To adjust the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm H2O scale

A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

2. Turn on the boiler

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

11. Turn on the boiler

12. Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

The NAVIEN Ace ATMO double-circuit gas wall-mounted with an open combustion chamber is fully adapted to the harsh operating conditions in Russia, is economical and durable, is not afraid of low water and gas pressure and does not fail due to voltage surges in the network. In addition, Ace ATMO is of good quality and a pleasantly low price. Ace boilers comply with Russian standards and norms, which is confirmed by relevant certificates.

The Ace ATMO boiler is designed for space heating and hot water supply. The special design of the built-in, quickly heating DHW heat exchanger allows you to quickly provide you with hot water, even if you have a very large family. And the electronic DHW control function ensures a comfortable temperature regardless of hot water consumption.

How much pressure should be on the Ariston boiler?

The pressure in the tank is checked when there is no water in the boiler and the pressure gauge = 0 Bar. The nitrogen or air pressure in the tank should be within 0.8 Bar. If your heating system contains a large amount of water - more than 100 liters - you need an additional expansion tank.

Interesting materials:

What is atomic radius and how to determine it? What is an outpost in Dota? What is Auto Assignment in Maxim Taxi? What is a buff and how to wear it? What is book value? What is ballet and its components? What is a fable and when did it appear? What is basic higher education? What is basic fuel consumption? What is a baby alpaca?

For boiler repair and maintenance, contact Profteplo

Our company offers repair and maintenance services for heating boilers of all types from various manufacturers and different years of manufacture. If you see that the system is not working properly, contact us. Our manager can tell you what pressure should be in the electronic boiler based on your usage criteria, and whether there is any reason to worry. If there really is a fault, we will arrive on site and carry out diagnostics, service and repairs on site. Our technician will bring the pressure in the heating boiler back to normal, provide a guarantee for the work, and also tell you how to prevent the situation from recurring in the future. For consultation or to use the service, call the number.

NAVIEN boiler error 03

In gas boilers, the presence of a flame on the burner is checked by a special sensor - an ionization electrode. The operating logic of the unit is to continuously check for the presence of a flame after opening the gas valve. Symptoms of error 03 on NAVIEN boilers can be divided into two groups:

unsuccessful ignition tests (no flame appears)

If ignition does not occur, you need to check:

gas pressure at the inlet and outlet of the gas valve (can only be performed by a qualified specialist using special equipment - a differential pressure gauge)

condition of the ignition electrodes (compliance of the gap with the manufacturer’s standard, contamination of the electrodes). The normal distance between the electrodes is 3.5-4.5 mm.

READ Why the new geyser does not heat the water

integrity of the insulation of the electrode power wire (you can visually verify that the spark breakdown occurs specifically on the body of the gas burner, and not somewhere else)

How to feed a Navien boiler. Creating pressure in the heating system.

correct setting of the boiler power on the DIP switch (valid if there is a problem during the first start of the boiler or after replacing the electronic board)

presence of voltage on the ignition transformer

Error 03 on a Navien will also appear if combustion is unstable (intermittent flame) or if the control unit is unable to detect the presence of a flame. In this case, you need to make sure that the connection between the ionization electrode and the control board is reliable, check that the boiler is grounded and that there is no contamination on the electrode. Unstability of combustion can be caused by an increase in fan speed, so you need to make sure that the yellow hose going from the turbine to the APS sensor is securely connected and not damaged.

If during the checks it was not possible to normalize the operation of the boiler, diagnostics of the boiler board, repair or replacement will most likely be required. We recommend watching a video in which one of the users simulates error 03 on a NAVIEN boiler:

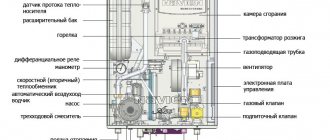

Navien Delux Coaxial device

The word Coaxial in the name of the boiler means the use of coaxial chimneys (pipe in pipe). This system is convenient in that only one pipe is used to supply air to the combustion chamber and remove exhaust gases, which can be led from the room to the street by the shortest route. In general, the boiler is not fundamentally different from products from other brands. You can note the convenient location of the expansion tank and the non-standard location of the fan - it is located below the burner.

