A small country house or cottage must be heated in the off-season and winter for people to stay comfortably in the premises. Due to limited space, the best option is a mini brick oven. Let's consider the advantages and common schemes of such a heater. We will also analyze the process of construction by professionals of one of the options for a small stove structure.

Construction of one of the options for a small brick stove Source na-dache.pro

Advantages of a small oven

For many decades, properly constructed brick heating structures have not let homeowners down. Although their configurations have changed over time, they are still one of the best options for space heating if built with skill. Therefore, even a small stove must be developed and rebuilt by professionals.

One of the advantages of a compact heating design is the small area it occupies. That is why such a stove is the best option for a country house. After all, it is usually a small building. At the same time, a wood-burning brick heater of a compact size is characterized by high heat transfer, which is why it is found not only in homes. Its laying is also carried out in bathhouses and even in buildings for utility purposes.

To build a compact stove, a minimum of materials is required. Therefore, its construction will not burden the budget of a standard family. Moreover, it is a practical option if it is built with a hob. This model will not only warm people, but also allow them to prepare hot food and heat water.

To build a small furnace, a minimum of material is required Source build-experts.ru

Another advantage of a brick compact heater is the minimum time required for its construction. Professionals need approximately 1 day to lay a small model. In extreme cases, work is completed within 48 hours. However, for quick and high-quality construction, it is necessary to first carry out thorough preparatory work. This is another reason why you need to seek help from professionals.

A small brick stove for a summer cottage looks much more attractive than a “potbelly stove”. If desired, a structure made from building blocks can be decorated with tiles. In this case, it will warm the house and decorate the room. They even create models with a niche for drying vegetables or a built-in tank for heating water. In fact, there are a great many options, and professionals from a specialized company will always help you sort them out.

Conclusion

A high-quality home convection oven can be used both to heat a room and to cook food on a special panel. At the same time, a household convection oven has significant differences from one intended for industrial use. Household heating can heat up to 100 cubic meters. In rare cases, options up to 600 cubic meters are purchased, but this is only relevant for large private houses.

There is also a separate type of combi oven in which food is prepared. This is a common technique for restaurants, but the principle of steam generation in it is the same as in standard ovens of this design. Before making a choice, you need to take into account your needs and the dimensions of the device, as well as determine the location for its installation.

Common designs for miniature brick ovens

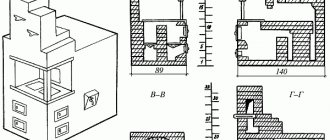

For small stove structures, the dimensions of the bases are usually 500-700 mm in width and 650-1000 mm in length. Moreover, their height varies from 1500 to 2300 mm.

The height of small stoves usually does not exceed 2300 mm Source aviarydecor.com

Small heating stove

This option is the simplest brick structure for space heating. Its standard width, length and height are 510, 890 and 2380 mm, respectively. Installation of this heater is usually carried out in the kitchen near one of the walls or in the middle of the room. It is capable of heating an area from 20 to 35 m². If it is placed against the wall, then not only the kitchen, but also the adjacent room is heated.

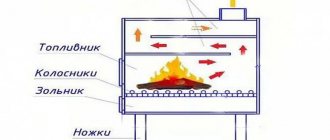

A small brick stove for heating only consists of the following parts:

- combustion chamber;

- smoke exhaust channels through which combustion products go into the chimney;

- blower with a door measuring 140*200 mm.

When developing a project, a combustion door of 200*300 mm is selected. It can be made of heat-resistant glass or cast iron only. The choice is made based on the homeowner's aesthetic preferences. If you install a glass door, then the process of burning wood will be visible through it. After its installation, the heating structure will look a little like a fireplace.

Glass combustion door option Source navetkah.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

This model also contains 2 smoke valves. They are located at the top and in the middle of the stove. To clean the smoke channels, the design provides one door measuring 400*200 mm. To build this model, use:

- ceramic bricks – 260 pieces;

- fireclay brick blocks – 130 pieces;

- grate 230*400 mm;

- a sheet of metal measuring 500*700 mm, which is placed in front of the firebox on the floor;

- sand and clay for preparing masonry mixture;

- two roofing felt sheets 600*1000 mm.

On a note! Due to the use of masonry mixture, the overall dimensions of the heater are increased by the total thickness of the seams.

The lower part and the top of a small stove for a summer residence are created from ceramic bricks. Fireclay brick blocks are used for masonry of the combustion chamber. The long side of the bottom of the structure consists of 3.5 bricks, and the short side - of 2 pieces of a standard length of 250 mm. 35 brick rows are being installed in height.

Fireclay bricks are used to lay the firebox, and the top and bottom of the stove are made from ceramic blocks Source na-dache.pro

Small heating stove with hob

This option is suitable for heating from 20 to 25 m². The standard length, width and height of this structure are 640, 510 and 2150 mm, respectively. In addition to the firebox, vent and smoke exhaust ducts, the stove also has a hob. You can also build a model with a niche for the oven.

The hob is a finished product. Manufacturers create it from cast iron with a hole that is covered with a disk, or in the form of a continuous flooring. A more practical option is a stove design with a niche. After all, it can be used not only to place a metal oven, but also to install a water heating tank. In addition, often the niche is not occupied by anything. In this case, things are dried in it.

When constructing a heating and cooking furnace, use:

- ceramic bricks – 222 pieces;

- combustion door with dimensions 200*200 mm;

- grate with dimensions 250*400 mm;

- hob 350*380 mm;

- a square door of the ash compartment, the height and width of which are 140 mm;

Option for a square blower door Source pechi-kamin.ru

- pre-furnace iron sheet measuring 500*700 mm;

- steel corner;

- sheet of flat slate;

- valves in the amount of 2 pieces;

- two doors measuring 140*200 mm to cover the cleaning holes.

