close ×

In country buildings or cottages, metal wood-burning stoves are often installed for heating rooms and cooking. This is economical, practical and functional, since by heating such a structure, you can simultaneously cook food, heat water and supply warm air to the rooms. Traditional brick stoves do not have such high productivity, so owners of country houses choose steel/metal stoves for heating.

Before installing such a structure in your own home, there are several factors to consider. First, the expected frequency of use of the oven. Secondly, will people live indoors permanently, or only periodically, and over what period of time this will happen. Thirdly, the area of the house and the location of the rooms are taken into account. If you are not in a hurry, you can choose the best option for a country stove that runs on wood.

Types of iron stoves for summer cottages

Modern stoves, which run on wood and are made of metal, bear little resemblance to a “potbelly stove”. Metal stoves for the home are usually divided into two groups:

- Classic ones that operate using a direct combustion system.

- Heating units designed for long-term combustion.

This or that system may be present in steel ovens that are intended for cooking or heating. There are a large number of such stoves on the market, among them the following are worth noting:

- A bell-type stove is a heating stove; it uses the principle of convective movement of gases that move through channels and then exit into the chimney. Instead of a hob, an open oven is installed, which is located directly under the hood. This helps keep food hot for a long time. Firewood is loaded horizontally; the firebox door is made of fire-resistant glass.

- Direct combustion furnace. Most often these are small-sized models, for example, Termofor or Cinderella. The design performs two functions at once - it heats the room and helps in cooking. The thermal power of such a “baby” is 4 kW or a little more, which allows you to heat a room up to 50 m2. There are models that are equipped with electricity generators, which increases the voltage production and power of the furnace. For example, the Indigirka cooking stove, which runs on wood, not only heats the house, but is also suitable for charging gadgets.

- Gas generator furnaces. They are perfect for summer cottages, since the designs are economical and compact in size, and have a high level of efficiency, which reaches 80%. For long-term operation of a stove of this type, it is necessary to equip a chimney and burn it with high-quality firewood. Gas fired stoves work by loading wood (or another type of fuel) into the combustion chamber, igniting it, and then closing the door. Fresh air flows through the telescopic pipe, which drops lower when the amount of firewood decreases. The air supply process is regulated by a damper. The operating life of the furnace is, on average, three days. If gas generator stoves have a water heating mode, you can save on the use of firewood.

Types of structures

They differ in structure and operating principles. Let's look at each type in more detail.

Open

The stones are laid on top of the stove structure and are not covered with anything. Due to this, the steam room warms up faster, reaching temperatures of up to 100 degrees. But the humidity in the room is low, so the heat turns out dry.

The product consists of three parts:

- fireboxes;

- compartments for stones;

- containers with water.

There should be few stones, otherwise the top layer will not warm up well and the steam room will not be warm enough.

To increase the level of humidity and the release of water vapor, the hot stones are simply watered. One or two ladles will be enough - this will give up to 15% humidity.

To increase the level of fire safety and reduce the risk of burns, it is recommended to lay fire-resistant bricks around the walls of the furnace or make a partition made of wood.

To heat a sauna, it is important that as much of the stove area as possible is in contact with the air space. This contributes to faster heating of the air in the steam room

Closed (lined with brick or stone)

If wood fuel is chosen for heating, you will have to prepare large reserves in advance. Such a stove takes a long time to reach the desired temperature, but, having reached the desired level, gives good heat transfer and retains heat for a long time.

Closed structures are great for large baths, where there is not only a steam room, a wash room, a dressing room, but also a relaxation room.

One of the advantages is closed stones. Therefore, there is no risk of getting burned.

In factory economical models, the stove has a double casing with a gap for air exchange between the walls.

Combined

For most manufacturers, the design consists of a high box with gratings and double valves (performs the function of a firebox). A chimney pipe emerges from the neck of the box. Stones are placed in the neck here.

There are devices available for sale with combined fuel types:

- gas-wood;

- electric wood-burning.

They do not need to be constantly monitored. Simply adjust to the desired temperature.

By design they are divided into 3 types:

- Monoblock. With heat exchanger, combustion chamber. Gas burner of a fixed type, covered with a steel sheet.

- Paired. They have two separate combustion chambers for wood and gas.

- Reconfigurable. Universal device. Can be modified for each fuel.

The first two types do not need to be reconfigured, since you can switch from one type of fuel to another.

Gas is used as main gas or liquefied in cylinders.

