During the process of a major overhaul, the question of reconstructing or modernizing the heating system may arise.

There may be several reasons for this: redevelopment of the premises, installation of an additional heat source (for example, a boiler), or simply the old heating system has become unusable and cannot cope with its direct task.

What is clear is that installation and dismantling work is only possible with written permission from the competent authorities, with the condition that the work will be carried out by qualified specialists.

Stages of installation of heating equipment

For simplicity, let’s assume that you already have a heating supply project, the necessary equipment (radiators, pipes, fittings, insulation), you just need to install it in the apartment.

Call us and outline the problem. Our manager will ask you a few questions to clarify the scope of work and make an approximate calculation of the cost of heating in your case. Approximate, because the final cost will be clear on the spot, after measuring the length of the pipes, the number of connections and clarifying other details. Professional heating work always begins with an on-site analysis of the project. It is not always possible to implement a planned project, but you can get as close as possible to the desired result with minimal costs. For example, the pipes may not be suitable for the coolant in your home, then they will have to be replaced, along with the fittings. Or the selected beautiful radiators turn out to be too weak; in order to avoid leaks, we recommend strengthening or replacing them too. Our heating installation company provides a guarantee for all work carried out, because we care about your safety.

Using glue

Holes of small and medium sizes, cracks can be sealed. This option is temporary and is only suitable so as not to drain water from the riser or deprive the room of a heat source. After the heating season, the aluminum radiator must be removed in order to carry out high-quality repairs.

You can seal the hole using:

- Epoxy glue.

- Cement.

- A solution called “cold welding”.

Repairing holes with epoxy glue

To use epoxy resin glue, you need to prepare fiberglass or thick fabric. Since any of these materials must be wrapped around the radiator, the use of such adhesive is limited. After all, not every place can be wrapped easily and tightly. For some versions of aluminum radiators, this method is not suitable at all.

To seal holes or cracks:

- Cut the fabric into long narrow strips.

- Clean the area from which water is flowing. That is, remove all paint that has peeled off and all particles that are easily removed. This is done with a spatula. Next, take a brush with metal bristles and clean the surface. There should be pure metal left. It happens that a crack appears in a place where it is impossible to reach with a brush. An iron cable can help in this situation. It is pushed through the desired part of the radiator and pulled by the ends one by one, cleaning the desired area. This area is then dried.

- Apply glue to the treated area and wrap it with cloth.

- Apply glue to the fabric and wind another turn. This should be done until there are 4-5 turns. No glue is applied to the top layer of fabric.

- Secure the fiberglass using clamps or wire.

- Wait for the glue to dry. It dries from 2 hours to 3 days. If the room temperature is 20-25 °C, then it will dry in 2-3 hours.

To enhance the properties of the glue, you can add aluminum or bronze powder to it. Such powder is obtained by grinding off an unnecessary aluminum or bronze part with a rasp. Before use, the glue and powder must be mixed well.

Cracks are repaired in the same way using cement. However, medical bandages should be used instead of cloth. They need to be soaked in the solution and wound around the radiator.

We use “cold welding”

It is very convenient for sealing cracks and holes. This is a putty that looks like plasticine. There are two types:

- Single color.

- Two-color.

The first type is easier to work with, since you need to cut off the desired piece and knead it with your hands. You should wear gloves on your hands, because the putty is chemically active and can harm the skin.

Two-color cold welding must be mixed until a homogeneous solution appears. It becomes sticky while mixing.

The fight against holes using “cold welding” is carried out as follows:

- Clean the damaged area from dirt and paint.

- Knead the cut piece of “cold welding”.

- Apply the solution to the hole and rub it in (this is done with a metal spatula). To prevent the putty from remaining on the spatula, it must be moistened with water.

- If after grouting the cork begins to come out (a bubble forms, which then bursts), it must be rubbed again with a spatula. This may have to be done before the “cold weld” has completely dried. It dries in 5 minutes.

- Secure the plug with a clamp or rubber.

You can also seal the hole with heat-resistant sealant. However, you need to use the right sealant because there are acidic sealants that can corrode aluminum. Practitioners advise using neutral solutions.

Extraneous noise

Sometimes noise may occur in the heating pipes - it can be either a knocking in the heating pipes, or various clicks, and a hum. Why are heating pipes noisy? There are several reasons:

- During operation, the diameter decreases.

- Pipes are leaking.

- A smaller pipe diameter was installed.

You may need to think about how to fix a leaking heating pipe. When you eliminate the leak, you will also eliminate the problem of noisy heating pipes.

