Double-circuit wall-mounted boilers "Baksi" - gas equipment for individual heating from an Italian company. They are compact, convenient and reliable. However, malfunctions also occur in the operation of the Baksi boiler, and it is worth finding out about their elimination in advance.

Boilers from this manufacturer have many advantages. The main advantage is cost-effectiveness. Their service life is quite long, and during operation they make virtually no noise. Using this heating device, one can also note its high performance and ease of operation. In addition, Baksi boilers are sold at affordable prices, and representatives of all segments of the population can afford them.

Baxi boiler installation instructions

Like any device, a gas boiler requires study before installation. Before installing the boiler yourself or with the help of a specialist, you should study the instructions. The boiler should be prepared for the first start-up. An experienced specialist should work at this stage, since the boiler is connected directly to gas.

At the stage of preparing the boiler for the first start-up, an experienced specialist should work

What to do

- Check that the parameters of the boiler and the parameters of the systems located in your room correspond to each other.

- Then you can connect the device.

Where is the most reliable automation for heating boilers sold? Look here.

Another interesting function is called “shower”. When used, the boiler generates hot sanitary water, which creates even greater comfort and coziness.

Construction of a Baxi floor-standing gas boiler

If necessary, the Baxi gas boiler can be converted from natural gas to liquefied gas. Under no circumstances do this yourself; use the services of qualified specialists.

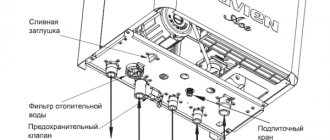

Manipulations before installation work

The presented boiler is designed to heat water as quickly as possible to the optimal boiling point temperature at atmospheric pressure. The Baxi MAIN Four 240 F device must be connected to heating installations

and distribution networks of hot domestic water. Before purchasing, each person should carefully read the instructions, and also determine the compatibility of all declared characteristics and power.

Before connecting the Baxi MAIN Four 240 F boiler,

- Thoroughly wash and clean the pipelines to remove possible impurities;

- Check the suitability of the boiler for operation with the supplied gas. This can be done thanks to the inscription on the original packaging or on the plate that is attached to the passport;

- Determine the optimal chimney draft values. The boiler must not have constrictions or other outlet pipes from other devices;

- Arrange the proper type of chimney so that there are no narrowings in it and exhaust pipes for other devices are connected;

- The boiler is connected to an existing chimney. The owner needs to carefully check its cleanliness, because during operation of the structure, slag can separate from the walls and become an obstacle to the free release of exhaust gas.

baxi boiler error codes

Baxi boiler error codes are known to almost all users. There are four most common: E 01, E 03, E 25, E 26 and E 35.

Gas boiler baksi and errors, unfortunately, are similar definitions to each other, but this does not mean that baksi are bad. The electronic boiler system is locked when these symbols appear on the screen.

Error E 01

Consider the baxi boiler, error e01.

This malfunction means the ignition is not working properly. It is because of this that the Baxi boiler error E 01 appears on the display. Most often it occurs when starting the boiler for the first time. Read the installation instructions carefully again, perhaps some error has occurred. Below we will name several possible reasons for the failure:

- Gas valve is not open

- The zero and phase are incorrectly observed at the stage of connecting the electric current.

- No spark or ignition electrode interference. This moment is visible to the naked eye during the pulse.

- Damage to the automated panel.

Check carefully to see if you have one of the listed errors. You can fix each of them yourself. If not, you need to seek advice from a specialist or company representative.

A more radical way is to do a hard reboot using the “reset” button.

Common error e03 on a baxi boiler

Let's now look at the baxi boiler: error e03.

This error may appear after a long time, when you are already actively using the boiler. For some users, it appears on the electronic monitor and disappears by itself. What is recommended to fix this error:

- Clean the blades thoroughly; there may be a lot of dust collected on them.

- The grease of the radiator bushing and axle on the rear of the engine has worn out. In this regard, the fan begins to spin slowly.

How much does a stainless steel pipe cost, price from the manufacturer. See here.

Branded thermostat for oventrop heating radiator. More information about the manufacturer at the link: https://prootoplenie.com/otopitelnoe-oborudovanie/batarei-radiatory/termoregulyatory.html

If nothing helps after cleaning, you need to contact a specialist.

Baxi boiler error e35 - problem with the flame control sensor.

E 35 is connected to a flame control sensor; it serves to signal the presence of fire even before the valve opens. The reasons why it may not work are varied, but the most likely of them are:

- Water or condensate gets on the electronic board located in the boiler.

- Parasitic flame. This is the name of the undying flame after the boiler is turned off. The manufacturer attributes this to insufficient tightness of the gas valve.

However, most often, error E 35 corrects itself after rebooting the boiler.

Error E 25

According to the manufacturer, this malfunction indicates that the maximum temperature has been exceeded. Here you should pay attention to the heating circuit temperature sensor. But first check the following:

- Pump. If error E 25 occurs, it may be blocked.

- It is likely that the heating system is completely or partially aired.

- The filters in the heating system itself are clogged and, as a result, there is insufficient coolant circulation.

- The heating temperature sensor in the device is broken.

The main advantages of Baksi boilers

- Size: the boilers are so compact that they fit into any room;

- Savings: unlike other boilers, they save up to 35% of gas while remaining very efficient;

- Modulation: the boiler itself determines when it can save, thereby automatically reducing energy consumption;

- Boilers can be installed in cascade;

- Silent;

- Possibility of smoke exit through the wall, without installing a special chimney;

- Environmental friendliness: air emissions are significantly reduced.

- The weight of the boiler is 98 kilograms, and the dimensions are 950/600/650. The dimensions of Baksi are almost 4 times smaller than those of the same boilers from other manufacturers.

