[contents]

There are several reasons why water boils in a heating boiler. For example, boiling is often a consequence of the fact that the liquid is heated in the boiler faster than the thermal energy is transferred to the heating main. This happens due to:

- incorrect installation of the system;

- the fact that there is no circulation (or its speed is low) - usually occurs in open-type systems with an expansion tank;

- too much power of the device compared to batteries;

- low amount of water in the main.

Low circulation rate

So, if the coolant circulates too slowly, the coolant will not fully transfer the resulting heat and, as a result, the water in the boiler will boil. This applies only to those systems in which there is natural circulation of liquid, and the angle of inclination or diameter of the pipes is chosen incorrectly.

Note! In systems with forced circulation, this happens only in cases where the pump power is too low or it has completely failed.

Chimney requirements

To determine what characteristics the manufacturer himself presents, you need to read the instructions, because specific data is given there, what is the minimum cross-section of the pipe needed, height, temperature conditions - these factors in a particular case are fundamental and you need to focus on them. As a rule, the instructions contain the manufacturer writes which chimney is better for a solid fuel boiler and what technical parameters need to be taken into account. The above listed characteristics, such as the height and length of the chimney, will allow you to choose a reliable and, most importantly, functional channel from the point of view of this particular model.

Consider the diameter of the chimney for a solid fuel channel, because not every channel will be able to remove the formed amount of gas in a certain time, and accumulated fumes and gases can enter the room through unsealed joints and cracks.

Not enough coolant

If there is too little water in the system or air pockets have formed, this may also be the reason why the water boils in the heating boiler. If there is an expansion tank, then you simply need to add water. In other cases, it is enough to bleed the air (if there is no automatic valve, of course).

To increase the circulation intensity, the heating system should be re-equipped, and it is better, if possible, to install a circulation pump. In this case, even if the pipes are not tilted correctly, the water will circulate properly.

Answer

Water in a heating boiler may boil because the rate of heating in the boiler exceeds the rate of heat transfer in the home heating system. This can happen for several reasons:

- insufficient coolant circulation rate or its absence;

- insufficient amount of coolant (water) in the system - most often happens in open systems with an expansion tank;

- excess power of the heating boiler compared to the total power (heat transfer) of the heating radiators of the house, taking into account losses - in the absence of a system for regulating the draft (power) of the boiler;

- improper installation of the heating system.

Now let's look at these reasons in more detail.

If the coolant circulation rate is insufficient, the heated water does not have time to release the heat received in the boiler into the system and can heat up in the boiler to the boiling point. This can happen in heating systems with natural coolant circulation if the correct pipe installation slopes are not observed or, less often, if their diameter is insufficient. With a forced circulation system, this can happen if the circulation pump is not selected correctly, is faulty, does not work, or there is no electric current supplied to it.

Also, the water in the boiler can boil if for some reason there is not enough water (coolant) in the system and air gets into it. If you have a heating system with natural circulation and a conventional expansion tank, this sometimes happens and in this case you just need to add water. Depending on the design of the heating system, sometimes it is necessary to bleed air from the system or some part of it (in the absence of an automatic valve).

To increase the circulation of water in the heating system, it is necessary to remodel the heating system or, best of all, install a circulation pump. Even with not entirely correct pipe slopes or in their absence, the circulation pump will provide the necessary circulation.

Water in the heating system can also boil if the installed boiler’s power is much higher than the heat transfer power of the entire system, especially if there is no or malfunction of the automatic regulation (draft) air supply system. In this case, it is necessary to install a semi- or automatic draft control system, replace the boiler (if it is homemade without a draft control system) or increase the number or power of radiators. Also, as an option, you can install an indirect water heater (boiler) in the system, which will take part of the heat from the system to heat water and serve as a kind of heat accumulator.

High boiler power

If the power of the device is higher than the heat transfer of the main line, this can also lead to boiling of water. Especially if the air supply control system is broken or missing altogether. There are several options to solve the problem:

- install an automatic adjustment system;

- install a similar one, but semi-automatic;

- change the boiler (if you made it yourself);

- increase the number of batteries;

- increase their power.

Note! In addition, you can embed an indirect heating boiler into the main line - this device will “absorb” some of the energy from the water heating system and serve as a kind of heat accumulator.

Using the Safety Valve

This is not the same thing as a safety valve. The latter simply relieves pressure in the system, but does not cool it. Another thing is the boiler overheating protection valve, which takes hot water from the system and instead supplies cold water from the water supply. The device is non-volatile and is connected to the supply and return lines, water supply network and sewerage system.

When the coolant temperature is above 105 ºС, the valve opens and, thanks to the pressure in the water supply system of 2-5 Bar, hot water is forced out of the heat generator jacket and pipelines with cold water, after which it goes into the sewer. How the solid fuel boiler protection valve is connected is shown in the diagram:

The disadvantage of this method of protection is that it is not suitable for systems filled with antifreeze liquid. In addition, the scheme is not applicable in conditions where there is no centralized water supply, because along with a power outage, the supply of water from a well or pool will also stop.