The electric-wood-burning design allows you to successfully heat the bathhouse using electricity or wood (optional). Moreover, firewood is considered the main raw material. When they burn out and the temperature drops, the electric heater automatically starts working. There are two heating elements on the sides of the product. Such stoves operate on a 220 W network, with a three-phase voltage of 380 V.

The owners can choose which fuel to heat the bathhouse with. But such designs are many times more expensive than simple wood-burning stoves.

Home stove models

Buleryan

This is a Canadian designed and built oven. It is quite easy to use and has a simple design. The main part of the stove (firebox) is made in the shape of a steel cylinder, the thickness of which is 5-6 mm. The hole for supplying coal (door) is made at the end of the furnace. Adjacent to the main part are round (or rectangular) pipes that are hollow inside. After heating, these pipes create the necessary transfer of warm air in the desired direction.

A grate for maintaining coal (grid) is made at the bottom of the firebox. At the top of the firebox there is a fence that divides the main part of the stove into two halves. This is done so that it can be heated with both coal and gas. The smoke exit hole is located on the back side of the door and is combined with the firebox, allowing smoke to escape safely to the street.

Butakov stove

It was tested in extreme conditions of a cold climate, not meeting the expectations of the owners of the patent for this invention. This brand has several varieties. The models, which are planned to be used around the clock, are improved with glass barriers. The stove consumes 12 times less fuel than a potbelly stove, and two times less than conventional brickwork.

Model "Student"

This happens due to the fact that in such a furnace the fuel does not burn, but smolders (pyrolysis process). The only negative is that the chimney pipe is not sealed enough and water may drip from there during the transition of steam into liquid. There are 6 types of such stoves. “Gymnasium student” is the most convenient in size.

Breneran

Russian model of the Buleryan stove. The oven is not heavy and compact. It is suitable for both living space and garage. Testing of such a stove was carried out in the mountainous areas of Tajikistan, where border office premises are equipped with stoves of this type. Breneran stoves come in 5 sizes, with a power of up to 35 kilowatts.

Teplodar-Matrix

This is a successful combination of design and functionality. In stoves of this type, it is possible to burn continuously for 8 hours (with one fuel supply). The convection compartment housing creates uniform heating and protects against negative radiation. The depth of the smoke exhaust compartment and the compact design of the stove saves space and creates additional advantages during installation - the chimney can be made in the direction in which it is necessary or convenient. This manufacturer has a fairly large selection of models, so you can choose the best option based on your needs and preferences.

Teplodar-Matrix 100

Teplodar-Matrix 200

Suitable if you need to heat a room up to 200 square meters. For garage premises, the best option is the Teplodar T series. For kitchen areas, a Vertical fireplace stove is ideal. If uniform heating of the living space is of paramount importance, it is better to choose the Vesuvius model.

Termofor

High-quality domestic stoves for heating areas with an air volume of 50 to 250 cubic meters. The power of such furnaces reaches 13 kilowatts. Suitable for heating both residential and non-residential premises. Some models have added fans for better dispersal of warm air. A large number of different models are presented - Ermak, Normal, Indigirka, Cinderella, etc. These stoves are compact and have an efficiency of up to 90%. Some models have glass shutters.

Types of steel furnaces

Depending on the functional features and appearance, steel furnaces are divided into several types.

Efimov Maxim Store manager on Vyborg highway. 212

We recommend reading our article “How to choose a wood-burning stove for your home.”

Stove-fireplaces. These are stoves with large glass to make it easy to watch the flames. The air intake holes in this type of stove are located at the bottom, often under the firewood door, and the outlet holes are at the top, on the top plate or immediately below it. You will find options for such stoves in the corresponding section of our website.

Fig 2. Stove-fireplace

Long-burning stoves of the “buleryan” type. We described these ovens in detail in a previous article. The body of such furnaces is completely enveloped in tubes for air circulation. Sometimes they are hidden under a cover. The range of stoves of this type is presented in the section “Long-burning stoves”.

Fig. 3. Long-burning furnace of the “buleryan” type

Heating and cooking stoves. This type of stove is a type of long-burning stove. There is a cooking surface on top of such an oven, so convection channels run along the sides. The range of heating and cooking stoves is also presented on our website.

Figure 4. Heating and cooking stove

Potbelly stoves. Let us immediately note that although potbelly stoves are steel ovens, they are not classified as convection ovens. The point is in their design, which historically was and remains as simple as possible - it is a metal box on 4 legs. Potbelly stoves are capable of heating small rooms (most likely even small ones), and at the same time their service life is also short. Nevertheless, even this type of steel furnace has its uses. Models of potbelly stoves can be selected on the website in the “Potbelly stoves” section.