Incorrect connections are often encountered, which leads to errors in Baxi boilers

Baxi has a fairly wide range of boiler models to suit the different needs and capacities of your premises. After installation, even a child can use this boiler. The electronic panel is simple and accessible without studying the instructions.

Positive Features

Malfunctions of the Baksi boiler, of course, sometimes occur, but it still has more positive features - automated operation, environmental friendliness, reasonable cost, ease of operation, and maximum adaptability to difficult conditions. The last feature is relevant for Russia.

Because the equipment is automated, it can operate for a long time according to a specific program. This is convenient for country cottages in which the owners do not live permanently, but from time to time. When such boilers operate, carbon dioxide is released into the air, which is absorbed by plants. This indicates the environmental friendliness of such devices. The manufacturer has made sure that the buyer repairs Baxi boilers as rarely as possible. The main faults and solutions are described below.

During the manufacturing process, equipment is equipped with protective chips that are capable of leveling out voltage fluctuations in the network.

Analysis of errors and malfunctions of Baxi gas boilers

Almost any buyer of Baxi wall-mounted gas boilers, sooner or later, encounters some malfunctions and breakdowns of the device. Experts strongly recommend carrying out gas boiler maintenance at least once a year: flushing the heat exchangers, cleaning off accumulated scale, checking the functionality of the sensors before the start of the heating season.

However, modern heating equipment tends to break down over time, which will require repair or replacement of spare parts. Let's consider one of the most popular brands in Russia - this is the Baxi gas boiler, its malfunctions and errors are displayed on the control panel under special codes under the symbol "E", which is an abbreviation for the English word "Error" - error.

Let's consider the main malfunctions that a user of a Baxi gas boiler may encounter when there is no hot water and why the boiler does not heat the water, the pressure drops, the burner of the Baxi Main Four 240F or Baxi Eco Four 24F and other models does not turn on or ignite.

We will analyze all the errors of the device according to the instructions, the reasons for their occurrence and methods for eliminating the problems that arise on our own or by specialists.

Display of the Baksi gas boiler

Italian wall-mounted double-circuit and single-circuit gas boilers are equipped with an informative digital display, which displays not only information (symbol “A”): the temperature of the water in the heating system or in the DHW circuit, or setting parameters (symbol “F”): operating modes and warnings, but also errors under codes “E”.

If the “R” symbol appears on the display, this means that a malfunction has occurred and you can try to fix this problem yourself. To do this, press the “R” button and hold it for several seconds. If this does not help, then it is better to immediately call a specialist gas specialist to your home.

However, let's take a closer look at the error codes that we may encounter when operating the Baxi boiler.

Error E01.

This is one of the most common errors that occur when operating Baksi brand gas boilers. It signals that there is no ignition in the device, as a result of which the boiler does not turn on.

Baxi Error E01

2. The flame electrode or the wire leading to the ignition unit may be faulty.

3. Gas valve or electronic board is faulty. Check all connections between them.

Error E02.

Another common error under the symbol “E02” indicates to us that the safety thermostat of the Baxi boiler has tripped. Usually this error is displayed when the boiler does not heat the water in the heating system well.

1. Check whether the pump impeller is blocked when there is no coolant circulation.

2. The main heat exchanger may be clogged and requires cleaning.

3. It is also necessary to check the limit thermostat connector and the NTS temperature sensor of the heating system at the boiler inlet.

4. A faulty electronic board may also be the cause of error E02.

Error E03.

This error indicates that parameter F43 was incorrectly set when setting up the boiler, which leads to an error in the configuration of the electronic board. To change settings, press and hold two buttons simultaneously for at least 6 seconds:

This malfunction can occur in two cases:

— no ignition; — the flame broke out.

1. It is necessary to check the integrity of the connections between the ignition unit and the flame sensor, as well as between the board and the gas valve.

Troubleshooting

If the flame is not powerful due to incorrect operation of the gas valve, the pressure in the system must be adjusted. This must be done in accordance with the requirements of the instructions. The diode bridge often fails. Then what is required is not repair, but complete replacement.

"Baksi" fee

If the coolant is not heating well, check the pressure at the outlet of the gas valve. Change the position of the regulator and try to start the boiler again. That's all the repairs.

If there are deviations in the sensor readings, they need to be changed.

When the temperature in the DHW is unsatisfactory, check the functionality of the three-way valve. Wait until the water has cooled completely, then close the heating taps, and then turn the heater back on to hot water supply mode. If the heating starts heating up, the valve is faulty. It needs to be replaced.

When strong pops are heard at the moment of ignition, the reasons for what is happening are as follows:

- Gas supply pressure too low.

- Increased distance from the nozzle to the igniter (due to improper transportation).

In such cases, the gap needs to be adjusted. It should be within 4-5 mm. Open the front panel, unscrew the screw securing the electrode, remove the electrode, bend it a little and put it in place.

Decoding

The factory interpretation of error E25—reduced coolant circulation—does not provide a complete understanding of the essence of the problem. In the instructions for various models of the Baxi boiler, the emphasis is on blocking the pump. But this is not the only reason such a fault code appears on the display.

p, blockquote 2,0,0,0,0 —>

Error e25 indicates an intense increase in temperature in the heating circuit. This parameter in Baksi units is determined by the difference in readings from sensors installed at the inlet and outlet of the boiler heat exchanger. When it grows at a speed above 1 0 C/sec, the operation of the unit is blocked by the protection circuit. A decrease in fluid circulation is caused by several factors, therefore there is no clear recommendation for eliminating error E25. The algorithm of actions given in the article will allow you to figure out the reason for the appearance of this fault code in a short period of time.

p, blockquote 3,0,0,0,0 —>