As a rule, those who install autonomous boiler equipment in their home for the first time encounter problems with its operation. Not everyone, for example, knows how to properly heat a boiler with coal or what type of solid fuel to choose for the designated purposes. Experts point out that any stove must be handled with extreme caution, carefully observing all fire safety standards. It is also useful to familiarize yourself with the operating features of the selected equipment in advance.

What kind of stoves are designed for lighting coal?

Furnaces that operate from coal have a special design. The main factor influencing the structure of the heating device is the high temperature during fuel combustion. In household stoves, depending on the type of coal, the temperature can rise to 1000 degrees. In industrial equipment this value often exceeds 2000 degrees.

In household ovens, the temperature can rise to 1000 degrees

In this regard, the firebox must be sufficiently reinforced and made of thick-walled metal or cast iron with high heat-resistant properties. To maintain a constant intensity of fuel combustion in coal-fired furnaces, a special system is installed that supplies oxygen to the firebox. Grate grates are also used. They are usually made from a strong cast iron alloy.

Types of coal and their characteristics

Coal is a natural fuel. It consists of flammable carbons and various impurities that do not burn. The quality and classification of raw materials depends on the ratio of such substances. The age of the fossil also affects the grade of fuel.

Several types of coal are used to light stoves - brown, anthracite, lingite or stone. Each fuel group has its own characteristics and features of use for stoves.

Brown coal

Due to its low carbon content, large amount of water and volatile compounds, brown coal has a low heat of combustion. Therefore, it is classified as a low category fuel. The color of this still “young” geological deposit is brown.

Brown coal consists of 30-40 percent moisture. A significant proportion is occupied by volatile substances, and the carbons necessary for combustion can range from 50 to 70 percent. When stored outdoors, the density of raw materials is significantly reduced. This occurs as a result of water evaporation. Prolonged exposure to the open air leads to the transformation of the fossil into powder.

What does brown coal look like?

Brown coal is used quite rarely for heating stoves. It is mainly used in subsidiary farms. The use of such raw materials for the firebox leads to excessive clogging of the chimney pipe with soot. When burning, a pungent odor and smoke are released, and after burning, quite a lot of ash is formed.

Lingit

This fuel is classified as a type of brown coal. Lingite is considered the “youngest” fossil. In some countries it is not classified as coal due to its too loose structure. It contains up to 45 percent water and the same amount of sulfur. This fuel has a brown tint. Often the name “black lingite” refers to subbituminous coal.

The use of such fuel is completely limited, since its combustion characteristics are somewhat lower than those of brown coal.

Coal

This type of raw material is best suited for furnace devices. Its deposits are located deeper and are formed under high temperature and pressure. The nitrogen content in such raw materials depends on its type and can reach 95 percent. Thanks to this, coal has good physical and chemical properties and is a fairly valuable fuel.

The raw material contains a low level of moisture - up to 32 percent and a lot of flammable substances. The specific heat of its combustion is 5.5 kcal/kg. The color of coal can be black or dark gray.

Anthracite

Anthracite is found deepest in the ground. In color it resembles coal, but only with a more pronounced metallic sheen. The main qualities of such fuel are high density up to 1700 kg/m3 and a significant thermal combustion rate of 9 kcal/kg.

There are quite a lot of volatile substances in anthracite, so it does not ignite easily, but due to the large amount of carbon, up to 97 percent burns well. The special value of such fuel is its smokeless combustion.

The advantage of anthracite is smokeless combustion

The type of fuel affects not only the productivity of the heating process, but also the operating time of the stove. The average service life of heating devices powered by coal is seven years. If used correctly, the operating period may increase slightly. The manufacturer of furnace equipment always indicates what type of raw material the furnace is intended for.

Traditional methods

The achievements of civilization are wonderful if a barbecue picnic is planned in advance. Otherwise, knowledge of how to properly light coals in a barbecue using traditional methods will come in handy.

How to light coals in a barbecue without lighter fluid:

You can simply roll up the newspaper into a tube. It is convenient to make a paper circle using a regular plastic bottle. The resulting ring is covered with fuel and set on fire. If there is no rain, a few minutes will be enough.

Chips are made from dry firewood. As it flares up, it ignites larger firewood.

Wood chips, wood chips, rolls of wood fibers, and birch bark for kindling can not only be found in the forest, but also on supermarket shelves. One roll burns for 5 minutes, which is enough to light coals or firewood.

Hardened tourists manage to light a fire with one single match. Harsh circumstances force you to learn how to quickly light a barbecue: frost, rain or hunger.

To light a barbecue in winter or in bad weather, you will need not only skills, but also combustion catalysts. The best option is a dry alcohol tablet or briquette. These small fire sources ignite quickly and burn for a long time, igniting the rest of the fuel.

Craftsmen suggest using moonshine or vegetable oil and soaking the paper in it. It turns out to be a kind of long-burning torch, from which the firewood ignites.

Important: you need to make sure that only the wood burns

Egg cartons are made from materials containing cellulose. It burns without smoke or unpleasant odor, lighting a fire perfectly. We put it on the bottom of the barbecue, pour fuel on top, and set fire to the package.

Recommendations and process of igniting the furnace firebox

The coal stove is fired a couple of times a day. The duration of combustion of raw materials in the furnace should not be more than two hours. It is recommended to load dry medium-fraction coal.

In order to heat the premises efficiently and safely using coal, you must properly light the stove. This should be done in stages:

- Initially, dry sheets of paper are placed at the bottom of the combustion chamber, on which small wood chips are laid out on top.

- Well-dried firewood is placed on top of the chopped pieces of wood. It is good to use birch logs for ignition.

- After placing all the necessary materials for kindling, the paper is set on fire. Immediately after this, you should open the blower and close the firebox door. The rate at which wood ignites depends on the presence of air masses. It is recommended to ignite with the ash pan open, as this creates a natural air flow that will allow the chimney pipe to warm up.

