relay that gives a signal when the coolant level drops.

When installing a container in the attic, be sure to insulate it. Otherwise, freezing of water will paralyze the heating operation and lead to an accident.

Maintenance and operation of the expansion tank

The operation of such a tank is simple. It is necessary to periodically inspect the container, hoses, pipes, and pipes suitable for it. Be sure to monitor the fluid level in the hydraulic tank. If its level decreases excessively, air will enter the system, an air lock will occur and heating operation will be disrupted.

An expansion tank for an open heating system is inexpensive, and the device eliminates water hammer, breakdowns and other technical problems. Its manufacture and installation do not require special professional skills, so you can make and install such a container yourself.

Features of choice

It may seem to you that the expansion tank has a simple design and you can choose it only based on volume. But there are a few more points to consider:

- The membrane material must be resistant to reagents and additives used in coolants;

- The inside of the tank must be covered with high-quality paint or other coating.

- The protective coating on the inside of the container should not react with the coolant;

- The membrane must be resistant to high temperatures;

- The maximum permissible pressure in the tank must correspond to the characteristics of your heating system;

- All connections and seams must be resistant to high pressure and water hammer.