How to pump up the expansion tank of a Navien boiler

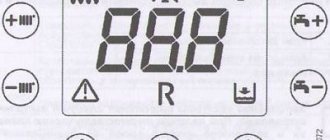

It is noteworthy that Navien boilers do not have a built-in control panel. All adjustments are made using a separate control panel. The remote control is also equipped with a temperature sensor and displays various information about the operating status of the equipment and will report a malfunction with an error code. A special feature of Navien is also the presence of an air pressure sensor, which not only performs a draft check function, but also sends data to the control unit for portion control and determines the presence of reverse draft. If there is excess pressure in the chimney, for example due to wind blowing, the gas supply to the burner will be stopped and the boiler will stop.

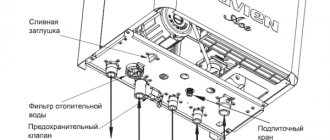

At the bottom of the boiler there are inlets and outlets of the heating and hot water circuits, a make-up tap, a drain plug, a cleaning filter and a safety valve for relieving excess pressure.

Reasons for increased pressure in case of boiler damage

It is difficult for a person who does not have experience in servicing heating systems to independently determine the true reason why the pressure in the heating boiler rises. However, to give you an idea of possible malfunctions, a list of probable causes is provided.

- Increasing pressure up to 1 atm. may occur as a result of depressurization of the heat exchanger. Such consequences result from the formation of cracks in the housing during prolonged operation. The appearance of cracks may be the result of a manufacturing defect or poor strength of the material, the consequences of a water hammer or equipment wear. In this case, the coolant volume systematically begins to replenish. However, it is not possible to visually determine the location of the leak due to the instantaneous evaporation of the liquid when the burner is running. This malfunction leads to replacement of the heat exchanger.

- An increase in pressure can occur when the make-up valve is open. The weak pressure inside the boiler contrasts with the increased pressure in the pipeline. This causes additional water to flow through the open valve. Thus, pressure will gradually increase until it is released. If the pressure in the pipeline decreases, the water supply to the boiler is shut off by the coolant, reducing the pressure in the circuit. The make-up valve must be kept closed, and if it is broken, replaced.

- An increase in pressure may occur due to a malfunction of the three-way valve. Such a breakdown leads to water entering the circuit from the expansion tank. Debris periodically collects on the valve, which can cause it to break. This element must be cleaned periodically and, if faulty, replaced. To prevent contaminants from entering the water supply, you can install a simple corner filter.

- If all signs indicate that the pressure in the circuit is increasing, and the pressure gauge needle does not respond, this means that it has failed. A broken device makes it impossible to control the operation of the system and needs to be replaced.

Excessive pressure in the heating circuit is determined by the readings of the pressure gauge; if the indicator exceeds the permissible level, measures must be taken immediately. In addition to the pressure gauge, an excess of the permissible norm can be indicated by a safety valve, from which water will begin to flow if the pressure has risen.

Expansion tank malfunctions

The expansion tank can look like a separate wall element or as part of the boiler. It is designed to collect excess coolant from the heating circuit. When water in the system is heated, its volume can increase by up to 4%, and the expansion tank is designed to compensate for this difference.

Incorrect calculation of the system volume may lead to the installation of a tank with a smaller capacity than necessary for compensation. In this case, all the excess water cannot leave the system and this becomes the explanation why the pressure . The dimensions of the tank are also affected by the power of the installed boiler.

When choosing a NAVIEN gas unit, you should install a tank whose volume is 10% of the total displacement of the system, and if solid fuel equipment is installed, this figure doubles.

A hidden breakdown is considered to be a rupture of the membrane in the expansion tank. Such damage may not be noticed immediately, but in the meantime, unfixed coolant can fill the entire internal cavity. The pressure in the circuit will decrease, but if, in this situation, the system is recharged, this will lead to an arbitrary increase in pressure.

Selecting a refueling option

Several methods are used to replenish the coolant supply:

- Manual recharge is the cheapest and most versatile option, suitable for all types of wiring.

- Automatic replenishment from the water supply is practiced only in systems operating under pressure.

- To fill a closed network with non-freezing coolant, a manual pressure test pump is also used. The design of an automated circuit with an electric pumping station connected to a container with antifreeze is practiced in industrial boiler houses.

