Heating appliances that use liquid or solid fuel function correctly only if the chimney pipe is installed correctly. The thrust in it should be sufficient and under no circumstances should it tip over. Many users of heating stoves (or those who are just planning to install it) think about what to do if backdraft occurs in the chimney.

The draft occurs in the channel due to the temperature difference between the external and internal air. If it is not enough, or the channel is too short, backdraft may occur, which is very dangerous for human health. Indeed, in this case, all combustion products enter the room.

What to do if there is no draft in the chimney

The main criteria on which the quality of draft in the chimney depends

:

- The cross-section of the pipe (it must be correctly calculated for each specific stove, because if it turns out to be too small, despite the sufficient speed in the pipe, the amount of combustion products removed will be insufficient for maximum heat transfer from the stove; on the other hand, if a person decided to play it safe and installed the pipe too large diameter - the air in it will cool very quickly and condensation may form, which has a detrimental effect on traction).

- The height of the chimneys (the minimum length is 50cm, however, many factors influence this value; detailed calculations and standards are prescribed in SNiP41-01-2003 and SP 7.13130.2009).

- Smooth or rough internal surface (irregularities inside the pipe reduce draft, as they create obstacles to the movement of air, and therefore increase pressure loss along the length).

- The difference in temperature between the outside air and the air inside the stove (hot air rises up the pipe, gradually cooling, which is why draft appears).

- Supply ventilation (for maximum efficiency of the stove, a sufficient air flow is necessary, because combustion products along with the air are emitted through the chimney to the street, which means that the same amount of air must enter the room to maintain stable combustion).

Craving as a physical phenomenon

- When there is no artificial ventilation (let’s mentally turn to natural conditions, as everything happens in nature), air masses behave as follows:

- air by default tends to where it encounters the least resistance;

- as soon as aerodynamic “help” appears in the form of an elongated “corridor”, the intensity of air flow increases. They are forced to move to where an empty, unoccupied place awaits them.

- As a matter of fact, chimneys and pipes serve precisely as such corridors. This is a man-made option to forcibly create draft to extract combustion products from the premises:

- as a result of certain engineering calculations, the pipe of a furnace, column or boiler has such characteristics as to create an aerodynamic directed air flow of flue gases;

- draft occurs due to the fact that the air pressure inside and outside the furnace is different.

Violation of draft is not a consequence of poor quality chimney.

Reverse airflow can occur even when using prestigious equipment. In this article you can learn about the pros and cons of a homemade long-burning wood-burning stove. Find out how to independently build stoves for a wood-burning cottage here. Read about the advantages and design features of a brick stove with a water circuit:

Rotary turbine

In the case when all of the above reasons are eliminated, and the draft is poor, a rotary turbine is installed. It is placed on top and will forcibly remove smoke and combustion products using a screw connected to an electric drive.

Switching on occurs automatically when the temperature and air speed sensors are triggered. The device is in great demand due to its simplicity and efficiency.

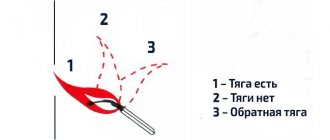

Backdraft Detection

To denote the reverse movement of air flows (not through the chimney, but back into the room), there is a term - overturning the draft. The name speaks for itself: the flow of gases from burning fuel tends back into the room, and not out. There are many videos about this on the Internet with detailed descriptions.

Before each start of heating devices, it is recommended to determine the strength and direction of draft with the ventilation devices turned off (if any are installed).

Traditional methods

- We’ll talk about the factors and reasons below, but now let’s figure out what needs to be done in order to identify the very fact of the thrust overturning:

- if the firebox has a glass door (for example, such an element is found quite often in fireplaces), you can clearly see through the glass how quickly it smokes. One has only to open the door slightly, and a cloud of smoke immediately rushes out, that is, into the room;

- It is enough to attach a sheet of thin paper to the opening of the open firebox and see in which direction it deviates. A smoking cigarette instead of a piece of paper will show the same thing.

Professional methods

There is measuring equipment that allows you to measure the draft in the chimney with maximum accuracy, in pressure units. Indicators within 10-20 Pa are considered normal.

- Measurements are made using a two-way method:

- at the top of the chimney;

- at its base.

However, this technique is hardly relevant for a private home - most people make do with traditional visual methods.

The anemometer does not provide objective information at wind speeds below 1 m/sec. That is, in calm weather there is no point in using such a device.

