In our age of high technology and new technical solutions, the concepts of many traditional heating devices that have come to us from the past are being revised. These changes also affected wood-burning stoves. It would seem like a simple product made of brick or metal, what else can you come up with? It turned out that it is possible. The “potbelly stoves” that are familiar to us have especially changed, both externally and internally. Now these are modern wood-burning heating stoves, which are very popular due to their low cost.

Metal furnaces

Pros and cons of metal stoves

To begin with, we can look at the main advantages of the design for private use:

- It is easier to get certified - every device in the house must be checked by a special authority, after which its safety is recognized. Devices that are made according to the drawings of metal furnaces without making mistakes are approved without any questions.

- High thermal conductivity - the materials are non-porous, heat up well and quickly. This point is more about efficiency; for heating a small room, like a bathhouse or utility room - such a stove will be enough.

- Cheap - the low cost is regulated by the fact that such a stove can be created with your own hands without special skills. The main thing is to have blanks of material on hand, as well as a welding machine, which can also be rented or free from friends.

Now about the disadvantages of a metal sauna stove:

- Such stoves do not “breathe” - if a brick, when heated, absorbs the air around it, thereby slowly but effectively heating it, then the metal quickly cools down and requires more resources for heating.

- Risk of fire - the walls become so hot that nearby objects can easily ignite.

- Short service life - as practice shows, the service life is a maximum of 20 years. Much depends on the frequency of use and conditions, the material is susceptible to corrosion, even the thickest walls will be destroyed at high temperatures.

If we are talking about equipping a bathhouse or a small room, then which option is quite suitable. The main thing is to build the structure taking into account the operating rules; the dedicated instructions will help with this.

Famous manufacturers

The Russian market offers a large selection of metal, cast iron and stainless steel stoves. Products from the following foreign manufacturers are in great demand:

- Trend.

- Magnum.

- Thorma.

- Alma Mons.

- Konig Feuer.

- Efel.

- Ferlux.

- Olimp.

The Harmony model from the Belgian manufacturer Efel has proven itself well. It is equipped with a hob and has enough power to heat a large house. The time interval between fuel loadings is about ten hours.

There are many models and domestic manufacturers:

Cinderella stove Termofor

- Termofor;

- Ligov;

- Teplodar;

- Eco fireplace;

- Ermak.

Domestic models come in various types, sizes and shapes. Some can be transported independently and moved from one place to another. Others are permanently installed and have a high mass. Many of the models are equipped with hobs, ovens and transparent doors made of heat-resistant glass.

How to choose metal for the stove

Technical characteristics depend on the material from which the stove will be made. Therefore, you need to pay special attention to this nuance. Most often, craftsmen make a device from what is already in the utility room or barn.

However, this is not an entirely correct approach; the following options must be taken into account:

- Structural steel - can withstand temperatures up to 400 degrees, it is better to choose sheets of at least 4 mm. It won’t be possible to use it often, as it can easily burn out in one winter. If it is used for a bathhouse that is heated once a week, it will last a long time.

- Heat-resistant steel - this option can withstand 30 years of operation. The thickness should be at least 1 cm. Many stores sell a ready-made structure that only needs to be assembled; no welding is required, which is very convenient and profitable.

- Cast iron takes a long time to heat up, but retains heat well and heats the room. They have a long service life; such stoves can provide heat every winter for 30-40 years. The material is quite expensive, but fully justifies itself. Self-production is a rather complicated process. Such a device is often used to heat greenhouses and outbuildings. It is advisable to choose thick material, since sheets up to 1 cm will crack at the first temperature change.

Based on these recommendations, you can choose a good material for making a metal stove with your own hands.

Main design features

A standard metal furnace consists of the following main elements:

- fireboxes;

- ash pan;

- containers for stones (if the stove is created for use in a bathhouse, under other circumstances such a container can be abandoned);

- hot water tank (if necessary);

- grates;

- smoke exhaust pipes;

- firebox doors;

- doors for the ash pan;

- valves for pipes.