At home, antifreeze is pumped into the heating network using a pressure test pump

Note. If the radiator network and heated floors are filled with antifreeze, simple replenishment is done with a small hand pump. But most often, filtered tap water is used in the heating system, because of the price of non-freezing coolants (especially harmless propylene glycol).

The operating principle of the automatic make-up unit is based on the operation of a pressure reducing valve that responds to a decrease in pressure in the heating network. When it drops below the set value, the valve mechanism opens and releases water from the main line. A pumping station operates in a similar way, pumping antifreeze from a separate tank.

Unit with gearbox (left) and station pumping coolant from the tank (right)

Let us take the liberty of recommending the use of a manual recharge scheme. Causes:

- The unit consists of 2-3 inexpensive elements and will never turn on without the knowledge of the homeowner.

- No matter how reliably and efficiently the heating network is installed, there is a possibility of leakage and valve operation.

- Situation: pipe break, prolonged leakage of coolant in the absence of the owners. A completely autonomous “smart” recharge will flood the entire house, ruining the flooring and causing expensive repairs.

- Imagine an identical situation in an apartment building - a leak from an individual system and the activation of automated replenishment will flood the neighbors below.

- Fine sand will accumulate under the valve seat and the element will lose its seal over time. Under pressure from the water supply of 4-7 bar, spontaneous replenishment will begin. The most harmless scenario is the release of excess coolant through the fuse on the boiler safety group.

To eliminate the consequences of the described troubles, it is better to allocate a little time for personal control over your heating. Having discovered signs of loss of coolant, you will make your own decision - to recharge the system immediately, look for a leak, or make repairs. For a negative example of using such automation, watch our expert’s video:

Navien Deluxe gas valve adjustment

To set the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm H2O scale.

A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

12 . Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

The material was prepared by an employee of heating-mtsensk.rf - Warm Home.

Source

Video

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power from 10 to 30 kW with a closed combustion chamber and forced smoke removal using a turbine. The manufacturer notes the following features of Navien Delux:

- Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

Fan with variable speed. Navien Delux boilers are equipped with a turbine with adjustable blade rotation speed depending on the readings of a special air pressure sensor. This ensures an optimal gas-air mixture ratio and increases boiler performance.

The heat exchanger is made of stainless steel. By using a fan with variable rotation speed and increasing combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

It is also noted that the boilers are protected from the influence of mains voltage surges by a special protective chip and the ability to operate at low (up to 4 mBar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

Gas boilers NAVIEN. How to fix breakdowns

The Navien Ace hanging boiler cannot heat up. water. She walks in almost cold. Help me understand what happened?

Problems can be looked for in the following areas. Alternatively, the DHW temperature sensor is faulty; the sensor must be replaced. Perhaps the power setting of the water heating unit has gone wrong.

From time to time the pressure of the heating system rises. We reduce the pressure in the expansion tank to a limit of 2.1-2.3 atm. Could it be that the heating circuit water is leaking from the hot water supply pipes?

An increase in pressure in the heating system is formed by the following main reasons. The pressure for the expansion tank is not set. The make-up tap is leaking.

NAVIEN gas boiler systematically overheat during operation ?

Main source. no circulation in the heating circuit. It is also possible that the filters are dirty or there is too much air in the heating system.

Yesterday there was trouble. When you close the cold water valve and open the hot water tap, all water disappears from the heating system. Why does this happen?

Apparently, the heating circuit make-up valve is not functioning properly. It allows water to move in two directions. If there is fluid pressure in the system, then passage in the other direction cannot happen.

The unit made a humming noise when starting up, but now it makes a louder noise. Initially the sound was heard for a short time, but now it lasts much longer. I haven't heard from you for long, have you encountered this problem?

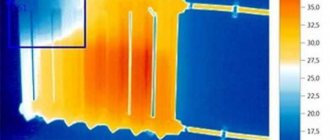

The formation of excessive unpleasant sound can be explained by the presence of mineral deposits inside the heat exchanger housing, the heating of which occurs unevenly due to different wall thicknesses. The more dirty the heat exchanger is, the stronger the noise is, and the heat transfer decreases accordingly.

NAVIEN boiler breakdown , showing error 02. What is the reason?