Advantages of wood stoves

The main advantages are:

- The presence of a casing that has holes for air or a combustion chamber with a system of pipes that exhaust air.

- The casing absorbs all the radiation, and when it heats up, it releases heat into the room.

- You can regulate the flow of fresh air into the firebox.

- The presence of several partitions located above the combustion chamber. As a result, the gases do not exit directly into the pipe, but first give off heat and only then go into the pipe.

- A long period of operation, which is associated with the use of refractory bricks in furnaces, the use of hobs made of cast iron, steel or other metal.

- The presence of heat exchangers that heat water, but such systems are only available in a few models.

- The so-called afterburning process of pyrolysis gases that are released during combustion occurs.

- The wood in the stove produces electricity.

- Wood-burning metal stoves release smoke to the right place, which allows you to regulate the heat balance in the living room. As a result, the rooms can maintain a stable temperature for 24 hours.

Other advantages of metal stoves, the operating principle of which is based on wood, include environmental friendliness, safety, and affordability. In particular, this applies to firewood, which is considered an environmentally friendly type of fuel. And its price is lower than for coal or peat. It is worth considering that firewood supplies must be replenished and placed in a specially designated place.

Long-burning potbelly stove

The potbelly stove has become a real symbol of Russia since the times of the Revolution and Civil War.

This is the name given to the simplest iron stove of a cylindrical or cubic shape. Its advantage was that the smoke channel - an ordinary iron pipe - could be taken out anywhere - through a wall or roof, into a window.

Taking the simplicity and practicality of a potbelly stove, you can make a small stove that will embody some simple ideas that significantly increase its efficiency, safety and environmental friendliness.

Basic scheme

The classic potbelly stove has a cylindrical design. However, it is difficult to do this when making it yourself, so you need to take a cube or parallelepiped as a basis.

Contains the following structural elements:

- Firebox. This is the chamber in which fuel combustion occurs, most often wood. The walls and bottom of the firebox must be thick, since they bear the main temperature load. There is a door in the front for storing firewood in the firebox; if desired, it can even be equipped with heat-resistant glass.

- Ash pit (ash pan). The compartment under the firebox is separated from it by a grate. The ash pan is also equipped with a door, only of a smaller size. It is used to remove ash and ash. which fall through the grate from burnt firewood. But this is not the only point of the ash pan - air is sucked in through the ash door and passes through the fuel layer from below, ensuring the best combustion.

- Smoke channel. To arrange it, a round hole is cut out in the upper part of the stove, a piece of steel pipe is inserted into it and scalded. In the future, you can attach other sections of the pipe here or use a factory sandwich chimney with special locks.

Expert opinion Dmitry Konstantinovich Levin

Some manufacturers of homemade stoves believe that the design with a blower and grate is not suitable for a sauna stove - it creates too much draft, which prevents complete combustion of the wood. Instead, it is proposed to lay the firewood directly on the bottom of the stove, and ensure air flow by drilling several round holes in the lower part of the combustion door and equipping them with a sliding damper.

How to make a door

The door is made of a thick sheet of metal. For fastening, you can use store-bought factory hinges or make your own. To seal the fit, an asbestos thread is used - it is wedged in a groove cut by a grinder.

If there is a suitable sheet of heat-resistant glass, it is inserted as follows: cut a window in the door and grind the cut area. Then they lay the glass, lay asbestos fiber around the perimeter, invisibly from the outside of the part, after which, using small steel tongues, I make tacks on each side.

The turning handle of the latch is easiest to make from the outside.

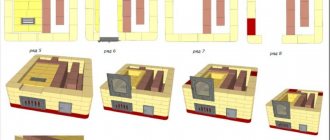

Homemade secondary gas afterburning system

The main disadvantage of a potbelly stove is its low efficiency. A stream of air passes quickly and strongly through the entire oven, carrying with it not only unburned food, but also heat. As a result, the case does not warm up sufficiently and gives off less heat. To solve this problem, a simple but ingenious modification was invented.

By placing two steel sheets above the firebox, the smoke passage channel can be significantly increased the length of the path that burnt gases travel before exiting through the chimney opening:

- The first horizontal sheet is welded directly above the firebox so that a channel remains for the passage of gases in the rear part of the stove.

- The next sheet is cooked higher, offset so that the passage is now at the front of the oven. It turns out that smoke, gases and heat, once in this labyrinth, snake through it all the way to the chimney. Along the way, they give off all the accumulated heat to the sheets, side walls and top plate of the oven.

