German Buderus boilers are productive, powerful equipment. It is popular not only in private houses and apartments, but also in production. A “smart” control system controls the operation of the heater - in case of problems, a special code is displayed on the display. What do Buderus boiler errors mean? What should I do to restore the operation of the equipment? We will describe in detail how to deal with the problem.

Probable errors and causes of occurrence

This article contains all possible malfunctions and options for eliminating them, as well as error codes for Buderus boilers.

All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article. The content of the article

- Error code A - Chimney sweep mode

- Error code H - Heating mode

- Error code (=) H - DHW mode

- Error Code 0A - Blocked

- Error code 0A for GB072-24K

- Error code 0C - Burner

- Error Code 0E - On-Off Mode

- Error code 0H - Heat demand

- Error code 0L - Delay

- Error code 0U - Startup

- Error code 0Y - Temperature higher than set

- Error Code 2E - Bleeding Air

- Error code 2H - Pump protection

- Error code 2P - Temperature rise

- Error Code 5H - System Test

- Error Code H11 - Temperature Sensor

- Error code 0Y - Temperature at the flow sensor is more than 95 C

- Error Code 0Y - Hot Water Temperature Sensor High Temperature

- Error code 3A - Fan does not work

- Error code 3F - Interruption in operation

- Error Code 4C - Blocked

- Error Code 4U - Temperature Sensor

- Error Code 4Y - Temperature Sensor

- Error code 6A - No flame detected

- Error code 6L - No ionization signal during burner operation

- Error code 8Y - AT90 temperature control relay has tripped

- Error code 8Y - Temperature control relay AT90 faulty

- Error code 8Y - There is no jumper between the terminals of the separate AT90 temperature control relay

- Error code 8Y - Temperature control relay blocked

- Error code EL

- Error code 3C - Fan operation error

- Error Code 3L - Fan turned off during delay time

- Error Code 3P - Fan is too slow

- Error code 3Y - Fan running too fast

- Error code 4C - Temperature limiter

- Error Code 4U - Temperature Sensor

- Error code 4Y - Flow temperature sensor faulty (open)

- Error Code 6A - Error: Flame Not Found

- Error code 6C - In shutdown mode, the boiler registers a flame

- Error Code 6C - Flame detected after gas supply is turned off

- Error code 7L - Timing error at first delay time

- Error code 7L - Timing error when trying to restart

- Error code 9L - Gas fittings faulty

- Error code 9P - KIM not recognized

- Error code EL - KIM or main regulator BC20 is faulty

- Error codes for gas wall-mounted boilers Buderus Logamax

- Error code 1A - Exhaust gas outlet at flow fuse

- Error code 1L - Exhaust gas outlet on the combustion chamber

- Error code 1Y - Exhaust gas temperature sensor not detected

- Error code 2E - Insufficient filling pressure of the heating system

- Error code 2P - Temperature difference too large

- Error code 4C - Flow limiter has tripped

- Error code 4E - Burner chamber temperature sensor not detected

- Error code 4Y - Flow temperature sensor does not work

- Error code 5H - EMS communication interrupted

- Error Code 6A - No Flame Detected

- Error Code 6C - Flame detected after gas supply is turned off

- Error code 8Y - Jumper not detected on ST8 161

- Error code 9C - Coding plug not detected

- Error code CL - Hot water temperature sensor is faulty

- CP Error Code - Boiler Sensor Not Detected

- EC Error Code - Internal Fault

- Error Code EL - Invalid Reference Voltage

- Error code EP - By mistake, the fault message reset button was pressed for too long (more than 30 seconds)

- Malfunctions of Buderus boilers

- The burner does not turn on

- The burner starts and switches to fault. No spark when igniting

- Burner starts and switches to fault

- The Buderus boiler burner starts and switches to fault. No ionization current

- The burner starts and switches to fault. Ionization current less than 1.5 mA

- Boiling sounds

Error code A - Chimney sweep mode

The device is in “chimney sweep” mode. After 15 minutes, the chimney sweep mode is automatically deactivated.

Error code H - Heating mode

The Buderus boiler is in heating mode.

Error code (=) H - DHW mode

The device is in DHW mode.

Error Code 0A - Blocked

The clock interlock is active: the delay time between turning off and turning on the burner has not yet expired (service function 2.3b).

Error code 0A for GB072-24K

Duration of hot water support: the time interval of hot water support has not yet been exhausted (service function 2.3F).

Error code 0C - Burner

The burner turns on.

Error Code 0E - On-Off Mode

Heat demand is less than the minimum heating capacity of the boiler. The boiler operates in on-off mode.

Error code 0H - Heat demand

The device is in a ready state, there is no need for heat.

Error code 0L - Delay

The gas valve opens, the first delay time.

Error code 0U - Startup

The boiler starts.

