Our family recently purchased a village house that has a stove. We had never used one, so we found a stove-maker grandfather in the village. He talked about the types of firewood (which ones are better to burn and which ones are worse) and gave some more tips on how to use the stove so that it serves for a long time. We learned a lot of useful things from him, thanks to him!

As it turned out, if you handle the stove and firewood correctly, you can reduce fuel consumption by 15-20 percent. You can also improve heat transfer and prevent increased soot formation in the chimney. At the same time, the service life of the stove largely depends on following the rules.

What kind of firewood is preferable?

It is best to take firewood from hard, deciduous trees. When they burn, no resin is released, and the high combustion temperature is maintained without problems. An additional advantage is that soot remains to a minimum inside the chimney.

It is not advisable to heat the stove with garbage; it is also bad to use spruce and pine wood. On the contrary, it is good to heat with sawdust. Briquettes are also used; they are made from peat or wood. The fuel should have a moisture content of about 20 percent. It is present if the firewood is stored in a dry room for a year.

They stopped expressing their opinions: signs of a decline in the morale of subordinates

Trends, new clients: why does a company need rebranding and when does it need it?

Plan your day: how to cope with anxiety when returning to work in the office

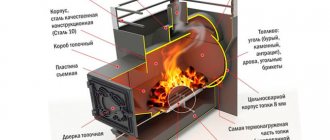

Firebox of long-burning furnaces

Before installing a long-burning stove, you should familiarize yourself with the heating features. Before ignition, you will need to thoroughly clean the ash chamber of any blockages. After this, paper and several dry splinters are placed on the inner grill of the chamber. Then several small logs are placed on top in a house shape. It is necessary to leave approximately ⅓ of the total space free so that air circulates well.

Before ignition, the view and the blower are opened slightly. Afterwards, you can set fire to the paper with torches and close the firebox. to light a long-burning stove with the door ajar during the ignition stage, if it is not transparent. This allows you to control the ignition process.

The air supply is regulated by the ash pan, which can be opened completely in case of poor draft.

What type of wood is best for firewood?

Different types of wood differ from each other in their calorific value and combustion characteristics. In this regard, when choosing fuel, you need to understand the performance characteristics of firewood.

- Pine has a high combustion temperature. The reason for this is the high resin content. This rock suggests many voids where tar deposits are present. When burning, they produce micro-explosions, sparks and ignited pieces of wood fly away.

- Spruce is less efficient in a firebox than pine. It contains less resins. Splitting wood is easy, but when burning the tree smolders and smokes. These conifers can be used for heating only in extreme cases.

- Alder. The main feature is the ability to burn without forming soot. At the same time, during combustion, deposits in the chimney will also be burned out. Such characteristics are unique to aspen.

- Poplar. It burns out quickly without providing enough heat. It should not be used to heat a bathhouse, but it is quite suitable for a home.

- Birch. Burns hotter than beech with acacia and oak. But there is also a drawback, and a significant one. It is necessary that there is sufficient air flow into the combustion chamber. Otherwise, there will be no heat, but only tar and smoke on the walls of the chimney.

- Oak. It is distinguished by its high density and ability to release heat. Its characteristics are similar to ash and also resemble beech. Oak wood is quite heavy when splitting.

- Maple. Its wood burns quickly without forming coals, as a result, there is a need to constantly add fuel. It's like burning linden wood.

- Apple trees. Like other fruit species, it pricks well and produces enough heat when burning. Apple firewood is also preferred because of the pleasant smell in the room.

Here's what else the stove maker said.

Nanny services in Russia have become more in demand: what is the average salary in the country

“The rich are selfish and stupid”: how parents program their children for poverty

Being Open to New Ways of Seeing: Secrets to Effective Listening

Lighting coal in the Stropuva boiler

The most common method is to pour fuel into a container, pour the flammable mixture into the duct and throw a lit match or burning wick into it. But anthracite will not ignite like that.

For it to light up you need:

- Pour in enough coal to reach the level of the bottom edge of the loading door. The consumption in this case depends on the volume of the chamber.

- Place a layer of dry small firewood on the fuel. Its thickness should be two-thirds of the height of the loading door .

- Light the wood and close the door.

- Wait until the fire burns. You can evaluate the intensity of combustion by looking through a special window made of heat-resistant glass.

- When the wood has burned down to burning coals, you need to open the door and add coal so that the top of the fuel is even with the top of the fire door.

- Fully open the air duct to obtain maximum draft.

- Wait 30-60 minutes.

- If the oven begins to heat up, close the air duct back to normal.

- The boiler must be heated in this mode until the coal is completely burned.

The question of how to properly heat a solid fuel boiler directly depends on its type. All these units operating with solid fuel can be divided into two main groups - boilers with automatic fuel supply and units with physical loading.