Why are the heating pipes still humming? This may be a reduction in pipe diameter. You can hear the heating pipes knocking right on the spot. You need to walk along the pipes and find the reason why the heating pipes are clicking. Usually the source from which the heating pipes click is located in the basement - because there is more pressure here

It is very important to find in time the reason why the heating pipes are shooting, humming or making noise - because this could be a prerequisite for a serious problem

Replacement of vertical heating pipes can be done in three cases:

- Overhaul of an apartment building.

- Construction and repair work related to changing the interior of the premises.

- Impossibility of further use of risers due to technical reasons.

At whose expense is the replacement of heating risers carried out? In accordance with the current legislation of our country, replacing risers is the responsibility of the service organization.

Here we are talking about risers that are the common property of residents, that is, about pipes located in entrances, attics, and basements. All work is carried out at the expense of the owners of the apartment building.

You need to know that the property of all residents of the house are the pipes to the valve, which is installed at the entrance to the apartment. The section of pipe after the valve is the responsibility of the homeowner.

In addition, if you live in the premises on the basis of a rental agreement, then the housing department will repair and replace pipes, and if the housing is privatized, then all work is carried out by the owner.

Installation - heating, water supply, sewerage turnkey.

In a country house, installation of water supply and sewerage begins with the preparation of the project. It takes into account the location of each tap, washbasin and toilet. You will have to calculate the amount of insulation for sewer pipes and other nuances. If the system is installed in an apartment, you must first remove elements of old communications.

We will carry out installation of heating and water supply on a turnkey basis and with a quality guarantee. Our teams work in Moscow and the region, offering affordable prices. When we finish installing or repairing utility networks, the room will remain clean and all parts of the system will be neatly assembled.

It is better to start installing sewerage, heating and water supply during the construction of a country house or major renovation of an apartment. But we also work on finished objects. After drawing up the project, the employee will prepare an estimate, purchase the necessary materials and send a team to you to carry out the work. And the result will definitely please you.

Stop heating the street!

Whether the radiators will be changed during the heating reconstruction process or not, but since they will still have to be removed for some time, it is highly advisable to cut off the outflow of heat to the outside. To do this, you need to cover the wall behind the batteries with heat-insulating mats aluminized on both sides. How such a bedding works in terms of heat can be read in the article on floor insulation; here it is enough to note that in a block Khrushchev house with radiators in niches, double heat shields behind the radiators are equivalent to covering the walls with 20 mm plywood.

In an alternative option for insulating the wall behind the radiator, heat-insulating material (1) and aluminum foil (2) are used separately.

Installing the shielding mat is simple: we cut holes in it for the hooks of the battery suspension, apply thin “sausages” of construction silicone or mounting adhesive using an “envelope” to the side adjacent to the wall, put it on the hooks and press it to the wall.

An indispensable condition: the mat must be organic, made of synthetic or natural fibers. The use of open mineral wool mats in residential premises is unacceptable - it is harmful to health.

What can be done?

There are many options for organizing heat supply: you can install individual heating with a gas or electric boiler, you can reschedule the heat supply so that it is convenient, you can simply replace the heating pipes with new ones. The first two options will save you from problems with heat, but in an apartment building they will require lengthy and complex approvals - independent major changes are illegal. However, simply installing heating with new pipes and radiators will solve many problems.

Most often, heating installation in Moscow is required for the following reasons:

a) due to scale, old batteries no longer heat up as before,

b) worn pipes leak and do not conduct coolant,

c) old batteries do not fit into the interior.

Our specialists will help you calculate the required number of batteries (sometimes you just need to add a couple of new radiators), select equipment that is suitable in design and construction, draw up a diagram and, finally, install and mount it all in the apartment. Qualified installation of water heating in your apartment will help you enjoy the warmth at any time of the year and protect you from leaks and unexpected accidents.

From metal to polypropylene

Today, four types of water pipes are used for installation in apartments, including:

Elements for metal-plastic water pipes: 1 - adapter; 2 - square; 3 - elbow joint; 4 - tee; 5 - union nut; 6 - fitting; 7 - valve; 8 - metal-plastic pipes.

- Metal, having different diameters. These can be steel, cast iron, galvanized water pipes. Pros: strength, reliability, long service life. But there are also numerous disadvantages, among which it should be noted: the complexity of installation (it is necessary to cut threads, use a welding machine to connect pipes), the inside walls are covered with rust and plaque. In order to crash into a water pipe, you need to have the appropriate skills. In addition, metal requires careful maintenance, constant checking for leaks, and painting.

- Copper pipes are more durable, replacing water pipes with copper can improve reliability and durability, in addition, copper is very aesthetically pleasing and looks great in any bathroom. But there are also disadvantages here: in order to replace copper pipes, you need to have special skills, the cost of the products is very high, and stray currents may occur.