Firstly, look at the passport for error codes. There are transcripts there; you can easily correct some errors yourself. Secondly, 02 may indicate 2 reasons: a) low water level in the unit, b) poor circulation in the heating system. In this case, check the filters, clean them if possible. Or bleed the air from the batteries.

Navien double-circuit gas boiler is in operation . Lifetime. 2.5 years. Today I noticed that the hot water temperature does not reach 40 degrees (the mode is set to maximum water heating). Although the water pressure is the same as before. A week ago the heating did not work. As a result, the room temperature dropped from 21 to 16 degrees. Restarting fixed everything.

Remove the cover and check the unit in hot water mode by turning on the faucet from the hot water. water. At the same time, the heating does not work at this moment. Touch the heating supply pipe (metal parts). They should cool quickly. If suddenly both heating and hot water work at the same time, then the problem is in the 3-way valve. If everything is normal, it means that you either need to clean the main heat exchanger from debris on the outside and scale from the inside, and also check the hot water plate heat exchanger on the heating side. During this period it could have become clogged with the same scale.

So I set the temperature of the house to 30, and for the radiator 80, and when it’s cold the temperature of the house shows 16-19. What could it be, I have Navien ace 13k boiler

Most likely, you simply do not have enough batteries. It is not difficult to check this. If you set the radiator to 80, and the boiler reaches this temperature, but the house is cold. Definitely, there are not enough sections or poor water circulation in the heating system.

In the work of Navien Ace 30k, a collector decoupling for heating is installed, an object of 140 m2, with water supplied to the collector at 80 degrees, radiators somewhere around 55-60, return 40-45, naturally there is not enough heat, maybe the whole question is the power of the circulation pump, and how to increase it rpm?

With such signs in your description, the reason is one thing: poor circulation. Check pipe diameters. If the pipes are plastic, then the diameter should be at least 25 mm, and preferably 32 mm throughout the house. Then the boiler pump would cope with the circulation. Surely your diameters are smaller. In this case, you can install another pump on the supply to help your loved one. The power of the built-in pump is not adjustable. At the same time, if you simply plug in the additional pump, then it is not advisable to use hot water. If you need hot water, then the additional pump must be connected to the automation system through an additional relay, so that when hot water is turned on, this pump is turned off. Otherwise, incorrect operation of the unit, water hammer in the heating system, and rapid release of the 3-way valve may occur.

The mounted Navien Ace 13 atmospheric boiler is in operation. Questions of importance: In operation for 3 years. When purchasing, they told me about after-sales service. But I gave up on it. Does the boiler need any maintenance during operation? If necessary, can I do it myself? (I installed the boiler myself). The device is set to a minimum temperature of 40 degrees, at which it does not work. Operates from 41 degrees. That's probably true for everyone. But in spring and autumn for my house 40 is a lot. I need from 25. And I have to switch to the operating mode not according to the temperature of the carrier, but according to the air temperature, which is not very convenient, since the unit is located in another room separate from the house. When it’s summer and the boiler doesn’t work and you only use hot water, very strange things happen. Always, when you open hot water, for some reason it is not clear why the circulation pump turns on, and the hot water switches off for some time. The question is, why?

READ The difference between a single-circuit gas boiler and a double-circuit one

The boiler requires servicing annually. Place the remote control where you need it (move it). The pump must work (drive heating water in the primary circuit to heat the secondary circuit, and you get hot water into the tap).

Gas wall-mounted boiler Navien Ace-24 (White). Question: does the device of this model provide forced circulation of coolant in the system, or is it desirable to install an additional circulation pump. The same question about the built-in expansion tank.

The expansion tank compensates for up to 80 liters of heating water, the pump circulates the coolant in the heating circuit.

The lights were turned off, and now Navien Ace 24k Coaxial boiler What to do?

Try to close the output wires to the control unit; it should work at full speed; just close it at the outlet of the boiler and do not confuse it with the 220 power supply.

I have an Ace 30K gas boiler and there is no hot water. It's cold, I changed the secondary heat exchanger. no effect, am I correct in thinking that the problem is in the three-way valve, taking into account the fact that during heating the water in the pipes is hot. Do I need to dismantle it, clean it and reinstall it?