The first group includes the so-called pellet heating products. Their design features are more complex, and the work is almost independent; it is necessary to heat such an apparatus, maintaining a fire in it, quite rarely.

The second type of solid fuel boilers is the most common. They come in three types:

- pyrolysis;

- classic;

- long burning.

Classic devices are practically not used today, this is due to the frequent need for their maintenance, as well as the insufficient safety of the unit for consumers. But pyrolysis apparatuses and long-burning boilers are widely used and popular. This popularity is due to their correct construction and fuel efficiency.

Rice. 1 Pyrolysis solid fuel boiler

What are the alternatives?

In addition to the types of wood listed above, peat briquettes are popular. Their advantage is that they do not need to be chopped, dried or otherwise prepared for burning.

Sawdust can be used instead of lump wood. But you still need firewood. With their help, kindling is carried out, followed by sawdust, which should make up no more than a third of the total volume of fuel.

Reviews

Lyubov, 60 years old, Taganrog

“In the 90s there was no gas. You wake up early in the morning, it’s cold, you add firewood. Annual maintenance gets boring. In the summer, you gather your strength and rake out soot all day. Once you’ve done everything, it’s time to take up the woodpile. At first it didn’t work, but then I got used to it. Now there is gas in the house, but I remember those times with warmth. Life felt different then.”

Konstantin, 45 years old, Moscow

“I bought a dacha. The house is small. The most important thing is that it is heated with a Russian stove. The owner sold it at a discount only because he didn’t know what to do with the beautiful stove. It's already 20 years old and hasn't been cleaned in that long. So I started smoking. But I'm glad."

Nowadays it seems that everything is mechanized, civilization is everywhere, and every problem can be solved by video. But as soon as you leave the city, you plunge into a world of tilting houses with black chimneys. You need to know how to use old structures. To get the maximum effect from a solid fuel stove, learn how to operate it - heat it correctly and manage the kindling process.

What is best to use for cleaning a chimney?

Chimney maintenance needs to be done periodically. Soot and resin deposits are removed from it. There are following reasons for this:

- The internal lumen becomes overgrown, causing traction to deteriorate and, accordingly, heat transfer decreases.

- If there is insufficient draft in the chimney, then a reverse draft effect may occur. Instead of going outside, the smoke will return indoors, which is the cause of carbon monoxide poisoning.

- Having reached a critical level, the soot ignites. Essentially, a micro-explosion occurs inside the chimney. During combustion, a lot of heat is released and heating occurs up to 1200 ° C. Then the chimney requires major repairs.

To prevent the condition of the chimney, among other things, in case of small deposits, burn aspen or alder firewood. The oven needs to be heated thoroughly. In addition to firewood, briquettes that have a special chemical composition are also used. However, if there are large soot deposits inside the chimney, burning off the tar will not help. Then mechanical cleaning of pipes is inevitable.

Security measures

Having a stove at home means interacting directly with fire. Failure to comply with safety measures can put all residents of the house at great risk. It is recommended to follow a few simple rules and calmly enjoy all the benefits of the Russian stove.

Furnace installation diagram.

- you should light a fire in a stove only using flammable materials such as birch bark or paper, and under no circumstances use flammable liquids such as gasoline;

- proper operation of the stove involves the use of firewood; polymeric materials and other household waste will prematurely clog or render the chimney unusable;

- Dry wood should be burned to avoid heat loss due to drying during combustion. To do this, the required amount of firewood is prepared at home in two or three days and stored in the oven. With each subsequent fire, the firewood is dried;

- to avoid fire, sparks or burning coals, the oven lid must always be tightly closed;

- It is not recommended to burn glossy printed publications, since the paint on them interferes with combustion and clogs the chimney. The ash left behind is not an environmentally friendly fertilizer;

- It is prohibited to heat the stove with small wood waste such as sawdust. Sawdust scatters evenly over the combustion site, interferes with normal draft, blocks access to oxygen and, if air is suddenly introduced, an explosion can occur;

- It is unacceptable to cover the ceiling with flammable materials. A fire hazard may arise;

- There should be no close contact between flammable objects and the walls of the stove, which could result in a fire. Heat transfer to the room deteriorates;

- do not exceed the maximum permissible combustion time, as this will lead to premature damage to the structure. It is good to have a special thermometer on the stoves, constantly monitor the temperature in the combustion area and keep it at 70 ̊ C. It is better to heat more often with the lowest intensity;

- in new buildings you should start lighting the stove only after completing the installation of all walls and ceilings. Heat must be contained in the house, otherwise the internal parts of the furnace may overheat.

How to heat correctly?