- Plastic pipelines are easy to install, they are reliable, durable, they can be connected to ordinary metal ones, but at the fastening points they can begin to leak due to sudden temperature changes, so a connection method using special welding is often recommended.

- Polypropylene is considered the best option when installing water supply in an apartment. Polypropylene is a very reliable material, can withstand temperature changes, and the connection method is simple and reliable. Polypropylene pipes are used for cold and hot water supply, heating, and sewerage. The diameter can be different, so choosing them is very easy, and the cost is affordable.

The following materials and equipment will be needed:

Replacing polypropylene water pipes is simple, but you should prepare everything you need for the job in advance. Today, several installation methods are offered. Depending on the choice of a specific method, the set of equipment also differs:

- pipe cutter (cutting scissors);

- pipe bender (to give the water pipe the required shape);

- soldering iron and nozzles (for hot, so-called diffuser welding);

- calibration scan (when using the press method);

- press pliers (for the pressing method);

- glue, building level, sandpaper, nozzles for any diameter for a soldering iron, fittings, couplings, adapters, etc.

Scheme of cold pipe welding

Methods for replacing old pipes

- Cold welding of plastic pipelines involves processing the inner surface of one pipe, after which a special adhesive composition is applied to the end of the other. Only 15-20 seconds are enough for gluing. This type of plumbing installation is considered the easiest; anyone can do it.

- Press fittings provide a more secure connection. For fastening, a pipe is put on the press fitting, and the crimp sleeve is pressed with special pliers. The work is done very quickly, you only need to select fittings of the required size and diameter. Additional sealing is only necessary when connecting to faucets and metal pipes.

- Hot welding is carried out using a soldering iron, the seams become monolithic, this connection is the most reliable, but often requires the presence of a specialist.

Read with this

- Disadvantages of polypropylene pipes in home heating

- Which pipe to choose for heating

- What kind of pipes are used for the gas pipeline?

- Houses made of kiln-dried profiled timber

- Air conditioning system maintenance

- Which rehau pipes are best for heating and water supply?

- Connection diagrams for bimetallic radiators

- Choosing between metal-plastic and polypropylene pipes

- Leningrad heating system for a private house

- Pipe box

Connecting radiators

The modern building materials market is distinguished by a wide selection of radiators: aluminum, bimetallic, copper, traditional cast iron, etc., of all shapes, colors and sizes that can harmoniously fit into any interior.

Most often, batteries are installed under a window opening, at an equal distance from the floor and window sill, and at a distance of 5-10 cm from the wall. This allows you to evenly distribute thermal energy throughout the room, as well as eliminate the unpleasant effect of “crying” windows, shifting the dew point.

Radiators are suspended on special brackets, after which they are checked for level. Correctly set horizontal line will have a positive effect on flow and reduce air accumulation. To increase heat transfer, the wall behind the radiator can be additionally shielded.

Next, pipes made of the selected material are connected to the batteries, the necessary shut-off elements, plugs, Mayevsky taps, etc. are connected.

Upon completion of the required installation stages, air is bled from the finished heating system and a leak test is carried out. To do this, coolant is supplied to the system, and this should be done extremely carefully, avoiding the possibility of water hammer. The joints are carefully examined for leaks. If they are identified, the problematic connection will have to be redone.

Mounting radiators on the wall

One ball valve is replaced by a thermal head or valve to coordinate the degree of heating and cooling of heating equipment. The throttle (valve) is manually adjusted and the thermostatic element operates automatically.

Residents of upper floors install vents on radiators to remove accumulated air. Mayevsky taps or automatic devices are installed. In a multi-storey building, the connections to the battery are equipped with a jumper to the valves or chokes. The connection ensures the movement of water in the riser when covering the underwater section. Complete or partial blocking of the supply without a jumper will lead to cooling of the neighbors' batteries.

Installation and replacement of heating, water supply and sewerage pipes

The SantekhKomplekt company offers its services for the replacement (installation) of all types of pipes. In our company, you can independently choose the material from which installation, installation, and replacement of pipes will be carried out. be it a riser for cold and hot water supply, installation of pipes for a heating system or sewerage system. When performing pipe replacement work, we use only high-quality materials.

Types of installation (replacement) of heating and water supply pipes

- Installation of metal-plastic pipes

- Installation of polypropylene pipes

- Installation of copper pipes

- Installation of steel pipes

- Installation of various plastic and polymer pipes

Installation of metal-plastic pipes

This type of pipe is used for internal (inside walls and screed) and external distribution of water supply and heating pipes. These pipes are inexpensive, easy to use and easy to bend.