- When the logs burn out and ash remains in their place, you can add fuel for the first time. For this purpose, fine coal is used, which easily ignites from hot wood residues. The laying layer should be fifteen centimeters.

- If the draft increases during combustion, the ash compartment must be closed and the fan activated.

How to use the boiler correctly

Preparing the oven

Before starting work, it is important to inspect the boiler for cracks and damage. If it has electronic control, then it is connected to the network and proper operation is checked. We remove slag and ash from the ash pan and combustion chamber.

Boiler ash pan

We wipe the walls of the firebox with a dry cloth. Checking the intensity of traction. If it is not active enough, we clean the chimney of soot. We inspect the area around and remove flammable objects.

Melting

When the preparatory work is completed, you can start kindling:

- Dry crumpled paper is placed on the grate. We place brushwood on top of it and thin chips and firewood even higher.

- The paper is set on fire from several sides. The blower opens and the combustion chamber door closes.

- When the wood burns out, sprinkle a thin layer of fine coal on top. After burning, mix it and add a portion of regular coal.

Every time you open the firebox door, you need to close the vent.

Ash removal

Ash remains from burnt coal, which, after passing through the grate, accumulates in the ash pan. It needs to be removed approximately every two days. In this case, you need to be very careful, since the ash may not have cooled down yet. It is also not recommended to inhale fly ash, it is very harmful to the body.

It is also necessary to carry out preventive cleaning of the entire boiler from time to time.

Causes of smoke

Sometimes, even when the stove is properly lit, smoke may form. The reason may be poor quality coal. But most often the following factors influence smoke:

- the appearance of cracks in brickwork;

- presence of blockages in the chimney and stove channels;

- destruction of the internal part of the heating device.

The appearance of smoke may be due to blockages in the chimney and stove channels

When igniting a very cool firebox and the entire stove system, smoke may also be released. Soot often forms when two stoves are directly connected to one chimney. To avoid smoke, a smoke damper is installed.

Features of furnace combustion after a long period of inactivity

Furnace equipment is usually used seasonally. Therefore, in the summer, the heating device often stands idle. After such a break, you cannot immediately start kindling, but first check and prepare the entire system.

The preparatory process consists of the following stages:

- Check the furnace masonry for defects - cracks, splits. Carbon monoxide or smoke can pass through damage to the surface of the stove structure during lighting. Such combustion products are dangerous for people in the room. If there are splits and cracks, they should be repaired with a solution of sand and clay.

- Inspect the integrity of the chimney structure. Clean the smoke exhaust pipe from accumulated soot.

- Remove flammable items stored near the stove. All flammable parts must be located at a distance of more than fifty centimeters from the heating equipment. Also, firewood and wood chips, which are used to heat the stove, should not be stored close.

- Before lighting, all blockages from the heating device itself are cleared. Ash and other residues from fuel combustion are filled with water and removed using a poker. Remove dust and dirt from the oven walls with a dry cloth.

In addition to the equipment itself, the condition of the fuel is checked. The coal should be well dried and not crumble in your hands. Dust is also removed from the furnace raw materials. Otherwise, when burning, a specific smell will be released.

The nuances of firing stoves with coal in winter

In winter, at low temperatures, it can be quite difficult to light the stove. In addition, the special draft that is formed due to cold air does not allow smoke to escape freely. There is no way to light the stove quickly. You can improve the kindling process by using a hairdryer, which warms up the inside of the heating equipment.

Such heating of the furnace device will avoid smoke, which is typical for cold structures. The stove should be warmed up several times a day in winter so that the system does not have time to cool down too much.

Coal is considered the most efficient type of fuel. It is successfully used to kindle stoves. The level of heat transfer of such raw materials is higher than that of wood raw materials. A good result from using coal for a stove can only be obtained by following all the rules for kindling and operating the heating device.

Modern solid fuel stoves have long been used as the main equipment for heating private houses and baths. And if the basic operating rules are observed, the costs of their maintenance are minimal.

To ensure the efficiency and duration of the combustion process, as well as reduce fuel consumption, every homeowner should know how to fire a stove with coal.

Is it possible to fire a stove with charcoal?

Coal is used to fire stoves and boilers - stone, wood and brown. Hard coal has the highest energy value, brown coal has the lowest energy value. Wood is less often used as the main fuel material, although its specific calorific value is higher than that of firewood or fuel briquettes.

The benefits of charcoal are as follows:

- During the combustion process, no unpleasant odors or smoke are released.

- Does not contain hazardous components.

- Has a high calorific value.

- Burns longer than other fuels.

- Does not crumble during transportation.

Despite all the advantages, fuel has a significant drawback - high cost. So, for 1 kg of charcoal you will have to pay twice as much as for the same volume of hard coal. You can reduce the cost of purchasing raw materials by making them yourself. To produce 1000 kg of charcoal, you will need to burn 10 cubic meters. m of wood.

It is possible to use charcoal to kindle heating equipment, but it is not economically profitable.

Rules for choosing coal for an individual heating system

The optimal choice of fuel is anthracite, since it has the highest heat transfer rates. Uniform combustion, a small amount of waste are advantages, the content of sulfur impurities is 1%, no more than 10% of ash explains the absence of combustion products clogging the chimney. Ignition of fuel takes a long time, the price is high - these are the disadvantages.

Long-flame coal in bags or in bulk is suitable for heating houses of various sizes and is used in all types of boilers. It is marked DPK, ignites quickly, burns for a long time and does not require blowing. The basic rule of choice is the size of the fuel. Answering the question of which coal burns longer, experts note WPC grades P (slab) to - M.

Types of coal

Such fuel is a rock consisting of a carbon compound and non-combustible components that, when burned, form ash. In different regions there are deposits with different amounts of impurities.