Visual cues

- If the ratio of combustion and draft processes is normal, then:

- the flame is yellow with a golden tint;

- smoke appears and immediately evaporates into the chimney channel - without jerking, smoothly and at the same time energetically.

A situation where the normal thrust is too high is not good, because the fuel will burn out too quickly. Excessive draft will be indicated by the white color of the flame and the roar in the chimney.

Trouble-shooting

In heating systems with complex electronics (Termotechnik, Dani, Ross boilers), you should not try to repair the electronic units yourself. This is a matter for specialists who have professional tools and equipment. And malfunctions not related to electronics can be eliminated on your own .

- If the reason why the gas boiler goes out is insufficient draft, you need to inspect the chimney. In winter, in its uppermost part, active formation of ice constantly occurs from the condensation of hot gases containing vapors of moist air. This condensate freezes on top of the inner walls of the chimney (pipe), narrowing the passage opening, causing the boiler to die out. This ice needs to be removed or melted until the area is completely dismantled. During repair work, in order to avoid defrosting of the heating system, maintain the minimum boiler power.

- If the reason for the extinguishing of the gas boiler lies in the low gas pressure on the burners, and the pressure in the suitable gas line is normal, then all fittings, including the gas meter, should be checked for cleanliness. Find which fittings are clogged, clean them and put them back into operation. If the pressure in the line has dropped, then ask the gas service to restore the pressure of the incoming gas. Some devices have the ability to operate on bottled gas - this should be used in case of accidents on the highway.

- A common cause of failures in Ross, Mayak and Dani boilers is a malfunction of the ignition devices. Therefore, you will need to find out why the pilot light on the gas boiler goes out. In some cases, you just need to remove it, clean it of carbon and dirt, clean the pilot hole with a wire of the appropriate diameter and check the contacts. In other cases, its settings on gas pressure, draft and position in relation to the main burner are lost. It is necessary to change the position and adjust the draft or gas pressure so that the pilot flame does not “come off” from the mouth of the burner.

- When a gas boiler does not turn on, the reason may be reflected on the electronic display, which displays error codes. This should not be forgotten. Having read about the boiler malfunction, it is eliminated, and the unit is ready for operation again.

Incorrect operation of protections or blockings is common. Automatic actions occurring with the equipment, as well as malfunctions in which the unit will turn off, are recorded in the memory of electronic devices. List of common false alarms:

- gas analyzer sensors;

- traction sensors;

- photocells for the presence of flame in the combustion chamber (some units are equipped with such sensors);

- gas pressure switch (torque oscillations).

All these errors can also be seen on the display, which will make it possible to quickly understand why the boiler is going out. If there is no smell of gas and the pressure has been restored, then you can safely light the burners and start the boiler when the gas analyzers and gas pressure switch are triggered. All other failures must be checked again by ignition and monitoring during operation.

Why does backdraft occur?

Of the reasons and factors why traction goes in reverse, the most common ones should be highlighted. In turn, they can be divided into simple (temporary, easily removable) and complex (requiring drastic intervention).

Complex reasons

- Most often it's this:

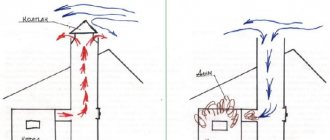

- structural defects of the chimney system (the presence of horizontal or too narrow sections in the chimney, incorrect calculation of the cross-section of the pipe, the height of the pipe is below the level of the ridge of the roof of the house) - engineering deficiencies must be eliminated;

- clogging of the smoke exhaust channel - you will have to clean it out;

- Trees growing too tall near a residential building or high-rise buildings are located - the issue of redesigning the entire chimney system needs to be resolved;

- errors when installing indoor ventilation (insufficient supply air) - accordingly, ventilation diagnostics, dismantling and reinstallation will be required.

Simple reasons

There are times when the thrust “overturns” for just a couple of days, although before that everything worked fine.

Reverse thrust occurs due to the fact that:

- cool weather set in;

- the firebox or stove has been idle for a long time and is not working.

How is this physical phenomenon explained? Very simple:

- a fair amount of heavy cold air has accumulated in the chimney;

- the cooled air mass will be the very obstacle that the air does not like to overcome (see the beginning of the article - the correct draft is always directed to where there are no obstacles).

Solution to the problem:

- endure the smoke in the room and continue heating the pipe - soon the cold “cushion” will be broken through and the draft will be restored. Burn 3-4 sheets of paper without firewood - there won’t be much smoke, and the chimney will warm up;

- use a device called a traction stabilizer in such situations. With its help, the secondary air supply will accelerate the movement of air in the chimney.