Installation of polypropylene pipes

Polypropylene is used for external plumbing and heating; they are also not difficult to work with and are more aesthetically pleasing. When installing pipes in cottages, polypropylene pipes are most often used. 85-90% of cottage owners choose them. When installing heating, pipes made of reinforced polypropylene are used.

Installation of copper pipes

Installation of copper pipes is carried out when laying heating and water supply pipes, mainly in apartments and country houses. Despite the higher cost, copper pipes are very popular due to their high technical characteristics and durability (the service life of copper pipes is more than 50 years).

Let's consider this example: you don't want to change the radiator, but the pipe going to the neighbors from above has already served its purpose, and the section from the ceiling to the radiator needs to be replaced. Find out if there is water in the system, and be sure to ask your neighbors above and below if they have replaced the radiators, is the original pipe still in place, or is it polypropylene? It is necessary to find out if heating radiators are installed in a new way. and connected with polypropylene transition couplings, then when you cut the pipe and start threading, the pipe in the ceiling may turn, and you will also redo it for your neighbor.

1 example. The neighbor above has radiators lined with polypropylene. You also need to run the riser with the same pipes (for heating, use only “shtabi” pipes) and the same diameter. We cut off the iron pipe, cut off the transition coupling, pull the pipe out of the ceiling, insert a polypropylene pipe into the ceiling, and solder to the neighbor through the polypropylene coupling,

the same as when replacing water pipes. Don't forget to remove the foil layer with a special stripper on the stacked pipe (soldering polypropylene pipes). If your radiators are connected without a jumper, then it’s easier, unscrew the rest of the pipe from the radiator, screw in a faucet with an American connection, screw the adapter into the faucet and solder it to the riser. If the radiator is of the chord type, then cut a thread on the pipe, screw in the tap, screw the adapter onto the American one, and solder it to the heating riser in the same way. If the connection to the battery is with a jumper, then do the same as when installing a radiator (correct installation of heating radiators).

When replacing old heating systems, more and more people are choosing polypropylene products.

Polypropylene pipes are especially distinguished by their ease of installation combined with sufficient practicality of the products.

Polypropylene has a number of advantages over metal:

- corrosion resistance;

- high strength, while it is several times lighter than metal;

- the inner surface of the pipes is protected from the formation of lime deposits;

- the material is heat-saving;

- does not affect the chemical composition of water;

- absence of water noise as it passes through the pipes;

- long service life without the need for repairs;

- aesthetic appearance;

- relative ease of installation.

Classification of polypropylene pipe products

Depending on the temperature of the pumped liquid, the pressure of the working medium, the method of installing pipelines and the purpose of the engineering system, different types of polypropylene pipes are used. Conventionally, they are divided into two groups. The first category includes homogeneous polypropylene products. The chemical additives in their composition and the wall thickness ensure trouble-free operation of the installed systems at a certain nominal pressure during the warranty period. The strength parameter in product labeling is indicated by the Latin letters “PN” and digital values in MPa: 10, 16 and 20.

The second group is represented by composite pipes. The assortment is represented by the following types:

- Polypropylene pipes with an aluminum layer that require stripping before soldering. The layer of perforated metal plays the role of a stabilizing base, which neutralizes linear expansion caused by the impact of a high-temperature working environment on polypropylene;

- Pipes with a metal insert that are not pre-cleaned before soldering;

- Composite three-layer products. Between two polypropylene layers there is a layer of fiberglass mass;

- Three-layer products with a basalt layer.

Multilayer (composite) pipes PN 20, 25 are used mainly in heating circuits or for organizing hot water supply.

Selection of polypropylene pipes to replace metal ones

The selection of pipes is influenced by the following factors:

With aesthetics everything is obvious. The white color of polypropylene products blends more organically with different textures of walls and, as a rule, echoes the color of window sills, heating radiators and sanitary fixtures (sinks, toilets, baths).

When installing pipelines on the surface of walls, a range with a nominal pressure of 16, 20, and 25 MPa is used

Particular attention is paid to the frequency of fixations to the wall using single or paired fasteners. This approach to selection should eliminate unsightly sagging of pipelines in the future.

The organization of heating of premises using a loop circuit of liquid coolant circulation involves the use of composite polypropylene pipes. Temperature changes in the working environment caused by seasonal use of heating circuits or different operating modes due to weather conditions lead to an emphasis on the stabilization properties of pipe products.