Depending on the level of specific heat of combustion, humidity and age of impurities, the following types of fuel are distinguished:

Lignite

A young type of coal with a specific calorific value of no more than 2.8 thousand kcal/kg. The raw material has a loose structure and a high percentage of ash formation. Lignite ensures the operation of industrial facilities - plants, factories, power plants, but is poorly suited for domestic use as fuel.

Brown coal

Product of the transition phase between black lignite and coal. During the combustion process, it forms a large volume of ash and coking derivatives. The calorific value of the fuel is 5 thousand kcal/kg. With an average humidity of 50%, the raw material is used for industrial boiler houses and chemical production plants. Due to the rapid clogging of the chimney system and heat exchanger, it is not recommended to burn household stoves and boilers with brown coal.

Coal

High-quality fuel with a calorific value in the range from 5 to 5.7 thousand kcal/kg. It is an intermediate link between brown coal and anthracite. It contains about 70% carbon and only 3% ash. Due to low humidity (20%), the raw material is not used for gas generating units, but is suitable for most models of household boilers and stoves.

Hard coal is divided into two groups:

- Long flame. The fuel is suitable for most domestic heating installations, provides a high flame and long-lasting combustion, and does not require additional blowing. You can use a small amount of wood or wood chips to light it.

- Low caking. The raw materials are suitable for heating a private home, bathhouse or industrial facilities. It is characterized by high thermal conductivity and lack of caking. The combustion process takes place without flame or smoke.

Troubleshooting Possible Problems

What to do if all the conditions were met correctly, but you still have problems with kindling?

In order to avoid smoke in the room, you need to be able to properly clean the stove chimney

. Firstly, a broom with a long pole or a special device for long pipes, which consists of a ball, is used. The weight of this tool can reach up to 3 kg. A brush made of hard bristles is mounted on the ball. The length of the rope for such a device is determined by the length of the pipe. During cleaning, all soot falls into the oven, after which it is easy to remove through the oven door.

Very often, fires occur in houses due to improper operation or poor condition of heating appliances. Any stove can serve its owners for many years if it is properly cared for, using only the right kindling materials and not used as a household waste disposal unit. Do not forget about simple and very important operating rules.

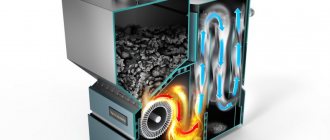

Most solid fuel boilers, which run on coal and wood, are a device of simple design. The boiler consists of two chambers, which are located one above the other. The upper chamber is used to store fuel material, and the lower chamber is used for products that remain after burning solid fuel. These chambers are separated in most cases using a cast iron grate, which has a large margin of safety.

In solid fuel boilers, complete combustion of wood and coal occurs due to secondary air channels, which act as a gas-forming nozzle. These same channels help remove ash.

There are a large number of boilers operating on solid fuel. When choosing a device, you should pay attention to the fuel combustion rate, as well as heat retention. In most cases, newer boilers will maintain a high temperature for 8 hours. When choosing coal as a fuel, you should select the best combustion mode that will be maintained constantly.

The boiler is heated using paper, small wood chips and a small amount of coal. Then a small amount of coal is poured in and the loading door is locked. Next, it will be necessary to correctly adjust the air supply, which determines the combustion time of the fuel. The more oxygen gets into the boiler, the more intense the combustion process will be, therefore, the fuel will burn faster, and the heat will not last long.

It is also not worth cutting off the air supply too much, since in this case the coal will smolder and emit smoke instead of the desired heat. In some cases, a lack of oxygen can even lead to attenuation.

When the air supply is well adjusted, it will be necessary to load a bucket of coal into the boiler. It is best to do it through the loading door located on top of the boiler. If 1/3 of the boiler furnace is loaded with fuel, you can count on 3 hours of continuous combustion. The coal supply to the boiler should be added based on the data shown by the temperature sensor.

In most cases, it is enough to keep the water temperature at 80 degrees to warm up your home well. In cases where it is necessary for the boiler to burn for a long time without adding fuel, you need to pour out enough fuel at a time so that it fills the boiler halfway. It is not recommended to use a very large amount of fuel at a time, as it will simply sinter and it will be difficult to clean the grates of such coal.

With the help of air supply, fuel combustion can be regulated every time. It is not advisable to allow a large amount of fresh air into the chamber, as this can cause a large flame to ignite and the water to boil. Very hot water will flow through the pipes, but the fuel will last for less time.

The combustion products - ash - will fall through the grate into the ash pan. This chamber should be cleaned daily, for example in the morning. It is important to understand that a clean ash chamber provides better smoke flow.

Having installed a boiler at home, we are faced with the issue of its proper operation. Not everyone has an understanding of how to properly light a boiler with coal, or what type of coal to use for these purposes.

In this case, it is worth taking into account the design features of the installed equipment, as well as strictly observing fire safety rules.

Operating principle of a coal boiler

The coal boiler consists of two chambers. Coal is loaded into the upper chamber, called the firebox. After the coal burns, residual combustion products (ash and slag) spill into the lower chamber - the ash pan, from where they are removed as the chamber fills. The chambers are separated by a cast iron grate - a grate.

Additionally, boilers can have an automatic fuel supply and draft control system. In its absence, all processes are controlled by humans. In the first case, boilers have significant operational advantages, but their cost is much higher.

Automation regulates the air supply. As its supply increases, the fuel burns more actively, releasing more heat, but at the same time, coal consumption increases. By reducing the air supply, the fuel burns more slowly, reducing the amount of heat generated, but at the same time significantly saving coal. The system can also include automatic addition of coal to the firebox.

The combustion temperature is measured by special sensors, which allows you to program the boiler. If the temperature level reaches the set value, the fan automatically stops supplying air. When the temperature drops, the fan turns on again, igniting the coal.

Choosing coal for the boiler

Coal consists mainly of carbon, as well as impurities that form ash and slag after combustion. It is the percentage of the various components of coal and its age that influence what grade of coal it is and its characteristics.