The stabilizer is equipped with a safety valve that prevents excessive pressure build-up.

Increasing the chimney height

But still, the most effective way to increase draft, of course, is to increase the height of the chimney pipe. Just don’t overdo it - too high a pipe leads to the opposite effect - too much traction. You can identify it by its characteristic sound. With such a draft, up to 50% of the useful heat can fly out into the “pipe”. Therefore, if there is good draft, it must be adjusted either with a gate (valve) or an ash pan door, or by combining these devices to achieve the desired goal.

A sign of a correctly installed draft is the absence of “howls” in the chimney and the bright, yellow color of the fire. White fire indicates excess traction, dark red indicates its lack.

Check the draft periodically, remember that this will ensure not only the material safety of your property, but also protect your life and health. Be careful and careful.

Reverse draft and ventilation

- No one has canceled the natural laws of ventilation:

- Warm air has a much lower density than cold air;

- therefore, warm air tends to rise;

- if somewhere inside the house windows or doors are open to the street with cool weather, when the heating devices are turned on, the air will go there, and not into the chimney (as the user would like).

Ventilation force during air outflow

- The internal architecture of the building is of great importance:

- if the house has many windows, there are balcony doors or stairs to the upper floor - all this will lead to the formation of drafts;

- On areas located above the firebox level, opening windows and doors to the street is not recommended.

Failure to follow such simple tips is a guarantee that air currents that disrupt the draft will be formed.

Providing ventilation with supply air

- Sometimes the following happens:

- the room is sealed (doors are locked, windows are closed);

- when the stove is lit or the gas boiler or water heater is turned on, low-pressure areas draw fresh air from the chimney;

- result - the thrust overturns;

- The solution suggests itself - it is necessary to create the required air circulation. What needs to be done for these purposes:

- install wall supply valves;

- install supply valves on PVC windows;

- place a forced ventilation device on the window to draw air masses from the street into the room (such devices cut directly into the window glass - you can watch the video on the Internet to see how to make the insert);

- slightly open the window, door or window.

The implementation of one of these measures will lead to the fact that the atmospheric pressure in the room will decrease and the reverse draft will disappear.

If there is a gas water heater

- A gas-powered dispenser has a number of features:

- its combustion chamber draws air out of the room;

- the lack of oxygen becomes noticeable quite quickly (the air becomes thinner, oxygen deficiency is felt);

- Air will periodically penetrate from the chimney, which will lead to the fading of the column and smoke in the room.

Sometimes the user rushes around looking for a defect in the gas water heater instead of carefully analyzing the ventilation - its consistency and efficiency.

What threatens the lack of normal vacuum in the furnace?

Modern, even the simplest gas heating equipment does not allow combustion with reverse draft or its complete absence. However, with insufficient, poor draft, not all boiler models interrupt combustion, and this is fraught with:

- the spread of natural gas throughout the room due to its under-combustion due to lack of oxygen. In this case, there is always a characteristic smell of gas;

- the entry of toxic combustion products into the room, sometimes, especially in small quantities, they are not noticeable by smell;

- increased soot formation, which leads to accelerated clogging of the chimney, heat exchanger and combustion chamber of the boiler.

Ways to normalize cravings

To summarize, let's once again clarify how to increase weak traction and prevent it from tipping over. The choice of method depends on the reasons for the disruption of air flow. Sometimes it is recommended to use more than one method - consult with professionals so as not to make even more mistakes.

Structural changes to the chimney

- It was noted just above that the chimney can be done incorrectly:

- the top edge of the pipe is too low;

- narrowed passages;

- a lot of unnecessary bends, etc.

Such defects must be eliminated.

Stabilizing devices

A reliable chimney draft stabilizer is one of the most effective solutions. Modern devices are equipped with automation. It is enough to turn on the device when problems arise in the chimney with the direction and strength of air flows. As soon as the pressure level reaches the optimal level, the device turns itself off.

- This device makes a significant contribution to improving traction:

- we are talking about an umbrella-shaped extension on the chimney;

- under the umbrella there is an open area for access of air from outside;

- under the umbrella cover there is a temperature sensor for recording the temperature of rising gases from the firebox or column;

- the sensor automatically turns off due to overheating due to gases accumulated due to poor draft.