Two options for creating horizontal devices

Installation of grates is carried out in the firebox of the structure above the ash pit. If there is a need to install a tank for hot water, the tank, as a rule, is attached directly to the stove or slightly above it. In this case, a smoke exhaust pipe is usually passed through the container to heat the water.

Wood burning heater

The mentioned doors will not allow small coals, wood and sparks to fly into the heated room.

Drawing of a metal furnace

To make the body of a metal furnace, you can use sheet iron, barrels, pipes with a diameter of 50 cm and even large fire extinguishers. The use of ready-made containers is more preferable, because in this case, the amount of welding work is significantly reduced.

Chimney pipes

Before using a pipe to make a stove, carefully examine its condition for rust and other damage. If holes are found, apply patches to them. In areas with the most serious damage, you can make a door for the ash pit or furnace firebox.

Classification of metal furnaces

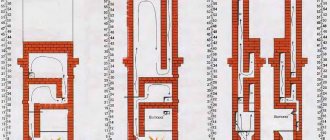

There are several types of stoves, which also differ from each other in performance characteristics. Briefly about three options for everyday life:

- Chamber ones are popularly known as “potbelly stoves”. The chimney is shortened to 2 meters; when the fuel burns out, the remaining flue gases contribute to combustion. Efficiency is 60%; such a device is cleaned 1-2 times a year. The main advantage is that there is no condensation, because the chimney heats up to 100 degrees and any liquid simply evaporates.

- Duct - inside there is a labyrinth of gas tubes. Operates on the principle of a burner. The efficiency is higher than in the previous version and is 80%. Can be used in several modes - flame and “afterburning”.

- Bell-type - when properly designed, gives an efficiency of 80%. It can run on coal due to the combustion of fuel in the bell. You can even heat a house of 60 square meters.

Each person decides which option to choose for household needs individually. Any type can be built with your own hands.

Preparing for installation

Equipping a dacha with stove heating with your own hands begins with preparation:

- The walls and floor closest to the device are covered with ceramic tiles.

- If the floor is wooden, then at the first stage drywall is placed on it. Then the ceramic tiles are attached with self-tapping screws. A layer of primer is applied on top, and it dries within 24 hours.

- If the base is concrete, then the tiles are laid directly on the glue.

- When using tile adhesive, use a notched trowel. The ceramic layer is laid out using a level.

- The tiles are laid end-to-end or with a gap using construction crosses.

- After the solution has hardened, the crosses are removed and the joints are rubbed.

- Wall tiles are laid using the same technology.

Diagram of an example of installing a stove in a bathhouse

Making a sauna stove

A good option for heating a bathhouse would be a simple steel stove; the device is lined with bricks for safety. The only negative is that it is not mobile, so it is better to immediately choose dense and high-quality sheets for arrangement. Tools that will be useful:

- Welding equipment;

- Bulgarian;

- 3 mm diodes.

Sheets must be at least 4 mm wide, and reinforcement - 10 mm.

Important! Such a metal stove will ensure safety due to the fact that it will heat up quickly and will not emit carbon monoxide.

How to build a metal stove with bricks:

- First you need to make a foundation. To do this, you can make a wooden formwork of 20 cm, an area of 1 * 1 m.

- Next, install the reinforcing mesh; it must be done in such a way that it does not touch the ground or floor.

- Next, you need to mix the cement and fill everything with mortar. The M400 is suitable for these purposes.

- The foundation takes at least 4 weeks to dry.

- During this time, you can assemble a metal stove according to any drawing.

- Next, they make a brick rim on top of the structure, which is placed on the foundation.

- Everything sets within another 2 weeks. During this time, you can equip the chimney structure, as it plays an important role in safety.

It doesn’t matter here whether the owner of the site will design and assemble the stove himself or purchase a ready-made kit. Since the preparation itself takes most of the time. If all the rules are followed, the stove will last a long time and will delight you with warmth for 20 years.