Error code 0Y - Temperature higher than set

The actual flow temperature is higher than the set temperature. The boiler turns off.

Error Code 2E - Bleeding Air

Error: The bleed function is active.

Error code 2H - Pump protection

The protection against jamming of the heating circuit pump and the three-way valve is active.

Error code 2P - Temperature rise

Limitation of gradients: temperature rises too quickly in hot water mode.

- Check the operating pressure in the heating system.

- Open the service valves.

- Make the electrical connection of the heating circuit pump to the BC20 main controller.

- Check or replace the heating circuit pump.

- Correctly set the pump power or its characteristic and match it to the maximum power.

Error Code 5H - System Test

Boiler control system test.

Error Code H11 - Temperature Sensor

Damage to the DHW temperature sensor (GB072-24K).

- Remove the temperature sensor.

- Check it and if it is faulty, replace it.

- Check the connecting cable for breaks and short circuits, replace if damaged.

Error code 0Y - Temperature at the flow sensor is more than 95 C

This message may appear in the absence of a fault, if all valves on the radiators suddenly close or after drawing hot water from the GB072-24K.

- Check the operating pressure in the heating system.

- Open the service valves.

- Make the electrical connection of the heating circuit pump to the BC20 main controller.

- Check or replace the heating circuit pump.

- Correctly set the pump power or its characteristic and match it to the maximum power.

- Check for damage or short circuit of the flow temperature sensor and its wire, replace if necessary.

Error Code 0Y - Hot Water Temperature Sensor High Temperature

- Check the correct position of the sensor.

- Check it and if it is faulty, replace it.

- Insert KIM correctly, replace if necessary.

Error code 3A - Fan does not work

Check it and if it is faulty, replace it.

Error code 3F - Interruption in operation

The burner and fan have been running for 24 hours without interruption and are switched off for a short time for safety reasons.

Error Code 4C - Blocked

The heat exchanger temperature limiter or the flue gas temperature limiter of the Buderus boiler has tripped. If a blocking fault exists for a long time, it becomes a blocking fault.

Error Code 4U - Temperature Sensor

Flow temperature sensor faulty (short circuit). If the fault exists for a long time, the display will show fault code 4U and operating code 222.

Error Code 4Y - Temperature Sensor

The flow temperature sensor is faulty (break). If the fault persists for a long time, the display will show fault code 4Y and operating code 223.

Error code 6A - No flame detected

After the 4th ignition attempt, the blocking fault becomes a locking fault.

Error code 6L - No ionization signal during burner operation

The burner restarts. If ignition is unsuccessful, blocking error 6A will be displayed; after the 4th ignition attempt, the blocking error becomes a failure.

Error code 8Y - AT90 temperature control relay has tripped

- Check the AT90 temperature control relay adjustment.

- Check the heating control setting.

Error code 8Y - Temperature control relay AT90 faulty

Check for damage or short circuit to the temperature sensor and its wire, replace if necessary.

Error code 8Y - There is no jumper between the terminals of the separate AT90 temperature control relay

If a temperature control relay is not connected, install a jumper.

Error code 8Y - Temperature control relay blocked

- Unlock the temperature control relay.

- Check condensate drainage.

- The condensate pump does not work - replace the condensate pump.

Error code EL

The main regulator BC20 is faulty - replace it.

Error code 3C - Fan operation error

Check the fan and its wire with plug, replace if necessary.

Error Code 3L - Fan turned off during delay time

Check and, if necessary, replace.

Error Code 3P - Fan is too slow

Check and, if necessary, replace.

Error code 3Y - Fan running too fast

- Check and, if necessary, replace.

- Check the flue gas system and clean or repair if necessary.

Error code 4C - Temperature limiter

Error in heat exchanger temperature limiter or flue gas temperature limiter.

- Check: for damage to the heat exchanger/flue gas temperature limiter and its connecting wire, replace if necessary, operating pressure in the heating system, temperature limiter, replace if necessary, pump pressure, replace the pump if necessary, fuse, replace if necessary.

- Remove air from the boiler.

- Check the water circuit of the heat exchanger, replace if necessary.

- For Buderus boilers with a divider in the heat exchanger, check whether the divider is installed.

Error Code 4U - Temperature Sensor

Flow temperature sensor faulty (short circuit).

Check for damage or short circuit to the temperature sensor and its wire, replace if necessary.

Error code 4Y - Flow temperature sensor faulty (open)

Check for damage or breakage of the temperature sensor and its wire, replace if necessary.

Error Code 6A - Error: Flame Not Found

- Check: protective conductor connection, whether the gas valve is open, gas supply pressure, electrical connection, electrodes with wires, flue gas exhaust system, clean or repair if necessary.

- Check the gas-air ratio, correct if necessary.