Deflectors

The purpose of these devices is to increase traction by deflecting air flows. The operating principle is based on the fact that when air flows over obstacles, pressure decreases. The disadvantage of the products is almost zero efficiency in calm weather. If there is no wind outside, the deflector is not only useless, but can also worsen traction.

Rotary pipes

A turbine is installed above the chimney head.

Wind energy rotates the turbine head. Rotation always occurs in one direction - due to this, a vacuum is created above the smoke channel. Unfortunately, in calm weather the effectiveness of the rotary tube is minimal. But the entry of debris and sediment into the chimney is almost completely eliminated. A video with step-by-step instructions will help you understand all the intricacies of this method.

An additional advantage of rotary pipes: the turbine continues to operate even when the heating is turned off.

Revision of the ventilation system

- In most cases, it is enough to analyze the ventilation in the house and thereby eliminate the reverse draft. As noted above, you should carefully:

- regulate the formation of drafts;

- do not allow rarefaction of air in the heated room;

- if necessary, install ventilation devices on the windows.

Never forget: the thrust should not reverse. If there is a strong rollover, there is a threat of not only smoke in the room, but also the release of sparks with subsequent ignition of surrounding objects. If you have any difficulties, invite an experienced specialist to solve the problem with traction.

Typical problems of double-circuit boilers

Double-circuit modifications of gas boilers, intended for the preparation of coolant and hot water, can also fade for all the reasons described above. But if there are no signs of the above breakdowns, perhaps the problem is caused by the specific features of the unit.

These include those that arise due to the operation of the water overheating protection system, namely:

- mixing hot and cold running water;

- thinning of the walls of the gearbox membrane.

The instructions for boilers with an additional heat exchanger for domestic hot water usually warn that two taps cannot be opened at the same time. It is better to initially select the most suitable temperature for heating hot sanitary water in the settings.

What to do if the gas boiler goes out

When the flame goes out, do not panic. First of all, the valve at the inlet shuts off the gas supply from the main line. The room is ventilated, since the smell of fumes or pure gas is not always noticeable.

The next step is to try to establish the cause. The problem of traction is solved independently. Inspect the chimney. If necessary, clean it of soot and ice.

To clean the burning or replace the thermocouple assembly, remove it from the boiler

If the device goes out due to minor faults, you can fix them yourself. To replace the thermocouple, you need to remove the igniter assembly from the boiler and unscrew the union nuts with a wrench.

When there is a power surge in electronic heating devices, fuses often burn

You can even repair a volatile gas appliance yourself. If it does not turn on, the fuses may have overheated due to a power surge. You need to get to the main unit and replace the failed elements.

All other malfunctions of complex components and gas equipment are entrusted to specialists. Mistakes made will not only lead to more serious damage, but are also life-threatening, since the gas is explosive.

The video explains why the pilot light on a gas boiler does not light up or goes out:

Making a deflector with your own hands

The sizes of the deflectors are different chimney pipes.

The walls of the upper cylinder take the wind pressure and direct the air around; smoke suction is achieved by sliding along the inner surface of individual jets. The deflector cannot be classified as a fan, since the device has a simple shape and does not have working mechanisms.

The contours of the parts that were calculated and plotted on the drawing are drawn on the cardboard and cut out. Using patterns, parts are transferred to metal with the addition of 1.5 - 2 cm along the edges of the lines for ease of assembly. Structural elements are obtained in expanded form after cutting with metal scissors.

A hacksaw is used to cut strips of metal or corners to connect parts into a finished product. The prepared parts are bent and rolled in accordance with the drawing. During assembly, the elements are superimposed on each other and connected with rivets.

Required Tools

During production, materials and tools are used that do not require professional skills from the master:

- rubber or wooden mallet;

- scissors and hacksaw for metal;

- ruler, tape measure;

- chalk for drawing lines on the metal surface;

- electric drill, rivet gun;

- metal drills;

- pencil and regular scissors.

The material is thin galvanized steel, a metal strip or a small section corner. The size of the rivets is selected in accordance with the diameter of the drill. Nuts and bolts are used for installation on the pipe.

Size calculation

A drawing is made on paper, which indicates the key dimensions for creating a pattern for a weather vane-draft amplifier for the chimney.

Ratio when calculating sizes:

- the deflector height is 1.7 d;

- the width of the cap is assumed to be 2 d;

- The diffuser width is taken to be 1.3 d.

The symbol d indicates the diameter of the chimney (internal). A different size ratio will result in poor efficiency.