Operating principle of a coal boiler

Each unit operating on coal fuel has individual operating characteristics. For example, some options are equipped with automatic mechanisms, others simply operate under the influence of the human factor.

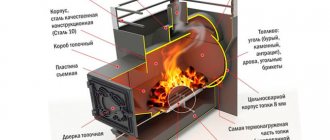

The operating principle of TT equipment is quite simple. Its interior consists of two chambers: the upper one is intended for the firebox, and the lower one is for collecting slag and ash, which are cleaned as the chamber becomes dirty. In order to properly heat the boiler, it is enough to purchase the necessary material. If you do not use chemical mixtures, then you can solder the boiler using paper and dry brushwood, and after it flares up well, add coal.

Request a call

Call around the clock, we work without holidays and weekends.8 495 744 67 74

Our contact page

The emergency service operates around the clock in Moscow and the Moscow region. Departure to the nearest areas is planned according to the schedule.

If you don’t have the opportunity to regularly look into the firebox or don’t want to, you can use long-burning equipment. In such situations, the question of how to properly heat a coal boiler will disappear without a trace. However, such stoves are several times more expensive than ordinary stoves intended for home use.

There are solid fuel boilers with automation on sale, let’s look at their advantages:

- automatic mechanism helps control the combustion process;

- regulates the supply of sufficient oxygen to the firebox;

- the normal operating temperature of the heating system is optimized;

- The heating of water in the pipes for each room is controlled equally.

The nuances of firing stoves with coal in winter

In winter, at low temperatures, it can be quite difficult to light the stove. In addition, the special draft that is formed due to cold air does not allow smoke to escape freely. There is no way to light the stove quickly. You can improve the kindling process by using a hairdryer, which warms up the inside of the heating equipment.

Such heating of the furnace device will avoid smoke, which is typical for cold structures. The stove should be warmed up several times a day in winter so that the system does not have time to cool down too much.

Coal is considered the most efficient type of fuel. It is successfully used to kindle stoves. The level of heat transfer of such raw materials is higher than that of wood raw materials. A good result from using coal for a stove can only be obtained by following all the rules for kindling and operating the heating device.

How to fire a coal boiler: preparation and kindling

Before you start using it, be sure to check that the device is working properly. To do this, it is necessary to exclude all sorts of cracks, metal tears, and also check the internal mechanism. After the inspection is completed, you can start kindling.

- Are you experiencing problems with your heating, water supply or sewerage systems?

- Do you want to replace your old washbasin or shower with a more modern and comfortable one?

- Or perhaps you decided to hide unattractive polypropylene or metal pipes?

- Then you've come to the right place! 8 495 744 67 74

Types of coal

Coal is of plant origin. For the most part, this fossil consists of carbon and non-combustible components, which turn into ash during combustion. Coal mined in different regions contains different amounts of such impurities. When ignited, the sulfur in the rock forms oxides that form sulfuric acid in the atmosphere. The largest proportion of sulfur comes from lignite. Based on its characteristics, coal comes in several types.

Coal is classified by age as follows:

- Lignite (youngest);

- brown (subbitominous) coal;

- coal;

- anthracite (the oldest deposits).

According to the content (B) of moisture and volatile impurities (MP):

- brown (subbitominous) coal: B=30-40%, LP > 50%;

- hard coal: B=12-16%, LP=40%;

- anthracite: B=5-7%, LP=5-7%.

Specific heat of combustion:

- brown coal – 3000-5000 kcal/kg;

- hard coal – 5000-5500 kcal/kg;

- anthracite – 7400-9000 kcal/kg.

Urgent plumbing services

The specialization of our company is the provision of plumbing services of the highest quality with excellent service and a mandatory guarantee for the work performed. For many years, we have been performing plumbing work of any level of complexity both in apartments and in the private sector. We have a team of highly qualified plumbers with extensive experience in this industry. Working for ten years, we have learned to find the right solution even in the most difficult situations.

In the middle of the content

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

We provide the following plumbing services to our clients:

- Installation and dismantling of plumbing systems

- Installation of any plumbing equipment (installation of a washbasin, installation of a faucet in the bathroom, installation of a faucet in the kitchen, installation of a toilet, installation of bathtubs, installation of a shower cabin, etc.)

- Installation and connection of household appliances (washing machine, dishwasher, boiler, etc.).

- Repair of plumbing equipment.

- Replacement of water supply pipes in the apartment.

- Call a plumber around the clock in Moscow and the region.

Basic principles of work of a plumber in our organization

The main principle of our work is an individual approach to everyone, because we value our clients. Our company's specialists work only with the latest equipment and use high quality materials. We are confident that only an experienced, constantly improving master is able to bear full responsibility for the work performed and guarantee high quality.

We work directly with clients and that is why we have the most favorable conditions for both parties. A flexible system of discounts applies to sanitary work. For each potential client, we provide free consultation on the selection of materials and inform on other issues of interest.