For example, brown coals have high humidity, about 50%, and in anthracite its amount does not exceed 7%. Due to this, anthracite has the highest calorific value. Between anthracite and brown coal, in terms of characteristics and properties, hard coal is located.

Using a solid fuel boiler

First, you need to prepare everything for kindling. Then load solid fuel correctly and light it. During combustion, it is necessary to regularly monitor the boiler, adjusting the air supply and promptly remove accumulated combustion products in the ash pan. Next, let's look at each step in more detail.

Preparing the boiler for lighting

Before starting to operate the boiler, you must make sure that there is no damage to it, as well as damage to the automation system, if any. Their presence can lead to the penetration of carbon monoxide and combustion products into the room, as well as incorrect operation of the automation system. If damage is detected, it must be repaired before starting the boiler.

Next, we remove all flammable objects located in the vicinity of the boiler and begin cleaning it internally. It is necessary to remove all ash and other combustion products from the lower chamber, and inspect the chimney for clogging with soot.

Important!

Soot settles in the chimney when wet fuel is used. When burning, it releases steam, which condenses on the walls of the chimney, mixing with combustion products to form soot, gradually drawing in the chimney. This leads to worsening cravings, and in severe cases, to its absence.

How to light coal

Paper (newspapers, notebook sheets) is placed at the bottom of the upper chamber, then a layer of small dry wood chips. Small firewood is placed on top of the chips; they must be laid in the form of a well or pyramid, which will allow the flame to ignite faster.

After setting the paper on fire, it is necessary to close the door of the upper chamber and slightly open the vent of the lower chamber, thus regulating the amount of supplied air to speed up the combustion process.

After complete combustion of the wood, fine coal with a layer thickness of 10–15 cm is poured onto the smoldering ash.

When the fine coal burns out, larger pieces of coal are placed on it; before this, it is necessary to stir up the smoldering remains of the fine coal, this will improve the flow of air.

Additionally, it is worth considering that poor quality coal can coke. And if you find yourself in such a situation, then you should lay a small layer of firewood between the layers of coal. This will give more air access and improve the combustion process, allowing more heat to be released to the fuel.

Ash removal

Ash is best removed when only wood is used in the combustion process. As it burns, the ash falls into the lower chamber (ash pan). As for coal, it has a long combustion time, so it is quite difficult to remove its combustion products in a timely manner. As with coking, the process is facilitated by alternating layers of coal-wood-coal. Increasing the combustion temperature can also help, so it is very important to know how to use the draft regulator correctly.

conclusions

Heating a home boiler using coal is much more profitable and easier than burning wood. When burned, coal releases more heat, and the time for complete combustion is several times longer. One load of coal can last for 12 hours of combustion, which reduces boiler maintenance time.

In order for the efficiency of a solid fuel boiler or stove to be maximum and the heating equipment to operate without failures, you need to use high-quality and dry fuel, install it correctly, and prevent condensation from forming. Monitor the serviceability of the structure itself. Even through a two-millimeter crack in the valve frame, about 15 cubic meters of air will penetrate inside per hour, which, when the furnace is heated to 100 degrees, will “eat up” about 10 percent of the total heat. When burning in a firebox with the door open, the heat loss will be 40 percent. With the vent open, the stove will lose another 15 to 20 percent of its heat.

Before lighting the stove, you need to remove the ash from the ash pan. Every year the structure must undergo complete cleaning and preventive repairs. The heating of the stove depends on the condition of the walls from the inside. When soot builds up, the stove will take longer to heat up, become weaker, and burn more fuel. Monitor the condition of the grate when adding fuel. If the grate is clogged, intense combustion will not be supported by the flow of fresh air from the ash pit.

The fuel itself must be dried. You can heat a stove with raw wood (and what can you do if there is no dry wood left), but when you burn wet wood, a lot of soot is formed on the walls and in the chimney, and the stove will need to be cleaned more often. Wet firewood has lower energy efficiency. When burning raw wood, water will actively evaporate, which will lead to condensation falling along the walls, which accelerates the destruction of the walls of the structure. To ensure uniform burning of firewood in the firebox, the wooden logs must be split equally and have a thickness of approximately 8-12 centimeters. Then heating will be carried out as efficiently as possible.

Firebox sequence.

Before placing the logs, spread out pieces of paper, lay down splinters, shavings and small wood chips, which must be dry. The first to enter the firebox is dry firewood in small quantities, slightly thinner than usual. This is a portion of fuel for heating the stove. There should be a distance between individual poles. At the same time, the laying out of firewood should not reach the top level of the firebox by 20 centimeters, so that all the particles have time to burn before they are pulled into the chimney. It is not recommended to use mixtures and means for starting a fire, as well as kerosene, diesel fuel, acetone and, especially, gasoline. If there is no dry firewood or wood chips, and you need to light the stove, you can use pine branches. Pine and spruce needles contain oils that can be used to light a stove (or fire) even on damp wood. If the stove immediately starts smoking, there is cold air in the chimney. Then you first need to burn several splinters and wood chips in the firebox to fill the space with heat. And only then add a portion of firewood for heating. (In general, it is useful to insulate the chimney with fireproof thermal insulation). Before adding coal to the firewood and switching to a coal firebox, you need to heat the chimney with wood, since coal requires more draft. The volume of firewood placed in the firebox depends on the design features of the stove. The recommended filling rate is the whole or almost the whole calculated volume of fuel at once. Watch the distance to the top cover of the firebox! After the initial filling has ignited well and the walls have warmed up a little, the fuel is completely filled.

Checking traction.

Typically, draft in heating stoves is determined by the color of the flame during fuel combustion. If you hear a characteristic hum in the smoke channel, and the flame has a bright white color, it means that the draft is too high and needs to be reduced. If the air supply and draft are normal, you will see a golden yellow flame.