- For natural gas: check the gas flow control relay, replace if necessary.

- When working with combustion air taken from the room, check the air supply to the room and the ventilation openings.

- Clean the condensate siphon drain.

- Remove the membrane in the fan mixing device and check for cracks and dirt on it.

- Clean the heat exchanger of the Buderus boiler.

- Check the gas fittings, replace if necessary.

- Insert KIM correctly, replace if necessary.

- Two-phase network (IT): install a resistance of 2 ohms between PE and N at the connection of the electronic board to the mains.

Error code 6C - In shutdown mode, the boiler registers a flame

- Check the electrodes for contamination and replace if necessary.

- Check the flue gas system and clean or repair if necessary.

- Check the humidity of the electronic board, dry if necessary.

Error Code 6C - Flame detected after gas supply is turned off

- Check the gas fittings, replace if necessary.

- Clean the condensate siphon.

- Check the electrodes and connecting wires and replace if necessary.

- Check the flue gas system and clean or repair if necessary.

Error code 7L - Timing error at first delay time

Replace the BC20 main regulator.

Error code 7L - Timing error when trying to restart

Replace the BC20 main regulator.

Error code 9L - Gas fittings faulty

The coil or connecting wire of the gas fitting is faulty.

- Check the wires, replace if necessary.

- Replace gas fittings.

Error code 9P - KIM not recognized

Insert KIM correctly, replace if necessary.

Error code EL - KIM or main regulator BC20 is faulty

Replace KIM. Replace the BC20 main regulator.

Features of operation

The Buderus company is famous for the production of boilers that operate on almost any type of fuel. You will find solid fuel models that do not depend on the availability of electricity. Firewood, coal, and briquettes are used for work. They have a long combustion period and high efficiency.

Liquid fuels operate on diesel and gas. Solid fuel can work in tandem with diesel equipment. Electrical ones are dependent on the availability of electricity. In production or in an apartment, tanks of various sizes and volumes can be installed; they can be wall-mounted or floor-mounted. Boilers can be single-circuit (for heating only) and double-circuit (for heating and hot water supply).

Error codes for gas wall-mounted boilers Buderus Logamax

Error code 1A - Exhaust gas outlet at flow fuse

Check the gas exhaust path.

Error code 1L - Exhaust gas outlet on the combustion chamber

Check the heat exchanger for contamination.

Error code 1Y - Exhaust gas temperature sensor not detected

Check the flue gas temperature sensor and connecting cable for damage.

Error code 2E - Insufficient filling pressure of the heating system

Check the filling pressure and increase it if necessary.

Error code 2P - Temperature difference too large

Check the pump and bypass line.

Error code 4C - Flow limiter has tripped

Check the pressure in the system, temperature sensors, check the operation of the pumps and the fuse on the printed circuit board, remove air from the device.

Error code 4E - Burner chamber temperature sensor not detected

Check the temperature sensor in the burner chamber and the connecting cable for damage.

Error code 4Y - Flow temperature sensor does not work

Check temperature sensor and connecting cable.

Error code 5H - EMS communication interrupted

Check connecting cable and regulators.

Error Code 6A - No Flame Detected

Is the gas valve open? Check the pressure in the gas network, the network connection, the starting electrode with cable and the ionizing electrode with cable.

Error Code 6C - Flame detected after gas supply is turned off

Check the ionizing electrode. Check gas fittings.

Error code 8Y - Jumper not detected on ST8 161

If there is a jumper, insert the plug correctly and check the external limiter. Otherwise: is there a jumper?

Error code 9C - Coding plug not detected

Insert the coding plug correctly, measure it and replace it if necessary.

Error code CL - Hot water temperature sensor is faulty

Logamax U054-24K

- Check the temperature sensor and connecting cable for damage or short circuit;

- The hot water temperature sensor is not installed correctly.

Logamax U054-24K

- Check the installation area, if necessary, remove the sensor and reinstall it using heat-conducting paste.

CP Error Code - Boiler Sensor Not Detected

Check the boiler sensor and connecting cable.

EC Error Code - Internal Fault

Check the connection of the electrical plug contacts and start lines and, if necessary, replace the printed circuit board.

Error Code EL - Invalid Reference Voltage

Replace the printed circuit board.

Error code EP - By mistake, the fault message reset button was pressed for too long (more than 30 seconds)

- Press the reset button again and hold it down for less than 30 seconds.

- The outside temperature sensor is not detected. Check the outside temperature sensor and connecting cable for damage.

How to replace a faulty pressure switch

Replacing a pressure switch is a simple, non-labor-intensive, but at the same time fairly quick procedure. To successfully dismantle the faulty part, you must perform the following manipulations:

- Disconnect the equipment from the power supply;

- Press the upper latches and pull the pressure switch towards you;

- Disconnect all connected pipes from the faulty pressure switch.