We give every client a guarantee . Thanks to this, you can be sure that our team of specialists carries out plumbing work to a high standard and in a short period of time.

Regular charcoal equipment will need matches, paper and thin brushwood.

Attention! Before lighting the boiler, clean it. Rake out the ash and remaining fuel from previous work from the ash pit. If you are heating the device for the first time, we skip this stage.

When everything is carefully prepared, we proceed in the following steps:

- Place dry paper on the grill. It is advisable to crumple it a little to make it easier to set on fire;

- put brushwood on top. It is better to place it evenly: you can lay it out in the form of a well or make a hut. Avoid carelessly laying out firewood; it will take too long to burn;

- We light a match and present it to the paper from different sides. This is done so that the sheets burn evenly;

- then close the firebox door and open the blower door;

- watch the combustion of the contents in the firebox. After a crust of ash remains, place a wide layer of fine coal on top up to 15 cm;

- Stir the burnt fine coal well, and then place a layer of larger coal on top. Monitor burnout regularly and add fuel.

Important! If you open the firebox door to load fuel, be sure to close the vent.

About firewood

As mentioned above, the quality of the fuel is of great importance. Both for the efficiency of heating equipment and for increasing its service life. This is especially true for firewood - a very unstable type of fuel. The efficiency of the boiler depends on the uniform supply of fuel, which is equalized in its calorific value

This is most important for modern technological heating devices, burdened with automation. Firewood differs in its technical qualities - humidity, specific heat of combustion

That is why manufacturers of boiler equipment insist on choosing high-quality fuel.

Pellets and fuel briquettes are more efficient fuel for a wood boiler

Log log discord

Wood of different tree species has different densities, which means their ability to produce heat. But, besides this, other features of firewood that affect the operation of the boiler are also important: the amount of non-combustible (ballast) substances and the presence of resins that pollute the chimney and the internal structure of the device during combustion.

Birch firewood

Birch has dense wood, so it burns hot and produces a lot of heat - 3750 kcal, even if the wood is damp. It is highly flammable. But when such firewood burns, especially damp wood, tar is released - a substance useful in medicine, cosmetology or for protecting surfaces from rotting, but extremely harmful to the insides of the boiler.

Soot on the boiler heat exchanger

Alder firewood

Burning alder wood produces virtually no soot. Moreover, burning alder wood helps clean the chimney. Alder is flammable, burns well and produces a sufficient amount of heat - 2100 kcal.

Aspen firewood

Burning aspen, like alder, cleans the chimney. But such firewood itself produces a little heat when burning - up to 1650 kcal.

Pine firewood

They burn well and quite hotly (3800 kcal), but pine wood is resinous and a lot of soot is formed during combustion.

Firewood in the storage meter

Spruce firewood

Spruce firewood is comparable in quality to pine, but has a slightly higher specific heat of combustion - 3900 kcal, and is also less resinous.

Poplar firewood

Poplar burns hot, but burns out quickly.

Firewood from apple and pear trees

Firewood from fruit trees - apple or pear - has dense wood, which means it produces a lot of heat, burns and smolders for a long time. But these species are usually grown for their fruits, so such firewood is not common. Another feature: the trunks of pear and apple trees are clumsy, the logs are difficult to prick, and the logs are knotty and difficult to pack tightly in the firebox.

Oak, beech, ash firewood

Oak, beech, and ash are dense wood; when these species burn, a lot of heat is released - up to 3600 kcal. The disadvantages of oak or beech firewood include their rarity on sale and the difficulty of splitting and heating a boiler with them. Considering the described qualities of wood as fuel, a good owner stores different types of firewood: some so that it flares up easily, others so that it burns long and hot, and others so that it can periodically clean the chimney of soot.

How to heat a long-burning boiler with coal?

Such installations are not used as often, but are still considered more alternative options for use. It is worth noting that the operation of this equipment is somewhat different, so you will have to heat it according to the attached instructions.

Long-burning heating boilers can operate on brown coal, but the question of what else can be used to heat such a unit has many answers. An operating mechanism created in this way will lengthen the burning time of the device, regardless of how many fuel loads were made into it.

First you need to put firewood in the upper chamber of the boiler, then paper and thin wood chips are placed. The entire contents are set on fire - you need to wait until it flares up, for better oxygen supply to the furnace, you need to pull out the damper, it can be adjusted depending on the desire to receive heat transfer from the boiler.

Attention! It is dangerous to leave the chimney damper closed - this entails the movement of carbon monoxide into the living room.

If you have lit a coal stove for the first time this season, do not worry if liquid appears on the pipes - this is condensation, which will disappear after some time. If this does not happen, your system may need repair. After the fuel in the boiler has ignited, you can turn on the control system.