That's right, it's a three-way valve. Cleaning will not help, only replacement.

Tell me I have an Ase 13K boiler. First it showed error 03 (no signal about the presence of a flame or an open circuit of the flame sensor), then 10 (malfunction of the smoke removal system) and finally 15 (malfunction or malfunction of the control board), and after opening the lid, water drips from the combustion chamber and There is also water in the fan.

Wall-mounted boiler of the Navien Ace 20k brand. It has been working for less than a year (10 months) and everything seems to be fine with it, but I am confused by the readings of the pressure gauge on its body: the needle does not rise above half a bar, and if it is not activated (not currently heating water or batteries), it generally stands at zero. However, I checked the factors and here are the circumstances: No alarm signals appear on the remote control; There is pressure in the heating system (the air outlet valve from the heating system steadily shoots a tight stream at the ceiling); the water filter inside has not yet been washed; The water filter at the entrance to the apartment system was a couple of months overdue for replacement, it was changed recently, it was unlikely to interfere, but you never know. Can you tell me what could be the matter?

I think low pressure in the water supply network (below 1 bar.). Although I do not rule out that the pressure gauge is faulty (hardly, I have never encountered this). Check the pressure in the expansion tank (inside the unit, the nipple looks like a car nipple), it should be 1 bar. Car pump, compressor.

Today I decided to disassemble the Navien Ace 30K gas boiler and flush the primary heat exchanger, after 3 years of operation. Now I’m boiling it in water with citric acid, is this normal? On the thermal sensor, as I understand it, the thermal paste is disposable. Will I need to re-anoint?

It is better to boil and rinse with circulation. Thermal paste is designed for more accurate transfer. This is your home and boiler safety. Emergency overheating sensor (OH).

I have NAVIEN 24k. For some reason there is a knock, as if someone is opening the door. Recently the indicator turned red and showed 10. The display jumps back and forth. What's the matter? Please tell me. One person came and said that there was scale and the radiator needed to be changed. It happened that when I came home and turned on a higher temperature, dirty water came out. Maybe the radiator is just clogged with rust? and can it be washed rather than replaced?

If you have knocking at the bottom. on the right side of the boiler, then the three-way valve needs to be changed. If in the upper part (as if the kettle is boiling), then flush the heating circuit. And dirty water is already a water circuit. Either wash it or just look at the filter, and then draw conclusions.

NAVIEN 13 boiler is installed the pressure drops to zero, and when turned on it rises to normal, and so on continuously. Could the expander diaphragm be torn?

When the boiler is zero, drain the heating water from it (glory below the pump). And check the pressure in the expansion tank. It should be 1.0 atm.

I bought and installed Navien 16K today. And after launch, the problem is almost the same as in Nikolai’s previous question. I set, say, room temperature to 23 degrees. The boiler runs for 25 seconds, then turns off, after 30 seconds it turns on and so on constantly, and the temperature. There is only 21 grams on the remote control. I set the temperature. according to the coolant, let's say 60 g. The boiler runs for about 40 seconds and reaches 61-62g. and turns off. In 15-20 seconds the temperature drops to 51 degrees. and it turns on again and so on constantly. The pump runs all the time. There is suspicion about the three-way valve because... The heat exchanger for hot water supply is hot, but the device is new. There are no problems with the hot water supply, when I turn it on and the heating pipes do not heat up. Maybe there are other settings that need to be made.

If there is no error on the display, then the reasons for this operation of the boiler (in addition to setting the temperature) are: the three-way valve does not work properly, the system is clogged somewhere, the pump does not work or does not push water, having lost power, the temperature sensor is faulty, the air is in system, the main heat exchanger is clogged. Well, in other cases an error should light up.

I am redoing the heating system, at first the water in the shower was normal, after two days the water stopped heating up altogether, it gives error 02 (low pressure in the heating system), heating will continue for three more days, what to do with warm water, can it be turned on?

Place plugs on the boiler on the heating circuit, feed the boiler to 1-1.5 bar. And using hot water supply is a pleasure.