Water supply in apartments and private houses is mainly soldered with pipes with a diameter of 20 mm. Components with a cross section of 16 and 25 mm are used much less frequently. Pipe products are sold in retail chains in 4-meter sections. For the convenience of delivering the purchase home, most often, the products are prudently cut in half and additional couplings are purchased.

Professional replacement of pipes in your apartment

Any water system, having served its life, requires replacement. This replacement of water pipes in an apartment is caused by several reasons:

— the presence of a large number of leaks;

- abundant sediment of salts and oxides;

- rust;

— low quality water at the outlet;

— incorrect laying and wiring;

— inconvenient and unaesthetic arrangement of pipes.

An old and clogged water supply is not only inconvenient, but also dangerous. Rust and salt deposits in pipes, even with very good filters, enter the body along with water. A dirty pipeline can lead to indigestion and infectious diseases if E. coli enters through microcracks in the pipe walls. Such water supply is especially dangerous in hot weather.

Replacing the water supply system in your apartment will help you get rid of all the troubles with drinking water, which will be carried out quickly and efficiently by qualified specialists of our company.

Modern pipes are more environmentally friendly and easier to install. They do not accumulate rust, almost no salts are deposited, they will last for many years, providing the apartment with clean water.

Our specialists work with any pipes. For this, there is the necessary equipment and tools for welding, gluing or soldering pipes, depending on their type.

Replacement of plumbing and heating systems

Replacing metal pipes with polypropylene pipes is carried out in several stages. First you need to draw a drawing of the layout of the future pipeline. After drawing up the drawing, you need to prepare the tools:

- special soldering iron for plastic tubes;

- a set of keys;

- grinder with disc;

- scissors for cutting tubes.

After preparing the tools and materials, you can begin work.

Dismantling

Step-by-step instructions for dismantling water supply or heating pipes:

- Drain the system.

- Shut off the water supply.

- Cut off old pipes.

It is necessary to leave pipe cuttings 5 cm from the ceiling and floor. Attach special adapters to the cut areas.

Preparation for installation

Before replacing steel pipes in an apartment, you need to calculate the required number of polypropylene elements and cut them using special scissors. The cuts must be straight to ensure strong connections. We must not forget about the coefficient of thermal expansion. When calculating the length of the tubes, you need to add about 2 cm to it.

Fitting

When installing polypropylene pipelines, you need to use special fittings to connect the pipes. There are several types of such parts:

- Tees - used to connect individual branches to the main line. They are convenient for installing various equipment.

- Angled - products for bending heating circuits to get around any obstacles.

- Couplings - suitable for fastening tubes of different diameters, creating a straight contour.

To secure individual pipeline elements to the wall, you need to use special brackets.

Polypropylene fittings for installation

What sets our company apart from others

There are several reasons that make people turn to us:

- extensive experience of our craftsmen - we can perform all plumbing work without exception;

- commitment - having taken on a job, we bring it to the end;

- responsibility – we are responsible for the quality of our work;

- reasonable prices - we do not inflate prices so that our services are accessible to everyone;

- efficiency – we do our work not only efficiently, but also quickly;

- politeness – our dispatchers respect their clients, they will politely and thoroughly answer all your questions asked by phone;

- preliminary agreement – you can agree with us in advance about any plumbing work in your home, our specialists will carry it out at a time convenient for you.

By choosing our company, you can be sure that all work will be completed with high quality and on time.

Creation of new heating

Installation of a new structure for conducting heat into the room is carried out using several schemes: single-pipe and two-pipe wiring. The latter option is considered more effective and reliable.

If the work is carried out in a private house, you will need to first install the boiler. Connection of heating and gas equipment can only be carried out by a specialist. After equipping the boiler room, it is necessary to mark out the future heating structure as a whole. Further work is carried out according to the following scheme:

- Connection of riser pipes with intermediate pipes to radiators is carried out;

- Bimetallic radiators are being installed. Before mounting the battery on the wall, you can glue a sheet of foil to reduce heat loss. You can also create a canopy on the battery that will protect the window sill from heating and allow hot air to be directed directly into the room;

- To connect plastic pipes, fittings are used, which must first be treated with sealant;

- Before pulling the pipes, wrap the end with film to prevent dirt from getting inside;

- Next, the system is filled with water and passes through all elements under maximum pressure;

- In new houses, they began to replace water with antifreeze in the heating system. The liquid is resistant to low temperatures. It does not freeze even at -50 degrees.

Installation of a new heating structure

The assembled structure must be checked. For this purpose, a special device is used - a presser. It creates increased pressure in the system to check the reliability and tightness of joints and pipes. If the sensor readings did not change during the test, then the tests were successful and there will be no leaks.

Using the information provided, you can replace and make a new high-quality heating system yourself.