Circulation problem

If you have a circulation pump, but the system is unstable, then the problem may lie there. To check the functionality, place your hand on the battery - if you feel a slight vibration, it means the pump is working normally, if not, follow these steps.

- Check and clean electrical contacts.

- Check the pump parts for wear and lime deposits (if using regular tap water).

- Finally, you can turn off the pump, unscrew the plug and turn the shaft with extreme caution. This should help for a while. Citric acid can be used to remove deposits.

Principle of operation

Schematically, the OS heating circuit can be represented as a long vertical ring. One side of the ring

- with hot water (supply riser from the boiler to the boiler),

the other side

- with cold water (riser with return from the radiators). The density of a hot coolant is less than that of a cold fluid - water expands when heated.

Consequently, the weight of water and the pressure of the water column in the cold part of the circuit will be higher than the weight of water and the pressure of the column in the hot leg.

According to the law of communicating vessels, the liquid will tend to balance the pressures - to move from the cold branch to the hot one.

Since the circuit is such a closed ring, circulation or gravity flow of the coolant occurs.

- The supply riser is maximally insulated along its entire height.

- The boiler is located as far down as possible from the last radiator.

- The circuit has a container for releasing the excess volume of heated coolant

- an expansion tank (to ensure a reduced density and low pressure of the water column in the heated branch).

With natural circulation

During natural circulation, the coolant moves under the influence of the circulation pressure Pн

(in mm water column):

Pn=H x (cold - phot).

- H

- height difference between the boiler and the last radiator, m; - phol

- density of water in the cold return riser,

kg/m³

; - phot

- density of water in the hot supply riser,

kg/m³

.

During circulation along the circuit, the coolant spends part of the pressure to overcome the hydraulic resistance of pipes, radiators, and shut-off valves. Therefore, when designing an operating system, materials with low hydraulic resistance

so that their total does not exceed the design pressure

Pn

(do not block the system).

Important! The OS coolant contains air, which is mixed in the expansion tank. To remove air, pipes are made with a slope of at least 3-5 mm per p.

m. pipes.

With circulation from a pump

To increase the natural pressure, a circulation pump is included in the OS circuit.

There are two pump insertion points

to existing OS:

- On the return pipe in front of the boiler.

The expansion tank is reconnected to the return pipe in front of the pump (in the suction zone). - On the upper supply pipe

immediately after the expansion tank connection point.

Reference!

The pump insertion point is equipped

with a bypass

with a reed check valve.

Single-pipe

A single-pipe system with natural circulation is made only with upper coolant distribution.

All radiators in the riser of a single-pipe OS are connected in series - the output of one battery is connected to the input of another.

- Small number of pipes.

- Easy to install.

- The system is unbalanced

- the top batteries are hot, the bottom batteries are cold. To equalize the temperature regime, lower radiators are installed with a large number of sections. - Impossibility of thermoregulation

due to high resistance of control valves.

Most common situations

The most common source of the problem is an air lock in one of the nodes. It is necessary to carefully examine the entire system, focusing on the circulation of hot water. If a warm liquid comes from a pipeline instead of a hot one, it means that this is where an accumulation of air has formed. It is necessary to bleed excess air from the system using bleed valves. If this problem was not detected during the inspection, most likely the cause of the boiling lies directly in the functionality of the boiler.

Overheating of a boiler based on a gravity heating system can be caused by insufficient coolant circulation in the circuit. In this situation, you should place the expansion tank at the highest point in the house, in which case an additional load will be placed on the boiler and the required heated resource will be directed to it.

Experts recognize the most practical method of solving the problem as installing a circulation pump and equipping the heating system with a mixture circuit. Both types of devices allow you to reduce the load on the functionality of the heating device; cooled water will be added to the network. The boiler will receive return flow, which will provide natural cooling.

Preventative measures and prevention of overheating

Measures to prevent and prevent emergency situations include the following:

- Install an additional circuit to cool a boiler that runs on solid fuel. In a double-circuit boiler, when the coolant increases, the liquid can be cooled due to the water supply system.

- Installing a buffer tank, it will prevent the boiler from boiling, take on excess temperature, and can also store heat for the heating circuit.

- You need to install an uninterruptible power supply. If there is a power outage, the uninterruptible power supply will automatically turn on, energy will come from the battery, and the system will continue to operate.

- Periodically clean the ventilation system.

Why does a gas boiler boil?

During normal operation of the equipment, the coolant in the circuit warms up to the set temperature. After which it is distributed naturally or forcibly through the heating system through the pump. This is how the radiators in the room warm up. The liquid then moves along the return circuit and returns to the boiler.

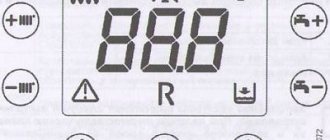

In case of overheating of the coolant, thermal sensors are activated. As a result, the operation of the device is blocked. What to do if the boiler boils? To restore heating, it is necessary to find the cause of the breakdown. Sometimes the self-diagnosis system displays an error code:

But if this does not happen, the problem can be identified by external signs.