Sources:

https://ooo-konditsionery.ru/raznoe/kotel-naven-kakoe-davlenie-dolzhno-byt-v-rasshiritelnom-bachke-pochemu-v-gazovom-kotle-padaet-davlenie-chastye-prichiny-i-sposoby- ustraneniya-pro-nastennyj-kotel-navien-ace.html https://stzm.ru/gvs_kotli_navien_ace.html

Troubleshooting other errors

Let's see how to repair a Navien wall-mounted boiler with your own hands or bring a floor-standing model to life. To do this, we will briefly go through the above error codes and identify troubleshooting algorithms.

Navien boiler shows error 01

Do not panic, as the reason for the display of this code may be a simple airing of the system and filter. It is necessary to bleed air from pipes and batteries using standard recommendations. The next step is to check the integrity of the circulation pump. Make sure that it is spinning and that its impeller is moving coolant through it normally.

Sometimes an error occurs due to a physical breakdown of the impeller. The worst thing is if the circulation pump fails - in this case you will have to send it for rewinding or even purchase a new model.

Error 04 in Navien boilers

We have already talked about malfunction code 02 - it manifests itself as a rapid increase in temperature followed by its drop. We also dealt with code 03. If the self-diagnosis system displays error 04, you need to check the condition of the flame sensor and its circuit. Make sure the sensor does not touch other metal parts. Sometimes the appearance of this code is associated with a malfunction of the system board; it will need to be repaired or replaced.

Most often, control boards are replaced rather than repaired. If you have doubts about its performance, contact a specialist.

Errors 05 and 06 in Navien boilers

Also check the condition of the connecting wires - they should not be shorted or broken. For diagnostics, use the most common ohmmeter.

Here we need to diagnose the water temperature sensor in the heating circuit.

Find data on its standard parameters, make sure they correspond (resistance to a certain temperature).

Errors 07 and 08 in Navien boilers

Double-circuit boilers give us heat and hot water. They are equipped with two circuits and two sets of sensors. For example, there are two temperature sensors here. One measures the temperature in the heating circuit, the other measures the temperature of the hot water. And the codes presented above indicate a breakdown of the temperature sensor of the DHW circuit or a malfunction in its circuit. Diagnostics and repairs are carried out in the same way as in the previous section - using an ohmmeter and visual inspection.

Eliminating errors 09 and 10

Here are typical fault codes for the Navien Ice boiler, indicating problems with the fan. It is necessary to check the integrity of its windings and test their resistance, to diagnose the presence of an interturn short circuit. A broken fan must be replaced with a new one.

If the fan turns out to be intact, you should test the control board - do it yourself if you have the appropriate knowledge, or call a specialist from the service center.

As for error 10, it indicates difficulties in the operation of the smoke removal system. The fan may be to blame here; you also need to check the length of the chimney and make sure it is passable - cleaning will be required. Often the culprit is incorrect operation of the air pressure sensor. The worst thing is if the error appears as a result of constant failures in the Navien boiler board. The simplest wind blowing into the chimney cannot be ruled out.

Error 13 - problem with the flow sensor

This code is typical for Navien Ice and Navien Ice Coaxial boilers. It appears when there is a short circuit in the sensor circuit, and also indicates problems with its performance. The sensor must be tested and, if faulty, replaced. We also check the connecting wires. In rare cases, the control board is at fault.

Error 16 in Navien boilers

This code appears when the heating equipment overheats. There can be many reasons here:

One of the rarest causes of this error is an increase in the gas supply level. Check this parameter and tighten the valve if necessary.

- For some reason the coolant overheated;

- There is not enough coolant in the circuit;

- Control board malfunction;

- Malfunction of the three-way valve;

- The temperature control sensor in the DHW circuit is broken.

Carefully check all components and localize the fault.

Error 18 in Navien Ice atmospheric boilers

This code indicates overheating of the temperature sensor in the smoke exhaust system. When it is triggered, the operation of the equipment is suspended. We check the passage of the chimney, check the sensor itself and the connecting circuits, and make sure there is no backdraft. It is also possible that the control board may not operate correctly, but this only happens in the rarest cases.

Error 27 in Navien boilers

The last code in our review indicates a malfunction in the air pressure sensor circuit in the Navien Ice and Ice Coaxial models. We check all connecting wires and change the sensor if necessary. As in all of the above cases, a code may appear if the control board is not operating correctly.