The combustion process.

While wood or coal is burning in the firebox, in order to ensure their uniform combustion, it is necessary not only to stir the filling in a timely manner (2-3 stirrings are needed), but also to close the ash door and chimney in a timely manner. If you don’t know exactly how to properly heat a brick oven, aim for 1.5-2.5 hours (depending on the size of the oven and the room, as well as the ambient temperature). During the combustion of wood, coal, peat - any type of fuel - you need to close both the firebox door and the valve (view), albeit partially. Only after half of the deposited coal has burned out can it be stirred and mixed; this is one of the basic rules on how to properly heat a stove with coal. After the main volume of the bookmark has burned out, the remaining brands must be placed in the center of the firebox, and then covered with burning logs or pieces of coal. In this case, you need to reduce traction; When burnt coals begin to burn out in a blue flame, which disappears after a few seconds, this means that CO, carbon monoxide, has begun to be released. The coals must be immediately leveled and the chimney pipe must be opened for at least 10 minutes so that the fumes are completely gone. If you are not sure how to properly light the stove, it is not recommended to do this at night. Then you will definitely not be poisoned by combustion products.

How to properly heat a stove with coal.

With a constant burning of coal, in any case, when laying it, you first need to burn a small portion of firewood in the firebox, and only after that add a 50-60 mm layer of coal onto the burning coals. After the coal burns, add the rest of the filling in a layer of up to 150 mm, then the stove will burn well, heating evenly. For the combustion of coal in a solid fuel boiler, the best firebox is a shaft with vertical walls, equipped with a grate. It is desirable that the firebox has a greater height. The firebox of a solid fuel boiler equipped for coal is suitable for burning other types of fuel. The kindling is laid out on the grate and ignited with the pipe valve slightly open. When the kindling flares up, the pipe valve opens completely and the first portion of finely chopped coal is thrown in an even layer of 50-80 mm over the entire grate. After this, close the combustion door and open the ash chamber. When the coal flares up, add a portion to a layer thickness of 120-200 mm.

When subsequently adding fuel, the following requirements must be met: . throw in new portions of coal when the previous one flares up well enough; . each time coal is thrown in, which involves opening the furnace doors, the ash door should first be closed; . Make sure that the fuel does not burn through to the grate and burns throughout the entire mass in an even layer. If there are fines or dust in the coals, they should be moistened with water before throwing them into the firebox. Fat, highly caking coals of the PZh and Zh grades, consisting of fines, are usually moistened abundantly so that the coal particles stick together, without allowing excess water. Steam-caking coals of the PS grade and low-caking coals of the SS grade are mostly small and require moderate wetting. Lean coals of grade T, usually consisting of fines and prepared for throwing into the firebox, are moistened until the entire mass is wet. Long-flame coals are wetted only enough to reduce dust formation. Anthracite does not require wetting; sometimes, with a large content of small particles, it is moistened to reduce dust emission.

During combustion, the combustion door should be kept closed, opening it only while adding a fresh portion of fuel. The coal should be stirred as little as possible to avoid excessive cooling of the firebox, large failure of coal through the grate and mixing it with slag. With high-ash brown coals (Moscow Region, Chelyabinsk, Central Asian, etc.), on the contrary, the drilling must be done more often, otherwise the pieces of coal will “ash” and go out. The throwing of these coals should be done more often and in small portions. When the fuel burns out, you should close the ash door, but if the doors are sealed, it can be closed. When the fuel layer reaches 30-40 mm, the ash door should be closed completely, and the pipe should be closed with a valve to ¾ of the cross-section of the gas duct. It is necessary to completely close the chimney when the coals burn completely. Closing the pipe prematurely can lead to death.

Does the coal need to be wetted?

Sometimes the coal is wetted before throwing it into the forge, sometimes after it is already in the forge. The heat of the forge burns the volatile components of the coal, and the water will help ensure that this operation takes place without unnecessary smoke. When the coal is already burning, you can moisten it to form a crust. The top layers of coal are sintered and the flame is concentrated in the required place, the coal under the crust burns out more slowly. This is especially useful for fine coal and dust (6mm or less), which always ends up in the general heap. At a minimum, it will stick together and will not clog the grate. A bucket of dry fine coal requires approximately 1 liter of water. If you heat with dry fines, then along with the slag you will throw away unburnt small coal that spilled into the ash pit. If the stove has poor air draft, fine dry coal burns poorly, but raw coal burns well and heats up faster. Such a crust is best formed in caking, coking, forging, and gas grades of coal. It is useless to wet some brands of coal. (Large pieces of coal burn well and give more heat than small pieces. Wetting them from a heating point of view is harmful, because it is the same as wet firewood. But you can moisten them so as not to overheat and burn the stove. Here is how to moisten charcoal in any case, it is harmful, if only to save consumption and cooling).

When burning with wood, it is recommended to stack the logs in the firebox tightly one to the other, immediately add at least half of the portion of firewood, and throw the rest as it burns out in one or two steps, depending on the amount of fuel and the capacity of the firebox. For uniform combustion of firewood, it is necessary to peel it two or three times per firebox, doing this quickly, without cooling the boiler.

It is not recommended to heat the stove too much; this will not prolong the heating of the room for several days. At first you will be hot, after which you open the window for ventilation, and then, when the heat goes away, it will be cold. At the same time, excessive fuel consumption will be simply enormous. Following the above recommendations and tips, after a while you will no longer think about how to heat the stove with wood or coal in order to achieve maximum efficiency and savings.

- 1 How does a coal boiler work?

- 2 Which coal to choose for the firebox?

- 3 How to use solid fuel units correctly?

- 3.1 Preparing the stove for lighting

- 3.2 How to properly melt coal?

- 4 How to remove ash?