When is heating removal necessary?

Partial or complete reconstruction of the system may be necessary in the event of a malfunction, defects or malfunctions. A private house needs to modernize the system when additional areas that need heating appear. And the apartment is often cold, in which case the owner can, with the written permission of the competent authorities, install an additional radiator. Dismantling steel heating pipes may be necessary in order to replace them with more modern plastic pipes that do not corrode. In the case of a complete redevelopment, both a private house and an apartment also need to change the heating system.

Dismantling old pipes and risers

Emergency replacement of heating risers is the most unpleasant and difficult case. According to the law, repairs must be carried out by the management company, but if this is your personal desire, you will need to comply with some rules.

If you are going to change the riser and the entire system inside the apartment. You will need permission from your neighbors, and you must notify them and the utility company about the upcoming repairs. In cases where the waste structure is changed from a valve indoors, no permit is required. Dismantling the old system is carried out in the following sequence:

- Liquid is drained from all pipes and batteries and the water supply is shut off;

- If the pipeline is made of metal, you will need a grinder, which is used to cut off old products. When the riser is replaced on all floors, it must be cut so that the structure does not crack and is easy to remove;

- Old radiators are disconnected from the pipeline using wrenches.

These steps will help you remove unnecessary elements and allow you to proceed with installing a new system.

Materials

Steel. Reliable and the cheapest material available on the market. When used in combination with HMS, it is almost eternal. HMS is a system that prevents impurities contained in the coolant from settling on the inner surface of the pipes.

But when using metal pipes, there are several obstacles that are difficult to overcome on your own:

- tools are needed: a welding machine, pipe dies, a pipe bender, etc. - they will need to be either purchased or rented.

- You will need the ability to perform high-quality pipe welding, otherwise you will have to hire a specialist;

Polypropylene (PRP). Replacing the heating system with polypropylene is a worthy alternative to steel pipes. In terms of its characteristics, PRP is in no way inferior to them. In multi-storey buildings it is also valuable because the material does not transmit sound to all floors when hitting the pipes. The only thing you should remember is that the pipes should not be water pipes, but special ones for heating systems (pressure marking PN25 and higher).

Polypropylene pipes - Photo 2

https://youtube.com/watch?v=fKf2kG7gHvw

Important! It is not recommended to purchase fittings and pipes from different manufacturers. It may turn out that it will take different temperatures and times to melt them

The connection may become problematic.

Other polymers. Here we can definitely say that replacing heating in an apartment using pipes made of modified polyethylene (PER) is categorically not recommended. This material has a fundamental drawback - a very low softening point, only 65 degrees. In addition, due to its high “slipperiness”, metal fittings are poorly fixed on it and leaks often occur. Such pipes do not serve for more than 10 years - this is for the middle zone, and even less in high latitudes.

Metal-plastic. Slightly more expensive than PRP pipes. In addition, this material also has technical disadvantages: it is afraid of shocks, fitting connections often leak for no apparent reason, large heat losses in the mains due to the small thickness of the pipe walls. However, installing a heating system with your own hands using such pipes is beneficial: they bend easily without the use of tools, therefore, you can save on buying expensive fittings, and you can not pay attention to heat loss - it will not go anywhere - it will remain inside the apartment.

Copper. No matter what anyone says, copper cannot be used in heating systems. It's not even a matter of the high cost of non-ferrous metal - the main problem is in soldering, or more precisely in tin, a component of solder. During operation, it changes its structure and connections become unreliable and fragile. And at high temperatures this process only accelerates.

Copper pipes - Photo 3

Summarize. The optimal choice for apartments in high-rise buildings would be polypropylene risers and the same or metal-plastic wiring.

Before purchasing materials, it is necessary to finally decide what type of installation of the heating system was in the apartment and options for laying heating pipes. As for the schemes, there are only two of them: one-pipe and two-pipe, and it is impossible to change them in an already built house or in a separate apartment. There is a choice when it comes to routing options. If, simultaneously with the replacement of pipes, repairs are carried out with the opening of the floors, then hidden wiring can be made under the floor. After this, it will become clear how much and what materials you need to buy.

Important! Simultaneously with the purchase of pipes, it is necessary to purchase shut-off valves, one tap for the supply and return of each heating device. This will make it possible, if necessary, to replace radiators without shutting down the entire system.

Rules for installation work

Work can only begin when all water has been drained from the risers and heating system. To do this, you will need to close the valves in the basement of your house. If you did everything correctly, then when you open the water drain valve in your apartment, you will hear a characteristic noise from the air inside the system and all the remaining coolant will leave the heating system. Now you can start replacing the pipes in the apartment. The installation sequence will be described taking into account the fact that you have chosen a galvanized pipe.