The laying of such a mini brick stove for a summer residence is also done using a mixture of sand and clay. A ready-made special solution is also used for installation.

Advantages and disadvantages

Such stoves have proven themselves to be excellent in heating houses, cottages, garages and other premises. They are able to operate in two modes: instant heating and heat retention . They are very easy to use. Firewood, peat, coal or paper can be used as a combustion product. But let's take a closer look at all the pros and cons.

Positive sides:

- does not need electricity.

- Distributes heat evenly throughout the house.

- Can operate on paper and wood waste.

- Extremely economical.

- Its efficiency (efficiency factor) is about 80%.

- It is possible to control the level of combustion.

- Such furnaces come in different shapes, types and capacities, which allows them to be perfectly adapted to a specific task.

- Durability.

However, the convector system also has its disadvantages.

Negative sides:

- When heated, hazardous combustion products are released.

- There may be problems during installation, since everything needs to be coordinated with the fire services.

- Ash released through the chimney contributes to pollution of the environment and the surrounding area.

The process of building a small stove

At the initial stage, preparatory work is always carried out. The quality of construction of a small brick stove for a summer cottage largely depends on them.

Project selection

When contacting professionals, you can choose one of the ready-made stove designs. Highly qualified specialists will also, if necessary, develop individual drawings taking into account the customer’s wishes. When choosing a specific option, consider:

- heated area;

- number of heated rooms;

- winter air temperature outside;

- purpose of a small stove;

- heater heating frequency;

- construction costs.

When choosing a furnace design, construction costs are taken into account Source ark-eng.ru

Device

Regardless of the individual secrets of each design, the general basics of how stoves operate are the same. The main task of the developer is to ensure natural or forced air movement along the heated body using special convective channels.

How the system works

The movement of air through the channel is ensured by the Archimedes force, but in some models the complexity of the labyrinth does not allow the air to overcome excessive resistance. In this case, small fans are installed that provide injection of cold air and automatic displacement of heated air. Such an addition to the design must be preliminarily assessed in terms of energy costs so that it does not work with zero efficiency.

Video description

The video will help you understand how to install one of the options for a small brick stove for a country house:

- On the 16th row, a continuous masonry is made above the cooking chamber and the smoke exhaust channel continues to be laid out.

- When installing the 17th row, a door is installed through which the chimney will be cleaned.

- During the laying out of the 18th row, the final fastening of the door is performed to clean the chimney.

- The laying of rows 19-22 is carried out according to the scheme depending on the selected furnace design.

- When installing rows 23-27, a wind niche is created. At the same stage, the oven itself is installed. It is first wrapped with asbestos rope. It allows you to improve the accumulation of thermal energy.

- When laying the 28th row, a second cleaning door is installed.

- During the laying of the 29th row, a chimney valve is installed.

- On the 30th row, the previously selected pattern is laid out.

- When installing 31 rows, a second chimney valve is placed.

Finally, the 32nd row is laid out, which serves as the basis for the chimney. Usually it is also mounted from brick. However, some homeowners choose to install a metal chimney.

Bavaria (Ekokamin, Russia)

The Russian company Bavaria calls itself a leader in the production of furnace equipment.

They have been working since 2000. Specialization: fireboxes, conventional and tiled stoves. The plant offers 3 product lines, the most popular of which is Bavaria. These are steel furnaces lined with fireclay bricks. They can be standard or corner, with or without a hob, lined with ceramic tiles or tiles. The range of this line includes products costing from 16 to 75 thousand rubles. Main characteristics of Bavaria stoves from Ecofireplace

| Characteristic | Bavaria | Bayern Corner | Bavaria Prismatic (wall-corner) |

| power, kWt | 6-13 | 6-13 | 7-15 |

| Volume of heated room, m³ | 90-195 | 90-195 | 105-225 |

| Maximum log length, mm | 300 | 300 | 400 |

| Chimney diameter, mm | 150 | 120 | 150 |

| Size, mm | 476x579x835 | 515x650x860 | 527x638x1000 |

| Weight, kg | 107 | 70 | 107 |

| price, rub. | 21 000 | 18 000 | 27 000 |

Impressions from use. Compact dimensions, laconic design that is suitable for any country house, interesting cladding solution, you can choose tiles to suit your taste. Warms up a cooled house of 50 square meters to +7°C at -15°C outside in 2 hours. The maximum burning time on one tab is 6 hours. The possibility of connecting a chimney behind or on top of the stove is conveniently implemented. However, you should not count on efficient use of the stove, because it heats up very slowly.

Watch a video review of the corner modification of Ecofireplace Bavaria with stove:

Briefly about the main thing

A small stove for a country house will take up minimal space in the room. Despite its compact size, it has high heat transfer and a more attractive appearance than a “potbelly stove”. Its construction requires a minimum of materials and time.

A small stove structure can be intended only for heating a room. The construction of models is also carried out, in which there is a hob and a niche for an oven or a water tank. For the construction of any of the structures, ceramic and fireclay bricks are used. The construction process begins after selecting or developing a project, preparing the necessary materials and foundation. The masonry itself is carried out using a solution of sand and clay according to a pre-selected pattern.

Principle of operation

Convection ovens can use almost any type of fuel to heat your home. This can be agricultural waste, firewood, fuel oil, pellets, briquettes, etc.

In fact, the type of fuel does not matter, because the principle of operation always remains the same and heating occurs due to the rapid supply of hot air through special holes in which pipes are welded into the body.

The supply of cold air is ensured by the fact that there are structures in the lower part through which cold air is drawn in. When the oven is heated to high temperatures, air circulation occurs very quickly.