What causes overheating:

- Clogged filters;

- Air accumulation;

- The heat exchanger is clogged with scale;

- Problems with the circulation pump;

- Failure to comply with regulations for the premises where the equipment is installed.

How to fix the problem?

We remind you once again: if gas equipment overheats, contact a specialist immediately. If repairs are delayed and the security system fails, the boiler may even explode.

Filters are clogged

Check the filters first. Turn off the boiler and wait until the water cools down. Turn off all taps and remove filters. If they are clogged, wash them in a solution of citric acid, or clean them with a soft brush. If the filters are completely worn out, it is better to replace them.

Air jams

Water boiling can also occur when the heating system is aired. Air can not only slow down the movement of the coolant, but also stop it completely.

Touch the radiators with your hand. If they warm up unevenly, an air lock has most likely formed. To do this, specialists use special equipment that detects cold spots in the heating circuit.

So, in case of air jams, follow the following algorithm of actions:

- place a basin or pan under the Mayevsky tap, and then open it;

- The air will begin to hiss and water will begin to flow. Do not close the tap until all the liquid has drained and all excess air has been released;

- repeat until the air lock disappears.

Heat exchanger clogged

Even when using high-quality coolant, during constant operation, various salts form on the pipes and walls of the heat exchanger. Due to scale, the passages narrow, the pressure decreases, and the water boils.

This is why experts recommend annual maintenance of gas boilers. During diagnostics, a specialist will assess the condition of the heat exchanger and flush it if necessary. If the heat exchanger is destroyed, then it will have to be replaced.

In addition to regular maintenance, fill the heating circuit with “soft” water or install magnetic filters and change them once a month.

Circulation pump malfunction

If you use a closed heating system, then check the operation of the pump. If not used for a long time, its parts could become stuck or clogged - usually the problem is solved by washing it.

Incorrect operation of the smoke removal system

Heating of the boiler body can occur if the smoke removal system is malfunctioning, and the heat exchange surface on the burner side may be dirty or clogged with soot.

Check the presence of draft in the chimney and the flow of combustion air into the room. Let the specialists clean and adjust the gas fittings.

High boiler power or low water flow

The problem can also arise if the power of the device is chosen incorrectly. For example, with high power and low water flow. The coolant simply will not have time to cool.

It is best to eliminate this problem at the stage of installation and purchase of equipment. Consult with specialists, they will calculate your needs and suggest the necessary equipment parameters.

If the heating system is already installed, try to increase the water flow. Install a more powerful pump, buy faucets with larger cartridges, replace watering cans with versions with more holes.

Or contact specialists for help in adjusting and configuring the device. It may be necessary to reduce the gas pressure.

Place of installation of boiler equipment

Make sure that there is no high humidity or low temperature in the room where the boiler is installed. Otherwise, the metal will gradually deteriorate due to corrosion.

Expansion tank device

Structurally, this container is very simple. The material used is translucent plastic. Also, a sensor can be additionally built into the tank, which signals the driver about a critical decrease in the coolant level.

The top of the tank is closed with a lid in which a valve is installed to regulate the pressure. If the pressure in the system increases, then the valve operates.

Also on the wall of the tank there is a level indicator in the form of o and “maximum”, allowing you to control the liquid level

It is important to understand that on a cold engine the level should not fall below the minimum. It is also not allowed to exceed the maximum level

As for the tank cap with the valve, it seals the container hermetically on a cold internal combustion engine. However, when the engine reaches operating temperature and the coolant heats up, the pressure in the cooling system and in the tank naturally increases.

If the pressure rise reaches an average of 120 kPa, the valve opens. When the pressure drops to an average of about 83.4 kPa, the valve closes. This operation of the valve is necessary in order to avoid rupture of pipes, damage to the radiator, etc.

At the same time, after the engine cools down, the pressure in the system begins to drop, the volume of coolant decreases and a vacuum is created. When the pressure drops, on average, below 3 kPa, the inlet valve of the expansion tank opens to take in air. As a result, the pressure difference is leveled, and the missing volume of liquid is compensated from the tank.

Expansion tank

Located in the attic. Since the attic is usually an unheated room, the tank must be insulated, otherwise the water in it may freeze in winter. The tank compensates for temperature fluctuations in the water level. In addition, sometimes water in the system can boil (this happens if you start heating the boiler too quickly), and the bubbles significantly increase the volume. This is what the excess volume in the expansion tank is for.

It is advisable to provide for the possibility of draining excess water from the tank when it overflows. To do this, water can be discharged either into the sewer or simply onto the street.

It should be borne in mind that water from an open system evaporates. Therefore, it is necessary to replenish the system with water. This can be done manually, periodically climbing into the attic and adding water, or you can make an expansion tank similar to a toilet - with automatic topping up of water.

But they rarely do this. Usually they just use a container.

It is better to close the top of the tank with a lid so that less water evaporates.