Thread cutting. At the very beginning, we cut the riser using a hacksaw or a small grinder with a metal disc installed. If you are going to replace all the risers along with the heating system, then you cannot do without a preliminary agreement on joint work. The order of cutting threads using a die must be done in the following sequence. First of all, you will need to remove a small chamfer on the pipe so that you can install the die without any problems. If the pipe has been painted, be sure to remove the paint before cutting the thread. Having installed the die in the holder, we begin to slowly scroll it with little effort. It is recommended to make two or three turns forward and then half a turn back. The pipe should be held with a wrench to prevent it from rotating with the die. The thread length must be at least five turns so that the fitting or coupling can be connected to the pipe without problems.

Installation of liners and risers

When working with galvanized pipe, special attention must be paid to sizing. When installing fittings made of brass or cast iron, you should not be too zealous, as this is a very fragile material

You will definitely need to use a winder. This can be a special sanitary linen or polymer material. To prevent it from fading during operation, it is recommended to apply a small layer of silicone sealant, drying oil or paint to the threads. If you plan to install shut-off valves for each heating device, which will allow, if necessary, to replace it without shutting down the entire heating system, then this must be done using a jumper. It is best to use modern ball valves.

Pressure testing of the heating system and its startup. After completing the work, you will need to remove air from the system and check the pressure. How can this be done at home? To do this, you will need to close the valves on the heating devices. Then, closing the water outlet, slowly fill the system to avoid possible water hammer. As soon as the noise of incoming water stops, open the second valve and you can begin inspecting the heating system for possible leaks. Excess air can be vented using a Mayevsky tap on the upper floors.

https://youtube.com/watch?v=B1XuHj04M5o

Thus, if everything is done correctly and consistently, you can replace the heating pipes in the apartment yourself, without the help of a specialist. However, if you still decide to turn to the masters of their craft, we recommend this company!

First steps in the event of an emergency

How to wrap a heating pipe? If you have a couple of clamps with rubber seals in stock at home, you can prevent some emergency situations. In the event of an accident, the most important thing to do is to shut off the coolant supply to the area where the heating pipe is leaking.

Covering the heating riser of a multi-storey building

You will need to stop the heating boiler, turn off the pump and turn off the necessary taps and valves. The clamp will solve the problem temporarily, so repairs will still be inevitable. Before you begin the repair, you will need to prepare the necessary materials and tools, turn off the heating, turn off all taps and drain the water from the system. Depending on the material from which the pipes are made, repairs can be carried out in various ways.

Examples of our work with prices

Moscow region, pos. Mostovik. Area: 300 m2

- Price

- Equipment

- Works

Completed work: heating, water supply, sewerage.

- The total cost of the object is 1,289,500 rubles.

- Total cost of materials and equipment: RUB 847,500.

- Total cost of work: 442,000 rubles.

Heating:

- Works: 281,500 rub.

- Materials and equipment: RUB 700,000.

Water supply:

- Works: 112,500 rub.

- Materials and equipment: RUB 135,500.

Sewerage:

- Work: 48,000 rub.

- Materials and equipment: 12,000 rub.

Equipment list:

- Gas boiler Vaillant 32 kW.

- Kermi steel panel radiators – 6 pcs. KZTO

- Trench convectors – 6 pcs. STOUT

- Thermostatic head, liquid – 8 pcs. Grota

- Heated towel rail EcoClassic 530x600 NP – 2 pcs.

- Storage water heater HAJDU for 300 liters – 1 pc.

- Boiler temperature sensor – 1 pc.

- PEX cross-linked polyethylene pipes (UPONOR, STOUT)

- The heating system is filled with Thermagent EKO coolant down to -30°C Consumables for installation of systems (ITAP, STOUT, FAR)

List of works:

- Installation of heating radiators - 6 pcs.

- Installation of in-floor convectors – 6 pcs.

- Installation and piping of the heating boiler – 1 pc.

- Installation of heating riser – 3 pcs.

- Installation of heated towel rail – 2 pcs.

- Installation of a three-way valve + boiler temperature sensor – 1 pc.

- Installation of heating manifold – 3 pcs.

- Installation of a heating manifold cabinet – 3 pcs.

- Installation of a heating expansion tank – 1 pc.

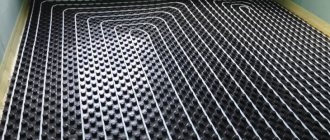

- Installation of heated floors - 110 m2

- Installation of a heated floor collector – 1 pc.

- Installation of a heated floor circulation pump

- Pipe routing F25, F20, F16.