- 5 Conclusion

Solid fuel boiler

As a rule, those who install autonomous boiler equipment in their home for the first time encounter problems with its operation. Not everyone, for example, knows how to properly heat a boiler with coal or what type of solid fuel to choose for the designated purposes. Experts point out that any stove must be handled with extreme caution, carefully observing all fire safety standards. It is also useful to familiarize yourself with the operating features of the selected equipment in advance.

What kind of coal burns for the longest time?

Often, long-flame coals are used to heat private homes, which are suitable for any type of solid fuel boilers, stoves and fireplaces. This is due to their long combustion process, rapid combustion and high calorific value. Charcoal for the firebox is easy to use and burns for a long time due to the formation of a flame with long tongues.

The combustion process of one load of fuel lasts several hours and contributes to the release of a large amount of thermal energy.

In addition, it is cheaper than anthracite, so it is used as the main fuel for heating government buildings. Marked with the letter "D".

How to remove ash?

Heating solid fuel boilers

When the stove is heated with wood, removing the ash is very simple. The fuel burns out and falls into the ash pan chamber.

Coal has a much longer burn time, so it is quite difficult to remove slags in time. Laying with wood saves the situation - a layer of firewood, a layer of coal. You can cope with this problem by increasing the combustion temperature. Therefore, it is useful to learn how to regulate cravings.

Improved combustion process

The intensity of fuel combustion in the stove is regulated by the volume of air entering the fuel compartment. You can properly regulate the air exchange in the firebox using a blower and a viewer.

The intensity of combustion can be determined by the color of the flame. Too much air results in a white flame and a humming furnace, while too little air results in a red flame and black smoke.

Normal combustion mode is an orange or golden flame with transparent smoke.

To improve the fuel combustion process, it is necessary to adjust the chimney view. Insufficient opening of the view leads to the penetration of carbon monoxide into the room, excessive opening leads to heat loss and poor heating of the heating equipment.

The selection of the optimal combustion mode is carried out taking into account the operational characteristics of the stove or boiler, as well as the type of fuel.

Operating principle of a coal boiler

How to properly heat a solid fuel boiler with coal? The coal boiler is an extremely simple installation, divided into two sections. The first acts as a firebox, where fuel is placed. At the moment of its combustion, ash and slag are released, falling into the lower compartment.

It will need to be cleaned on a regular basis. The two chambers are separated by a standard grid made of cast iron.

How to properly heat a boiler with coal in the house? Modern models are often equipped with automation, through which the consumer can activate the autonomous operation of the stove or control the draft. Well, in older models there are no such delights, and the ovens will function through normal circulation.

Is it possible to leave dead coals in the stove?

Many homeowners are interested in a completely logical question - what to do with the extinct coals that remain after fuel combustion?

After finishing the fire, you need to make sure that all the coals are really extinguished and do not give off flames. Extinguished coals can be left in the fuel compartment until the next filling. They will help you quickly and easily light up an already cooled stove and reduce overall fuel consumption. At the same time, it is recommended to complete the process of heating a potbelly stove or boiler 1.5 hours before going to bed or leaving the house.

If there is no free time for the fuel to burn out, the remains are laid out in a free container and filled with water.

Possible reasons for restricting access:

Access is limited by court decision or on other grounds established by the legislation of the Russian Federation.

A network address that allows you to identify a site on the Internet is included in the Unified Register of domain names, page indexes of Internet sites and network addresses that allow you to identify sites on the Internet containing information the distribution of which is prohibited in the Russian Federation.

A network address that allows you to identify a site on the Internet is included in the Register of domain names, indexes of pages of sites on the Internet and network addresses that allow you to identify sites on the Internet containing information distributed in violation of exclusive rights.

What is more profitable: wood or coal?

Why is it more profitable to use coal than firewood for heating rooms in winter and organizing hot water supply?

Firewood is much cheaper than coal; it seems that it is economically profitable to use it. But is this really so?

The main parameter of choice is the calorific value of the fuel material, i.e. the amount of thermal energy that is released during its combustion.

Firewood has a low level of heat transfer in the range from 1400 to 2500 kcal. High calorific value is provided by raw materials from oak, alder and birch, low - from pine, spruce, white alder and linden.

When determining the calorific value of firewood, one should take into account its moisture level, which should not exceed 15%.

Coal of various grades is capable of releasing from 5000 to 9000 kcal of thermal energy, which is several times higher than that of firewood.

Firewood will be cheaper than coal, so 1 kW of energy obtained by burning it will also be cheap. In this case, the volume of thermal energy when burning 1 ton of raw materials will be: for coal - 6.46 Gcal, for firewood - 3.44 Gcal.

Heating a boiler with coal is beneficial for the following reasons:

- low fuel consumption;

- high heat transfer;

- burning duration.

The main disadvantage is the formation of slag and unpleasant odor during the combustion process.

The main reasons why it is profitable to heat a wood-burning stove or solid fuel boiler with wood:

- environmental safety of raw materials;

- affordable price;

- possibility of storage in bulk or boxes;

- a small amount of ash and no unpleasant smoke.

Despite its cheapness, firewood has a lower calorific value, which means burning with coal is more efficient and profitable.

Burning coal, how to heat it, long-term burning

The quality of coal determines the amount of energy that can be obtained from it, as well as the maintenance time, the amount of ash produced, the ability to use it for heating... Which coal is better for home heating? How to burn it correctly in order to achieve maximum energy output and minimum worries?

Coal combustion temperature and other characteristics

People often ask, “What is the combustion temperature of coal?”, although this value has little effect. Other parameters are much more important.

More details about ash content

The ash content is as follows.

It must be borne in mind that adding rock significantly enriches those selling coal. Therefore, buying coal is not an easy task. It is necessary to check the fuel for the presence of pieces of rock, including those sprinkled, directly in the carriage, in the car, before unloading. And refuse to purchase, if anything...

What is the calorific value of different grades of coal?

How much heat can we get from coal, is it enough to heat the house?