After dismantling the unsuitable pressure switch, you need to purchase a new part and begin installing it. It is sold both in regular construction stores and on online markets. The average cost of such a spare part for repairing a Buderus boiler model Logamax U072 is 2500-4500 Russian rubles.

Malfunctions of Buderus boilers

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

The burner does not turn on

The emergency switch for the heating system is in the off position - on.

Control system start switch in off position - turn on.

The circuit breakers are faulty - check their functionality and, if necessary, replace the defective circuit breaker.

The boiler water temperature regulator is damaged - check and, if necessary, replace defective parts.

The safety temperature limiter is damaged - check and, if necessary, replace defective parts.

Error message from external safety devices (for example, from a water level safety device) - the consumer must check the Buderus boiler, eliminate the fault and, if necessary, replace the element.

The flue gas monitoring system has activated:

- AW 10 - unlock the flue gas control system;

- AW 50 - Wait a maximum of 15 minutes.

The boiler will turn on automatically if there is a request for heat. If it is triggered multiple times, check the flue gas path and check the functionality of the flue gas control system. If there is a defect, replace it.

The burner starts and switches to fault. No spark when igniting

Is there a sound when an ignition spark forms when the ignition cable is removed?

- If not, then replace the ignition transformer;

- If yes, then replace the ignition electrode or ignition burner.

Burner starts and switches to fault

All gas shut-off valves are closed - open the gas shut-off valves.

Natural gas supply pressure is more than 8 mbar - if not, determine the cause and correct the problem.

Has air been removed from the gas pipeline? Remove air until gas can be ignited.

The Buderus boiler burner starts and switches to fault. No ionization current

If connections N and L are mixed up, eliminate the error.

Is there voltage between L and PE? If not, ground the PE, in this case install an isolation transformer.

Poor contact of the ionization wire - eliminate the error, in this case, replace the defective part.

Short to ground on the ionization electrode - correct the damage.

Burner control defective - replace element.

The burner starts and switches to fault. Ionization current less than 1.5 mA

The core or ceramics of the ionization electrode is dirty - clean the ionization electrode and, if necessary, replace the ignition burner.

Buderus error 3c (fourth indicator 80 flashes)

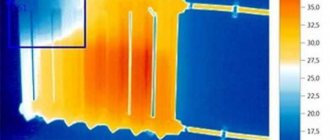

If such an error occurs, the boiler control board does not receive a signal from the differential pressure switch, that is, its contacts do not close after the fan starts. The pressure switch is used to determine the necessary conditions for removing combustion products.

The procedure for putting the boiler into operation is as follows:

- The control unit gives a signal to start the fan

- The fan creates the necessary vacuum in the exhaust pipe

- The differential relay registers the vacuum and the microswitch contacts close

- The board sends a signal to open the gas valve and ignite

Therefore, to understand the problem, you need to determine at what specific moment the boiler goes into error. If the fan starts, but the relay does not click, it is tedious to inspect the supply pipes; perhaps there is a blockage or condensation, or there is actually a blockage in the chimney itself.

If the fan does not start, you need to check whether voltage is supplied to it. A faulty electronic board may be the reason why the fan does not start.

If the fan is working, there are no problems with the chimney and the pneumatic relay tubes, you need to check the pneumatic relay itself, creating a vacuum yourself and checking for a characteristic click.

Constantly closed relay contacts or their opening during burner operation will also be regarded by the security system as a malfunction.

Buderus boilers can be equipped with a fan with adjustable rotation speed, which is controlled electronically and equipped with a sensor.

Problems not shown on the display

When they occur, the Buderus error is not displayed, but a number of signs indicate incorrect operation of the boiler or the entire heating system.

Adjusting the circulation pump

1. Slow heating of batteries; noise of fluid circulating along the circuit. The main reason is the incorrectly set pump speed. The switch is located on its body.

2. “Difficult” ignition, boiler efficiency is lower than declared. There are several options: from poor burner performance to the use of gas with characteristics that do not meet the manufacturer’s requirements.

Recommendation : carry out Buderus service, check the set parameters.

The article provides explanations for all problems that can be resolved independently. It’s better not to go deeper - the boiler is expensive, and unprofessional intervention in its operation will not lead to anything good.

Other breakdowns

In addition to those described above, automation can also give signals about other malfunctions on gas boilers:

There are problems that the display does not detect. For example, if you hear loud water noise or the water takes too long to heat up, you should adjust the pump speed. If the outlet water temperature is insufficient, check the turbine and replace it if necessary.

If you have problems with ignition, you need to check the gas pressure, whether the electricity is turned off, see if the connections of the electrodes with the wires are oxidized, if the chimney is clogged and sealed, and if the burner is clogged.

Source