If you drill several holes from the bottom from the back and cover them with a screen made of steel sheet, then at the top point, when fresh air, but already heated by the screen wall, meets unburned gases, the process of afterburning secondary gases will take place in the channel, which will lead to a significant increase in efficiency ovens.

Disadvantages of metal stoves

No matter what high-quality stove model that is suitable in size and functionality is chosen, it must be remembered that any stove, no matter how ideally it fits, always has disadvantages.

Metal stoves are inferior to brick stoves in terms of heat retention. When heating a room with such models, warm air is retained in it for only a couple of hours, and in the morning there will be no heat. But we can solve this drawback if we buy a metal stove that operates continuously. After purchasing and installing it, you can forget about adding fuel for 8 hours.

The operation of metal furnaces can last up to 20 years. According to statistics, much earlier than this, the metal in the firebox burns out and requires replacement.

When buying a metal stove, you need to think about who will service it and how. If you plan to install it for residential premises, then it is worth considering the presence of people with chronic diseases of the respiratory tract or cardiovascular system. In addition to the fact that such stoves create powerful radiation, they create the effect of “dry air.” This problem can be solved if you cover the metal base of the stove with bricks (calculate whether the floor can withstand the additional weight). This will greatly reduce the operating time of the stove and void the product warranty. The heating rate will become slower, but the heat capacity will increase.

Description of a metal sauna stove and its main characteristics

You can, of course, buy a metal stove for the bathhouse. However, the best option would be to make it yourself. A simple option is a potbelly stove, which is a metal structure equipped with a door and a pipe. Low heat transfer and significant financial costs for purchasing fuel do not allow the heating installation to be used effectively, so it can be seen in rare cases.

Another thing is modern iron stoves. Their attractiveness, high efficiency and highest fire safety rating are impressive. They are made from sheet iron, more than 0.4 centimeters thick. The structural components are:

- It is customary to use a thermal chamber for filling and storing stones;

- There is a tank designed to store water with a volume of 30-70 liters.

An iron sauna stove requires lining with refractory bricks. This makes it possible to evenly heat the air in the room and makes the structure completely safe for use.

Features of metal furnaces

Wood-burning metal stoves for summer cottages are considered super economical because they consume a small amount of oxygen during combustion. While they smolder, heat is released and the room is heated.

You can try to find models that have an additional combustion chamber designed to burn carbon monoxide. To reduce the amount of firewood and oxygen consumed, it is necessary to properly stack the firewood in the firebox. The fewer gaps remain between them, the longer the tree will smolder. Considering that oxygen in heating furnaces is supplied to places of smoldering and not combustion, the process is prolonged several times.

Particular attention should be paid to the design of the chimney, which is needed to create draft and remove combustion products. In metal home stoves that burn wood, it is necessary to install round chimneys so that they do not create air turbulence, characteristic of rectangular models, and it is difficult to clean such a structure. Round chimneys are excellent for cleaning from soot and soot. There should be no bends in the pipe, or their number should be kept to a minimum. The chimney is installed before the stove itself is installed.

Simple heater for a summer house

Such a heating metal stove is well suited for quickly providing heat to a small bathhouse or even a sauna.

The main advantages are that it is mobile and easy to manufacture.

Preparing for vaping takes 1.5 hours, the walls heat up quickly. One caveat - you need to attach 2 chimneys to the stove. The first will participate in heating the room itself, the second will remove carbon monoxide.

What does the oven consist of:

- Steel - iron sheets of at least 3 mm.

- It is better to make the firebox from thicker steel -6 mm.

- The kit also includes latches and a metal grill.

This structure can be assembled using a welding machine. Such sets are purchased in a disassembled state, the instructions are already included. Designing a metal stove will not be difficult, as it will fully comply with fire safety rules.

How to install the stove correctly

- The first priority is choosing the installation location and measuring the area. Everything must comply with safety regulations. The stove should be installed at a distance of at least 60 cm from the plaster and 80 cm from the wallpaper.

- The stove must stand on a concrete slab (at least 0.7 cm), asbestos or basalt cardboard.

- The furnace elements are assembled according to the instructions, after which it is necessary to check the tightness of the assembled structure.

- A protective element must be attached above the stove, on the ceiling.

- Installation of a chimney (it is better to choose a round option - rectangular ones have worse draft).

- If you want to paint the stove, then any paint will not work for this. You need to choose special enamels (silicate or organic).

- Call a fire inspector who will check the correct installation.

- Test check of the entire system.

Metal selection

The technical characteristics of the future heating device largely depend on the metal chosen for it, which affects the cost of the work and the complexity of its implementation.