Device efficiency and options that increase its efficiency

The main improvements affected the air supply system. It was they who turned the gluttonous and inefficient primitive potbelly stove into a fairly economical heating unit with high efficiency. So, the oxygen necessary for combustion can enter the firebox in several ways. The first and main one is through the grate. In most modern models, the amount of oxygen is regulated, and if you reduce it to a minimum, the logs will not burn, but will smolder, and then one load of fuel will be enough for 4–7 hours. It is better to use the long-burning mode only after the firebox has warmed up well. And yet, it is impossible to achieve complete combustion of fuel during smoldering; soot deposits will remain on the glass and walls of the chamber. But when the device operates at maximum power, the firewood burns out entirely, but the glass and fireclay lining are not contaminated.

Note! Some foreign manufacturers are disingenuous, indicating in the column “working time from one stack of firewood” the period until the ash cools completely. We generally believe that the device operates as long as there is a fire or smoldering coals in it

Design of a fireplace stove with an afterburning chamber

Another option that increases the efficiency of the device is an afterburning system

, that is, a series of additional holes in the upper part of the combustion chamber. It would seem, how can such a small thing have a positive effect on the operation of the fireplace stove? The fact is that in smoldering mode the firewood is on a “starvation ration”. The carbon does not burn completely, and carbon monoxide is formed in the firebox. This substance is flammable, but it does not have enough oxygen to burn. Along with other combustion products, carbon monoxide rushes upward, and if you additionally give it a little air, you can burn it out. As a rule, fireplace inserts have this option, but it is also found in some models of potbelly stoves. These products cost approximately 20% more than regular ones, but over time the costs pay for themselves.

And finally, another useful option is the unregulated oxygen supply through the holes in the upper part of the door.

These air flows do not affect the efficiency of the fireplace stove; their task is to create an air curtain that will protect the glass from soot. Of course, it will not eliminate the need to wash off black deposits from the glass, but you will need to do this less often.

Simple heater for a summer house

Such a heating metal stove is well suited for quickly providing heat to a small bathhouse or even a sauna.

The main advantages are that it is mobile and easy to manufacture.

Preparing for vaping takes 1.5 hours, the walls heat up quickly. One caveat - you need to attach 2 chimneys to the stove. The first will participate in heating the room itself, the second will remove carbon monoxide.

What does the oven consist of:

- Steel - iron sheets of at least 3 mm.

- It is better to make the firebox from thicker steel -6 mm.

- The kit also includes latches and a metal grill.

This structure can be assembled using a welding machine. Such sets are purchased in a disassembled state, the instructions are already included. Designing a metal stove will not be difficult, as it will fully comply with fire safety rules.

Where is the best place to install?

The choice of location for installing the furnace device must be approached thoroughly:

- It is better to place it away from external walls. This way you will retain a large amount of heat and the most optimal efficiency indicators.

- If your product is small in size and therefore weighty, it can be installed directly on the floor. If you have a rather heavy option, then it is better to make a foundation. It is not necessary to fill the perimeter with concrete; even a reinforced concrete slab can serve as the basis.

- When installing, you need to maintain a distance to the walls, which should not be less than 1 meter. This is especially true for flammable coatings.

- Next, you should take care of fire safety and call an inspector. He must approve the installation and issue the appropriate permit.

Photos of metal stoves for a country house

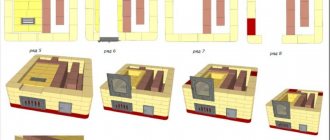

Brick cladding

To get rid of the harsh radiation of the metal, the stove can be lined with brick. The work is carried out in the following order:

- A power calculation of the floor is required. The weight of the structure reaches 0.5 tons.

- The distance between the metal wall and the brickwork is up to 8 cm.

- If the floor is wooden, an iron sheet 4 mm thick and asbestos are laid on it.

- Concrete floors do not require additional preparation.

- The wall thickness is half a brick. It is placed on a mixture of cement and sand.

- In each row, holes are left at the height of the brick for air exchange.