It is better to set the temperature at a high temperature, and during the heating process it can be reduced to a suitable level.

Consumption rates and rules for calculating the required volume of fuel

According to technical standards, 2 kg of coal is required to generate 10 kW of thermal energy. Knowing this, you can calculate its required volume using the formula:

M x =X/fuel calorific value (in this case 5 kW/kg)

- where M x is fuel consumption for a limited period of time (day, month, season);

- X – heat loss during the heating period, determined by the formula:

X = S×D×24×0.7×70

- where S is the heated area of the house, including all residential and utility rooms;

- D – duration (number of days) of the heating period;

- 24 – burning time (number of hours) of the boiler per day;

- 0,7 – average operating factor of coal boilers;

- 70 – average heat loss per hour (for a standard house in a temperate climate).

If we take the average heating period of 6 months (175 days) as a basis, then with an area of 100 m2 the heat loss will be X = 100 × 175 × 24 × 0.7 × 70 = 20,580 kW per season or 117 kW per day. Coal consumption for the same period will be equal to M1=20,580/5=4,116 kg and M2=177/5=23 kg, i.e. it will be necessary to purchase about 4.5 tons of coal.

Reference . Quite primitively, you can rely on the “living” experience of other owners of coal boilers: when the temperature outside is + 1 ... or more °C per day, 1 bucket of fuel burns, if - 5 ... - 15 °C, then 2-3 buckets, and especially frosty in winter - 20 ... and less °C, you will need to load up to 10 buckets* per day.

* a standard bucket (12 l) holds about 18 kg of medium-sized coal.

Heating a house 100 m²

Really, honestly, really

| Heating a house 100 m² from | RUR 49,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 10 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 25,000 rub. |

| Radiator pipe routing | 12,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 49,500 |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 100 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 120,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

House heating

Coal selection

To have an idea of how to properly heat a long-burning boiler, you must definitely consider the fuel used for this. Coal is a natural material containing carbon and non-combustible elements. When burned, the latter become ash and other solid deposits. The ratio of components in the composition of coal can be different, and it is this parameter, coupled with the duration of occurrence of the material, that determines the grade of the finished fuel.

The following grades of coal exist:

- Lignite, which has a rather loose structure, has the shortest period of occurrence among all types of coal. It makes no sense to consider this material, since it is not suitable for heating private houses.

- More ancient deposits are brown and hard coal, as well as anthracite. Anthracite has the highest heat capacity, followed by hard coal, and the least efficient is brown coal.

When deciding what kind of coal to heat a boiler with, you need to evaluate the characteristics of a specific brand of raw material. Good coal for heating has a fairly high heat transfer and a long period of complete combustion - one load of fuel can burn for up to 12 hours, which allows you to reduce the number of loads per day to two. The presence of different types of coal on the market allows you to choose the most suitable material, depending on your financial capabilities.

Heating a house 150 m² - 52,500 rub.

Really, honestly, really

| Heating of a house 150 m² from | RUB 52,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 10 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 25,000 rub. |

| Radiator pipe routing | 15,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 52,500 |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 150 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 200,000 rubles

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

House heating

Main disadvantages

Like any other equipment, they have their disadvantages. The production process uses quite complex automation, which can significantly increase the cost of the device. As a result, the price turns out to be 2 times higher compared to conventional designs that have the same power.

Among other things, due to the fact that the combustion process is automated, the owner of the equipment cannot interfere with the operation of the boiler while the coal is smoldering. This indicates that it is not possible to extend the combustion life in such a device. Sometimes this creates certain difficulties during operation.

Heating a house 200 m² - 72,500 rub.

Really, honestly, really

| Heating a house 200 m² from | RUB 72,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 15 pieces)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 35,000 rub. |

| Radiator pipe routing | 25,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | RUB 72,500. |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 200 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 250,000 rubles

Detailed estimate for installation of heating system

Included by type of work

| Boiler installation | Installing an electric boiler on a wall or floor |

| Installation of pipes without “grooving” | Open pipeline installation with wall or floor mounting |

| heating radiators | Mounting the heating device on the wall, installing fasteners |

| System pressure testing | Pressure testing of the assembled system with an air compressor to identify possible leaks |

| Commissioning works | Filling with coolant (antifreeze or water), removing air from the heating system during work |

| !!! No heated floors | It is calculated additionally, it requires coordination of the type of substrate for the pipes, the type of use of the pipe, the possibility of control and automatic control, and of course the footage |

| !!! Without external chimney | To calculate the cost, an engineer’s visit is required, an inspection of the roof structure, window location and much more. |

Sahara

A steam room equipped with a Sahara stove-heater can easily turn into both a traditional Russian bathhouse and a classic Finnish sauna. The stoves have a unique ergonomic design; they embody the principle of the “golden ratio” without violating proportions or smoothing corners. This shape allows it to fit well into almost any interior.