To create aggregates use:

- Surrogates . These include, for example, aluminum milk cans. But their use cannot be called the best option. The reason is that afterburning of exhaust gases, during which the temperature reaches at least 400 degrees, can provide high efficiency, and when operating an environmentally friendly stove, it rises to 600 degrees. But at 660 degrees aluminum melts. This means that the can will not make a long-lasting stove.

- Ordinary structural steel . It is characterized by a tensile strength of up to 400 degrees (over 2 hours) and 600 degrees (up to 2 hours). Only thick steel is suitable for stoves - at least 4 millimeters. But frequent use of such a unit is impossible, since it will burn out in just one winter.

- Heat-resistant steel . Factory furnaces are made from it using special steel 1.5 - 3 millimeters thick. These structures last up to 20 - 30 years. They are compact, light weight and high efficiency. Factory units are usually certified by the relevant services and can be installed in residential buildings. On top they have low-power water heating registers or hobs. It is quite possible to make a metal stove from heat-resistant steel with your own hands, since the assembly of individual models does not require major welding, and the connections are made differently, for example, using steel rivets. An example of such a device is the Slobozhanka product.

- Cast iron . Iron with an admixture of carbon is characterized by an insignificant thermal conductivity and thus retains heat well inside the furnace. The cast iron unit warms up quickly, and after heating it continues to provide heating for another 3–4 hours. It is used to supply heat to rooms up to 60 square meters. For the manufacture of stoves, cast iron with a thickness of 6–25 millimeters is suitable. A thinner alloy is more brittle, while an alloy that is too thick may crack during the first heating. Due to their significant weight, cast iron stoves cannot be installed directly on the floor, and therefore it is necessary to install a concrete screed. To do this, the floor is dismantled and a concrete pad of the required height is poured. It will not be possible to make a stove from cast iron yourself, since it is impossible to process it in artisanal conditions. Such units are used for heating utility rooms or greenhouses.

Tips for use

- The more densely the wood is stacked in the stove (this increases the smoldering time), the greater the fuel savings.

- Regular chimney cleaning is an essential safety measure.

- To ensure that no one touches the stove or gets burned on the structure, you can install screens or cover the metal body with bricks.

- If the oven door is glass, then it will constantly turn black from soot. It is better to clean before the glass has cooled, otherwise you will have to deal with resin. Cleaning can be done with regular glass cleaner and a sponge or newspaper. You should not use metal scrapers as they will cause scratches.

- Make sure that the metal parts (especially the grate) do not burn through. They need to be changed in a timely manner.

- The ash pan needs to be inspected and cleaned regularly.

A metal stove for a wood-burning home is an effective solution to the heating problem, which is popular due to its intuitive operating principle and easy maintenance. When choosing from the presented options, you should take into account not only the cost, but also the technical characteristics and reviews of owners who already own one or another model.

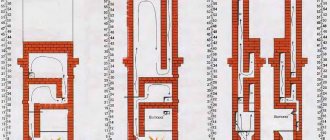

Classification of furnace units

Most often, homemade stoves are made with cooking surfaces.

According to the characteristics of the device they are made:

- chamber;

- duct;

- bell-shaped

In chamber stoves, flue gases enter a special chamber and are completely burned there due to natural circulation. Their design creates a similarity to the burning of an ordinary fire in a confined space. In domestic models, the combustion compartment is connected to the afterburning compartment into a single module called the crucible. Its vaulted shape ensures complete combustion of fuel. An example of such a design is the classic Russian stove.

In a ducted unit, the flue gases first burn out, then gradually cool down and move through the channels located between the partitions. When moving, they give off heat to the furnace body. There is no afterburning inside until the temperature in the combustion chamber reaches 400 degrees. The efficiency of these devices does not exceed 60%.

In a bell-type furnace, combustion products move to the roof of a special bell and linger there, burning out completely. Then the gases sink to the bottom and give off heat to the body. To kindle such a unit, it is enough to warm up only a small area of the hood. Its efficiency can be 75%.

Calculation of the volume of the steam room and furnace firebox

Here it is necessary to measure the dimensions of the room, and it is necessary to take into account the surface (what material it is made of).

If there are windows, a glass door, concrete surfaces, brick or tile, it is necessary to measure their area.

Therefore, for 1 m2 of such surface you can additionally add 1.5 cubic meters to the volume of the room. All these indicators will be taken into account when calculating the size of the furnace.

Oven requirements

Perhaps the most important and basic requirement for such stoves is safety. The stove must meet all safety requirements; it must not be a fire hazard or cause burns to humans.

In addition, there should be no smoke entering the room, and the temperature regime should be recorded on working devices.