To reduce wood consumption and improve combustion, the stove maker advised doing the following:

- You need to put logs into the stove that are approximately 5 cm shorter in size than the length of the firebox. If, when preparing firewood, you make it approximately the same size, it will be much easier to burn.

- The logs are laid in such a way that there are gaps for air.

- Although the stove can, in principle, be heated with raw wood, this is fraught with the release of tar with smoke and in considerable quantities. In this regard, it is better to deal with dry fuel (no more than 25 percent humidity).

And finally - about how to start lighting the stove.

It's never too late to learn new things: why it's not a shame to be an intern in adulthood

They leave because of momentary revenge: mistakes during dismissal that affect a career

In the closet or on the windowsill: how to equip an impromptu home office

Stages of kindling

For kindling, take birch bark, wood chips and shavings from dry firewood. Lighting the stove with flammable and explosive substances is prohibited!

The prepared kindling is placed on pre-crumpled paper, and several logs are placed on top. When filling for the first time, the fuel chamber does not need to be filled to the limit; it should be filled to a third of its height. If you immediately load the firebox, it will be difficult for the stove to reach operating mode. In addition, the height of the stack depends on the quality of the firewood. The damper the logs, the lower their layer should be.

Firewood for the stove

As soon as the kindling flares up, close the fuel door and fully open the ash chamber. We wait until the bookmark burns out.

We stack the first main portion of firewood tightly, over the entire area of the grate, so that at least 100 mm remains to the top of the fuel chamber. We regulate combustion by partially closing/opening the valve and the ash door:

- Normally, the flame should be straw-colored.

- If the fire turns red and soot appears, you need to increase the access of fresh air (i.e. open the valve or ash door).

- The flame becomes almost white and the stove begins to hum - the draft is excessive, you need to cover the vent.

The main batches of firewood should be laid as tightly as possible to ⅔ of the volume of the firebox, so as not to unnecessarily open and cool the firebox. If one load is not enough, subsequent bookmarks are performed after the first one has completely sunk.

There may be several floods, but it is worth remembering that a brick stove “does not like” overheating. And a long time of heating will ruin it. Therefore, do not make more than two bookmarks.

The firebox is considered complete if the flame completely disappears in the chamber. However, you should not close the valve or view if there are still smoldering coals in the stove. This is life-threatening! You must first wait until they burn out completely and only then close the chimney.

Safety regulations

A brick oven is a fire hazardous structure. Therefore, when operating it, first of all, it is necessary to adhere to fire safety rules. There should be no flammable substances or materials near the structure. When opening the oven, make sure that no coals fall out.

The stove is a fire hazard

The second danger is the formation of a significant amount of carbon monoxide when burning fuel. That's why:

- do not operate the structure if there is no traction;

- light the stove long before bedtime and do not leave it running unattended at night;

- do not close the valve until the coals have completely burned out;

- if the structure has not been used for a long time, first inspect it for cracks through which carbon monoxide can enter the room.

In addition, a furnace is a structure with an increased risk of injury, and it is easy to get burned on the heated elements (furnace doors, cast iron stoves, side surfaces of individual structures). When working, be careful and keep children away from the structure.

How should you light the stove?

Lighting a stove can be considered a kind of art. If you do this incorrectly, as well as ineptly maintain the fire, then it will be impossible to achieve a temperature in the firebox of more than 40-50 ° C, and this is not enough to heat the room. Kindling involves the following steps:

- Preparation. It is necessary to remove ash and coals from the ash chamber and clean the grate. Then the traction is checked. This is done by lighting paper or a candle. The firebox should draw flames into itself.

- Laying the first of the fuel layers. A seed is prepared. A couple of bars need to be placed, moving them apart by 15 cm. Insert crumpled paper between them, onto which a pile of wood chips, shavings, and sawdust is poured. You need to put a couple more logs diagonally on top.

- Ignition. Use a torch or lighter to ignite the seed. The use of flammable liquids is prohibited. As for dry fuel, it is allowed with wet firewood. Ignition is carried out by opening the ash pan, waiting for a buzz to appear. The noise is an indication of a fire breaking out. The damper does not need to be closed completely.

- Additional loading of firewood is carried out 15 minutes after igniting the seed. And then the logs need to be added every 2 hours, until the temperature reaches the required level.

Found a violation? Report content

Alexander Batsulin

Born in Moscow on September 7, 1976.

Graduated from the Faculty of Chemistry of Moscow State University with a degree in Chemical Kinetics. He has been involved in the furnace business since 2000. Interests: construction and design of stoves for heating individual houses. Traditional timber construction. Tel. 8 (915) 169 1733 8 (950) 259-6401 e-mail: sashbats (а) mail.ru Russian Teplushka stove is designed for heating a room and cooking food by boiling, simmering, baking and frying. The oven can also be used for drying herbs, mushrooms, berries, apples, plums, pears, etc.