When developing the design of the Sahara stove, the principles of maximum comfort in operation with aesthetic appearance and operational efficiency were embodied. Heating of the stones is ensured from five sides; the fastest heating is achieved due to the successful placement of the chimney parallel to the axis.

The creation of a microclimate similar to a Russian bath and Finnish sauna is ensured by installing an additional converter.

Teplodar sauna stoves can be called, without a shadow of exaggeration, a work of stove art; all products are characterized by a stylish design, high functionality, reliable operation and ease of operation.

" What

Heating a house 250 m² - 87,500 rub.

Really, honestly, really

| Heating of a house 250 m² from | RUB 87,500 |

| Installation of heating boiler | 8,000 rub. |

| Installation of heating radiators (no more than 20 pcs)!!! The cost of installing a standard (mounted, not in-floor convector) heating radiator is 4,000 rubles | 45,000 rub. |

| Radiator pipe routing | 30,000 rub. |

| Pressure testing and filling with coolant | 4,500 rub. |

| TOTAL turnkey: | 87,500 rub. |

| Drilling holes, rigging, dismantling, paid extra | according to_estimate |

Heating a house 250 m² Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Cost of materials from 300,000 rubles

What coal to choose for the fire?

What is coal? This is a product of plant origin, which contains carbons and non-flammable impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the “age” of natural fuel, that determines the grade of coal. Experts distinguish several varieties.

The “youngest” type of coal is lingite. It has a rather loose structure. If you pick up a lump of lingite, it will quickly crumble and lose its shape. This type of coal is most often used in thermal power plants, but lingite is not suitable for heating a home.

In addition to lingite, brown coal, hard coal, and anthracite are also mined - the most ancient carbon deposits. All varieties have different humidity levels. In brown coal, for example, humidity is 50%; in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal/kg. Coal has a lower figure - 5.5 kcal/kg. The brown variety has a specific heat of only 3 kcal/kg. Considering all this, it is easy to understand what type of fuel to purchase for heating the house.

What to pay attention to

The operation of any heating device using coal, wood and other semi-finished fuel products is inextricably linked with the ventilation system. The performance characteristics of heating equipment and the technological parameters of the entire heating system in the house depend on the quality of ventilation and the condition of the chimney.

The hood must operate in accordance with established fire safety standards.

A properly made chimney and cleaning of the heating device will ensure long-term operation of the solid fuel boiler at optimal operating conditions. Frequently changing one type of fuel to another can cause unstable operation of the heating unit, failures in the hot water supply system and heat supply. Each unit should have one main fuel, while other types can be used for a short time, as needed.

A couple of reviews

Commenting and posting links is prohibited.

has been producing sauna stoves for over a decade and a half. The company's product range is represented by four series (lines) of heater stoves, differing from each other not only in shapes and sizes, but also in design features. All Teplodar bath stoves are of high quality, which thousands of customers have been able to verify in practice. That is why the company was able to acquire a reputation as a stable, reliable and very reputable manufacturer.

The quality of heater stoves should be understood as design features and characteristics that allow the model, without exaggeration, to be classified as a work of stove art.

Each of the heater stoves presented below provides quick heating of the steam room with minimal energy costs. The resulting steam has a beneficial effect on the human body, allowing you to relax well and enjoy the sauna.

KUBAN 20L

- The presence of a steam gun effect

- No cooking surface

- The oven is designed for a steam room with a volume of up to 20 cubic meters.

- Works in wet steaming mode, Russian bath effect

- The firebox is made of stainless steel

- Steam is achieved by stones + steam gun

- Remote type fuel channel

- Has an additional function - water heating

- The Kuban sauna stove is equipped with a blind door

- Purpose of the device – household

- Loading stones up to 40kg

- Operational service life up to 10 years

- Possibility to use firewood and briquettes

- The chimney of the sauna stove has a diameter of 115 mm

- Oven parameters – 865x500x700

- Weighs 49kg

- Provides a two-year warranty

- The manufacturer is Teplodar

- Price from 22000 rubles

Useful tips

For efficient and trouble-free operation of a coal-fired stove, follow a number of simple rules:

- To light coal, you cannot use flammable liquid mixtures - kerosene, gasoline, etc. It is also prohibited to use household waste.

- During kindling, be sure to monitor the process and move on to the next stage in time. It is convenient to observe the combustion through the door with heat-resistant glass. Many Teplodar stoves are equipped with this option.

- Either the ash pan or the flap must be open. When coal and wood are burning, the combustion chamber must be closed.

- The normal combustion mode can be determined by the color of the flame - it should be golden and the smoke should be transparent.

In addition, regardless of the type of solid fuel used, it is always necessary to monitor the draft in the pipe. You need to clean the chimney 1-2 times a month.

For efficient and trouble-free operation of a coal-fired stove, follow a number of simple rules.