The amount of heat in kilowatts that can be released from different brands of coal compared to dry firewood is given below, kW/kg

In addition to the brand, you need to choose a coal size class.

For advertising purposes, the seller writes on the packaging just that...

Coal size class, why they don’t burn coal dust

Coal dust and coal pellets are the cheapest and burn well, but only in special furnaces at power plants. There they burn in a cloud with fuel oil and air. And in a boiler, they simply seal the passage of air through them, so combustion inside their layer is impossible. A piece of coal does not burn in stoves, except with small additions, poured on top of the burning coal.

There are many unburnt elements left in coal ash. After burning, the zealous owners sift the ash on a 5 mm metal grid, and all the large unburned parts are sent back to the boiler along with a fresh portion. This saves 10–15% of fuel.

They try to moisten coal dust into cakes, which are dried and fed into the boiler in the form of pellets.

How to burn coal correctly

If oxygen is not added to the combustion zone, then instead of carbon dioxide, carbon monoxide is formed - CO, the efficiency from incomplete combustion decreases by 20 - 50%. Modern boilers provide secondary air for afterburning CO and soot particles at high temperatures. With old equipment, with stoves, you need practical skill in supplying air over burning coals for better afterburning and preventing the release of unburned gases into the atmosphere.

Supplying a large amount of primary air directly into burning coal can turn the boiler into a forge, lead to rapid combustion of a large mass of coal, a sharp increase in the temperature of the exhaust gases up to 1500 degrees and melting of the equipment, ignition of soot in the chimney, a sharp drop in efficiency several times, from -for the removal of energy into the pipe.

The efficiency of coal combustion can be monitored by the temperature of the exhaust gases, which should not increase. There should be enough air so that complete combustion of the fuel occurs without CO and at the same time there is no increase in temperature in the chimney above normal. As a rule, modern coal boilers are able to burn fuel as required with a maximum efficiency of about 78%.

How to make coal burn for a long time

Normal long-term combustion with high efficiency is achieved better with modern equipment. But even on old boilers and furnaces, you can find the optimal approximate opening of the lower and upper dampers to ensure a normal air supply over the fuel for afterburning CO on the heat exchanger.

For example, a regular old coal stove provided the following adjustments:

- then the portion of coal smolders - long-term combustion occurs, but the afterburning of the gases is, as a rule, complete.

In modern boilers, such modes are monitored by the equipment itself.

High-power coal boilers (large load possible) from well-known manufacturers with secondary air supply are suitable as a cheap and universal option for home heating. They can be used to burn a large load of coal for a long time by redistributing the air supply.

Automated boilers are becoming more and more popular now. Their combustion duration is ensured by a coal bunker and a constant supply of small portions to the combustion zone. Moreover, the equipment is not necessarily too expensive. Boilers with a bunker from which fuel is loaded under its own weight have an affordable price. Boilers with screw feed are more expensive, but they can do a little more. Thus, the bunker allows you not to worry about adding fuel every day. Combustion occurs, as a rule, in small portions, but with a full supply of air without the formation of large volumes of CO - European environmental requirements for equipment.

In any case, the increased burning time of coal will be ensured primarily by equipment for large loads - in a bunker or directly in the furnace. The choice of a boiler for coal is based on this consideration.

Which coal to choose

Coal occurs in the earth's crust in the form of layers. Each of them is labeled and has its own quality characteristics. But even in the same seam, but in different areas, coal can vary greatly in quality - the degree of metamorphism, the amount of ash, volatiles, sulfur, humidity change...

Alternative fuels

Today, the most popular type of fuel used for heating residential and industrial facilities is coal. If desired, it can be replaced with alternative raw materials:

One of the most efficient types of fuel raw materials. Peat is suitable for stoves with special fuel chambers that increase draft during its combustion.

The material is produced in pieces and pressed briquettes. Peat moisture levels range from 22 to 40%, which leads to the formation of large amounts of ash. In terms of its calorific characteristics, it is significantly inferior to firewood, which is the main disadvantage.

Pellets

Fuel pellets are produced from dry biomass (sawdust, wood chips, bark and wood dust) by hot pressing. These are small capsules whose humidity level does not exceed 10%, so they are an excellent fuel for a brick or metal stove.

Unlike firewood, pellets can burn for quite a long time, releasing carbon dioxide and water. They are distinguished by environmental friendliness, safety and high calorific value.

Eurodrova

Highly efficient and environmentally friendly fuel, which is successfully used for solid fuel boilers and Russian stoves. Fuel briquettes are made from sawdust by pressing under high pressure.

The main advantages of Euro firewood are the duration of combustion and high calorific value, so stacking is done less frequently than with conventional firewood.

In order to properly heat a stove and boiler with coal, experts recommend following the prescribed safety rules and precautions.

Content:

The process of lighting a stove is not as simple as it seems to many people who have little knowledge of the stove business. It is not enough to throw some wood, some paper and set everything on fire, like a simple fire. Everything is much more complicated. It is necessary to take into account the design of the stove, the type of solid fuel, and even fire safety.

Coal as a fossil fuel

Coal is a type of fossil fuel. The process of its formation occurs from ancient plants deep underground without access to oxygen, for quite a long time. Coal rock is, first of all, carbon containing non-combustible impurities. Coal is generally classified as follows:

- Lignite is the lowest age type of coal, has a brown color, up to 45% moisture content, high sulfur content, and is the most friable compared to other types of coal. Mainly used in power plants.

- Brown coal is also a fairly young type of solid fossil. Carbon content up to 70%, humidity about 40%, volatile substances 38-50%. It is used as local fuel, sometimes as a chemical raw material.

- Coal is a sedimentary rock formed as a result of the decomposition of plant remains. Here the composition is more saturated with carbon (from 75% to 95%) and contains less water (8-20%) and impurities that form ash.