- Holes, hydraulic tests, filling the system with coolant, pressure testing upon completion of work.

- DHW points – 17 pcs.

- Installation and piping of the boiler – 1 pc.

- Installation of a recirculation pump

- Installation of a water supply expansion tank

- Installation of water supply collector – 3 pcs.

- Installation of water supply riser – 2 pcs.

- Tracing of F25, F20 pipes, holes, hydraulic tests, pressure testing upon completion of work.

- Sewage points – 9 pcs.

- Installation of sewer riser – 3 pcs.

- Holes, hydraulic tests, pressure testing upon completion of work.

Moscow region, Losino-Petrovsky urban district, SNT Solovushka.

- Price

- Equipment

- Works

Completed work: heating, water supply.

- Total cost of the object: 344,500 rubles.

- Total cost of materials and equipment: RUB 172,500.

- Total cost of work: 172,000 rubles.

Heating:

- Works: 118,600 rub.

- Materials and equipment: RUB 131,900.

Water supply:

- Works: 53,400 rub.

- Materials and equipment: 40,100 rub.

Equipment list:

- Electric boiler PROTHERM RAY (SKAT) 9 kW.

- ROMMER bimetallic radiator Profi BM 500 – 10 pcs.

- ROMMER Thermostatic head, liquid - 10 pcs. Grota

- Heated towel rail EcoClassic 530x600 NP – 1 pc.

- Gorenje storage water heater for 100 liters – 1 pc.

- Boiler temperature sensor – 1 pc.

- Kalde polypropylene pipes reinforced with glass fiber.

- The heating system is filled with Thermagent EKO coolant down to -30°C

- Consumables for system installation (Kalde, STOUT)

List of works:

- Installation of heating radiators – 10 pcs.

- Installation and piping of the heating boiler – 1 pc.

- Installation of a heating riser (1st-2nd floor)

- Installation of heated towel rail – 1 pc.

- Installation of a three-way valve + boiler temperature sensor - 1 pc.

- Tracing of F25, F20 pipes, holes, hydraulic tests, filling the system with coolant, pressure testing upon completion of work.

- DHW points – 11 pcs.

- Installation and piping of the boiler – 1 pc.

- Tracing of F25, F20 pipes, holes, hydraulic tests, pressure testing upon completion of work.

- Additional equipment: An ATEK water treatment system is installed at the facility - the cost including installation is RUB 128,000.

Features of installation of one-pipe and two-pipe heating systems

Before you start laying the pipeline, it is worth deciding which of the two heating schemes will be implemented in the apartment: one-pipe or two-pipe. Each option has the right to exist and has its own strengths and weaknesses:

- A single-pipe system assumes the presence of a single pipeline through which the media circulates. The heating of radiators in such a scheme occurs unevenly, since the carrier reaches the furthest fuel elements when it has already cooled down greatly. But you will definitely be able to save on the implementation of such a project, since much less pipes and connecting elements will be required.

- A two-pipe heating system has two working circuits through which the media circulates. Through the first (supply) hot water flows into the radiators, through the second, the cooled medium is collected from the radiators and removed for subsequent heating. In such a system, you can replace one or more elements at any time without disconnecting the entire riser. However, for all these advantages you will have to pay for double the number of pipes, taps and connecting elements.

We recommend that you read: Which gutters for water collection should you prefer: metal or plastic?

Work order

When completely replacing the heating system, you should follow a certain sequence of work:

- Development of a project that takes into account the number of pipes, radiators, connecting and shut-off fittings.

- Selection of pipe material. The complexity of the project, its cost, operating conditions and service life will depend on this.

- Purchase of all necessary elements of the heating system, as well as special tools.

- Dismantling the old heating system.

- Installation of radiators in predetermined locations.

- Laying the pipeline and connecting all elements.

- Hydraulic testing of the heating system.

Dismantling risers

The first stage of replacing the heating system in an apartment is draining water from the risers. This is done using appropriate valves, located, as a rule, in the basement of an apartment building.

Regardless of the material chosen for the future heating system, a threaded connection will need to be made at the point of its connection with the risers. An exception is a comprehensive replacement of the heating system in the entire house or entrance, when the riser is replaced along its entire height, but work of this scale is still more often carried out by specialized contractors.

Using a grinder or a hacksaw, the riser is cut above the ceiling (or below it) with a small indentation for ease of threading.

Next, the chamfer is removed so that the die can be easily inserted. By rotating the die, 4-5 turns of thread are carefully cut. During the cutting process, the end of the pipe should be held with a gas wrench to compensate for the torque and prevent damage to the pipeline.