Tips for more efficient heating

If before refueling the boiler has recently been operating, and the chimney has excellent draft and has not yet lost its high temperature, it is enough to close the doors and, after turning on the control, record the desired temperature. After some time, you can remove the control unit and check whether the previously added part of the coal has ignited. If so, then it’s time to add additional combustion material. In this case, there is no need to close the slots in the front part of the grille.

Rice. 2 Automatic coal boiler

If the chimney is not preheated, after setting the paper on fire, the bottom door of the ash pan must be opened. Next, without turning on the fan, it is important to give the device some time to warm up using natural draft. After the combustion intensifies, its thrust will increase significantly; noticing this, you can close the door tightly and activate the control unit by turning it on.

When the chimney has not been used for a very long time, or it is new, it is worth warming it up well before lighting it. To do this, it is enough to set fire to the paper while inspecting the chimney until the draft in the boiler increases.

Choosing fuel for a solid fuel boiler

Many users of solid fuel boilers are very careful when choosing fuel. This is not at all surprising, since the quality operation of the unit depends on this product. Moreover, it needs to be purchased in large quantities, not only because of the cold climate, but also because the long-burning device requires refilling with large quantities of raw materials.

The following types of gas stations are considered the most popular today:

Not knowing what is the best way to heat a solid fuel boiler, you should pay attention to briquettes and pellets, which are easy to use and have a long burning time. But when using them, there is also a significant disadvantage - the high price, which is derived from the difficulty of manufacturing these products.

Firewood is no less convenient to use, but in some cases it has high humidity, which is difficult to deal with even for the newest boiler models.

But heating with coal is beneficial from all sides - its combustible effect is quite long, and during combustion it does not emit any harmful substances. The low price of the material is no less pleasing.

Periodic boiler cleaning

After learning how to fire a coal boiler, you need to learn how to clean it. These actions will help prolong the performance and neat appearance of the unit. During the smoldering process of coal at high temperatures, the device leaves a minimal amount of waste, which is dumped into the ash pit. The amount of waste is practically invisible; it becomes visible only after prolonged use of the device.

The entire combustion process takes place on a grate. But over time, the time comes when the solid fuel boiler needs to be cleaned. Such cleanup activities are not considered particularly time- or financially expensive.

You don’t have to worry about the best way to clean the device: any specialized store offers a large number of products used to clean soot and tar from boilers.

These products are thrown directly onto hot coals, resulting in the formation of acrid smoke, which will remove all the toxins inside the boiler and chimney. In this case, the operation of the device can not be interrupted. In addition, the walls of the device can be cleaned with a brush and a wire brush, which are usually included when purchasing the equipment.

Close the valve in a timely manner

The stronger the draft, the faster the wood burns. But if there is not enough air, they burn poorly and form a lot of soot. Balance is important so that the minimum amount of air necessary for combustion reaches the firewood.

- Before ignition, open the heater damper to the maximum to ensure good draft for igniting the wood.

- When the wood starts to burn, begin to gradually close the valve. If the firewood starts to go out, open the valve slightly and increase the draft. Over time, you will find the optimal valve position.

The drier and denser the wood, the less air is required to burn it.

Why is a solid fuel boiler an economical solution?

The choice of device is primarily correct for residents of dachas and cottages not connected to centralized heating. Even if such a connection is present, this unit will help to significantly save on gas bills; solid fuel is widely available and has a low price.

On the modern market you can find suitable equipment for planning a house of any complexity, even with a fairly large area. Having studied the above recommendations on how to use and maintain the boiler, these actions will take a minimum of time.

The same amount of wood can burn at different speeds and produce different amounts of heat. Next, we will tell you how you can increase the efficiency of burning wood: extend its burning time, increase heat transfer and reduce consumption without special costs.

This is the second article in a series about efficient wood burning:

Features of using a solid fuel pyrolysis boiler

Regardless of what you use to heat a solid fuel boiler, the principle of its use remains the same.

Option for lighting the unit with coal:

- small wood chips and additional paper, which is required for quick ignition, are placed in the fire door;

- Larger firewood is placed in the loading door, with a small amount of coal placed on top of it;

- the paper is set on fire, you need to wait a certain time before the wood chips are ignited and you can close the door.

After these operations, the device will solve the problem of maintaining the temperature independently. The owner’s only task will be to stir the coal from time to time, since some types of coal tend to coke. If you do not want to carry out such operations, it is better to spread the fuel in layers. That is, firewood, the above-mentioned black fuel on top, the other two layers in a similar sequence.