- Anthracite is coal of the most ancient origin, has high density and shine. Carbon content 95%. Solid fuel from such coal does not ignite well, having the highest calorific value.

What stoves can be heated with coal?

Not all stoves can be fired with coal, this is due to the higher combustion temperature of coal than that of various types of wood. For example, a Russian stove involves heating exclusively with wood. The Dutch woman is also not adapted to this type of fuel, due to the fear of overheating and soot deposits.

Furnaces made of steel and cast iron (potbelly stove) can easily burn coal. It is easy to recognize a coal stove: a steel stove has a wall thickness of at least 4 mm, while a brick stove has a firebox lined with fireclay stone. Although, by making some changes to the design of a conventional brick oven, that is, thickening the walls of the firebox, moving the grate lower and constructing a separate exhaust system, coal can be used.

It happens that boilers with water are installed inside the firebox, performing the function of a room heater, while at the same time protecting the furnace masonry from overheating. Having built such a structure, it is especially important to control the presence of a sufficient amount of water in them. Also, to avoid heat loss, you should select the ash pan and grate of the appropriate size. The draft is enhanced with the help of special nozzles on the stove.

Firewood for barbecue: which is better

Before experimenting with wood species, you need to learn the main rule. It sounds like this: good firewood for a barbecue is dry firewood! The axiom has been proven by generations of humanity trying to get fire.

Seriously though: the choice of a summer resident is the wood of fruit trees. The choice of the tourist is birch or linden. If you find firewood made from grapevines in Kamchatka or Altai, take it, the kebab will be excellent. If there are no deciduous trees, then coniferous trees will do: the hike is a hike, and lunch is still on schedule.

Boards, building materials and other recyclable materials are not suitable for cooking

Why does smoke appear from a coal stove?

The stove is a complex structure that requires constant care, inspection and cleaning. This is a guarantee of safety and reliable operation of the stove, however, despite all efforts, troubles occur in the form of smoke. The main reasons for this situation may be a number of reasons:

- blockage in the smoke riser;

- the formation of cracks in the masonry, leading to a decrease in draft and temperature of exhaust gases, letting them into the room;

- quite strong cooling of the chimney;

- incorrect stove design;

- wear of the internal masonry.

Preparatory stage of lighting the stove

If you are planning to light a stove that has not been used for a long time, you should carry out a number of preparatory measures. This procedure must be carried out in order to ensure trouble-free operation of the stove, as well as to avoid unpleasant situations that sometimes lead to fires or harm to human health and life.

• Inspect for cracks. Their presence can facilitate the penetration of smoke and even carbon monoxide into the room. If any are found, minor repairs should be immediately carried out using a mixture of clay and sand. • Clean soot from all flues and chimneys. Wipe off dust from the internal walls with a dry rag so as not to smell a bad aroma when kindling. In general, it is advisable to perform this procedure 2-3 times a month. • Pay attention to the doors, especially their fit and the functionality of the locking mechanisms, to avoid the appearance of smoke. • Select fuel of the appropriate quality, suitable specifically for your type of stove. • Properly equip solid fuel storage areas.

During further operation, you should also follow a number of simple rules. Using plastic, construction and household waste for kindling will lead to severe contamination of the stove. It is incorrect to open the vent and the oven door at the same time. It should be heated several times a day for one and a half to two hours to avoid overheating. Dry, medium-sized, dust-free charcoal will provide excellent functionality.

It is strictly prohibited to use flammable mixtures (gasoline, kerosene, etc.) for kindling.

Avoid storing flammable objects near hot walls. Do not leave the stove unattended while lighting, especially in homes with children.

A set of measures before starting the fire

For the normal passage of the entire combustion process, it is necessary:

- carefully inspect the stove structure, starting from the firebox door of the stove and ending with the chimney. If cracks are found in the brickwork or chimney pipe, they must be sealed with a sand-clay mixture. Otherwise, the room will instantly fill with smoke, a large amount of carbon monoxide may appear, and small cracks will turn into large cracks and can actually damage the masonry;

- whitewash the pipe if you have not used the stove for a year or more;

- clean the chimney structure, including chimney channels, pipes from soot (if you have not used the stove for 3-4 months);

- clean slag and ash from the furnace. To avoid the appearance of dust in the room, combustion waste must first be filled with water, then raked out and taken outside;

- check for traction. To do this, insert a newspaper folded lengthwise into the firebox, set it on fire, and if smoke goes up the chimney, then everything is fine;

- use a dry cloth to wipe the outer part of the heating structure, otherwise an unpleasant odor will appear during the fire;

- Heat a little at a time 2-3 times a day, if the unit has not been heated for a long time, to prevent overheating of the stove.

Simple rules for using the oven

Having carried out the preparatory activities, you can begin kindling. To begin with, on the bottom of the firebox, cleared of ash and soot, we place a kind of pillow of crumpled newspapers and paper, then small dry wood chips. Next, we put small firewood, for example, birch (they burn easier).

Firewood should be stacked in the form of a “well” or “hut”, leaving space between the firewood so that nothing interferes with air circulation. Now you can set it on fire, whether it’s a match or a special spray can, it makes no difference. We close the door. Using a blower we regulate the intensity of combustion. We open it, letting in a sufficient flow of air, without which the flame can simply go out.

When the stove has warmed up using wood, you can add coal. The first layer is usually small 10-15 centimeters. After the first layer flares up, we increase the layer of coal rock to 60 cm (if the size of the furnace allows), using coals of a larger fraction. It should be remembered that clearance is required between the fuel layer and the upper arch of the firebox. All that remains is to ensure that the coal mass does not sinter; to do this, we periodically carry out a poker, ensuring an air flow.

As a rule, coal is loaded through the firebox door. However, if there is a hob, then by moving the elements of a large burner, we get a more convenient way of bookmarking.

The rules are simple, but there are many benefits. Following them will ensure the safe operation of your oven. The warmth and comfort of your home is in your hands.